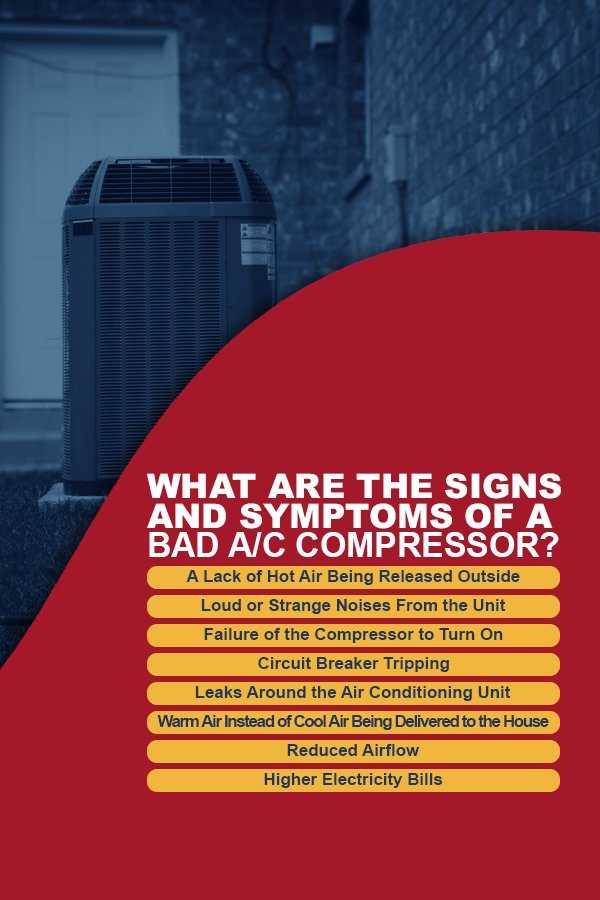

Signs that your air compressor might be faulty

Regular maintenance and care are essential for the proper functioning of an air compressor. However, even with proper maintenance, air compressors can sometimes develop faults or issues that need attention. Recognizing the signs of a faulty air compressor is crucial to ensure the safety and efficiency of the machine.

One of the most common signs of a faulty air compressor is a noticeable decrease in performance. If you notice that your air compressor is not generating the same level of pressure it used to, or if it takes longer to reach the desired pressure, it could be a sign of a problem. It is essential to address this issue promptly, as a drop in performance can lead to inefficient operation and reduced productivity.

Another sign of a faulty air compressor is unusual noises. During normal operation, air compressors often emit some noise. However, if you hear new or excessive noises such as grinding, banging, or squealing, it could indicate a problem. Unusual noises can be an indication of worn-out components, loose parts, or improper lubrication. Ignoring such noises can lead to further damage to the compressor and even pose potential safety risks.

Leaks are another indicator of a faulty air compressor. If you notice air or oil leaks around the compressor, it is a clear sign that something is wrong. Leaks can occur due to loose connections, worn-out seals, or faulty valves. Ignoring leaks can result in poor performance, decreased efficiency, and unnecessary wear and tear on the compressor components.

In conclusion, recognizing the signs of a faulty air compressor is crucial for its proper maintenance and efficient operation. Regularly inspecting and addressing any drop in performance, unusual noises, or leaks can prevent further damage and increase the lifespan of the compressor. Timely maintenance and repair can save you from costly repairs and downtime in the long run.

Signs of air compressor malfunction

1. Decreased Air Pressure

If you notice a decrease in the air pressure produced by your air compressor, it may be a sign of a malfunction. This could be caused by a variety of issues, such as a clogged air filter, a worn-out pressure switch, or a leak in the air hose. It’s important to address this issue promptly, as low air pressure can affect the performance of your pneumatic tools and equipment.

2. Unusual Noises

An air compressor in good working condition should operate relatively quietly. If you start hearing strange or excessive noises coming from your compressor, it could indicate a problem. This could be due to a worn-out motor, loose components, or internal damage. It’s important to investigate and fix the source of the noise to prevent further damage to the compressor.

