Choosing the Right PSI Setting for Your Air Compressor: A Guide

When it comes to using an air compressor, the PSI (pounds per square inch) setting you choose can have a significant impact on the outcome of your project. Whether you’re inflating tires, painting a surface, or operating pneumatic tools, selecting the correct PSI is crucial for achieving optimal results.

One of the first steps in choosing the right PSI setting for your air compressor is to consult the manufacturer’s recommendations. Every air compressor has a maximum PSI rating that should not be exceeded. It’s important to follow these guidelines to prevent damage to your compressor and ensure your safety.

In addition to the manufacturer’s recommendations, you should also consider the specific task or application you’re working on. Different tasks require different PSI settings. For example, if you’re inflating tires, the recommended PSI setting may vary depending on the size and type of tires you have. On the other hand, if you’re using pneumatic tools, each tool will have its own PSI requirement.

Another factor to consider when choosing the right PSI setting is the desired outcome or effect you want to achieve. For example, if you’re painting a surface, a higher PSI setting may result in a smoother and more even coat. However, if you’re using a nail gun, a lower PSI setting may be sufficient to drive the nails in without damaging the material.

In conclusion, choosing the right PSI setting for your air compressor is essential for the success of your project. By consulting the manufacturer’s recommendations, considering the specific task at hand, and thinking about the desired outcome, you can ensure that you’re using your air compressor effectively and efficiently.

How to Choose the Ideal PSI Setting for Your Air Compressor

1. Consider the specific application: The first step in choosing the ideal PSI setting for your air compressor is to consider the specific application you will be using it for. Different tasks require different levels of pressure, so it’s important to determine the optimal PSI range for your intended use.

2. Consult the manufacturer’s recommendations: The next step is to consult the manufacturer’s recommendations for your air compressor. The manufacturer will often provide guidelines or specifications regarding the ideal PSI settings for various applications. Following these recommendations can help ensure that you are using the air compressor within its intended limits.

3. Test and adjust: Once you have a general idea of the PSI range recommended for your application, it’s time to test and adjust. Start with the lowest recommended PSI setting and observe the performance. If the task is not being completed effectively, gradually increase the PSI until you achieve the desired results. It’s important to find the sweet spot that delivers optimum performance without putting unnecessary strain on the air compressor.

Additional Tips:

- Consider the equipment being used: Different tools and equipment may have specific PSI requirements. Be sure to take these into account when selecting the PSI setting for your air compressor.

- Monitor for signs of overpressure: It’s important to keep an eye out for signs of overpressure, such as leaking air, excessive noise, or vibrating equipment. If you notice any of these signs, reduce the PSI setting immediately to prevent damage.

- Maintain proper maintenance: Regular maintenance of your air compressor, including cleaning filters and checking for leaks, can help ensure that it is operating at optimal efficiency. This, in turn, can help prolong the lifespan of the compressor and improve performance.

In conclusion, choosing the ideal PSI setting for your air compressor requires careful consideration of the specific application, consultation of manufacturer recommendations, and testing and adjusting until the desired results are achieved. By following these steps and considering additional tips, you can ensure that your air compressor operates at its best and delivers the optimal level of performance for your needs.

Understanding PSI and Its Importance

When it comes to using an air compressor, one of the most important factors to consider is the PSI, or pounds per square inch, setting. PSI measures the amount of pressure that a compressor can generate. Understanding PSI and its importance is crucial for ensuring the proper functioning and safety of your air compressor.

The PSI setting plays a crucial role in determining the performance of your air compressor. It determines the maximum amount of pressure that the compressor can generate, which in turn affects the force with which air is delivered to your tools or equipment. Choosing the correct PSI setting is essential for achieving optimal performance and efficiency.

Incorrect PSI settings can have negative consequences. If the PSI is set too low, the air compressor may not be able to deliver enough power to operate your tools effectively. On the other hand, if the PSI is set too high, it can put unnecessary strain on the compressor and increase the risk of accidents or equipment failure.

It is important to consult the manufacturer’s recommendations for the appropriate PSI setting for your specific air compressor model. This information can usually be found in the user manual or on the manufacturer’s website. Following these guidelines will help you find the right balance between delivering enough power to your tools and ensuring the longevity and safety of your air compressor.

Additionally, it is important to periodically check and adjust the PSI setting as needed. Factors such as changes in temperature, altitude, or the type of tools being used may require adjustments in the PSI setting to maintain optimal performance. Regular maintenance and monitoring of PSI levels will help you avoid potential issues and maximize the lifespan of your air compressor.

