How to Properly Oil Your Air Impact Wrench for Maximum Performance

An air impact wrench is a powerful tool that can deliver a tremendous amount of torque to quickly tighten or loosen fasteners. To ensure that your air impact wrench performs at its best and has a long lifespan, it is crucial to properly oil it on a regular basis.

Oiling your air impact wrench helps to lubricate its internal components, prevent rust and corrosion, and reduce wear and tear. Without proper lubrication, the wrench may become less efficient and may not deliver the necessary power.

First, before oiling your air impact wrench, make sure to disconnect it from the air supply to avoid any accidents. Then, locate the oil port on the wrench. It is usually located near the trigger or on the body of the tool. Refer to the manufacturer’s instructions if you are unsure.

Next, you will need a high-quality, lightweight air tool oil. Using a heavier oil or other lubricants may clog the wrench and impair its performance. Apply a few drops of oil into the oil port, ensuring that it gets into the mechanism. Avoid over-oiling, as it can lead to oil leaks and excessive buildup of oil residue.

In conclusion, regular oiling is essential for maintaining the performance and longevity of your air impact wrench. By following these simple steps and using the right type of oil, you can ensure that your tool operates at its maximum potential, delivering the power and efficiency you need for your projects.

Why Properly Oiling Your Air Impact Wrench is Crucial for Optimal Performance

An air impact wrench is a powerful tool commonly used in various automotive applications and other heavy-duty tasks. To ensure its optimal performance and longevity, it is crucial to properly oil your air impact wrench on a regular basis.

Reduced Friction and Heat

Properly oiling your air impact wrench helps reduce friction between moving parts. Friction can cause excessive heat buildup, leading to premature wear and damage to the tool. By lubricating the components, you minimize the friction and heat generated during operation, allowing your wrench to perform efficiently for longer periods.

Prevents Rust and Corrosion

Oiling your air impact wrench creates a protective barrier that helps prevent rust and corrosion. Moisture, dirt, and other contaminants can easily find their way into the tool, especially when used in demanding environments. The oil acts as a barrier, preventing these elements from causing damage and ensuring the longevity of your wrench.

Proper Lubrication for Smooth Operation

A well-lubricated air impact wrench operates smoothly, delivering consistent power and accuracy. Without proper lubrication, the moving parts can become stiff, causing the tool to seize up or lose efficiency. By oiling the wrench regularly, you ensure that it operates at its full potential, allowing you to complete tasks more effectively.

Prevents Premature Wear and Damage

Regularly oiling your air impact wrench helps prevent premature wear and damage to its internal components. Over time, the constant movement and pressure on the parts can cause them to wear down, leading to reduced performance and eventual failure. By providing the necessary lubrication, you reduce the friction and stress on the parts, prolonging their lifespan.

Improves Overall Performance

Properly oiled air impact wrenches exhibit improved overall performance. The lubrication allows the tool to operate more smoothly, resulting in better power transfer and increased torque output. This ultimately leads to enhanced productivity and efficiency, as you can accomplish tasks at a faster rate and with greater accuracy.

In conclusion, properly oiling your air impact wrench is crucial for maintaining its optimal performance and increasing its lifespan. Regular lubrication helps reduce friction, prevent rust, ensure smooth operation, prevent premature wear, and improve overall performance. By taking the time to oil your air impact wrench, you can maximize its effectiveness and enjoy its benefits for years to come.

The Importance of Regular Maintenance and Lubrication

Regular maintenance and lubrication are essential for ensuring the optimal performance and longevity of your air impact wrench. By taking the time to properly maintain and lubricate your tool, you can avoid costly repairs and extend its lifespan.

1. Preventing Wear and Tear

One of the main benefits of regular maintenance and lubrication is that it helps prevent excessive wear and tear on your air impact wrench. The moving parts of the tool can experience friction and heat during operation, which can lead to accelerated wear if not properly lubricated. By regularly lubricating these parts, you can reduce friction and heat, helping to prevent premature wear and damage.

2. Enhancing Performance

Proper maintenance and lubrication can also greatly enhance the performance of your air impact wrench. When the moving parts are well lubricated, they can operate smoothly and efficiently, allowing the tool to deliver maximum power and torque. This can result in faster and more effective loosening and tightening of nuts and bolts, saving you time and effort.

3. Extending Tool Lifespan

Regular maintenance and lubrication can significantly extend the lifespan of your air impact wrench. By keeping all the parts well lubricated and clean, you can prevent rust, corrosion, and other forms of damage that can gradually deteriorate the tool over time. This can help ensure that your air impact wrench remains in optimal condition for years to come, saving you money on frequent replacements.

4. Avoiding Costly Repairs

By properly maintaining and lubricating your air impact wrench, you can avoid costly repairs. Neglecting regular maintenance can lead to issues such as seized or damaged components, which may require professional repairs or even replacement of the entire tool. Regular lubrication can help prevent these issues, reducing the likelihood of unexpected breakdowns and costly repairs.

How to Properly Maintain and Lubricate Your Air Impact Wrench:

- Refer to the manufacturer’s instructions for specific maintenance and lubrication guidelines.

- Regularly clean the exterior of the tool to remove dirt, dust, and other debris.

- Inspect the air impact wrench for any signs of damage or wear. Replace any worn or damaged parts as necessary.

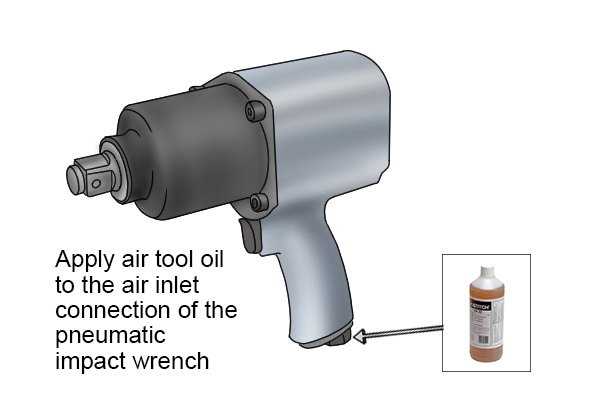

- Apply a few drops of lubricating oil to the tool’s air inlet before each use.

- Periodically disassemble the air impact wrench to clean and lubricate the internal components.

- Store the air impact wrench in a clean and dry environment when not in use.

By following these maintenance and lubrication practices, you can ensure that your air impact wrench performs at its best and lasts for many years of reliable service.

Choosing the Right Lubricant for Your Air Impact Wrench

Why lubrication is important

Proper lubrication is crucial for the optimal performance and longevity of your air impact wrench. It helps reduce friction and wear between moving parts, prevents rust and corrosion, and ensures smooth operation.

Types of lubricants

When it comes to choosing the right lubricant for your air impact wrench, there are a few options available:

- Air tool oil: This is the most commonly used lubricant for air impact wrenches. It is specifically designed for use with pneumatic tools and provides excellent lubrication and protection against rust and corrosion. Air tool oil is typically lightweight and formulated to withstand the high temperatures and pressures generated by the tool.

- Synthetic lubricants: Synthetic lubricants offer enhanced performance and durability compared to traditional mineral-based oils. They have a higher resistance to heat and pressure, which makes them ideal for heavy-duty applications. Synthetic lubricants also provide better protection against rust and corrosion.

- Multi-purpose lubricants: If you don’t have access to air tool oil or synthetic lubricants, a multi-purpose lubricant can be used as an alternative. However, it’s important to note that multi-purpose lubricants may not provide the same level of protection and performance as dedicated air tool oils.

Choosing the right lubricant

When selecting a lubricant for your air impact wrench, consider the following factors:

- Manufacturer recommendations: Check the user manual or contact the manufacturer to find out their recommended lubrication practices. Using the specified lubricant will help ensure optimal performance and prevent any potential warranty issues.

- Application: Consider the specific application or environment in which the air impact wrench will be used. If you work in dusty or dirty environments, a lubricant that offers extra protection against contaminants may be beneficial.

- Frequency of use: If you use your air impact wrench regularly, it may require more frequent lubrication. In such cases, choosing a lubricant with longer-lasting properties can help minimize downtime for maintenance.

How to lubricate your air impact wrench

Proper lubrication is simple and quick. Here’s a basic guide to help you:

- Before lubricating, make sure the air impact wrench is turned off and disconnected from the air supply.

- Locate the oil port on the wrench, usually found near the air inlet.

- Apply a few drops of the chosen lubricant into the oil port.

- Operate the wrench for a few seconds to distribute the lubricant evenly.

- Wipe off any excess oil.

Remember to follow the manufacturer’s recommendations for lubrication intervals and quantities to ensure proper maintenance.

Conclusion

Choosing the right lubricant for your air impact wrench is essential for maintaining its performance and durability. Consider the type of lubricant, manufacturer recommendations, application, and frequency of use when making your selection. Proper lubrication will keep your air impact wrench running smoothly and extend its lifespan.

Step-by-Step Guide to Oil Your Air Impact Wrench

Properly oiling your air impact wrench is essential for ensuring maximum performance and longevity. Follow these simple steps to keep your tool in top shape:

- Gather the necessary supplies: Before you begin, make sure you have the following items on hand:

- Air impact wrench oil

- Air filter

- A rag or towel

- Prepare your work area: Find a clean and well-ventilated area to work in. This will ensure that no dirt or debris enters the tool during the oiling process.

- Disconnect the air supply: Make sure the air supply to the impact wrench is disconnected to prevent any accidental start-up while you are working on it.

- Locate the oil inlet: The oil inlet is typically located at the back of the wrench, near the air inlet. It is usually marked with an oil icon or label.

- Clean the oil inlet: Use a rag or towel to clean the oil inlet and remove any dirt or debris that may have accumulated.

- Apply air impact wrench oil: Using the manufacturer-recommended oil, apply a few drops into the oil inlet. Be careful not to overfill; consult your tool’s manual for the correct amount.

- Replace the air filter: If your air impact wrench has an air filter, check its condition and replace it if necessary. A clean air filter will help prevent dirt and contaminants from entering the tool.

- Reconnect the air supply: Once you have completed the oiling process, reconnect the air supply to the impact wrench.

- Test the tool: Before using the air impact wrench, briefly test it to ensure that it is working properly. Listen for any unusual sounds or vibrations.

By following these simple steps and regularly oiling your air impact wrench, you can ensure that it operates at its full potential and has a longer lifespan.

Common Mistakes to Avoid When Oiling Your Air Impact Wrench

Properly oiling your air impact wrench is essential for maintaining its performance and longevity. However, there are some common mistakes that people often make when oiling their impact wrenches. Avoiding these mistakes will ensure that your tool operates at its maximum efficiency and lasts for a long time.

1. Using the Wrong Type of Oil

One of the most common mistakes is using the wrong type of oil for your air impact wrench. It is important to use air tool oil specifically designed for pneumatic tools. Regular motor oil or other lubricants may not provide the necessary protection and can cause damage to your tool.

2. Over-Oiling or Under-Oiling

Finding the right balance when oiling your impact wrench is crucial. Over-oiling can lead to excessive oil buildup, which can attract dirt and debris, potentially damaging your tool. On the other hand, under-oiling can cause premature wear and decrease the tool’s overall performance. Follow the manufacturer’s recommendations for oiling frequency and amount to ensure optimal performance.

3. Neglecting to Clean the Tool

Cleaning your air impact wrench before oiling is an important step that is often overlooked. Dirt, debris, and old oil can accumulate inside the tool, affecting its performance. Use a clean cloth or compressed air to remove any buildup on the exterior and interior parts of the wrench before applying oil.

4. Failing to Lubricate the Tool after Each Use

Proper maintenance of your air impact wrench includes oiling it after each use. Some users forget or neglect to apply oil, leading to increased friction and wear on the internal components of the tool. Develop the habit of oiling your impact wrench after every use to prevent unnecessary damage and ensure its smooth operation.

5. Improper Storage

Storing your air impact wrench without proper protection can also lead to problems. Exposing the tool to moisture or harsh environments can cause rust and corrosion. After oiling, store your impact wrench in a clean and dry place, preferably in a case or toolbox, to protect it from external elements.

6. Failing to Check for Leaks

Regularly checking for air leaks is essential to maintain the efficiency of your impact wrench. Before oiling, inspect the tool for any leaks or damage in the air hose, fittings, or connections. Fix any leaks immediately to prevent loss of power and maintain the proper functioning of your impact wrench.

Avoiding these common mistakes when oiling your air impact wrench will ensure that your tool remains in excellent condition and performs at its best. Proper oiling and maintenance will extend the life of your wrench, saving you time and money in the long run.

Signs That Your Air Impact Wrench Needs to be Oiled

An air impact wrench is a powerful tool that requires regular maintenance, including proper oiling. If your air impact wrench is not properly oiled, it can lead to decreased performance and potential damage to the tool. Here are some signs that indicate your air impact wrench needs to be oiled:

- Decreased Performance: One of the most obvious signs that your air impact wrench needs to be oiled is a decrease in performance. If you notice that the wrench is not as powerful as it used to be or is struggling to complete tasks, it is likely due to lack of lubrication.

- Overheating: Another sign that your air impact wrench needs to be oiled is overheating. If you find that the tool gets excessively hot during use, it is a clear indicator that the internal components are not properly lubricated.

- Increased Noise: A properly oiled air impact wrench should operate smoothly and quietly. If you notice increased noise or strange sounds coming from the tool, it is a sign that the moving parts are not properly lubricated.

- Sticky Trigger: The trigger of your air impact wrench should move smoothly and without resistance. If you experience a sticky or stiff trigger, it may be a result of inadequate lubrication.

To avoid these issues and ensure maximum performance from your air impact wrench, it is important to follow the manufacturer’s instructions for oiling. This usually involves applying a few drops of oil to the air inlet before each use or as recommended by the manufacturer. Regularly oiling your air impact wrench will help to prolong its lifespan and maintain its powerful performance.

Other Maintenance Tips to Extend the Life of Your Air Impact Wrench

Properly oiling your air impact wrench is essential for maximum performance, but there are other maintenance tips you should follow to ensure the longevity of your tool. Here are some additional steps you can take to extend the life of your air impact wrench:

1. Regular Cleaning

Regularly clean your air impact wrench to remove dirt, dust, and debris that can accumulate over time. Use a soft cloth or a brush to gently wipe the exterior of the tool. Be sure to clean the air intake vents as well to prevent clogs that can affect the tool’s performance.

2. Inspect and Replace Worn Parts

Periodically inspect your air impact wrench for any signs of wear or damage. Check the hoses, fittings, and couplers for leaks or cracks. If you notice any issues, replace the worn parts immediately to prevent further damage and maintain the tool’s performance.

3. Adjust the Air Pressure

Adjusting the air pressure is crucial for optimal performance and preventing damage to your air impact wrench. Make sure to check the manufacturer’s recommended air pressure range and adjust it accordingly. Avoid exceeding the maximum recommended pressure, as this can cause premature wear and damage to the tool.

4. Lubricate Moving Parts

In addition to oiling the air impact wrench, lubricate the moving parts regularly. Apply a small amount of lubricant to the trigger, ratchet mechanism, and other moving components. This will help reduce friction and keep the tool operating smoothly.

5. Store Properly

When not in use, store your air impact wrench in a clean and dry place. Protect it from moisture, dust, and extreme temperatures. Consider using a tool box or a storage case to keep it safe and organized.

6. Follow the Manufacturer’s Instructions

Always follow the manufacturer’s instructions for proper use and maintenance of your air impact wrench. They have valuable information specific to your tool that will help keep it running smoothly and extend its lifespan.

7. Get Professional Servicing

If you notice any major issues or if your air impact wrench is not performing as it should, consider taking it to a professional for servicing. They can diagnose and repair any underlying problems to ensure your tool operates at its best.

By following these maintenance tips, you can extend the life of your air impact wrench and enjoy consistent performance for years to come.

Frequently Asked Questions About Oiling Air Impact Wrenches

1. Why is it important to oil an air impact wrench?

An air impact wrench, like any other mechanical tool, requires lubrication to ensure smooth functioning and prevent wear and tear. Oiling the wrench regularly helps to reduce friction, keep the moving parts well-lubricated, and extend the lifespan of the tool.

2. How often should I oil my air impact wrench?

It is recommended to oil your air impact wrench before each use. This ensures that the tool is properly lubricated and functions optimally. Additionally, if you are using your wrench frequently throughout the day, it may be necessary to add oil periodically to maintain its performance.

3. What type of oil should I use for my air impact wrench?

It is best to use air tool oil or a specially formulated pneumatic tool oil for lubricating your air impact wrench. These oils are designed to withstand the high temperatures and pressures generated by air tools and provide proper lubrication for their specific components.

4. How do I oil my air impact wrench?

To oil your air impact wrench, follow these steps:

- Disconnect the tool from the air supply.

- Locate the oil port on the tool. This is usually identified by an oil droplet symbol.

- Using a few drops of air tool oil or pneumatic tool oil, apply the oil into the oil port.

- Connect the tool back to the air supply and run it for a few seconds to distribute the oil internally.

- Wipe off any excess oil from the exterior of the tool.

5. Can I over-oil my air impact wrench?

Yes, it is possible to over-oil your air impact wrench. Excessive oil can lead to fluid buildup, attracting dust and debris, which can hinder the tool’s performance. It is important to use the recommended amount of oil and wipe off any excess after oiling.

6. Can I use any type of oil if I don’t have air tool oil?

While it is not recommended, in a pinch, you can use a lightweight machine oil or motor oil as a temporary substitute for air tool oil. However, it is important to switch to the appropriate oil as soon as possible to ensure the long-term health and performance of your air impact wrench.

7. What are the signs that my air impact wrench needs oiling?

Some signs that your air impact wrench may need oiling include increased friction and resistance during use, excessive heat generation, unusual noises, and reduced performance. If you notice any of these signs, it is a good idea to oil your wrench before using it again.

8. Can I use too little oil for my air impact wrench?

Using too little oil can lead to inadequate lubrication and cause premature wear and damage to the internal components of your air impact wrench. It is important to follow the manufacturer’s recommendations for oiling and ensure that the tool is properly lubricated.

9. What other maintenance tasks should I perform on my air impact wrench?

In addition to regular oiling, it is important to keep your air impact wrench clean and free of dust and debris. You should also inspect the tool for any signs of wear or damage, and replace any worn-out or damaged parts as necessary. Following the manufacturer’s maintenance guidelines is crucial to keep your wrench in optimal condition.

10. Can I use WD-40 to oil my air impact wrench?

No, WD-40 is not recommended for lubricating air impact wrenches. WD-40 is a water-displacing spray, not a lubricant specifically designed for air tools. It is best to use a proper air tool oil or pneumatic tool oil for lubricating your air impact wrench.

FAQ

Why is it important to oil an air impact wrench?

It is important to oil an air impact wrench because it helps to lubricate the internal components, reduce friction, and prevent wear and tear. This ultimately leads to better performance and a longer lifespan for the tool.

How often should I oil my air impact wrench?

The frequency of oiling your air impact wrench depends on how frequently you use it. As a general guideline, it is recommended to oil the wrench every 25-50 hours of use. However, if you notice any decrease in performance or unusual sounds coming from the tool, it is best to oil it immediately.

What type of oil should I use for my air impact wrench?

It is recommended to use a high-quality air tool oil or a specific oil recommended by the manufacturer of your air impact wrench. These oils are designed to provide proper lubrication and protect the internal components of the tool.

How do I oil my air impact wrench?

To oil your air impact wrench, first, disconnect it from the air supply and make sure it is turned off. Then, locate the oil port, usually located on the bottom of the tool’s handle. Apply a few drops of oil into the port using a dropper or an oil dispenser. Finally, reconnect the tool to the air supply and run it for a few seconds to distribute the oil throughout the internal components.

Can I use other lubricants instead of air tool oil?

No, it is not recommended to use other lubricants like motor oil or WD-40 instead of air tool oil. These lubricants may not provide the necessary viscosity and protection required by the internal components of an air impact wrench. It is always best to use the oil specifically designed for air tools.

What are the signs that my air impact wrench needs oiling?

Some signs that your air impact wrench needs oiling include a decrease in performance, unusual sounds or vibrations, increased air consumption, and difficulty in loosening or tightening bolts. If you notice any of these signs, it is best to oil your wrench as soon as possible.

Video