3. Excessive Heat

If your air compressor feels excessively hot to the touch, it may be a sign of a malfunction. Overheating can occur for various reasons, such as a malfunctioning cooling fan, a blocked air intake, or insufficient lubrication. Continuous operation of a hot air compressor can lead to further damage, so it’s important to identify and address the cause of the overheating.

4. Constant Cycling

If your air compressor is constantly turning on and off, it may be a sign of a malfunctioning pressure switch or a leak in the system. This cycling, also known as “short cycling,” can put unnecessary strain on the compressor and decrease its overall lifespan. It’s important to have the pressure switch and system checked to ensure proper functioning.

5. Oil Leaks

Finding oil leaks around your air compressor can indicate a problem with its internal components, such as worn-out seals or gaskets. Not only does this reduce the efficiency of the compressor, but it can also lead to damage if left unaddressed. Regular inspection and maintenance are essential to ensure the longevity and optimal performance of your air compressor.

In conclusion, it’s crucial to pay attention to these signs of air compressor malfunction. By addressing them promptly and seeking professional assistance if needed, you can prolong the lifespan of your compressor and ensure its efficient operation.

Odd sounds and vibrations

One of the signs that your air compressor may be faulty is the presence of odd sounds and vibrations. If you are hearing strange noises such as grinding, clanking, or banging coming from your air compressor, it could be an indication that something is wrong.

These noises could be caused by a variety of issues such as loose or worn-out parts, a malfunctioning motor, or even debris stuck in the compressor unit. It is important to pay attention to these sounds as they can indicate a potential problem that may require immediate attention.

In addition to strange sounds, vibrations can also be a sign of a faulty air compressor. If you notice excessive vibrations coming from your compressor, it could be an indication that the unit is not functioning properly. This could be caused by a misaligned motor, loose mounting bolts, or worn-out bearings.

If you experience any odd sounds or vibrations coming from your air compressor, it is recommended to shut it off and have it inspected by a professional technician. Ignoring these signs can lead to further damage to the compressor and potentially more expensive repairs.

Low air pressure

Low air pressure is one of the common signs that your air compressor might be faulty. If you notice that the air pressure is not reaching the desired level, it could indicate several issues with your compressor.

1. Leaks: One possible reason for low air pressure is the presence of leaks in the system. Leaks can occur in various places such as pipes, fittings, or valves. It is important to check for any visible signs of leaks and repair them as soon as possible to maintain proper air pressure.

2. Clogged filters: Another reason for low air pressure is clogged air filters. Over time, the filters can become dirty and clogged with dust and debris, causing a decrease in the airflow. Regularly cleaning or replacing the filters can help prevent low air pressure.

3. Malfunctioning pressure switch: The pressure switch is responsible for monitoring and controlling the air pressure in the compressor. If the pressure switch is faulty, it may not accurately detect the pressure levels, resulting in low air pressure. Replacing the pressure switch can resolve this issue.

4. Worn-out or damaged compressor parts: The air compressor consists of various components that work together to generate and maintain the air pressure. Over time, these parts can wear out or become damaged, affecting the overall performance of the compressor. Regular maintenance and inspection of the compressor can help identify any worn-out or damaged parts and replace them as needed.

Leaking air

A common sign that your air compressor might be faulty is if it is leaking air. Air leaks can occur in various parts of the compressor, including the hoses, valves, fittings, and tank. If you notice a hissing sound or can feel air escaping from the compressor, it is a clear indication of a leak.

Leaking air can significantly affect the performance of your air compressor. It can cause a drop in air pressure, leading to reduced efficiency and slower work times. Additionally, air leaks can put a strain on the compressor’s motor, as it has to work harder to compensate for the lost air. This can result in increased energy consumption and potential damage to the motor over time.

When dealing with a leaking air compressor, it is important to identify the source of the leak. Start by inspecting the hoses and connections for any visible damage or loose fittings. Tighten or replace any damaged parts as necessary. If the leak persists, it may indicate a problem with the valves or tank, which may require professional repair or replacement.

Regular maintenance is key to preventing air leaks in your compressor. Make sure to check the hoses, valves, and fittings regularly for any signs of wear or damage. It is also important to keep the compressor clean and free of debris, as dirt and dust can contribute to leaks. By taking proactive measures, you can prolong the lifespan of your air compressor and ensure optimal performance.