Factors to Consider When Selecting PSI Settings

When choosing the right PSI setting for your air compressor, there are several important factors to consider. These factors can greatly affect the performance and efficiency of your compressor, as well as the quality of the end result. Here are some key factors to keep in mind:

Type of Application

The type of application you will be using the air compressor for is one of the most important factors to consider when selecting PSI settings. Different applications require different levels of pressure. For example, if you are using the air compressor for painting, you would typically need a higher PSI setting to achieve a smooth and even coat of paint. On the other hand, if you are using the air compressor for inflating tires, a lower PSI setting would be sufficient.

Size and Type of Compressor

The size and type of compressor you have will also impact the PSI settings you should choose. Smaller compressors may have lower maximum PSI limits and may not be suitable for applications that require higher pressure. Additionally, different types of compressors, such as reciprocating or rotary screw compressors, may have different PSI requirements. It is important to consult the manufacturer’s recommendations and specifications to determine the appropriate PSI settings for your specific compressor.

Air Tool Requirements

Consider the specific requirements of the air tools you will be using with the compressor. Each tool has its own recommended PSI range for optimal performance. It is important to match the PSI setting of the compressor to the requirements of the tool. Using too little or too much pressure can affect the tool’s performance and lead to inefficient operation or potential damage.

Air Quality

The quality of the air being supplied by the compressor also plays a role in selecting the PSI settings. Different applications may require different levels of air quality, such as filtration or drying. It is important to consider any air treatment requirements and adjust the PSI settings accordingly to ensure the desired air quality is maintained.

By considering these factors when selecting PSI settings for your air compressor, you can optimize performance, efficiency, and end results for your specific application.

Assessing the Application’s Air Pressure Requirements

When choosing the right PSI setting for your air compressor, it is crucial to assess the specific air pressure requirements of the application you will be using it for. Different applications have different air pressure needs, and using the wrong PSI setting can lead to inefficiency and potential damage to your equipment.

Determining the required PSI:

1. Start by understanding the manufacturer’s recommendations for the equipment you will be using. They often provide guidelines for the ideal air pressure range that should be used. This information can typically be found in the equipment’s manual or specifications.

2. Consider the nature of the application. Some applications, such as inflating tires or operating pneumatic tools, may require higher air pressure levels. On the other hand, applications like painting or operating sensitive machinery may require lower air pressure levels.

3. Take into account any potential variations or fluctuations in the air pressure that may occur during the application. Some applications may require a continuous and consistent air pressure, while others may allow for slight variations.

Testing and adjusting the PSI setting:

1. Once you have determined the range of air pressure required for your application, it is important to test and adjust the PSI setting on your air compressor accordingly. Start with the lowest recommended setting and gradually increase it until you achieve the desired results.

2. Use a pressure gauge to monitor the actual air pressure output of your compressor. Compare it to the required PSI and make any necessary adjustments.

3. Be cautious not to exceed the recommended air pressure range, as it can lead to equipment damage or safety hazards. Always follow the manufacturer’s guidelines and use common sense when adjusting the PSI setting.

By carefully assessing the application’s air pressure requirements and properly adjusting the PSI setting on your air compressor, you can ensure optimal performance and safety for your specific needs.

Determining the Maximum PSI of Your Air Compressor

Understanding PSI Ratings

The maximum PSI (pounds per square inch) of your air compressor is an important specification to consider when choosing the right setting for your tasks. PSI refers to the air pressure that the compressor can generate and sustain. It determines the power and performance of the machine, as well as its capacity to handle different tools and applications.

Checking the Compressor’s Manual

One of the most reliable ways to determine the maximum PSI of your air compressor is by referring to the machine’s manual. The manual usually provides detailed information about the compressor’s specifications, including its maximum PSI rating. It is essential to consult the manual to ensure that you are using the compressor within its recommended limits.

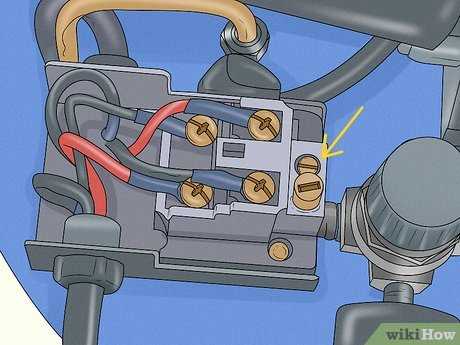

Inspecting the Compressor’s Pressure Gauge

If you cannot find the information in the manual or if you want to double-check the maximum PSI rating, you can inspect the compressor’s pressure gauge. The pressure gauge is typically located on the control panel or the tank. It displays the current air pressure and may also indicate the maximum PSI that the compressor can reach. However, keep in mind that the pressure gauge may not always be accurate, so it should be used as a general guideline rather than the sole source of information.

Researching Online or Contacting the Manufacturer

If the manual and pressure gauge do not provide the maximum PSI rating, you can try researching online or reaching out to the manufacturer for more information. Many manufacturers have websites or customer support lines where you can find additional details about their air compressors, including their maximum PSI. You may also find user forums or online communities where people with the same model of air compressor can share their experiences and knowledge.

Safety Considerations

It is crucial to operate the air compressor within its maximum PSI rating to avoid potential damage to the machine and ensure your safety. Using a higher PSI setting than what the compressor can handle can lead to overheating, leaks, and even the risk of explosion. On the other hand, using a lower PSI setting may result in insufficient power and inadequate performance for your tasks. Always prioritize safety and consult the manufacturer’s guidelines when determining the maximum PSI of your air compressor.

Adjusting PSI for Specific Tasks

When it comes to using an air compressor for specific tasks, it’s important to adjust the PSI to ensure optimal performance and efficiency. Different tasks require different PSI settings, and knowing how to adjust it can make a big difference in the outcome of your project.

1. Painting and Finishing

When it comes to painting and finishing, it’s important to use the right PSI setting to achieve a smooth and professional finish. Typically, a lower PSI is recommended for this task, around 20-30 PSI. This will allow for better control and less overspray, resulting in a clean and even coat.

2. Inflating Tires and Sports Equipment

If you’re using your air compressor to inflate tires or sports equipment, such as basketballs or soccer balls, you’ll need to adjust the PSI accordingly. It’s important to refer to the manufacturer’s recommendations for the specific item you’re inflating. In general, a PSI of 30-40 is often suitable for most tires and sports equipment.

3. Powering Pneumatic Tools

If you’re using an air compressor to power pneumatic tools, such as nail guns or impact wrenches, it’s crucial to adjust the PSI to match the requirements of the tool. Refer to the tool’s user manual or consult with the manufacturer to determine the optimal PSI setting. This will ensure proper functioning of the tool and prevent any damage.

4. Cleaning and Dusting

When using an air compressor for cleaning and dusting purposes, it’s important to use the appropriate PSI setting to avoid causing damage. A PSI of around 70-90 is typically recommended for this task. This provides enough pressure to effectively remove dust and debris without causing any harm to the surface being cleaned.

5. Sandblasting and Surface Preparation

If you’re using an air compressor for sandblasting or surface preparation, it’s crucial to adjust the PSI based on the specific requirements of the project. Higher PSI settings, typically ranging from 80-100, are often necessary for these tasks to achieve proper abrasion and removal of paint or rust.

Remember, always refer to the manufacturer’s recommendations for specific tasks and tools as the PSI requirements may vary. It’s also important to regularly monitor the PSI levels during operation to ensure optimal performance and avoid any potential issues.

Avoiding Over or Under Inflating with the Right PSI

When using an air compressor, it is important to set the correct PSI (pounds per square inch) to avoid over or under inflating your equipment. Over inflating can lead to damage, while under inflating can affect performance and safety. Therefore, understanding the right PSI for your specific needs is crucial.

Determining the Correct PSI

The correct PSI setting depends on a few factors, such as the type of equipment you are inflating, the manufacturer’s recommendations, and the intended use. It is always a good idea to consult the equipment’s manual or contact the manufacturer directly for precise PSI guidelines.

In some cases, you may need to make adjustments based on the size and weight of the equipment. Heavier or larger equipment usually requires a higher PSI setting, while lighter or smaller equipment may require a lower PSI setting.

Importance of Avoiding Over Inflation

Over inflating can have detrimental effects on your equipment. It can lead to premature wear and tear, causing parts to fail or break. Over inflating can also put unnecessary strain on the motor, reducing its lifespan. Additionally, over inflating can compromise safety, as it can lead to the equipment becoming unstable or difficult to control.

Impacts of Under Inflation

Under inflating your equipment can also have negative consequences. It can result in reduced performance, as the equipment may not be able to operate at its full potential. Under inflation can also lead to increased fuel consumption, as the equipment needs to work harder to compensate for the lack of pressure. Moreover, under inflating can increase the risk of accidents, as it affects traction and stability.

Overall, finding the right PSI setting for your air compressor is essential to ensure the longevity, performance, and safety of your equipment. Take the time to research and consult guidelines to avoid the pitfalls of over or under inflating. Remember, the right PSI can make all the difference in maintaining the efficiency of your equipment.

Importance of Regularly Checking and Adjusting PSI Settings

1. Safety:

Regularly checking and adjusting the PSI settings of your air compressor is crucial for ensuring safety. When the PSI settings are not properly calibrated, it can lead to over-inflated or under-inflated tires and equipment. Over-inflated tires can increase the risk of blowouts, while under-inflated tires can compromise the stability and handling of vehicles. By regularly checking and adjusting the PSI settings, you can maintain the optimal pressure for each specific application and minimize the risk of accidents and equipment failure.

2. Efficiency:

Keeping the PSI settings of your air compressor at the right level is essential for optimal performance and efficiency. When the PSI settings are too high, it can result in excessive air pressure, which can cause damage to equipment and result in energy wastage. On the other hand, if the PSI settings are too low, the compressor will struggle to provide enough power, leading to poor performance and increased energy consumption. By regularly checking and adjusting the PSI settings, you can ensure that your air compressor operates at its peak efficiency, saving you time and money in the long run.

3. Equipment Longevity:

Properly calibrated PSI settings are crucial for maintaining the longevity of your air compressor and the equipment it powers. When the PSI settings are not regularly checked and adjusted, it can lead to excessive wear and tear on the compressor itself, as well as the tools and machinery connected to it. Over time, this can result in increased maintenance costs and shorter equipment lifespan. By regularly monitoring and adjusting the PSI settings, you can ensure that your air compressor and the equipment it powers are operating within their intended parameters, prolonging their lifespan and reducing the need for costly repairs or replacements.

Getting the Most out of Your Air Compressor by Optimizing PSI

Setting the right PSI on your air compressor is crucial for achieving optimal performance and efficiency. By properly adjusting the PSI, you can ensure that your air compressor operates at its best and delivers the desired results for your specific applications.

One of the key factors to consider when optimizing PSI is the type of tool or equipment you will be using with the compressor. Different tools have different PSI requirements, and using the wrong PSI setting can lead to poor performance or damage to the tool.

To determine the ideal PSI setting for your specific tool, refer to its manual or consult with the manufacturer. They will provide recommended PSI ranges that will ensure optimal functionality and longevity of the tool.

Additionally, it’s important to consider the air demands of your application. Some tasks may require higher PSI settings to deliver the necessary power and airflow. For example, powering pneumatic nailers or spray guns may require higher PSI settings compared to inflating tires or running air-powered staplers.

Regularly monitoring and adjusting the PSI setting can also help optimize your air compressor’s performance. By fine-tuning the PSI based on your specific needs, you can ensure that you are using the right amount of air pressure without wasting energy or risking overpressure situations.

In conclusion, getting the most out of your air compressor requires optimizing the PSI setting. Consider the specific requirements of your tools and applications, consult manuals and manufacturers for recommended PSI ranges, and regularly monitor and adjust the PSI to achieve optimal performance and efficiency.

FAQ:

What is PSI and why is it important in an air compressor?

PSI stands for pounds per square inch, and it measures the amount of pressure that the air compressor outputs. It is important because the PSI setting determines the power and performance of the air compressor.

How do I determine the right PSI setting for my air compressor?

The right PSI setting for your air compressor depends on the specific application and tools you will be using. It is generally recommended to consult the manufacturer’s instructions or guidelines for the tools and equipment you will be using to determine the appropriate PSI setting.

What happens if I set the PSI too high on my air compressor?

If you set the PSI too high on your air compressor, it can put excessive pressure on your tools and equipment, causing them to malfunction or even break. Additionally, high PSI can also lead to safety hazards, such as bursting air hoses or exploding tanks.

Can I use different PSI settings for different tools with the same air compressor?

Yes, you can use different PSI settings for different tools with the same air compressor. However, it is important to adjust the PSI setting accordingly and not exceed the maximum recommended PSI for each tool.

What are some common PSI settings for air compressors?

Common PSI settings for air compressors can vary depending on the specific application and tools. However, for small pneumatic tools, such as nail guns or inflators, a PSI range of 70-90 is often sufficient. For more demanding tools, such as sanders or sprayers, a higher range of 90-120 PSI may be required.

Can I use a lower PSI setting on my air compressor to save energy?

Using a lower PSI setting on your air compressor can help save energy. However, it is important to ensure that the lower PSI setting is still sufficient to power and operate your tools effectively. Using a significantly lower PSI setting may result in reduced performance or even damage to your tools.

What are the potential risks of using the wrong PSI setting for an air compressor?

Using the wrong PSI setting for an air compressor can lead to various risks. If the PSI is too high, it can cause damage to your tools, equipment, or even personal injury. If the PSI is too low, it may result in poor tool performance or the inability to complete tasks effectively.

Video: