When was the air compressor invented: A historical overview

The invention of the air compressor has played a significant role in the development of various industries, revolutionizing the way we use and manipulate air. The history of air compressors dates back centuries, starting with ancient civilizations seeking ways to harness the power of air.

One of the earliest mentions of compressed air can be traced back to the 3rd century BC in Greece, where a device known as a Euodias was used to compress air for practical purposes. However, it wasn’t until the 17th century that the first documented design of an air compressor was created by Italian physicist and engineer Otto von Guericke.

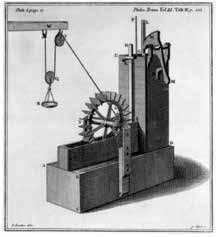

Von Guericke’s design, known as the “Hemispheres,” consisted of two copper hemispheres that, when pressed together, expelled air. This invention became the foundation for further advancements in air compressor technology. In the following centuries, various inventors and engineers made significant contributions to improving the efficiency and functionality of air compressors for industrial use.

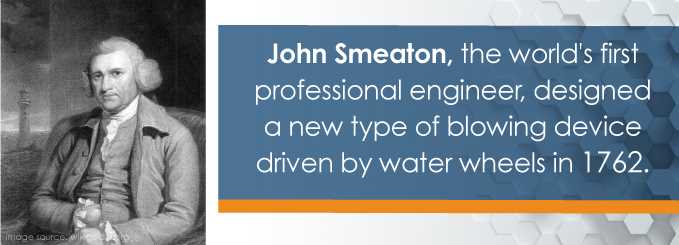

One such milestone came in the 19th century with the invention of the reciprocating compressor by John Smeaton. This design incorporated a piston and cylinder mechanism, allowing for more reliable and efficient air compression. The reciprocating compressor quickly gained popularity and became a staple in many industries, including mining, construction, and manufacturing.

The Origins of Compressed Air

In the quest for harnessing and utilizing air as a source of power, the concept of compressed air dates back centuries. The origins of compressed air can be traced back to ancient civilizations, where human ingenuity and primitive tools laid the foundation for its discovery.

Ancient Innovations: The ancient Egyptians and Greeks are believed to have experimented with compressed air, although they may not have fully understood the scientific principles behind it. They used simple bellows and blowpipes to generate compressed air, which they utilized for various purposes such as fire-making, metallurgy, and even medical treatments.

The Advent of Pneumatics: It was during the Renaissance period that advancements in engineering and science led to a more systematic study of compressed air. Inventors like Leonardo da Vinci explored the potential of pneumatic machines, designing devices such as compressors and pneumatic cannons. The concept of compressed air as a source of mechanical power began to take shape.

The Industrial Revolution: The industrial revolution in the 18th century marked a turning point in the development of compressed air technology. With the advent of steam power and the growing need for efficient machinery, compressed air became a crucial element in the operation of factories and mining operations. Innovators like John Smeaton and George Medhurst designed and improved upon compressors and air engines, propelling the industrial revolution forward.

Modern Innovations: The 19th and 20th centuries witnessed significant advancements in compressed air technology. With the invention of the air compressor in the mid-19th century, the industrial applications of compressed air expanded exponentially. Compressed air found its way into a wide range of industries, including manufacturing, construction, and transportation.

Today, compressed air continues to be a vital source of power and energy in various sectors. From operating pneumatic tools to powering industrial machinery, the uses of compressed air are vast and diverse. It is a testament to the ingenuity and resourcefulness of humans throughout history that the concept of compressed air has evolved from ancient innovations to become an integral part of modern technology.

The Beginnings of Air Compression Technology

Air compression technology has a long and fascinating history that dates back thousands of years. While the concept of compressing air is a relatively simple one, the development of the tools and techniques to efficiently harness this power has evolved significantly over time.

Ancient Origins

The origins of air compression technology can be traced back to ancient civilizations such as Egypt and Greece. The Egyptians used a type of bellows, known as a “dobson fly” bellows, to blow air into the fire and increase its intensity. These early examples of air compression technology laid the foundation for the development of more sophisticated devices in the future.

The Greeks were also pioneers in the field of air compression, with the invention of the “fire syringe.” This device used a piston to compress air and create high temperatures, allowing for the ignition of flammable materials. The fire syringe was an important precursor to the modern air compressor, as it demonstrated the potential of compressed air as a source of power.

The Industrial Revolution and Beyond

The Industrial Revolution in the 18th and 19th centuries marked a significant turning point in the history of air compression technology. During this period, inventors and engineers began to explore new ways to harness the power of compressed air for a wide range of industrial applications.

One of the key developments during this time was the invention of the steam engine by James Watt. The steam engine utilized pressurized steam to generate mechanical power, and it became a crucial component in the development of early air compressors. By using the power of steam to drive a piston, these early compressors were able to produce higher levels of compressed air than ever before.

As the industrial revolution progressed, air compressors became essential tools in a variety of industries, including mining, construction, and manufacturing. The invention of new compressor designs, such as rotary screw and reciprocating compressors, further improved the efficiency and effectiveness of compressed air systems.

In the modern era, air compression technology continues to evolve, with advancements in energy efficiency, control systems, and environmental sustainability. From small portable compressors to massive industrial systems, air compression technology plays a vital role in countless applications across the globe.

The First Patent for an Air Compressor

The history of air compressors dates back to the 17th century, with the first patent for an air compressor being granted to a French engineer, Denis Papin, in 1675. Papin’s invention was a precursor to modern air compressors and played a vital role in the development of this technology.

Denis Papin’s patent described a device that used a cylinder and a piston to compress air. The cylinder was sealed, and as the piston was moved back and forth, air was drawn into the cylinder and compressed. This compressed air could then be used for various purposes, such as operating machinery or pumping water.

Papin’s air compressor was a significant advancement at the time, as it provided a more efficient and reliable method of compressing air compared to previous methods. His invention laid the foundation for future innovations in air compression technology.

Although Papin’s air compressor was a breakthrough, it was not widely adopted immediately. It took several decades for the technology to gain traction and become more commonplace in industrial applications. However, his patent marked a crucial milestone in the history of air compressors, paving the way for further advancements and improvements in the years to come.

The Industrial Revolution and the Rise of Air Compressors

The Industrial Revolution, which took place in the 18th and 19th centuries, brought about significant advancements in technology, making way for the rise of air compressors. This period saw a shift from manual labor to machine-based production, and the need for efficient power sources became apparent. Air compressors played a crucial role in powering machinery and driving various industrial processes.

During the Industrial Revolution, the demand for compressed air grew rapidly across industries such as manufacturing, mining, and transportation. Compressed air was utilized to power pneumatic tools, operate machinery, and provide ventilation in mines. The invention and development of air compressors revolutionized industrial processes, making them faster, more productive, and efficient.

One of the significant advancements in air compressor technology during this time was the introduction of the reciprocating air compressor. These compressors featured pistons that moved back and forth, compressing air and storing it in tanks. This design allowed for a continuous and reliable source of compressed air, meeting the increasing demands of the rapidly growing industries.

Another notable development was the introduction of rotary screw compressors. Unlike reciprocating compressors, these machines used rotating screws to compress air. Rotary screw compressors provided a more efficient and continuous source of compressed air, making them ideal for large-scale industrial applications.

The Industrial Revolution not only fostered the growth of air compressor technology but also created a need for innovations in compressor design and efficiency. This led to further advancements such as the use of electric motors to power compressors, the implementation of air receivers for storing compressed air, and the development of portable and mobile compressors.

In conclusion, the Industrial Revolution brought about a significant increase in the demand for compressed air, which led to the rise of air compressors. These machines played a crucial role in powering machinery and driving industrial processes, making them essential for the rapid growth and development of various industries.

The Use of Air Compressors in Mining and Construction

The use of air compressors in mining and construction has revolutionized these industries, enabling them to achieve higher levels of efficiency and productivity.

Mining: In the mining industry, air compressors are used for a variety of purposes. One important application is in the drilling operations. Air compressors provide compressed air that powers drilling machines, allowing them to easily penetrate the earth and extract valuable minerals. Compressed air is also used to power pneumatic tools like rock drills and breakers, making it easier to excavate and remove large quantities of rock and debris. Additionally, compressed air is utilized in ventilation systems to provide fresh air to underground mines and remove harmful gases.

Construction: Air compressors play a crucial role in the construction industry as well. They are used to power a wide range of tools and equipment, such as pneumatic hammers, nail guns, and paint sprayers. These tools are not only more efficient and effective when powered by compressed air, but they also eliminate the need for manual labor, saving time and reducing the risk of injuries. Air compressors are also used in concrete production, where they provide the necessary pressure for the mixing and transportation of concrete materials. Furthermore, air compressors are employed in compressed air systems for construction site dust suppression, helping to create a safer and healthier working environment.

Overall, air compressors have greatly contributed to the success of the mining and construction industries by increasing productivity, improving safety, and reducing manual labor. Their versatility and reliability make them an indispensable tool in these demanding fields.

The Role of Air Compressors in the Transportation Industry

Air compressors play a crucial role in the transportation industry, providing a reliable source of compressed air for various applications. From maintaining tire pressure to powering braking systems, air compressors are utilized in multiple facets of transportation.

Tire Inflation: Air compressors are used in the transportation industry to inflate and maintain optimal tire pressure. Properly inflated tires are essential for safe and efficient driving, improving fuel efficiency, reducing wear and tear, and minimizing the risk of blowouts.

Braking Systems: Air compressors are integral to the operation of air brakes, commonly found in heavy-duty vehicles such as trucks and buses. Compressed air powers the braking system, providing the necessary force to engage the brakes and bring the vehicle to a stop. This ensures reliable and efficient braking performance.

Suspension Systems: Air compressors are also used in transportation for air suspension systems. These systems utilize compressed air to adjust the suspension height of a vehicle, improving ride comfort, stability, and handling. Air suspension systems are commonly found in luxury cars, commercial vehicles, and heavy-duty trucks.

Air Tools: In the transportation industry, air compressors are employed to power air tools for various tasks. These tools include impact wrenches, pneumatic drills, air ratchets, and sanders, among others. Air-powered tools are preferred due to their high torque, efficiency, and versatility.

Onboard Systems: Air compressors are often integrated into the onboard systems of transportation vehicles. For example, trains utilize air compressors to power air conditioning systems, horn signals, and pneumatic doors. In commercial aircraft, air compressors are used for cabin pressurization, cooling systems, and hydraulic power generation.

Overall, air compressors are indispensable in the transportation industry, facilitating various essential functions such as tire inflation, braking systems, suspension adjustments, powering air tools, and supporting onboard systems. Their reliability and efficiency make them vital components in ensuring safety, performance, and comfort in transportation vehicles.

Air Compressors in Modern Applications and Everyday Life

Air compressors play a vital role in modern applications and are often found in various industries and everyday life. They are used to generate compressed air, which can be utilized for a wide range of purposes due to its versatility and ease of transport.

Industrial Applications

Air compressors are extensively used in industrial applications for powering machinery and tools. They provide a reliable source of compressed air for pneumatic systems, allowing for efficient and precise control in manufacturing processes. From assembly lines to automation systems, air compressors are an integral part of modern industrial operations.

Air compressors are also utilized in various industrial processes such as cooling, filtration, and drying. They can provide a constant supply of compressed air for cooling down equipment, removing dust and particles, and drying materials or surfaces. In industries such as automotive, construction, and food processing, air compressors are indispensable for improving productivity and ensuring product quality.

Construction and Home Improvement

In the construction industry, air compressors are indispensable for powering a wide range of tools and equipment. From pneumatic nail guns and jackhammers to paint sprayers and sandblasters, air compressors provide the necessary power and pressure for efficient and precise work. They save time and effort, allowing construction projects to be completed more quickly and effectively.

Air compressors are also commonly used in home improvement projects. They are often employed for tasks such as inflating tires, powering air tools, and cleaning surfaces. Whether it’s inflating a bicycle tire or operating a pneumatic wrench, air compressors make tasks easier and more manageable, even for non-professionals.

Medical and Dental Applications

In the medical field, air compressors are crucial for various applications. They are utilized in medical air systems, providing compressed air for respiratory therapy, anesthesia delivery systems, and surgical equipment. Air compressors play a vital role in maintaining a sterile environment, powering instruments, and facilitating patient care in hospitals and clinics.

Dental offices also rely on air compressors for a wide range of procedures. From powering dental drills and suction systems to cleaning instruments and delivering compressed air for dental chairs, air compressors are an essential component of dental offices. They ensure a reliable source of compressed air for high-quality dental care and patient comfort.

In conclusion, air compressors are an integral part of modern applications and everyday life. From industrial operations and construction projects to medical and dental applications, their versatility and reliability make them indispensable in numerous industries and in the hands of everyday people. The benefits they provide in terms of efficiency, precision, and convenience make them a valuable tool in contemporary society.

The Future of Air Compressor Technology

1. Efficiency and Energy-saving

The future of air compressor technology lies in improving efficiency and energy-saving capabilities. As the demand for compressed air continues to grow in various industries, there is a need for more efficient and environmentally friendly compressor systems. Manufacturers are investing in research and development to design compressors that can deliver higher performance while consuming less energy.

2. Integration of Internet of Things (IoT)

The integration of Internet of Things (IoT) technology is expected to revolutionize the air compressor industry. With IoT capabilities, compressors can be connected to a network and monitored remotely, allowing for real-time analysis and optimization of performance. This connectivity also enables predictive maintenance, as the compressors can send alerts when maintenance is needed, reducing downtime and improving overall efficiency.

3. Advanced Control Systems

Advanced control systems will play a crucial role in the future of air compressor technology. These systems utilize artificial intelligence and machine learning algorithms to optimize compressor operation based on specific application requirements. By continuously analyzing data and making adjustments in real-time, these control systems can improve efficiency, reduce energy consumption, and extend the lifespan of the compressor.

4. Noise Reduction

Noise reduction is another area that will see advancements in air compressor technology. Compressors can be loud and disruptive in various settings, including industrial and residential areas. Manufacturers are developing innovative solutions to reduce noise levels, such as sound-insulated enclosures and vibration-damping technologies. These advancements will allow for the use of compressors in noise-sensitive environments without causing disturbances.

5. Integration with Renewable Energy Sources

The future of air compressor technology will also involve the integration of renewable energy sources. Compressors can be powered by alternative energy such as solar or wind power, reducing reliance on fossil fuels and minimizing carbon emissions. This integration will not only make compressors more sustainable but also contribute to environmental conservation efforts.

In conclusion, the future of air compressor technology holds exciting possibilities. With advancements in efficiency, IoT integration, control systems, noise reduction, and renewable energy integration, air compressors will become more energy-efficient, intelligent, quiet, and sustainable. These innovations will not only benefit industries that heavily rely on compressed air but also contribute to a greener and more efficient future.

FAQ:

Who invented the air compressor?

The air compressor was invented by Otto von Guericke, a German physicist and engineer, in the 17th century.

What was the purpose of the first air compressor?

The first air compressor was invented to demonstrate the power of air pressure and was used to perform various experiments and create a vacuum.

When was the air compressor first used for industrial purposes?

The air compressor started being used for industrial purposes in the mid-19th century. It was initially used in mining operations to power drills and remove debris.

How has the technology of air compressors evolved over time?

Over time, air compressors have become more efficient, compact, and versatile. Modern air compressors use advanced technologies such as rotary screw and piston-driven compressors to provide high-pressure air for various applications.

Video: