How Does a Socket Wrench Work? Explained in Detail

A socket wrench, also known as a ratchet, is a versatile hand tool commonly used for tightening or loosening nuts and bolts. It consists of a handle, a ratchet mechanism, and a set of sockets that attach to the ratchet. The socket wrench is designed to provide leverage and allow for quick and efficient tightening or loosening of fasteners.

The key component of a socket wrench is the ratchet mechanism, which is located inside the handle. This mechanism allows the user to turn the socket in one direction while the handle remains stationary, and then switch the direction without having to remove the socket from the fastener. This is achieved through the use of a gear and pawl system, where the gear engages with the pawl in one direction and slips past it in the opposite direction.

When the user applies force to the handle in the tightening direction, the gear engages with the pawl, causing the socket to rotate. As the handle is turned back in the opposite direction, the gear slips past the pawl, allowing the socket to remain stationary. This allows the user to maintain a consistent grip on the fastener while quickly repositioning the socket for the next turn.

The sockets themselves come in a variety of sizes and types, typically measured in inches or metric units, to fit different fasteners. They are designed with a square drive that corresponds to the shape of the ratchet mechanism. This drive fits securely into the ratchet and allows for easy attachment and detachment of sockets.

Overall, a socket wrench is a simple yet effective tool that makes the task of tightening or loosening nuts and bolts much easier. Its ratchet mechanism provides convenience and efficiency, allowing for quick changes in direction and saving valuable time. Whether you’re a professional mechanic or a DIY enthusiast, a socket wrench is a must-have tool for any toolbox.

Understanding the Basics of a Socket Wrench

A socket wrench, also known as a ratchet, is a versatile hand tool commonly used in mechanical work for tightening or loosening nuts and bolts. It consists of a handle, a ratcheting mechanism, and a socket at one end, which can be attached to various sizes of bolts or nuts.

Handle

The handle of a socket wrench is usually made of metal or durable plastic. It provides a grip for the user to hold and apply force while using the tool. Some handles are designed with a rubberized or textured surface to improve grip and reduce slippage during use.

Ratcheting Mechanism

The ratcheting mechanism is what sets a socket wrench apart from a regular wrench. It allows the user to quickly tighten or loosen a fastener without having to reposition the wrench after each turn. The ratcheting mechanism consists of a gear inside the handle that interacts with a pawl or a set of teeth.

When the user applies force in one direction, the gears engage the pawl or teeth to turn the socket and tighten or loosen the fastener. When the user reverses the direction of force, the gears disengage from the pawl or teeth, allowing the socket to reset for the next turn.

Socket

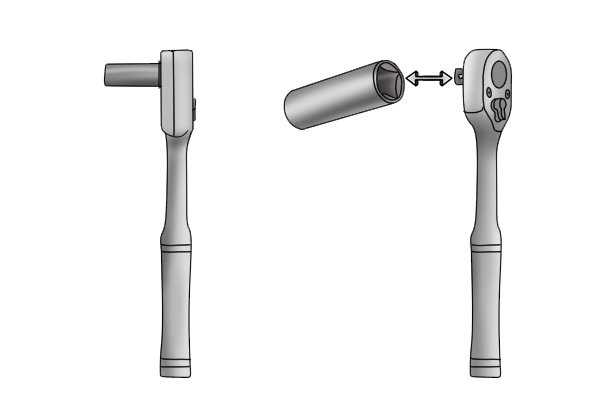

The socket is the removable attachment at the end of the socket wrench. It comes in various sizes and shapes to fit different types of bolts and nuts. The socket is secured to the handle using a square drive, commonly known as a ratchet drive. The drive has a small ball bearing or detent mechanism that holds the socket in place while allowing for quick attachment and detachment.

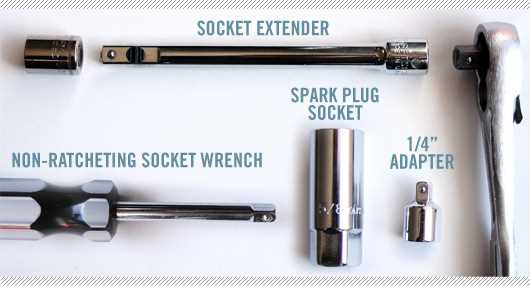

Extension Bars and Accessories

Socket wrench sets often come with extension bars and other accessories to provide additional reach or flexibility. Extension bars are used to access fasteners that are deep or in hard-to-reach places. Other accessories include universal joints, adapters, and spark plug sockets, which expand the functionality of the socket wrench and make it suitable for various applications.

Using a Socket Wrench

To use a socket wrench, the user selects the appropriate socket size for the fastener. The socket is then attached to the handle using the ratchet drive. The socket is placed onto the fastener, and the user applies force in the desired direction to tighten or loosen the fastener. The ratcheting mechanism allows for continuous turning without having to reposition the wrench.

Conclusion

A socket wrench is a fundamental tool in any toolbox, allowing users to efficiently tighten or loosen bolts and nuts. Understanding the basic components of a socket wrench and how to use it properly is essential for any mechanical work or DIY projects.

Components of a Socket Wrench

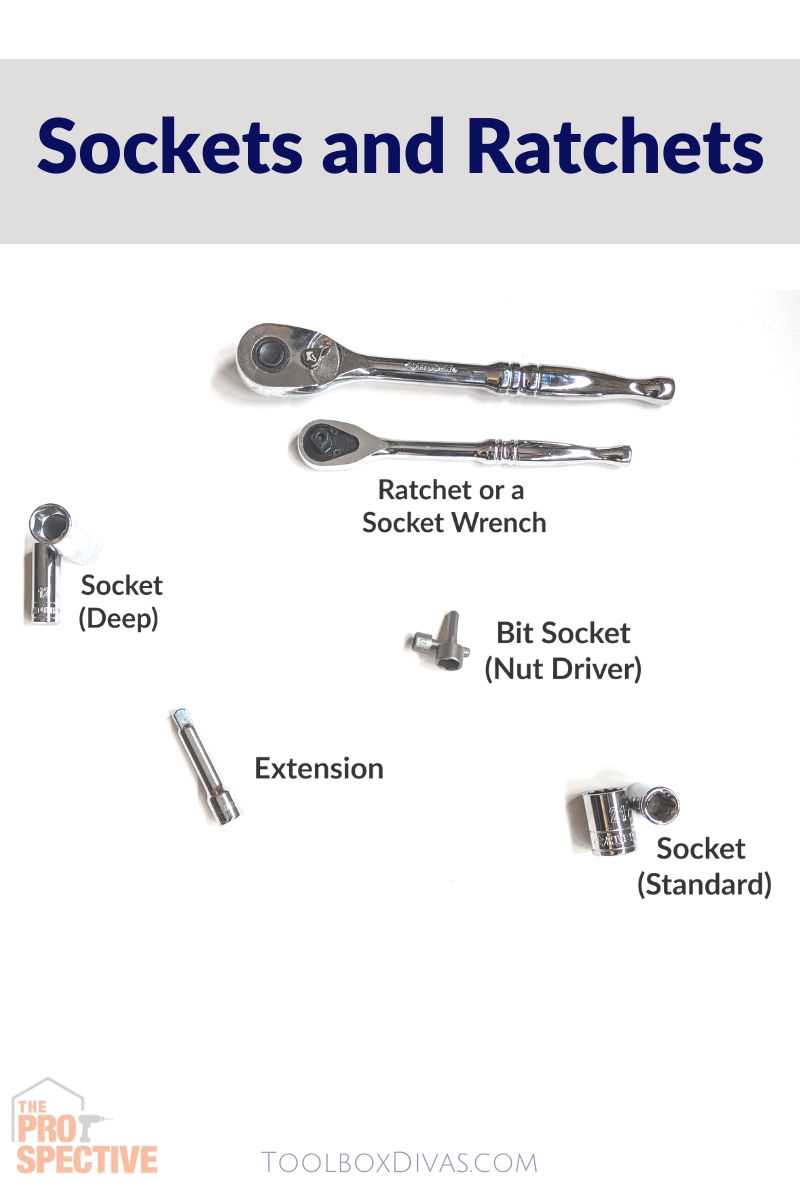

A socket wrench is made up of several key components that work together to give the tool its functionality. These components include:

- Handle: The handle is the part of the socket wrench that a user holds onto and uses to apply torque. It is typically made of a durable material like metal or plastic and is designed for a comfortable grip.

- Ratchet mechanism: The ratchet mechanism is a vital part of a socket wrench. It allows the socket to rotate in one direction while preventing it from rotating in the opposite direction. This mechanism is made up of gears, pawls, and springs that engage and disengage as the handle is turned.

- Socket: The socket is the interchangeable component of the socket wrench that attaches to the ratchet mechanism. It comes in various sizes and shapes to fit different types of fasteners, such as nuts and bolts. The socket is usually made of durable steel and is designed to provide a secure fit on the fastener.

- Socket drive: The socket drive is the square-shaped opening at the end of the socket that connects to the ratchet mechanism. It is usually available in different sizes, such as 1/4 inch, 3/8 inch, or 1/2 inch, to match the corresponding size of the ratchet handle.

- Extension bar: An extension bar is an optional component that can be attached between the socket and the ratchet handle. It provides additional length to reach fasteners that are deep within a confined space.

Overall, these components work together to create a versatile and efficient tool that allows users to tighten or loosen fasteners with ease.

How the Ratchet Mechanism Works

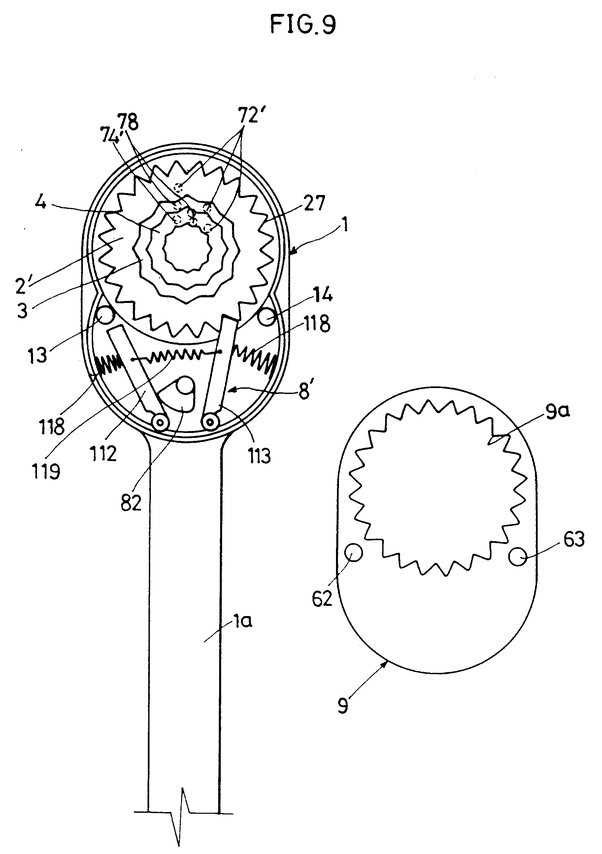

The ratchet mechanism is the key component of a socket wrench that allows for easy tightening and loosening of nuts and bolts. It consists of several parts that work together to enable the ratcheting action.

Ratchet Pawl

The ratchet pawl is a small toothed metal piece that engages with the gear teeth of the socket wrench. It is usually spring-loaded and able to move up and down or side to side within the socket wrench.

Ratchet Gear

The ratchet gear is a circular metal piece with gear teeth on its outer edge. It is positioned inside the socket wrench and is connected to the handle of the wrench. When the handle is turned, the ratchet gear also rotates.

Direction Selector

The direction selector is a small lever or switch located on the socket wrench. It allows the user to choose the direction in which the ratchet mechanism operates – either clockwise or counterclockwise.

Ratchet Switch

The ratchet switch is a spring-loaded metal piece that sits on top of the ratchet gear. It has a small groove in the center that allows the ratchet pawl to engage with the gear teeth when the handle is turned in one direction, but prevents engagement when the handle is turned in the opposite direction.

Ratchet Action

When the handle of the socket wrench is turned in the selected direction, the ratchet gear rotates. If the ratchet pawl is engaged with the gear teeth, it moves in sequence with the gear, allowing the socket wrench to tighten or loosen the nut or bolt. However, when the handle is turned in the opposite direction, the ratchet pawl moves over the smooth part of the ratchet gear and does not engage with the gear teeth, preventing the socket wrench from moving.

This ratcheting action allows the user to quickly and easily tighten or loosen nuts and bolts without having to lift the wrench and reposition it for each turn. It is especially useful in tight spaces where there may not be enough room to rotate the wrench a full 360 degrees.

Different Types of Socket Wrenches

A socket wrench is a versatile tool that is used to tighten or loosen nuts and bolts. It consists of a handle and a socket that fits onto the head of the nut or bolt. There are several types of socket wrenches available, each with its own unique design and purpose.

1. Standard Socket Wrench

The standard socket wrench, also known as the ratchet wrench, is the most common type. It features a ratcheting mechanism that allows the socket to be rotated in one direction while preventing it from rotating in the opposite direction. This allows for efficient and quick tightening or loosening of nuts and bolts.

2. Impact Socket Wrench

An impact socket wrench is designed to withstand high torque and is used for heavy-duty applications. It is commonly used in automotive and industrial settings. The impact socket wrench has a thicker and stronger build compared to a standard socket wrench, allowing it to handle more force without breaking.

3. Allen Socket Wrench

An Allen socket wrench, also known as a hex socket wrench, is used specifically for tightening or loosening hexagonal screws or bolts. It features a hexagonal socket at the end of the wrench that matches the shape of the screw or bolt head. This type of socket wrench is commonly used in furniture assembly and bicycle repairs.

4. Torx Socket Wrench

A Torx socket wrench, also known as a star socket wrench, is used for tightening or loosening Torx screws or bolts. Torx screws have a star-shaped recess in the head, and a Torx socket wrench has a corresponding star-shaped socket. This type of socket wrench is commonly used in electronics, appliances, and automotive applications.

5. Universal Socket Wrench

A universal socket wrench, also known as an adjustable socket wrench or a multi-fit socket wrench, can fit a wide range of different sizes and shapes of nuts or bolts. It features a set of spring-loaded pins that conform to the shape of the nut or bolt head when pressure is applied. This type of socket wrench is versatile and eliminates the need for multiple socket sizes.

6. Spark Plug Socket Wrench

A spark plug socket wrench is a specialized tool used for removing or installing spark plugs in an internal combustion engine. It has a rubber insert inside the socket to grip the spark plug securely and prevent damage. Spark plug socket wrenches come in different sizes to fit various spark plug types.

These are just a few examples of the different types of socket wrenches available. Each type is designed to serve a specific purpose and can be useful in various applications. Whether you are working on a vehicle, assembling furniture, or doing DIY projects, having the right socket wrench can make your tasks easier and more efficient.

Socket Sizes and Compatibility

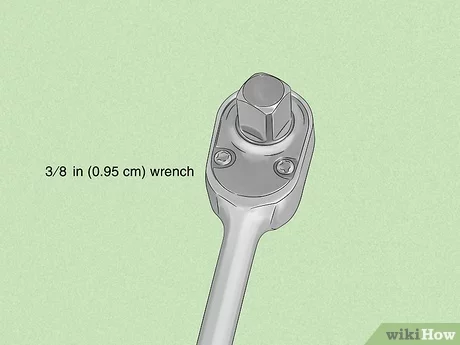

Socket wrenches come in different sizes to accommodate various nuts and bolts. The size of the socket refers to the diameter of the opening that fits over the fastener. Common socket sizes include 1/4 inch, 3/8 inch, 1/2 inch, and 3/4 inch.

The most commonly used socket size is the 3/8 inch socket, which is versatile and can be used for many tasks. The 1/4 inch socket is smaller and used for light-duty applications, while the 1/2 inch and 3/4 inch sockets are larger and used for heavy-duty tasks that require more torque.

When choosing a socket, it’s important to consider the compatibility with the fasteners you will be working with. Sockets are available in different types and designs to fit specific fastener shapes, such as hexagonal, square, or Torx. It’s essential to select a socket that matches the shape of the fastener to ensure a proper fit and prevent slipping or rounding of the edges.

In addition to the socket size and shape, compatibility also depends on the type of drive the socket has. Most socket wrenches have a square drive that matches the corresponding square drive on the socket. Common drive sizes include 1/4 inch, 3/8 inch, and 1/2 inch. The drive size must match the size of the socket for them to connect securely and transfer torque effectively.

Furthermore, the compatibility extends to the type of socket wrench being used. There are different types of socket wrenches, such as ratcheting wrenches, flex-head wrenches, breaker bar wrenches, and impact wrenches. Each type has its own advantages and may require specific sockets for optimal use.

It’s also worth noting that some socket sets come with both metric and imperial sizes to accommodate different measurement systems. Metric sockets are measured in millimeters, while imperial sockets are measured in inches. Using the incorrect size socket may result in damage to the fastener or the socket itself, so it’s important to have the right measurements for the job.

In summary, socket sizes and compatibility play a crucial role in the effectiveness and safety of using a socket wrench. Choosing the right socket size, shape, and drive ensures a proper fit and prevents damage to the fasteners and the tool itself. Additionally, considering the type of socket wrench being used and having the appropriate measurement system further enhances compatibility and efficiency.

Tips for Using a Socket Wrench Safely

1. Choose the Right Socket Size

Before using a socket wrench, it’s important to select the correct socket size for the task at hand. Using the wrong size can result in the socket slipping off the bolt or nut, causing potential injury or damage to the tool or workpiece. Always check the size of the bolt or nut and choose the corresponding socket size that fits securely.

2. Inspect the Socket and Ratchet

Prior to using the socket wrench, inspect both the socket and the ratchet for any signs of damage or wear. Look for cracks, chips, or any other defects that could impact the tool’s performance. If any issues are found, replace the socket or ratchet before proceeding. Using a damaged tool can lead to accidents or the tool failing during use.

3. Use Proper Technique

When using a socket wrench, it’s important to apply force in the correct direction. Always push or pull in a straight line, parallel to the socket and ratchet handle. Avoid applying force at an angle as it can cause the socket or ratchet to slip, potentially leading to injury.

4. Secure the Workpiece

Before using a socket wrench, ensure that the workpiece is properly secured. If possible, use clamps or other methods to hold the workpiece firmly in place. This will prevent it from moving or rotating while applying force with the socket wrench, reducing the risk of accidents or injuries.

5. Avoid Overexertion

When using a socket wrench, it’s important to apply pressure gradually and with control. Avoid using excessive force or overexerting yourself, as this can lead to fatigue or loss of control over the tool. If additional force is required, consider using a breaker bar, which provides additional leverage.

6. Keep Hands Clear

When using a socket wrench, always keep your hands and fingers clear of the moving parts. Be aware of the handle and any rotating components, as they can cause injury if they come into contact with your body. Keep a firm grip on the handle and position your hands in a safe manner to avoid accidents.

7. Store Properly

After using a socket wrench, store it in a safe and secure manner. Make sure the tool is clean and free from any debris that could interfere with its performance. Store the socket and ratchet in a dry and organized toolbox to protect them from damage and ensure they are readily available for future use.

By following these essential tips for using a socket wrench safely, you can reduce the risk of accidents, injuries, and damage to both yourself and your tools. Always prioritize safety and take the necessary precautions when using any hand tool.

Common Uses of a Socket Wrench

1. Automotive Repair

A socket wrench is an essential tool for any automotive repair job. It can be used to remove and tighten nuts and bolts in various parts of a vehicle, including the engine, brakes, and suspension systems.

2. Construction and Building

In the construction and building industry, socket wrenches are commonly used for assembling and disassembling scaffolding, securing bolts and nuts in structural components, and tightening fasteners in plumbing and electrical installations.

3. Home Maintenance and DIY Projects

Socket wrenches are handy tools for various home maintenance tasks and DIY projects. They can be used to repair furniture, assemble or disassemble appliances, tighten or loosen bolts and nuts in plumbing fixtures, and perform general maintenance work around the house.

4. Mechanical Engineering and Manufacturing

In mechanical engineering and manufacturing industries, socket wrenches are frequently used for assembling and maintaining machinery and equipment. They are crucial for tightening and loosening fasteners in engines, gearboxes, turbines, and other mechanical systems.

5. Plumbing and Pipework

Plumbers and pipefitters rely on socket wrenches for connecting and disconnecting pipes, fittings, and valves. These tools enable them to tighten and loosen nuts and bolts in tight spaces, making it easier to assemble and repair plumbing systems.

6. HVAC and Electrical Work

Socket wrenches are often used by HVAC technicians and electricians to install and maintain equipment. They are particularly useful for fastening and unfastening nuts and bolts in air conditioning units, electrical panels, and other HVAC and electrical components.

7. Aerospace and Aviation

In the aerospace and aviation industries, socket wrenches play a crucial role in assembling and maintaining aircraft. They are used for tightening and loosening fasteners in engines, landing gear, control systems, and other critical aircraft components.

8. Furniture Assembly

When it comes to furniture assembly, socket wrenches are commonly used to tighten bolts and nuts in various pieces of furniture, such as beds, tables, chairs, and cabinets. They offer a quick and efficient way to assemble furniture without the need for excessive manual labor.

9. Bicycle and Motorcycle Maintenance

Socket wrenches are essential tools for bicycle and motorcycle enthusiasts. They are used to adjust and tighten bolts and nuts in handlebars, pedals, wheels, and other parts of the bike or motorcycle.

10. General Maintenance and Repairs

Socket wrenches have a wide range of applications in general maintenance and repair work. They can be used for tasks such as replacing light fixtures, tightening screws, assembling or disassembling small appliances, and performing various repair jobs around the house or workplace.

Overall, socket wrenches are versatile tools that find extensive use in various industries and everyday tasks. They offer an efficient way to tighten and loosen fasteners, making them an invaluable tool for both professionals and DIY enthusiasts.

Maintaining and Repairing a Socket Wrench

Cleaning and Lubricating

Regular cleaning and lubrication are essential for maintaining the performance and longevity of a socket wrench. Over time, dirt, debris, and rust can accumulate on the tool, affecting its smooth operation. To clean the wrench, use a mild detergent or solvent to remove any grease or grime. Scrub the surfaces with a brush and wipe them dry with a clean cloth. It is important to ensure that all moving parts are free from dirt and particles.

After cleaning, apply a lubricant to the moving parts of the socket wrench. This will reduce friction and help the tool operate smoothly. Use a lightweight oil or silicone lubricant and apply it to the ratchet mechanism, pivot points, and other movable components. Be sure to follow the manufacturer’s instructions for lubrication.

Inspecting for Damage

Regular inspections are necessary to identify any damage or wear in the socket wrench. Check for any cracks, bends, or signs of excessive wear on the handle and socket attachments. If any damage is found, it is important to address it promptly to prevent further issues.

Inspect the ratchet mechanism to ensure that it engages and releases properly. Check for any broken or worn teeth on the ratchet and make sure that the switch or lever is functioning correctly. If the ratchet mechanism is not working properly, it may need to be repaired or replaced.

Replacing Parts

If any parts of the socket wrench are broken or worn beyond repair, they should be replaced. Most socket wrenches have interchangeable sockets, so if a socket becomes damaged, it can be easily replaced. Additionally, if the ratchet mechanism or handle is damaged, replacement parts can often be purchased to restore the tool to its original condition.

When replacing parts, make sure to select the correct size and type of socket or component that is compatible with the wrench. Follow the manufacturer’s instructions for replacing parts to ensure proper assembly and functionality.

Store Properly

Proper storage is important for maintaining the condition of a socket wrench. After use, clean the tool and ensure that it is free from any moisture or debris. Store the socket wrench in a dry and organized location to protect it from damage. Consider using a tool box or hanging rack to keep the wrench easily accessible and protected from other tools.

By following these maintenance and repair practices, a socket wrench can remain in good working condition for many years, providing reliable performance for various projects and repairs.

FAQ

What is a socket wrench?

A socket wrench is a specialized tool used for tightening or loosening nuts and bolts. It consists of a handle with a ratcheting mechanism and interchangeable socket attachments.

How does a socket wrench work?

A socket wrench works by utilizing a ratcheting mechanism. When you rotate the handle in one direction, the ratchet allows the socket to turn with it. When you rotate the handle in the opposite direction, the ratchet locks the socket in place, preventing it from turning.

What are the parts of a socket wrench?

A socket wrench typically consists of a handle, a ratchet mechanism, and interchangeable socket attachments. The handle provides the grip, the ratchet mechanism allows for the tightening or loosening of nuts and bolts, and the socket attachments are used to fit onto different sizes of nuts and bolts.

Can you explain how the ratchet mechanism works?

Sure! The ratchet mechanism in a socket wrench is designed with a set of gears that allow motion in only one direction. When you rotate the handle in the direction that tightens or loosens the nut or bolt, the gears inside the ratchet engage and allow the socket to turn. When you rotate the handle in the opposite direction, the gears disengage and lock the socket in place.

What are the benefits of using a socket wrench?

Using a socket wrench provides several benefits. Firstly, it allows for quick and easy tightening or loosening of nuts and bolts. Secondly, the interchangeable socket attachments allow for versatility, as they come in different sizes to fit various nuts and bolts. Finally, the ratcheting mechanism makes it possible to work in tight spaces with limited movement.

Are there different types of socket wrenches?

Yes, there are different types of socket wrenches available. The most common types include the standard socket wrench, which has a straight handle, and the ratchet wrench, which has a bent handle for easier access in tight spaces. There are also specialty socket wrenches designed for specific purposes, such as spark plug wrenches or torque wrenches.

Video