How to Bypass Pressure Switch on Air Compressor

If you own an air compressor, you may have encountered situations where the pressure switch malfunctions or fails. The pressure switch is a crucial component that monitors and regulates the pressure in the air compressor. When it fails, it can prevent the air compressor from functioning properly or even cause it to stop working altogether.

One possible solution to this problem is to bypass the pressure switch. Bypassing the pressure switch allows you to manually control the pressure in the air compressor and continue using it until a replacement pressure switch can be installed. However, it is important to note that bypassing the pressure switch should only be done as a temporary solution and it is recommended to replace the faulty switch as soon as possible.

To bypass the pressure switch, you will first need to identify the location of the switch on your air compressor. The pressure switch is typically located near the motor and is connected to the compressor tank by a tube. Once you have located the pressure switch, you can disconnect the wires or tubing connected to it. It is important to note the original configuration of the switch before disconnecting any wires or tubing.

Once you have disconnected the wires or tubing from the pressure switch, you can use a wire or jumper cable to connect the two terminals of the pressure switch. This will effectively bypass the switch and allow the air compressor to operate without the pressure switch regulating the pressure. However, it is important to exercise caution when using the air compressor in this bypassed state, as you will need to manually monitor and regulate the pressure to prevent damage to the compressor or any connected equipment.

Disclaimer: Bypassing the pressure switch on your air compressor should only be done as a temporary solution. It is strongly recommended to replace the faulty pressure switch as soon as possible to ensure the safe and proper functioning of your air compressor.

What is a Pressure Switch?

A pressure switch is an essential component of an air compressor that helps control the pressure level within the system. It is a mechanical device that monitors the air pressure and activates or deactivates the compressor based on the set pressure limits.

Pressure Regulation: The pressure switch is responsible for ensuring that the compressed air remains within safe operating limits. It typically has adjustable pressure settings that allow the user to set the desired pressure range for the compressor.

Automatic Operation: When the pressure falls below the set lower limit, the pressure switch activates the compressor, allowing it to pump air until the pressure reaches the upper limit. Once the upper limit is reached, the pressure switch deactivates the compressor, preventing further pressurization.

Protection Mechanism: The pressure switch acts as a safety mechanism for the compressor. It is designed to detect abnormal pressure conditions, such as excessive pressure or pressure drops, and automatically shut off the compressor to prevent damage and potential hazards.

Diagnostic Tool: Pressure switches often include visual indicators, such as pressure gauges or lights, that provide real-time feedback on the pressure level. This allows the user to monitor and diagnose any issues with the air compressor system.

Variety of Applications: Pressure switches are used in various industries and applications, including automotive, manufacturing, construction, and more. Their versatility and reliability make them integral to maintaining optimal pressure levels in pneumatic systems.

Understanding the Functionality

Before learning how to bypass the pressure switch on an air compressor, it is important to understand its functionality. The pressure switch is a crucial component in regulating the air pressure within the compressor tank. It is designed to automatically shut off the compressor when the desired pressure level is reached, and to turn it back on when the pressure drops below a certain threshold.

The pressure switch consists of a sensor that detects the pressure in the tank and a control mechanism that triggers the compressor motor. When the pressure in the tank reaches the upper limit, the sensor signals the control mechanism to stop the motor, preventing the compressor from over-pressurizing. Conversely, when the pressure drops below the lower limit, the sensor signals the control mechanism to start the motor, allowing it to build up pressure again.

In a bypass operation, the pressure switch is essentially overridden, allowing the compressor to continue running without being affected by the preset pressure limits. This can be useful in certain situations, such as when you need to temporarily increase the pressure output or when the pressure switch is faulty and needs to be replaced.

It is important to note that bypassing the pressure switch should only be done temporarily and with caution. Running the compressor without the pressure switch can be dangerous, as it eliminates the safety mechanism that prevents over-pressurization. It is recommended to consult the manufacturer’s instructions or seek professional advice before attempting to bypass the pressure switch.

Why Bypass the Pressure Switch?

1. Overcoming Malfunctioning Pressure Switch

One of the main reasons to bypass the pressure switch on an air compressor is to overcome a malfunctioning or faulty switch. The pressure switch is designed to monitor and control the pressure within the tank, automatically turning the compressor on and off when necessary. However, over time, the pressure switch can wear out or become damaged, causing it to malfunction. Bypassing the pressure switch allows you to continue using the air compressor without relying on the faulty switch.

2. Immediate Air Supply

Bypassing the pressure switch can provide you with an immediate air supply, particularly in situations where you need to use the air compressor urgently. When the pressure switch is bypassed, the compressor runs continuously, providing a constant flow of compressed air. This can be helpful in situations where you don’t have time to diagnose and repair a faulty pressure switch, or if you need continuous air supply for a specific task.

3. Temporary Solution

Another reason to bypass the pressure switch is as a temporary solution until you can repair or replace the switch. By bypassing the switch, you can continue using the air compressor until you are able to address the underlying issue. This can be especially useful if you rely on the air compressor for important tasks and cannot afford to wait for a replacement switch to be installed.

4. Testing and Troubleshooting

Bypassing the pressure switch can also be helpful in testing and troubleshooting scenarios. If you suspect that the pressure switch is causing issues with the compressor, bypassing it allows you to determine whether the switch is indeed the root cause of the problem. This can assist in identifying the exact issue and developing a plan for repair or replacement.

In conclusion, bypassing the pressure switch on an air compressor can be a practical solution in certain situations, such as when the switch malfunctions, when immediate air supply is needed, as a temporary solution, or for testing and troubleshooting purposes. However, it is important to note that bypassing the pressure switch should only be done temporarily and as a last resort, as the switch plays a crucial role in the safe operation of the air compressor.

Potential Reasons to Bypass

There are several potential reasons why someone might want to bypass the pressure switch on an air compressor. These reasons may vary depending on the specific situation and needs of the user.

Mechanical Failure:

One possible reason to bypass the pressure switch is if there is a mechanical failure in the switch itself. If the switch is not functioning properly, it may prevent the compressor from turning on or off at the desired pressure settings. Bypassing the switch can temporarily fix the problem until a replacement switch can be installed.

Adjusting Pressure:

Another reason to bypass the pressure switch is if the user needs to adjust the pressure settings of the compressor. By bypassing the switch, the user can manually control the pressure output of the compressor without being limited to the preset pressure range determined by the switch. This can be useful in situations where a specific pressure level is required for a certain task or application.

Emergency Repairs:

In emergency repair situations, bypassing the pressure switch can provide a quick solution to getting the compressor up and running again. If the switch is damaged or not functioning, bypassing it allows the compressor to operate without relying on the switch to control the pressure. However, it is important to note that bypassing the switch should only be done as a temporary measure, and a proper repair or replacement of the switch should be done as soon as possible.

Custom Applications:

In some cases, users may have custom applications or specific requirements that necessitate bypassing the pressure switch. This could include applications where the compressor needs to operate at a non-standard pressure setting or where the pressure switch interferes with the desired operation of the compressor. Bypassing the switch allows for more flexibility and customization in these situations.

Overall, bypassing the pressure switch on an air compressor should only be done with caution and for specific reasons. It is important to understand the potential risks and implications of bypassing the switch, and to ensure proper maintenance and repair of the switch if necessary.

How to Safely Bypass the Pressure Switch

Introduction

The pressure switch on an air compressor is responsible for controlling the cut-in and cut-out pressure levels. However, there may be situations where you need to temporarily bypass the pressure switch. This could be due to a faulty switch or the need for continuous operation beyond the pressure limits set by the switch. In such cases, it is important to follow certain safety precautions to ensure the process is carried out safely.

Safety Precautions

1. Power Off: Before attempting to bypass the pressure switch, make sure to turn off the power supply to the air compressor. This will prevent any accidental start-ups or power surges during the process.

2. Release Air Pressure: After turning off the power, release any remaining air pressure in the compressor tank. This can be done by opening the drain valve located at the bottom of the tank. This step is important to avoid any sudden release of pressure or injury.

3. Disconnect Wires: Once the air pressure is released, carefully disconnect the wires connected to the pressure switch. It is essential to handle the wires safely and avoid any contact with live electrical components.

Bypassing the Pressure Switch

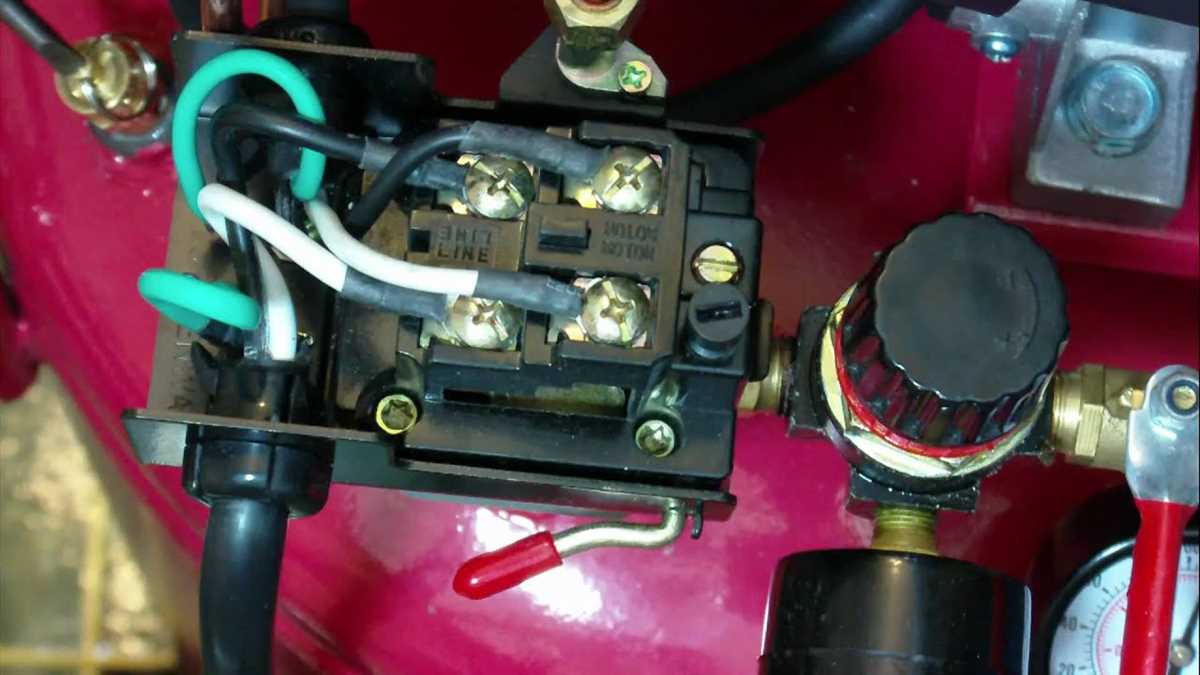

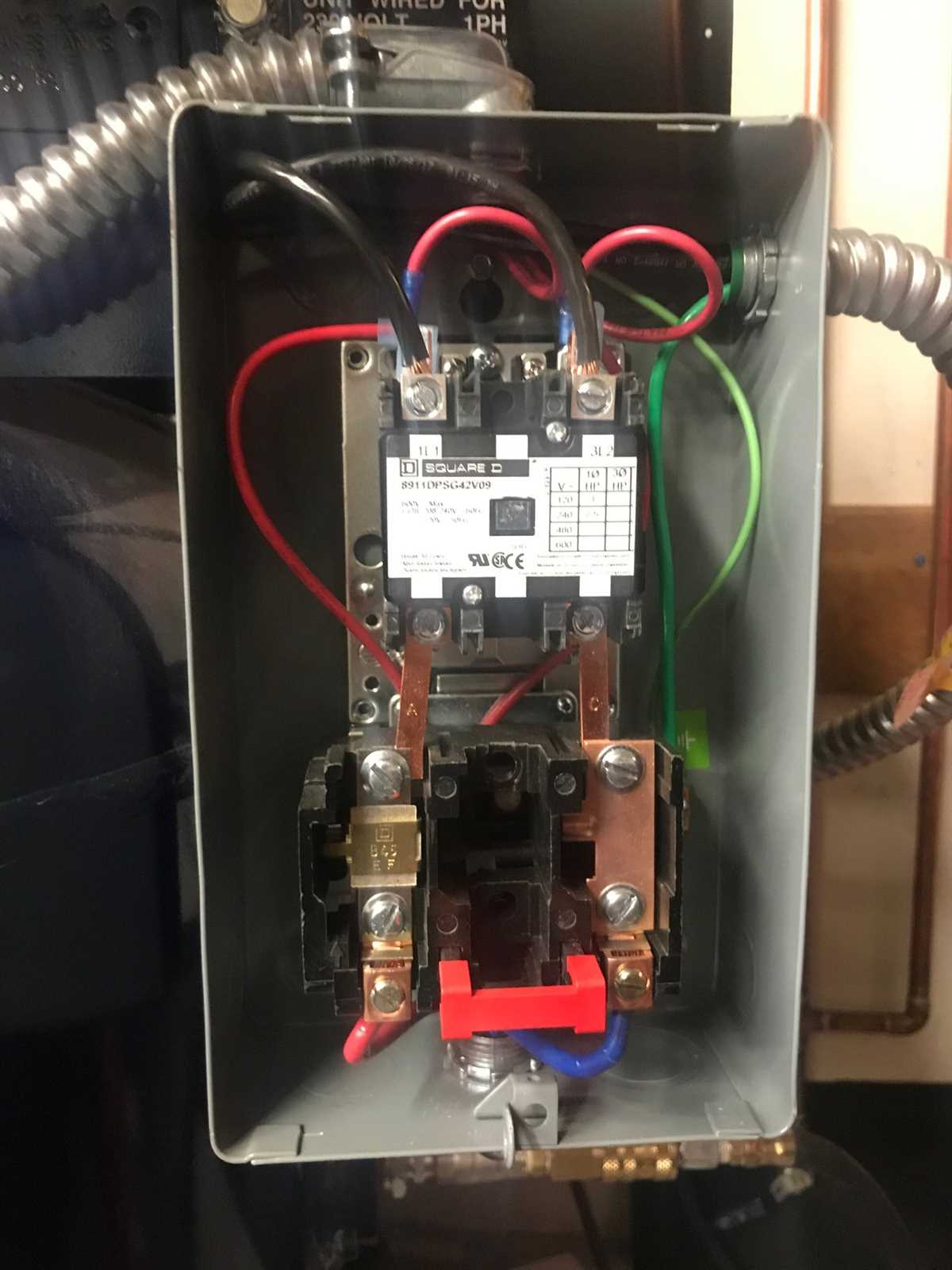

- Identify the Pressure Switch Terminals: The pressure switch will have two sets of terminals – one for the power supply and another for the motor. Identify the terminals and make note of their positions.

- Connect the Power Supply Wires: Take the wires that were connected to the power supply terminals of the pressure switch, and connect them directly to the power source. Make sure to secure the connections properly using wire nuts or electrical tape.

- Connect the Motor Wires: Take the wires that were connected to the motor terminals of the pressure switch, and connect them directly to the motor. Again, ensure that the connections are secure.

Final Checks

After bypassing the pressure switch, perform a final check to ensure everything is in order:

- Tighten all connections: Double-check all the wire connections to ensure they are securely tightened.

- Inspect for any damage: Look for any visible damage or wear on the wires or terminals. Replace any damaged components if necessary.

- Restore power: Once all checks are done, carefully restore the power supply to the air compressor.

Conclusion

Bypassing the pressure switch on an air compressor should only be done when absolutely necessary, and with proper precautions in place. Always prioritize safety and ensure that all connections are secure before powering on the compressor. If you are unsure about any aspect of the process, it is advisable to consult a professional or seek guidance from the manufacturer.

Step-by-Step Guide

1. Gather the necessary tools and materials

Before you begin bypassing the pressure switch on your air compressor, make sure you have all the necessary tools and materials. You will need a screwdriver, wire cutters, electrical tape, and a jumper wire.

2. Disconnect the power

Before working on any electrical components, it is crucial to turn off the power to the air compressor. Locate the power switch or unplug the compressor from the outlet to ensure safety.

3. Remove the pressure switch cover

Using a screwdriver, carefully remove the cover of the pressure switch. This will allow you to access the internals of the switch and make the necessary modifications.

4. Identify the power wires

Inside the pressure switch, you will find a set of power wires that connect to the compressor motor. Identify the wires labeled “line” or “power” and “motor” or “load.” These wires control the electrical flow to the motor.

5. Cut and strip the wires

Using wire cutters, carefully cut the power wires leading to the motor. Strip the ends of the wires to expose the bare metal. This will allow you to connect the jumper wire later on.

6. Connect the jumper wire

Take the jumper wire, which should be long enough to reach both severed ends of the power wires, and connect it between them. Use electrical tape or wire connectors to ensure a secure connection.

7. Secure the jumper wire

Once the jumper wire is securely connected, make sure it is positioned away from any moving parts or surfaces that may cause damage. Use zip ties or clips to secure the wire in place.

8. Test the compressor

After completing the bypass, turn on the power to the air compressor and observe its functionality. The motor should now start without requiring the pressure switch to activate. If everything is working properly, you have successfully bypassed the pressure switch.

- Note: Bypassing the pressure switch should only be done as a temporary solution. It is essential to replace a faulty pressure switch to ensure proper operation and safety.

Precautions to Take

When bypassing the pressure switch on an air compressor, it is important to take certain precautions to ensure safety and prevent damage to the equipment. Here are some precautions to keep in mind:

1. Wear Protective Gear

Before working on the air compressor, make sure to wear appropriate protective gear such as safety goggles, gloves, and ear protection. This will protect you from any potential hazards that may arise during the process.

2. Disconnect Power

Before attempting to bypass the pressure switch, always disconnect the power supply to the air compressor. This will prevent any accidental start-ups or electrical shocks while working on the equipment.

3. Release Built-up Pressure

Prior to bypassing the pressure switch, it is crucial to release any built-up pressure in the air compressor tank. This can be done by opening the drain valve and allowing the air to escape slowly. Failing to release the pressure can result in sudden releases of air and potential injuries.

4. Follow Manufacturer’s Instructions

It is important to read and follow the manufacturer’s instructions carefully when bypassing the pressure switch. Each air compressor may have specific steps or guidelines that need to be followed in order to safely bypass the pressure switch.

5. Use Correct Tools

Make sure to use the correct tools for the job. Using improper tools can lead to damage to the air compressor or result in injuries. Refer to the manufacturer’s instructions or seek professional advice if unsure about the tools required for bypassing the pressure switch.

By taking these precautions, you can ensure a safe and successful bypass of the pressure switch on your air compressor. Always prioritize safety and consult professionals if you are unsure about any steps or procedures.

Ensuring Safety Measures

Evaluate the risks

Before attempting to bypass the pressure switch on an air compressor, it is crucial to evaluate the potential risks involved. Understand that the pressure switch is designed to ensure safe operation by turning off the compressor when it reaches a certain pressure level. Bypassing this safety feature can lead to over-pressurization and potentially cause a catastrophic failure of the compressor.

Follow manufacturer instructions

Prior to bypassing the pressure switch, it is important to consult the manufacturer’s instructions to determine if it is permissible or recommended. Some air compressors may have specific guidelines or procedures for bypassing the pressure switch, while others may explicitly prohibit it. Following the manufacturer’s guidance helps ensure that you are not compromising the safety of yourself or the equipment.

Use appropriate safety equipment

When working with an air compressor, it is essential to use appropriate safety equipment. This includes wearing protective eyewear, gloves, and hearing protection to prevent injuries from flying debris, loud noise, or accidental contact with moving parts. Additionally, ensure that you are working in a well-ventilated area to minimize the risk of exposure to fumes or other hazardous substances.

Properly maintain the compressor

Regular maintenance is key to ensuring the safe operation of an air compressor. This includes regularly checking and replacing worn-out parts, cleaning filters, and lubricating moving components. By maintaining the compressor according to the manufacturer’s recommendations, you can mitigate the risk of malfunctions or accidents that may require bypassing the pressure switch.

Seek professional assistance if unsure

If you are unsure about bypassing the pressure switch or have concerns about the safety implications, it is always best to seek professional assistance. A trained technician or air compressor specialist can provide guidance and ensure that the necessary safety measures are taken. Remember, safety should always be a top priority when working with machinery.

Wrapping Up

In conclusion, bypassing the pressure switch on an air compressor can be a useful solution in certain situations. However, it is important to consider the safety implications and consult with a professional if you are unsure about the process.

Before attempting to bypass the pressure switch, it is crucial to understand the potential risks involved. Working with compressed air can be hazardous, and bypassing the pressure switch may result in over-pressurization, which can cause damage to the compressor or even lead to injury.

If you decide to bypass the pressure switch, make sure to follow these steps carefully:

- Ensure the compressor is turned off and unplugged.

- Locate the pressure switch and identify the wires connected to it.

- Disconnect the wires from the pressure switch.

- Connect the wires together using wire nuts or another secure method.

- Double-check that all connections are secure.

- Turn on the compressor and monitor its operation carefully.

It is important to emphasize that bypassing the pressure switch should only be done as a temporary solution and should not be relied upon for long-term use. The pressure switch serves as a safety measure to prevent over-pressurization and protect both the compressor and the individual operating it.

If you are experiencing issues with your air compressor, it is always recommended to consult with a professional or refer to the manufacturer’s instructions for proper troubleshooting and repair. Safety should always be the top priority when working with any type of machinery or equipment.

By following proper safety procedures and seeking professional advice when necessary, you can ensure the safe and efficient operation of your air compressor, and avoid any unnecessary risks or damage.

FAQ:

What is a pressure switch?

A pressure switch is a component in an air compressor that automatically turns the compressor on and off based on the pressure levels in the tank.

Why would I want to bypass the pressure switch on my air compressor?

There are a few reasons why someone might want to bypass the pressure switch on their air compressor. One reason could be if the pressure switch is faulty or not functioning properly. Bypassing the pressure switch would allow the compressor to operate without relying on the switch.

How can I bypass the pressure switch on my air compressor?

To bypass the pressure switch on an air compressor, you will need to access the wiring and remove the wires connected to the switch. Once the wires are removed, you can connect them directly to bypass the switch. However, it is important to note that bypassing the pressure switch can be dangerous and should only be done by someone with experience and knowledge of electrical systems.

Is it safe to bypass the pressure switch on an air compressor?

Bypassing the pressure switch on an air compressor can be unsafe if not done properly. The pressure switch is designed to protect the compressor and prevent it from operating at unsafe pressure levels. By bypassing the pressure switch, you are removing this safety mechanism and potentially putting yourself and others at risk. It is recommended to consult a professional or the manufacturer before attempting to bypass the pressure switch.

What are the potential risks of bypassing the pressure switch on an air compressor?

Bypassing the pressure switch on an air compressor can lead to several risks. One major risk is the possibility of the compressor building up excessive pressure, which can cause damage to the tank or other components of the compressor. Additionally, bypassing the pressure switch can also increase the risk of personal injury if the compressor is not properly monitored or if it operates at unsafe pressure levels.

Can I replace a faulty pressure switch instead of bypassing it?

Yes, if your pressure switch is faulty or not functioning properly, it is generally recommended to replace it rather than bypassing it. A new pressure switch can be purchased from the manufacturer or an authorized dealer. Replacing the faulty switch will restore the safety mechanisms and ensure the compressor operates at safe pressure levels.

Can I use my air compressor without a pressure switch?

Using an air compressor without a pressure switch is not recommended. The pressure switch is an important safety feature that prevents the compressor from operating at unsafe pressure levels. Without a pressure switch, the compressor may build up excessive pressure, which can cause damage to the tank or other components and increase the risk of personal injury. It is best to ensure that the pressure switch is functioning properly or replace it if necessary.

Video: