Step-by-Step Guide: How to Use an Adjustable Wrench Properly

An adjustable wrench is a versatile tool that every DIY enthusiast should have in their toolbox. Whether you’re tightening a loose bolt or loosening a stubborn nut, an adjustable wrench can come in handy in a wide range of situations. However, using an adjustable wrench properly is essential to ensure safety and efficiency.

In this step-by-step guide, we will walk you through the process of using an adjustable wrench properly. We will cover everything from selecting the right size wrench to gripping techniques and common mistakes to avoid. By following these instructions, you’ll be able to tackle various tasks with confidence and avoid damaging your tools or workpieces.

Before we dive into the details, it’s important to note that different types of adjustable wrenches may have slightly different features and instructions. However, the basic principles of using an adjustable wrench remain the same. This guide will provide you with a solid foundation to build upon, regardless of the specific type of adjustable wrench you are using.

Note: It’s always a good idea to refer to the manufacturer’s instructions and guidelines for your specific adjustable wrench.

Understanding the Adjustable Wrench

An adjustable wrench is a versatile tool used for tightening and loosening bolts, nuts, and other fasteners. It is also known as a crescent wrench or a spanner wrench. Adjustable wrenches come in various sizes, allowing them to fit different fastener sizes.

Parts of an Adjustable Wrench

A typical adjustable wrench consists of the following parts:

- Jaw: The part of the wrench that grips the fastener.

- Handle: The long, straight section of the wrench that provides leverage.

- Head: The adjustable part of the wrench that can be moved to fit different fastener sizes.

- Knurl: The textured pattern on the head of the wrench that provides grip.

- Scale: Some adjustable wrenches have a scale on the head, indicating the size of the fastener the wrench is set to.

How Adjustable Wrenches Work

Adjustable wrenches work by adjusting the position of the movable jaw to fit the size of the fastener. To use an adjustable wrench, follow these steps:

- Select the appropriate-sized wrench for the fastener you want to tighten or loosen.

- Hold the handle of the wrench with one hand and rotate the head of the wrench with your other hand.

- Adjust the position of the jaw until it fits snugly around the fastener.

- Hold the handle of the wrench firmly and turn it clockwise to tighten or counterclockwise to loosen the fastener.

It’s important to adjust the wrench properly to ensure a secure grip on the fastener. If the wrench is not adjusted correctly, it may slip or damage the fastener.

Tips for Using an Adjustable Wrench

Here are some tips to keep in mind when using an adjustable wrench:

- Position the wrench so that the force applied is perpendicular to the handle. This will help prevent the wrench from slipping.

- Ensure that the jaw of the wrench is fully engaged with the fastener before applying pressure.

- Use the correct size of wrench to avoid damaging the fastener or the wrench itself.

- If possible, support the fastener with another hand or a wrench to prevent it from turning.

- Regularly inspect the wrench for any signs of wear or damage, such as rust or worn-out teeth. Replace the wrench if necessary.

By understanding the different parts of an adjustable wrench and following the proper technique, you can effectively use this versatile tool for a variety of tasks.

Choosing the Right Size

When using an adjustable wrench, it is crucial to choose the right size for the job. Using the wrong size wrench can lead to inefficiency and even damage to both the wrench and the object you are working on. Here are some tips to help you choose the right size:

1. Measure the Nut or Bolt

The first step in choosing the right size adjustable wrench is to measure the nut or bolt you need to loosen or tighten. Use a measuring tape or a caliper to accurately measure the diameter of the nut or bolt. This measurement will help you determine the appropriate size of the wrench.

2. Consider the Length of the Handle

In addition to the size of the nut or bolt, you should also consider the length of the handle on the adjustable wrench. Longer handles provide more leverage, making it easier to apply more force. However, longer handles can also make the wrench bulkier and less maneuverable in tight spaces. Consider the space you will be working in and choose a handle length that is appropriate for the job.

3. Consult a Size Chart

If you are unsure of the appropriate size of the wrench, consult a size chart. Many manufacturers provide size charts that match the wrench size to the corresponding nut or bolt size. These charts can be a useful reference when choosing the right size wrench.

4. Test the Fit

Before using the adjustable wrench, it is important to test the fit on the nut or bolt. Make sure the wrench securely grips the nut or bolt without slipping or wobbling. A loose or incorrect fit can lead to inefficiency and potential damage to the wrench and the object you are working on.

5. Consider Adjustable Jaw Wrenches

If you frequently work with a variety of nut and bolt sizes, you may want to consider investing in an adjustable jaw wrench. These wrenches have a built-in mechanism that allows the jaws to be adjusted to fit different sizes. With an adjustable jaw wrench, you can quickly and easily switch between different sizes without having to carry multiple wrenches.

By following these tips, you can choose the right size adjustable wrench for the job and ensure efficient and safe use.

Inspecting the Wrench

Before using an adjustable wrench, it is essential to inspect the tool to ensure that it is in proper working condition. This step helps to ensure the safety of the user and the effectiveness of the wrench.

Here are some key points to consider when inspecting an adjustable wrench:

- Check for any visible damage: Examine the wrench for any visible signs of damage, such as cracks, dents, or bends. Damaged wrenches should not be used as they may fail during use.

- Inspect the adjustment mechanism: Test the adjustment mechanism by moving the wrench jaws. The adjustable part of the wrench should move smoothly and lock securely into place. If there are any issues with the adjustment mechanism, the wrench may not be able to grip properly.

- Look for wear and tear on the jaws: Inspect the jaws of the wrench for signs of wear and tear. Worn-out jaws may not provide a secure grip, which can lead to slipping and injury. If the jaws are excessively worn, it may be necessary to replace the wrench.

- Check the handle for any defects: Examine the handle of the wrench for any defects, such as cracks or loose parts. The handle should be sturdy and comfortable to hold. If there are any defects, it is advisable to replace the wrench.

- Ensure the wrench is clean and free of rust: Clean the wrench thoroughly and ensure that there is no rust present. Rust can cause the wrench to become stiff and difficult to adjust, reducing its effectiveness. If there is rust present, it may be necessary to clean or replace the wrench.

By thoroughly inspecting the adjustable wrench before use, you can ensure that it is in good condition and will perform effectively. Additionally, proper maintenance and regular inspections can extend the lifespan of the wrench, providing you with a reliable tool for a longer period of time.

Adjusting the Wrench

Before using an adjustable wrench, you need to make sure it is properly adjusted to the size of the nut or bolt you will be working with. Here are the steps to adjust the wrench:

- Hold the adjustable wrench in your dominant hand.

- Locate the knurled adjustment nut at the base of the wrench. This nut allows you to adjust the size of the wrench opening.

- Turn the adjustment nut counterclockwise to increase the size of the opening or clockwise to decrease the size of the opening. Start with a smaller opening and make adjustments as needed.

- Check the size of the nut or bolt you will be working with. You can use a ruler or a set of wrenches with marked sizes to determine the correct opening size.

- Place the jaws of the wrench around the nut or bolt, making sure they are properly aligned.

- Turn the adjustment nut clockwise to tighten the jaws around the nut or bolt. Make sure the jaws are secure and properly gripping the fastener.

It is important to adjust the wrench properly to avoid slipping or damaging the nut or bolt you are working with. Always double-check the size of the opening and ensure the jaws are securely tightened before applying force with the wrench.

If you are unsure about the proper adjustment, it is always better to use a wrench with a slightly larger opening rather than a smaller one. This will help prevent stripping or rounding off the fastener.

Positioning the Wrench

Once you have selected the appropriate size of adjustable wrench for your task, it’s important to position the wrench correctly to ensure maximum leverage and control. Follow these steps to position the wrench properly:

- Choose the right jaw size: Before using the adjustable wrench, make sure the jaws are set to the correct size. The jaws should be adjusted to fit snugly around the nut or bolt you are working on. This will ensure a secure grip and prevent slippage during use.

- Hold the wrench: Place your hand on the handle of the wrench and grip it firmly. Your hand should be positioned near the end of the handle, with your fingers wrapped around the grip. This will give you better control and leverage while using the wrench.

- Align the jaws: Position the jaws of the wrench around the nut or bolt you need to loosen or tighten. The jaws should be aligned parallel to the sides of the nut or bolt, ensuring even pressure distribution when turning the wrench.

- Apply pressure: Once the jaws are properly aligned, apply pressure on the wrench handle in the direction you want to turn the nut or bolt. Use your arm strength to exert controlled force on the handle, avoiding excessive force that could damage the fastener or wrench.

- Check the position: As you turn the wrench, periodically check the position of the jaws to ensure they stay securely fastened around the nut or bolt. Adjust as necessary to maintain a strong grip.

Remember to always position the wrench properly before applying force. Incorrect positioning can result in slipping, rounded heads, or even injury. Following these steps will help you use an adjustable wrench effectively and efficiently.

Gripping the Wrench Handle

Properly gripping the wrench handle is essential for effectively using an adjustable wrench. Follow these steps to ensure a secure grip:

- Hold the wrench handle with one hand.

- Position your hand so that your palm is facing upward.

- Wrap your fingers around the handle, making sure to grip it firmly.

- Adjust your grip if necessary to find a comfortable position.

- Keep your fingers and thumb away from the moving parts of the wrench.

- If additional leverage is needed, you can place your other hand on the end of the handle for more control.

Remember to maintain a firm grip throughout the entire process to prevent any slipping or accidents. A secure grip will help you apply the necessary torque to tighten or loosen nuts and bolts effectively.

Applying Force

When using an adjustable wrench, it’s important to apply the right amount of force to avoid damaging the tool or the object you’re working on. Here are some steps to follow when applying force:

- Position the wrench correctly: Place the jaws of the adjustable wrench on the nut or bolt you want to turn. Make sure the jaws are securely locked onto the fastener.

- Adjust the size: If necessary, adjust the size of the wrench by turning the adjusting nut or wheel. Ensure that the jaws fit tightly around the fastener, as any play can result in slipping and potential injuries.

- Use both hands: To apply force, grip the handle of the wrench firmly with one hand and place your other hand on the end of the handle for additional leverage.

- Position your body: Stand or position yourself in a way that allows you to use your body weight to help apply force. This can help reduce the strain on your arms and wrists.

- Start with a gentle force: Begin by applying a gentle force and gradually increase it if needed. Avoid using excessive force, as this can cause the wrench to slip, round off the fastener, or cause injury.

- Turn in the correct direction: Remember that wrenches are designed to turn either clockwise or counterclockwise. Verify the direction you need to turn the fastener and apply force in the appropriate direction.

By following these steps, you can effectively and safely apply force when using an adjustable wrench. Remember to always use caution and follow any specific instructions provided by the manufacturer or professional guidelines for the task at hand.

Proper Care and Maintenance

Proper care and maintenance of your adjustable wrench are important for its longevity and optimal performance. By following these guidelines, you can ensure that your wrench stays in great condition for years to come.

Regular Cleaning

After each use, it is essential to clean your adjustable wrench to remove any dirt, grime, or debris that may have accumulated. To clean it, use a clean cloth or rag dampened with soapy water, and wipe the wrench thoroughly. Make sure to dry it thoroughly before putting it away to prevent any potential rusting.

Lubrication

To keep your adjustable wrench functioning smoothly, it is recommended to lubricate it regularly. Apply a few drops of lubricating oil or a silicone-based lubricant to the moving parts of the wrench.

Storage

Proper storage is important to avoid any damage to your wrench. Store it in a clean and dry place, away from excessive moisture or extreme temperatures. You can also consider using a toolbox or a tool cabinet to keep your wrench organized and protected from any potential impact or damage.

Inspect for Damage

Regularly inspect your adjustable wrench for any signs of damage or wear. Check for any loose or damaged parts, such as the handle or adjusting mechanism. If you notice any issues, it is important to address them promptly to prevent further damage and ensure the safe use of your wrench.

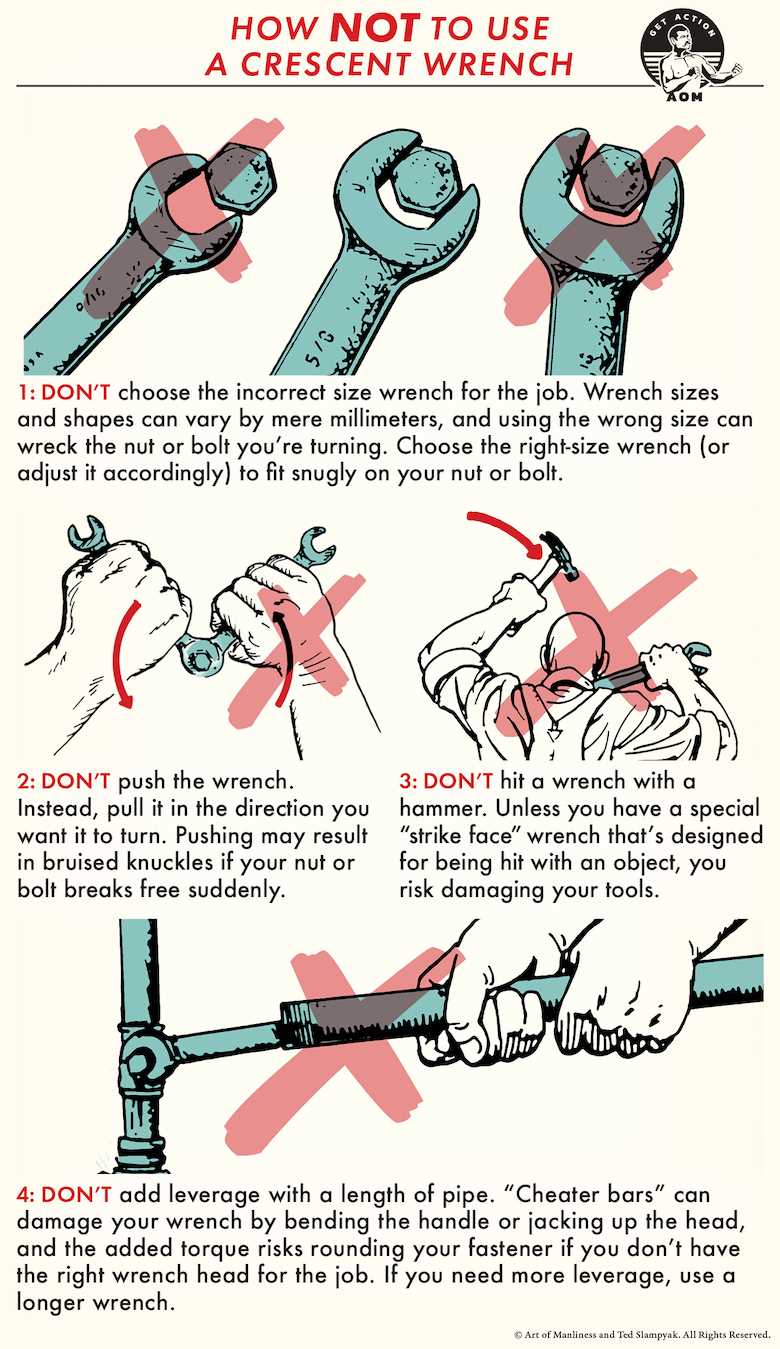

Avoid Misuse

Using the adjustable wrench for purposes it is not designed for can cause damage to the tool and pose safety risks. Avoid using excessive force, using the wrench as a hammer, or using it on oversized or rounded-off fasteners. Always use the wrench within its recommended capacity and for its intended purpose.

Professional Maintenance

If you encounter any significant issues with your adjustable wrench or if it requires complex repairs, it is advisable to seek professional maintenance or consult the manufacturer’s guidelines. Attempting complex repairs without the necessary knowledge and tools can result in further damage or injury.

By following these care and maintenance guidelines, you can keep your adjustable wrench in excellent condition, ensuring its longevity and optimal performance.

FAQ

What is an adjustable wrench?

An adjustable wrench is a versatile hand tool that has a movable jaw, allowing it to fit different sizes of nuts and bolts. It is commonly used for tightening or loosening fasteners.

How do I adjust an adjustable wrench?

To adjust an adjustable wrench, you need to locate the adjustment knob on the wrench handle. Turn the knob clockwise to tighten the jaw or counterclockwise to loosen it. Adjust the jaw to the desired size and make sure it fits securely around the nut or bolt before using.

Can I use an adjustable wrench for any size of nuts and bolts?

An adjustable wrench can typically fit a range of sizes, but there may be limitations. It is important to check the maximum jaw opening of the wrench to ensure it can accommodate the size you need. If the nut or bolt is too small or too large for the wrench, you may need to use a different tool.

What are the advantages of using an adjustable wrench?

One of the main advantages of using an adjustable wrench is its versatility. With just one tool, you can work with different sizes of nuts and bolts. It is also easy to adjust and provides a good grip on the fasteners, which helps prevent slipping and stripping.

Are there any safety precautions to keep in mind when using an adjustable wrench?

Yes, there are a few safety precautions to follow when using an adjustable wrench. First, make sure the wrench is properly adjusted to fit the nut or bolt to avoid slipping. Always apply force in the direction that allows maximum contact between the wrench and the fastener. Avoid using an adjustable wrench on rounded or damaged nuts or bolts, as it could make the problem worse. Finally, wear protective gloves to prevent injury to your hands.

Video