Understanding the 3 most common issues with a pneumatic air compressor

Operating a pneumatic air compressor can greatly improve efficiency and productivity in many industries. However, like any mechanical equipment, air compressors can encounter issues that can hinder their performance. Being aware of the most common problems and understanding how to troubleshoot them is essential for maintaining a reliable and efficient pneumatic air compressor system.

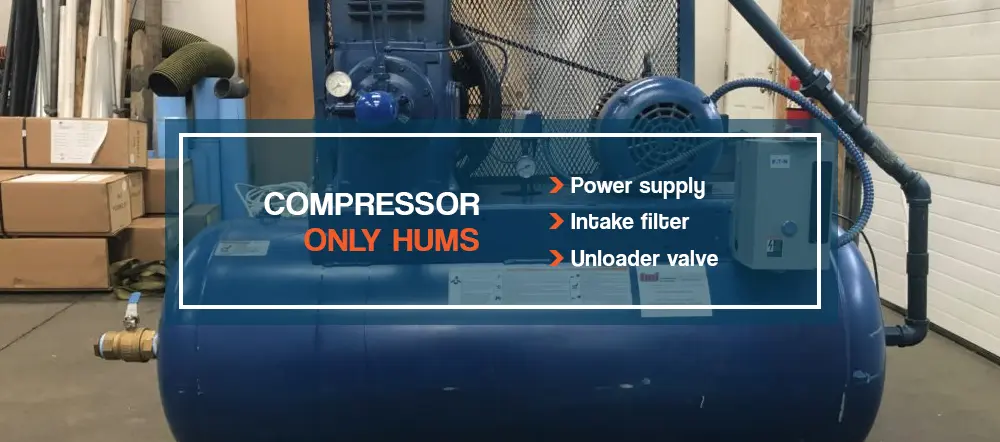

One of the most common issues with a pneumatic air compressor is inadequate pressure. If the compressor is not producing enough pressure, it can significantly affect the performance of pneumatic tools and machinery. This can be caused by a variety of factors, such as a faulty pressure switch, worn-out valves, or leaks in the system. Identifying and resolving the root cause of inadequate pressure is crucial to ensure optimal performance.

Another common issue is excessive noise. Air compressors can be noisy, but if the noise level becomes unbearable or significantly increases over time, it may be a sign of a problem. Excessive noise can be caused by worn-out bearings, loose components, or vibrations. Regular maintenance, such as lubricating moving parts and tightening loose components, can help reduce noise levels and prevent further damage.

Leakages are also a frequent issue with pneumatic air compressors. Even small leaks can lead to significant energy losses and decreased efficiency. Leaks can occur in various parts of the system, such as the tubing, fittings, or even the compressor itself. Inspecting the system regularly for signs of leakage, such as hissing sounds or drops in pressure, and promptly repairing any identified leaks is crucial for maintaining the efficiency and longevity of a pneumatic air compressor system.

Understanding the importance of a pneumatic air compressor

A pneumatic air compressor is an essential tool in many industries and applications. It plays a crucial role in providing compressed air to power various pneumatic tools and equipment. Understanding the importance of a pneumatic air compressor is essential for ensuring its proper operation and maximizing its efficiency.

Powering pneumatic tools:

A pneumatic air compressor is used to power a wide range of pneumatic tools, such as pneumatic drills, impact wrenches, air hammers, and paint sprayers. These tools rely on compressed air to generate the necessary power for their operation. Without a reliable source of compressed air, these tools would not function effectively or efficiently.

Versatile applications:

A pneumatic air compressor is versatile and can be used in various applications across different industries. It can be used in automotive workshops for tire inflation and operating air-powered tools. In manufacturing plants, it can power air-operated machinery and equipment. Additionally, it is used in construction sites for powering pneumatic nail guns and jackhammers. The versatility of a pneumatic air compressor makes it an indispensable tool in many industries.

Efficiency and productivity:

A pneumatic air compressor is designed to provide a steady and reliable supply of compressed air, which is essential for maintaining optimum efficiency and productivity. It ensures that pneumatic tools and equipment receive an adequate amount of compressed air to operate at their full potential. A properly functioning pneumatic air compressor can also help reduce downtime and increase productivity in various applications.

Proper maintenance:

Understanding the importance of a pneumatic air compressor also includes knowing the need for regular maintenance. Regular maintenance, such as changing filters and checking for leaks, is crucial to ensure the longevity and efficiency of the compressor. Proper maintenance not only extends the lifespan of the compressor but also prevents potential issues and costly downtime.

In conclusion, a pneumatic air compressor is an important tool in various industries and applications. It powers pneumatic tools, has a wide range of applications, improves efficiency and productivity, and requires proper maintenance. Understanding its importance helps ensure its proper operation and maximizes its benefits.

Insufficient air pressure

In the context of a pneumatic air compressor, one common issue that can arise is insufficient air pressure. This occurs when the compressor is unable to generate enough pressure to meet the demands of the pneumatic system.

There are several reasons why an air compressor may have insufficient air pressure. One possible cause is a malfunctioning pressure switch. The pressure switch is responsible for monitoring and controlling the air pressure. If it is not functioning properly, it may not be able to maintain the desired pressure level.

Another reason for insufficient air pressure could be a leak in the pneumatic system. Air leaks can occur in various parts of the system, such as hoses, fittings, or valves. When there is a leak, the compressor has to work harder to compensate for the loss of pressure, leading to reduced overall air pressure.

Additionally, if the compressor is not properly sized for the pneumatic system, it might not be able to generate enough pressure. Each pneumatic system has its own specific air pressure requirements, and if the compressor is too small or underpowered, it may struggle to meet those requirements.

To address the issue of insufficient air pressure, it is important to first diagnose the root cause. Checking the pressure switch for any malfunctions and inspecting the pneumatic system for leaks are the first steps. If a leak is found, it should be promptly repaired. If the compressor is undersized, it may need to be replaced with a larger, more powerful one that can meet the air pressure demands of the system.

Identifying the causes of low air pressure

Low air pressure in a pneumatic air compressor can be caused by a variety of factors. It is important to accurately identify the causes in order to effectively address and resolve the issue. Here are some common causes of low air pressure:

1. Air Leakage

One of the most common causes of low air pressure is air leakage. Leaks can occur in various parts of the compressor system, such as hoses, fittings, valves, or even in the compressor itself. It is essential to carefully inspect all the components and connections to identify any signs of leakage. A simple way to check for leaks is to listen for hissing sounds or feel for any air escaping.

Once a leak is detected, it is important to fix it promptly to prevent excessive energy consumption and maintain optimal air pressure levels.

2. Inadequate Compressor Size

If your pneumatic air compressor is continuously running at maximum capacity but still can’t generate sufficient air pressure, it may be due to an inadequate compressor size. The compressor may not have the necessary power or capacity to meet the demand for air pressure in your specific application.

To address this issue, you may need to consider upgrading to a larger or more powerful compressor that is better suited for your needs. Consulting with a professional can help you determine the appropriate compressor size for your specific requirements.

3. Clogged Air Filters

Clogged air filters can also result in low air pressure. Over time, dust, debris, and other particulates can accumulate on the air filters, restricting the airflow and reducing the overall efficiency of the compressor. Regularly inspecting and cleaning or replacing the air filters is crucial to maintaining optimal air pressure.

It is recommended to follow the manufacturer’s guidelines for filter maintenance and replacement intervals to ensure proper functioning of the compressor system.

In conclusion, low air pressure in a pneumatic air compressor can be caused by air leakage, an inadequate compressor size, or clogged air filters. Regular inspection and maintenance are key to identifying and resolving these issues to maintain optimal air pressure levels.

Air leaks

Air leaks are one of the most common issues with pneumatic air compressors. They can reduce the efficiency and performance of the compressor, leading to wasted energy and increased operating costs.

Symptoms of air leaks can include hissing or whistling sounds, fluctuating pressure, and a compressor that runs more frequently than usual.

Sources of air leaks can be found in various parts of the compressor system, such as fittings, hoses, valves, and seals. Over time, these components can wear out or become damaged, leading to air leaks.

Effects of air leaks include reduced air pressure, which can affect the performance of pneumatic tools and equipment. Additionally, air leaks can lead to increased wear and tear on the compressor system, as it has to work harder to compensate for the lost air.

Preventing and fixing air leaks involves regular maintenance and inspection of the compressor system. This includes checking and tightening fittings, replacing damaged hoses, valves, and seals, and using appropriate sealants or tape to prevent leaks. It is also important to properly lubricate moving parts to reduce friction and wear.

In conclusion, air leaks are a common problem in pneumatic air compressors that can have negative effects on performance and efficiency. Regular maintenance and inspection can help prevent and fix air leaks, ensuring the optimal functioning of the compressor system.

Locating and fixing common air leaks

One of the most common issues with pneumatic air compressors is air leaks. Air leaks can significantly decrease the efficiency of the compressor and waste valuable compressed air. Here are some tips for locating and fixing common air leaks.

1. Listen for hissing sounds

One way to locate air leaks is by listening for hissing sounds. Start by turning off all the equipment powered by the air compressor, then carefully listen for any unusual sounds around the compressor or air lines. A hissing sound is often a sign of air leakage.

2. Inspect the air lines and fittings

Inspect the air lines and fittings for any signs of wear and tear or damage. Look for cracks, holes, or loose connections. Pay close attention to joints, bends, and unions, as these areas are more susceptible to developing leaks. Use a solution of soapy water to help identify leaks – bubbles will form where there is a leak.

3. Tighten or replace faulty fittings

If you find any loose or faulty fittings, tighten them using a wrench or replace them if necessary. Ensure that all fittings are properly tightened to prevent air leaks. Use thread sealant tape or pipe sealant to create a tight seal on threaded fittings.

4. Check the pressure relief valve

The pressure relief valve is designed to release excess pressure to prevent damage to the compressor. However, if the valve is faulty, it can lead to air leakage. Inspect the pressure relief valve and make sure it is functioning properly. If necessary, replace the valve to eliminate the leak.

5. Consider using thread sealant

If you are experiencing frequent air leaks at threaded fittings, consider using a thread sealant to create a stronger and more durable seal. Thread sealant can help prevent air leaks caused by loose or imperfectly sealed connections.

By carefully inspecting your air compressor and air lines, listening for unusual sounds, and addressing any leaks promptly, you can improve the efficiency of your pneumatic air compressor and prolong its lifespan.

Overheating

One of the most common issues with a pneumatic air compressor is overheating. When an air compressor overheats, it can lead to reduced efficiency and potential damage to the equipment.

Overheating can be caused by a variety of factors, such as running the compressor for extended periods of time without giving it a chance to cool down, using the compressor in a hot environment, or a malfunctioning cooling system.

To prevent overheating, it is important to follow the manufacturer’s recommendations for operating the air compressor. This may include taking regular breaks to allow the compressor to cool down, ensuring proper ventilation in the compressor’s area, and checking and maintaining the cooling system.

If an air compressor is overheating, it is important to address the issue promptly to prevent further damage. This may involve checking for any obstructions in the cooling system, cleaning or replacing filters, and ensuring proper lubrication of moving parts.

Regular maintenance and inspection of the air compressor can help identify and prevent overheating issues. By taking steps to prevent overheating, you can ensure the longevity and efficiency of your pneumatic air compressor.

Preventing the overheating of a pneumatic air compressor

An overheating pneumatic air compressor can result in reduced performance and even potential damage to the compressor itself. To prevent overheating, it is important to take certain precautions and implement proper maintenance practices.

1. Ensure proper ventilation:

Proper ventilation is essential for preventing the overheating of a pneumatic air compressor. Make sure that the compressor is located in an area with adequate airflow and is not surrounded by obstructions that could restrict airflow. Additionally, it is important to regularly clean the compressor’s vents and filters to remove any dust or debris that can hinder ventilation.

2. Check oil levels regularly:

Oil plays a crucial role in keeping the compressor’s components cool. It is important to check the oil levels regularly and maintain them within the recommended range. Insufficient oil levels can lead to increased friction and heat generation, resulting in overheating. If the oil level is low, make sure to add the appropriate type and amount of oil as specified in the compressor’s manual.

3. Monitor pressure and temperature:

Monitoring the pressure and temperature of the compressor is vital in preventing overheating. Use a pressure gauge to ensure that the compressor is operating within the recommended pressure range. Excessive pressure can cause the compressor to work harder, leading to overheating. Similarly, keep an eye on the temperature gauge and make sure it stays within safe limits. If the temperature rises abnormally, it may indicate a problem that needs to be addressed.

4. Regular maintenance:

Regular maintenance is essential for the proper functioning of a pneumatic air compressor and for preventing overheating. This includes tasks such as cleaning or replacing air filters, checking for leaks, inspecting and tightening connections, and lubricating moving parts. Following the manufacturer’s recommended maintenance schedule and procedures will help ensure that the compressor operates efficiently and does not overheat.

By implementing these preventive measures and conducting regular maintenance, you can significantly reduce the risk of overheating your pneumatic air compressor. This will not only extend the lifespan of the compressor but also improve its performance and reliability.

Excessive noise

One of the most common issues with pneumatic air compressors is excessive noise. This can be a nuisance in both industrial and residential settings. The noise produced by an air compressor can be caused by several factors, including the type of compressor, improper lubrication, worn-out or damaged components, and excessive vibration.

1. Type of compressor: Different types of compressors produce different levels of noise. Reciprocating compressors, for example, are known for their loud operational noise, while rotary screw compressors are usually quieter. If noise level is a concern, it is important to choose a compressor that is designed for low noise emissions.

2. Improper lubrication: Inadequate lubrication of the compressor can cause increased friction and wear, leading to higher noise levels. Regular maintenance and proper lubrication can help reduce noise by ensuring smooth operation of the moving parts.

3. Worn-out or damaged components: Over time, certain components of an air compressor, such as the piston rings, valves, or bearings, may wear out or become damaged. This can result in increased noise during operation. Regular inspection and replacement of worn-out parts can help prevent excessive noise.

4. Excessive vibration: Excessive vibration can also contribute to noise issues with air compressors. Vibrations can be caused by unbalanced rotating parts, loose fittings, or worn-out motor mounts. Proper maintenance and inspection can help identify and resolve vibration issues, reducing noise levels.

In conclusion, excessive noise is a common issue with pneumatic air compressors, but it can be mitigated by choosing a compressor with low noise emissions, ensuring proper lubrication, conducting regular maintenance, and addressing any worn-out or damaged components or excessive vibrations.

Reducing the noise levels of a pneumatic air compressor

A pneumatic air compressor can be a noisy piece of equipment, which can be disruptive and cause discomfort in the workplace. Fortunately, there are several ways to reduce the noise levels and create a quieter working environment.

1. Soundproofing

One effective way to reduce the noise levels of a pneumatic air compressor is by soundproofing the area in which it is located. This can be done by installing soundproofing materials such as acoustic foam or insulation on the walls and ceiling of the compressor room. Additionally, using vibration isolation pads or mounts can help reduce the transfer of vibrations and further decrease noise levels.

2. Regular maintenance

Regular maintenance of the pneumatic air compressor can also help reduce noise levels. Ensuring that all components are properly lubricated and tightened can minimize mechanical noise. Additionally, replacing worn-out parts or repairing any leaks can prevent unnecessary noise generation. Regularly cleaning and inspecting the compressor can also help identify and address any potential noise issues before they become significant.

3. Distance and barriers

Another way to reduce the noise levels of a pneumatic air compressor is by increasing the distance between the compressor and the workspace. Placing the compressor in a separate room or using barriers such as walls or partitions can help block the direct transmission of noise. Additionally, using noise-absorbing materials on the walls or installing noise curtains or sound barriers can further dampen the noise and create a quieter environment.

By implementing these measures, it is possible to significantly reduce the noise levels of a pneumatic air compressor, creating a more comfortable and productive working environment.

Maintenance and lubrication

Regular maintenance

Proper maintenance is essential for the smooth operation and longevity of a pneumatic air compressor. Regularly inspect the compressor for any signs of wear or damage, such as leaks, cracks, or loose connections. Clean the exterior and ensure that the air intake is free from any debris that could obstruct airflow.

Lubrication

Lubrication is crucial for the efficient functioning of a pneumatic air compressor. The compressor should be lubricated according to the manufacturer’s instructions. This typically involves adding oil to the lubrication ports or oil sump at regular intervals. It is important to use the correct type of lubricant specified by the manufacturer to ensure optimal performance and prevent damage to the compressor.

Regular lubrication helps reduce friction and heat generated during operation, which in turn reduces wear and extends the lifespan of the compressor.

Oil level and quality

Checking the oil level is an important part of maintenance for a pneumatic air compressor. Make sure the oil level is within the recommended range, neither too low nor too high. Additionally, monitor the quality of the oil regularly. Over time, the oil can become contaminated with dust, moisture, and other impurities, which can impair the compressor’s performance. If the oil appears dirty or discolored, it should be drained and replaced with fresh oil.

Oil filter replacement

The oil filter in a pneumatic air compressor helps remove any particulate matter or debris from the oil, ensuring the oil remains clean for optimal lubrication. It is important to regularly inspect and replace the oil filter as recommended by the manufacturer. A clogged or dirty oil filter can restrict oil flow and lead to inadequate lubrication, potentially causing damage to the compressor. Follow the manufacturer’s guidelines for the appropriate timing and procedure for oil filter replacement.

FAQ:

What are the common issues that can occur with a pneumatic air compressor?

There are several common issues that can occur with a pneumatic air compressor. The three most common ones are air leaks, low pressure, and overheating.

How can I detect an air leak in my pneumatic air compressor?

If you suspect an air leak in your pneumatic air compressor, you can use a soapy water solution to check for bubbles. Apply the solution to the connections and observe if any bubbles form. If bubbles appear, it indicates the presence of a leak.

What should I do if my pneumatic air compressor has a low pressure?

If your pneumatic air compressor has a low pressure, you should first check the air filter and clean or replace it if necessary. Then, inspect the pressure regulator and adjust it as needed. If these steps don’t solve the problem, there may be a larger issue such as a faulty pressure switch or a worn piston ring, and it would be best to consult a professional for further diagnosis and repair.

Why does my pneumatic air compressor overheat?

There are several reasons why a pneumatic air compressor might overheat. It could be due to a lack of proper lubrication, a faulty pressure switch, or a blocked cooling fan. It’s important to address the issue of overheating promptly as it can lead to damage to the compressor’s components. Regular maintenance, such as checking and changing the oil, cleaning the cooling fan, and inspecting the pressure switch, can help prevent overheating.

Can I prevent the common issues with a pneumatic air compressor?

While it’s not always possible to prevent all issues with a pneumatic air compressor, there are certain steps you can take to minimize the occurrence of common problems. Regular maintenance, including checking and changing the oil, cleaning or replacing the air filter, and inspecting the connections for leaks, can help keep your compressor in good working condition. Additionally, following the manufacturer’s instructions for operating and maintaining the compressor can also help prevent issues.