In summary, leaking air is a common sign of a faulty air compressor. It can lead to reduced performance, increased energy consumption, and potential damage to the motor. Regular maintenance and prompt repair of any leaks are crucial for maintaining the efficiency and longevity of your air compressor.

Unusual smell or smoke

If you notice an unusual smell or smoke coming from your air compressor, it could be a sign of a serious problem. A burning or electrical smell could indicate that the motor or wiring of the compressor is overheating or damaged. This could be caused by a faulty motor, worn-out belts, or a malfunctioning control panel.

If you see smoke or notice a strong burning smell, it is important to immediately turn off the air compressor and unplug it from the power source to prevent further damage or potential fire hazards. Continuing to use a faulty air compressor can lead to further damage or even pose a safety risk.

If you are experiencing an unusual smell or smoke, it is recommended to have your air compressor inspected and repaired by a qualified technician. They will be able to identify the source of the problem and make the necessary repairs to ensure the safe and proper operation of your air compressor.

Difficulty starting or shutting off

If you are experiencing difficulty starting or shutting off your air compressor, it could be a sign that there is a problem with the electrical system or the components responsible for controlling the compressor’s operation.

One possible cause of difficulty starting or shutting off could be a faulty pressure switch. The pressure switch is a device that monitors the pressure inside the air compressor tank and controls when the compressor starts or stops. If the pressure switch is faulty, it may not accurately detect the pressure and cause the compressor to have trouble starting or shutting off.

Another potential issue could be a malfunctioning motor or capacitor. The motor is responsible for providing power to the compressor, while the capacitor helps to start the motor. If either of these components is faulty, it could prevent the compressor from starting or shutting off properly.

Additionally, a clogged or dirty air filter can also contribute to difficulty starting or shutting off. A dirty air filter can restrict airflow to the compressor, making it harder for the motor to start or causing it to run longer than necessary.

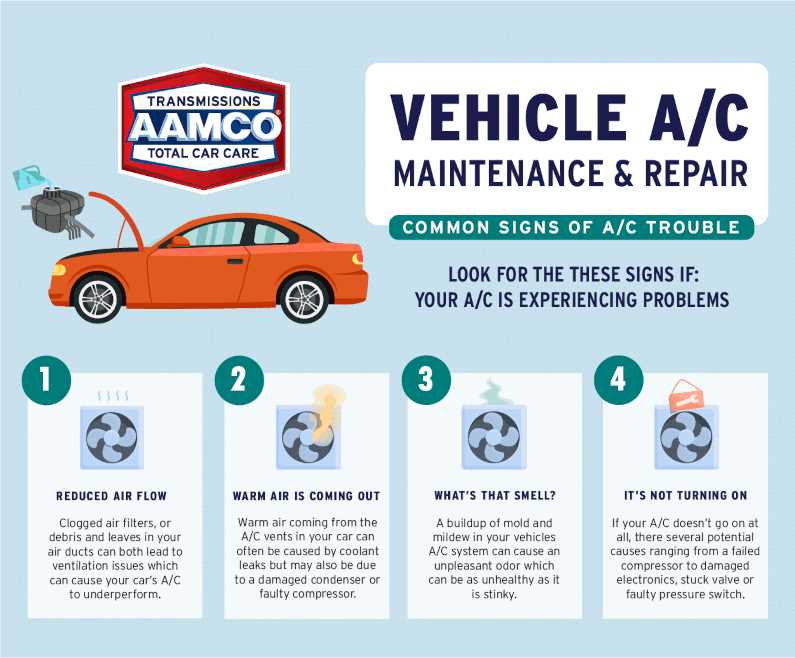

Inconsistent airflow

One of the signs that your air compressor might be faulty is inconsistent airflow. You may notice that the airflow from your air compressor is not consistent, meaning that it may come out in bursts or be unusually weak. This can be a sign that there is a problem with the compressor’s motor or that there is a blockage in the air lines.

If you experience inconsistent airflow, it is important to address the issue as soon as possible. A lack of consistent airflow can affect the performance of your air tools and machinery, as well as result in inefficient operation. In some cases, you may need to replace the compressor’s motor or clean out any blockages in the air lines. It is also a good idea to regularly clean and maintain your air compressor to prevent future airflow issues.

Here are some common causes of inconsistent airflow:

- Motor issues: If the motor of your air compressor is faulty, it may not be able to provide a consistent airflow. This could be due to worn-out motor brushes, a faulty capacitor, or a damaged motor windings, among other things.

- Air leaks: Air leaks in the air lines or fittings can cause inconsistent airflow. These leaks can occur due to loose connections, damaged fittings, or worn-out seals. It is important to inspect the air lines and fittings regularly for any leaks and repair them as needed.

- Blocked air filter: A clogged or dirty air filter can restrict the flow of air and result in inconsistent airflow. It is crucial to clean or replace the air filter regularly to ensure proper airflow.

- Damaged pressure regulator: A faulty pressure regulator can also lead to inconsistent airflow. If the pressure regulator is not functioning correctly, it may not be able to maintain a consistent pressure, leading to irregular airflow.

Overall, inconsistent airflow from your air compressor can indicate various issues that need to be addressed. By identifying and resolving these issues promptly, you can ensure the reliable operation of your air tools and machinery.

Increased energy consumption

One of the signs that your air compressor might be faulty is an increase in energy consumption. If you notice a sudden spike in your energy bills without any other explanation, it could be a sign that your air compressor is not functioning efficiently.

A faulty air compressor may require more energy to generate the same amount of compressed air. This could be due to a variety of reasons, such as a clogged or dirty air filter, worn-out compressor components, or leaks in the compressed air system.

As the compressor works harder to produce the desired amount of compressed air, it will consume more electricity, leading to higher energy bills. If you notice a significant increase in your energy consumption, it is important to have your air compressor inspected by a professional technician to identify and resolve any potential issues.

Addressing the issue of increased energy consumption not only helps to reduce your energy bills but also ensures that your air compressor operates efficiently, prolonging its lifespan and minimizing the risk of further damage or breakdowns.

Poor overall performance

If you notice that your air compressor is not operating at its usual level of performance, it could be a sign of a faulty compressor. Poor overall performance can manifest in different ways, such as decreased air pressure, slower inflation times, or difficulty starting the compressor.

One possible cause of poor overall performance is a malfunctioning motor. If the motor is not running at its full capacity, it may struggle to generate the necessary power to compress air efficiently. This can result in lower air pressure output and slower inflation times.

Another potential cause of poor performance is a leaking air compressor tank. If the tank is leaking air, it can lead to a decrease in overall pressure and make it more difficult for the compressor to perform effectively. Additionally, a leaking tank can put added strain on the motor, further exacerbating the issue.

Furthermore, worn-out components such as valves or gaskets can also contribute to poor overall performance. These components play a crucial role in regulating the airflow and maintaining proper compression. If they become worn or damaged, they can cause air leaks and reduce the efficiency of the compressor.

In summary, poor overall performance can be a sign that your air compressor is faulty. It may indicate issues with the motor, a leaking tank, or worn-out components. If you notice any decrease in air pressure or slower inflation times, it is advisable to have your compressor inspected and repaired to ensure optimal performance.

FAQ:

What are the signs that my air compressor might be faulty?

Some signs that your air compressor might be faulty include strange noises, oil leaks, low air pressure, and frequent cycling on and off.

How can I tell if my air compressor has a problem with the motor?

If your air compressor is struggling to start, makes a humming sound, or trips the circuit breaker, it might have a problem with the motor.

Why does my air compressor keep shutting off?

There are a few reasons why your air compressor might keep shutting off, such as a faulty pressure switch, a clogged air filter, or a problem with the motor or pump.

What should I do if my air compressor is leaking oil?

If your air compressor is leaking oil, you should first check the oil level and make sure it is at the correct level. If the oil level is fine, the problem might be with a faulty seal or gasket, and you may need to replace it.

Is it normal for my air compressor to make loud noises?

While air compressors can be noisy, if your air compressor is making unusually loud or strange noises, it might be a sign of a problem, such as a loose component or a failing motor.

Video: