Understanding Lathe Swing: Definition and Importance

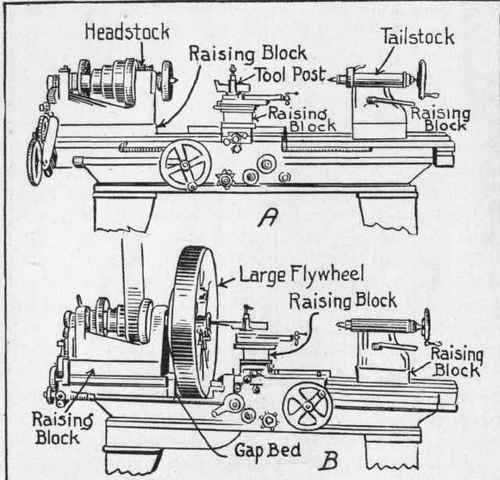

When it comes to lathes, one important factor that often gets overlooked is the lathe swing. The swing of a lathe is defined as the maximum diameter of the workpiece that can be rotated on the lathe without any obstructions. In simpler terms, it is the distance between the lathe spindle and the bed, multiplied by two.

The lathe swing plays a crucial role in determining the size of the workpiece that can be turned on the lathe. It sets the limit on the diameter of the workpiece and is an essential specification to consider when choosing a lathe for a particular project. Whether you are a professional machinist or a hobbyist, understanding the lathe swing is vital for selecting the right lathe and ensuring that it can handle the size of the workpiece you intend to work on.

Having a lathe with a sufficient swing is important because if the workpiece is too large for the lathe, it can lead to interference with the bed or other components, causing damage to the lathe and compromising the accuracy of the turning process. On the other hand, if the lathe has a larger swing than the workpiece requires, it allows for more flexibility in choosing the size of the projects and provides room for future expansion.

In conclusion, the lathe swing is a key specification to consider when selecting a lathe for any turning project. It determines the maximum diameter of the workpiece that can be rotated without obstructions and plays a crucial role in ensuring the accuracy and safety of the turning process. By understanding the lathe swing and matching it with the size of the workpiece, you can make informed decisions and achieve the desired results in your turning projects.

What is Lathe Swing?

Lathe swing is a term used in the field of machining to describe the maximum diameter of a workpiece that can be accommodated on a lathe. It refers to the distance between the centerline of the lathe spindle and the closest point on the bed or carriage of the lathe.

Essentially, the lathe swing defines the size of workpieces that a lathe can handle. It determines the maximum diameter of materials that can be turned on the lathe without any interference from the lathe’s components.

The lathe swing is an important specification to consider when selecting a lathe for a specific machining task. It is crucial to choose a lathe with a swing capacity that matches the size of the workpieces you plan to work on. Using a lathe with a smaller swing than the diameter of the workpiece will result in incomplete machining, while using a lathe with a larger swing may lead to inefficient use of the machine and unnecessary cost.

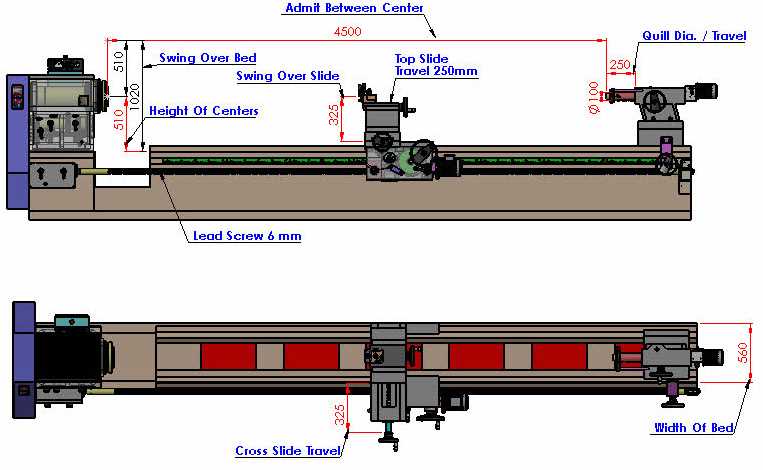

Lathe swing is typically measured in inches or millimeters, and the specified swing of a lathe can be found in its technical specifications. The swing capacity may vary depending on the specific model and type of lathe, so it is important to carefully review the specifications before making a decision.

In addition to the swing capacity, other factors such as bed length, motor power, and spindle speed should also be considered when selecting a lathe. These factors will determine the overall capabilities of the lathe and its suitability for various machining tasks.

The Significance of Lathe Swing

The term “lathe swing” refers to the largest diameter of the workpiece that can be turned on a lathe without any obstructions, such as the lathe bed or the tool rest. It plays a critical role in determining the size and type of projects that can be undertaken on a lathe, and understanding its significance is essential for any machinist or woodworker.

1. Size Limitations

The swing capacity of a lathe sets a limit on the maximum size of the workpiece that can be turned. For example, if a lathe has a swing capacity of 12 inches, it means that the maximum diameter of the workpiece that can be turned is 12 inches. This can be a determining factor when selecting a lathe for a specific project or understanding the capabilities of an existing lathe.

2. Versatility

A higher lathe swing allows for greater versatility in the types of projects that can be undertaken. With a larger swing, it becomes possible to turn larger bowls, platters, or even table legs. This opens up a wider range of possibilities for woodturners or machinists who require the ability to work on larger workpieces.

3. Safety Considerations

Understanding the swing capacity of a lathe is also important from a safety perspective. Exceeding the recommended swing capacity can lead to accidents or damage to the lathe. Knowing the swing capacity allows machinists and woodworkers to choose the appropriate size workpiece and make adjustments to their projects accordingly to ensure safe and smooth operations.

4. Compatibility with Accessories

In addition to the lathe itself, the swing capacity also determines the compatibility with various lathe accessories. For example, the size of a faceplate or a chuck may need to match the swing capacity of the lathe to ensure a secure and stable grip on the workpiece. Understanding the swing capacity helps in selecting the appropriate accessories for a specific lathe.

5. Design Complexity

The swing capacity can also impact the complexity of the designs that can be achieved. A larger swing allows for the creation of more intricate and detailed designs on the workpiece. The ability to turn larger diameters opens up possibilities for ornamental turnings, fluting, or any other decorative elements that require a larger canvas to work with.

Conclusion

The lathe swing is a critical factor in determining the capabilities and limitations of a lathe. It sets the size limit for workpieces, affects the versatility and compatibility with accessories, has safety implications, and influences the complexity of designs that can be achieved. Having a clear understanding of the significance of lathe swing is essential for anyone working with a lathe, allowing them to make informed decisions and push the boundaries of their craft.

How to Measure Lathe Swing

Measuring the lathe swing is an essential step in understanding the capabilities and limitations of a lathe machine. It helps determine the maximum diameter of the workpiece that can be accommodated on the lathe and is often one of the specifications provided by lathe manufacturers.

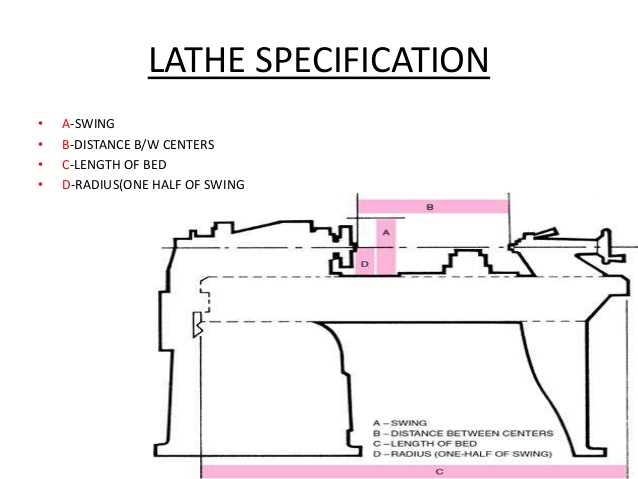

1. Lathe Swing Definition

The lathe swing is defined as the maximum diameter of the workpiece that can be turned on a lathe machine. It is measured by taking the distance from the centerline of the lathe spindle to the closest point on the lathe bed, and then multiplying it by two.

2. Measuring the Lathe Swing

To measure the lathe swing, follow these steps:

- Clear the lathe bed and make sure it is free from any obstructions.

- Place a straight edge or a measuring tape from the centerline of the lathe spindle to the closest point on the lathe bed.

- Take note of the measurement from the centerline to the closest point.

- Multiply the measurement by two to get the lathe swing.

It is important to note that the lathe swing may vary depending on the configuration of the lathe, such as the type of headstock and the presence of any attachments or accessories.

3. Importance of Measuring Lathe Swing

Measuring the lathe swing is crucial for several reasons:

- It helps determine the maximum size of the workpiece that can be handled by the lathe.

- It assists in selecting the appropriate lathe for a specific project or application.

- It allows for proper tool positioning and tool clearance, preventing collisions and damage to the lathe or the workpiece.

- It helps the operator plan and design workpieces that fit within the lathe’s swing capacity.

By accurately measuring the lathe swing, operators can ensure efficient and safe lathe operations, optimize their machining processes, and achieve high-quality results.

Factors Affecting Lathe Swing

The lathe swing is a critical factor in determining the size and complexity of workpieces that can be machined on a lathe. Several factors affect the lathe swing, including:

- Spindle Configuration: The design and construction of the lathe spindle can limit the maximum swing. A larger spindle size and higher bearing capacity can allow for a larger swing.

- Bed Length: The length of the lathe bed determines the distance between the headstock and the tailstock. A longer bed length allows for a larger swing, as it provides more space for the workpiece.

- Tool Rest Position: The position of the tool rest relative to the lathe bed affects the swing. If the tool rest is set close to the lathe bed, it can limit the swing by interfering with the workpiece.

- Tailstock Design: The design of the tailstock can impact the swing. A compact tailstock may allow for a larger swing by minimizing interference with the workpiece.

- Toolpost Size: The size of the toolpost and its position on the lathe carriage can limit the swing. A large toolpost or one positioned closer to the spindle centerline allows for a larger swing.

- Motor Power: The power of the lathe motor can influence the swing, especially when working with larger and heavier workpieces. A more powerful motor can provide the torque necessary for a larger swing.

- Stability and Rigidity: The overall stability and rigidity of the lathe machine play a significant role in determining the maximum swing. A more stable and rigid lathe can handle larger workpieces without deflection or chatter.

Considering these factors when selecting a lathe machine is crucial to ensure that it meets the required swing capacity for your specific machining needs. Failure to account for these factors can result in limitations and difficulties when working with larger or more complex workpieces.

Choosing the Right Lathe Swing

The lathe swing refers to the maximum diameter of the workpiece that can be accommodated by a lathe. Choosing the right lathe swing is essential to ensure that you can work on projects of the desired size and complexity.

Consider the Size of Your Projects

One of the first factors to consider when choosing the right lathe swing is the size of the projects you plan to work on. Determine the maximum diameter of the workpieces you will be turning, and make sure the lathe swing can accommodate that size.

For example, if you primarily work on small projects such as pens or small bowls, a lathe with a smaller swing may be suitable. However, if you plan to work on larger projects such as table legs or large bowls, you will need a lathe with a larger swing to accommodate the size of the workpiece.

Consider the Available Space

Another important factor to consider is the available space in your workshop. The lathe swing will determine the overall footprint of the lathe, so make sure you have enough space to accommodate the lathe with the desired swing size.

If you have limited space, you may need to consider a smaller lathe with a smaller swing. However, if space is not an issue, you can opt for a larger lathe with a larger swing to have more flexibility and versatility in your projects.

Consider Your Budget

Your budget will also play a role in determining the right lathe swing for you. Larger lathes with larger swings typically come with a higher price tag. Evaluate your budget and determine how much you are willing to spend on a lathe.

Keep in mind that there are various options available at different price points, so you should be able to find a lathe with a swing that fits your budget.

Conclusion

Choosing the right lathe swing is crucial for your woodworking projects. Consider the size of your projects, the available space in your workshop, and your budget to make an informed decision. By doing so, you can ensure that your lathe meets your needs and allows you to work on projects of various sizes and complexities.

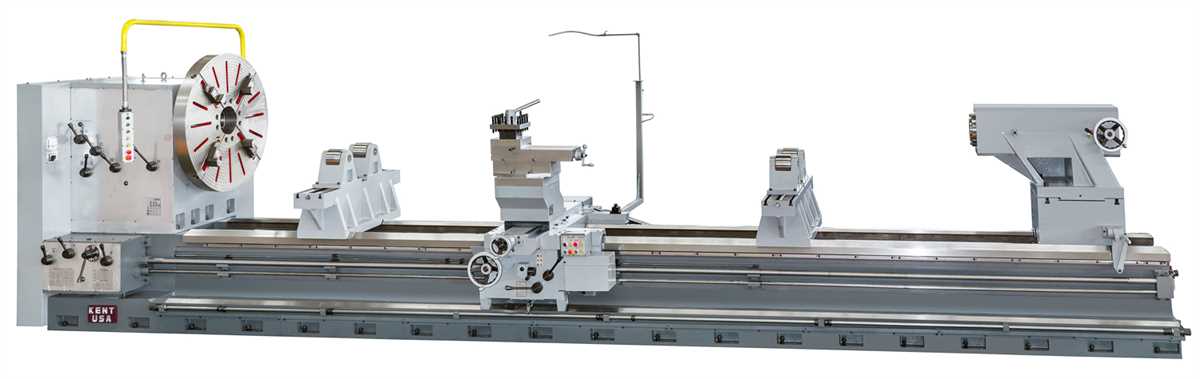

Benefits of a Larger Lathe Swing

A lathe swing refers to the maximum diameter of a workpiece that can be accommodated on a lathe. The size of the lathe swing is an important consideration when choosing a lathe for a specific project or workshop. While smaller lathes may have their advantages, there are several benefits to having a larger lathe swing.

1. Increased Versatility

One of the main advantages of a larger lathe swing is the increased versatility it provides. With a larger swing, you can work on larger workpieces and undertake a wider range of projects. Whether you are turning bowls, vases, or table legs, a larger swing allows for greater flexibility and creativity in your woodworking or metalworking endeavors.

2. Ability to Accommodate Larger Diameter Stock

Having a larger lathe swing also means that you can work with larger diameter stock. This is particularly beneficial when working with projects that require larger diameter components, such as stairway newel posts or bedposts. With a larger swing, you won’t be limited by the size of the lathe and can take on more challenging projects.

3. Improved Stability and Accuracy

A larger lathe swing often translates into a more stable and accurate machine. The increased size allows for a more rigid structure, reducing vibrations during operation. This stability is especially important when working on larger workpieces, as any movement or vibration can result in mistakes or imperfections. Additionally, the increased size provides more room for attachments and accessories, allowing for greater precision and accuracy in your turning projects.

4. Enhanced Safety

Working with larger workpieces on a lathe can present safety concerns if they are not properly supported or stabilized. Having a larger lathe swing provides more space and stability for larger workpieces, reducing the risk of accidents or injuries. It allows for better control and maneuverability, promoting a safer working environment.

5. Future-Proofing

Investing in a lathe with a larger swing is a way to future-proof your workshop. As your skills and projects grow, you may find yourself needing to work on larger and more complex workpieces. By choosing a lathe with a larger swing from the beginning, you won’t have to upgrade your equipment down the line, saving you time and money.

In conclusion, a larger lathe swing offers increased versatility, the ability to work with larger diameter stock, improved stability and accuracy, enhanced safety, and future-proofing for your woodworking or metalworking projects. Consider these benefits when choosing a lathe for your workshop.

Limitations of a Smaller Lathe Swing

1. Size and Weight Constraints

A smaller lathe swing means there are certain limitations on the size and weight of the workpiece that can be accommodated. Larger workpieces may simply not fit into the smaller lathe swing, or their weight may be too much for the machine to handle.

2. Reduced Versatility

With a smaller lathe swing, the range of projects and materials that can be worked on is limited. The smaller size may restrict the types of cuts and operations that can be performed, and may also limit the availability of accessories and attachments that can be used.

3. Limited Spindle Speed

Smaller lathes often come with lower spindle speeds compared to larger ones. This can be a limitation when it comes to machining certain materials or achieving higher quality finishes. Higher spindle speeds are often required for precision work and smoother results.

4. Reduced Stability

A smaller lathe swing typically has a lighter and less rigid construction compared to larger ones. This can result in reduced stability and increased vibrations during operation. It may be more challenging to achieve precise and accurate cuts on a smaller lathe swing due to these stability limitations.

5. Limited Chuck Capacity

The chuck capacity of a lathe refers to the maximum diameter of workpiece that can be held securely. A smaller lathe swing typically has a smaller chuck capacity, meaning it can only accommodate smaller diameter workpieces. This can be a limitation when working on larger projects or when needing to hold larger diameter materials.

6. Less Power and Torque

Smaller lathes often have less powerful motors and lower torque compared to larger ones. This can limit the amount of force and power that can be exerted on the workpiece, potentially affecting the efficiency and effectiveness of the machining process.

7. Limited Tool Rest Range

With a smaller lathe swing, the range of movement and adjustment of the tool rest may be limited. This can make it more difficult to position the cutting tools properly and achieve the desired cutting angles for different operations.

8. Longer Machining Times

Given the reduced size and capabilities of a smaller lathe swing, it may take longer to complete machining tasks compared to using a larger lathe. This can be due to the limited spindle speed, reduced power and torque, and other factors that affect the overall efficiency and productivity of the machine.

Overall, while a smaller lathe swing may be suitable for certain smaller projects and materials, it does come with certain limitations that need to be considered before making a purchase or deciding on its use for specific machining tasks.

Tips for Using a Lathe with Different Swing Sizes

When it comes to using a lathe, understanding the swing size is crucial. The swing size refers to the maximum diameter of workpiece that can be turned on the lathe without any interference. Different lathes have different swing sizes, and it’s important to know how to use a lathe with different swing sizes effectively. Here are some tips to consider:

1. Understand the limitations

Before starting any project, it’s important to understand the limitations of your lathe’s swing size. This will help you determine the appropriate size of workpiece that can be turned without any issues. Trying to turn a workpiece that exceeds the swing size can cause interference and damage to the lathe.

2. Choose the right workpiece size

When using a lathe with a smaller swing size, it’s important to choose workpieces that are within the range of the lathe’s swing. This will ensure smooth and efficient turning without any interference. Measure the diameter of the workpiece and make sure it is smaller than the swing size of the lathe.

3. Consider the tool rest position

Depending on the swing size of the lathe, the position of the tool rest will vary. For lathes with a smaller swing size, the tool rest needs to be positioned closer to the workpiece to provide proper support. Adjust the tool rest accordingly to avoid any issues during turning.

4. Take lighter cuts

When using a lathe with a smaller swing size, it’s best to take lighter cuts to avoid putting excessive strain on the lathe. Taking lighter cuts will ensure smoother and more precise turning without any strain on the lathe’s motor or other components.

5. Use steady rests

If you need to turn workpieces that exceed the swing size of your lathe, consider using steady rests. Steady rests can provide additional support to the workpiece and prevent any interference or damage to the lathe. Make sure to position the steady rests properly and secure the workpiece tightly for stability.

By following these tips, you can effectively use a lathe with different swing sizes and ensure smooth and precise turning operations. Remember to always consider the limitations of your lathe’s swing size and choose workpieces accordingly to avoid any issues or damage to the lathe.

FAQ

What is the definition of lathe swing?

Lathe swing refers to the maximum diameter of a workpiece that can be accommodated on a lathe. It is determined based on the distance between the lathe’s bed and the centerline of the spindle. Essentially, it is the size limit of the workpiece that can be rotated and machined on the lathe.

Why is understanding lathe swing important?

Understanding lathe swing is important because it determines the size and type of workpieces that can be machined on a lathe. It is crucial information for machinists and manufacturers to ensure that the workpiece can fit properly and be effectively machined within the lathe’s capacity.

How is lathe swing measured?

Lathe swing is measured by taking the distance from the lathe’s bed to the centerline of the spindle and doubling it. This gives the maximum diameter that can be accommodated on the lathe. For example, if the distance is 10 inches, the lathe swing would be 20 inches.

Are there different sizes of lathe swing available?

Yes, there are different sizes of lathe swing available. The size can vary depending on the specific lathe model and manufacturer. Some lathes have smaller swings, typically used for smaller workpieces, while others have larger swings for machining larger workpieces.

What factors can limit the lathe swing?

Several factors can limit the lathe swing. The main factor is the distance between the lathe’s bed and the centerline of the spindle. If the distance is limited, it will restrict the maximum diameter that can be accommodated. Additionally, the design and construction of the lathe, including the size and configuration of the spindle, may also restrict the lathe swing.

Can the lathe swing be increased?

No, the lathe swing cannot be increased beyond the maximum capacity determined by the distance between the bed and the centerline of the spindle. The lathe swing is a fixed limitation based on the physical dimensions of the lathe. If a larger swing is required, a different lathe with a larger capacity would need to be used.