Best cnc lathe turning parts quotes

When it comes to CNC lathe turning parts, getting the best quotes is crucial for businesses in various industries. CNC (Computer Numerical Control) lathe turning is a manufacturing process that involves shaping and finishing components using computer-controlled tools. It is widely used in industries such as automotive, aerospace, medical, and more.

Getting the best CNC lathe turning part quotes is essential for businesses looking to manufacture high-quality components at competitive prices. By obtaining multiple quotes, companies can compare prices, production capabilities, and lead times to make informed decisions.

To get the best CNC lathe turning part quotes, it’s important to provide detailed specifications and requirements. This includes dimensions, material type, tolerances, surface finish, and any other specific features or considerations. By providing precise information, manufacturers can accurately assess the complexity of the job and provide accurate quotes.

What are CNC lathe turning parts?

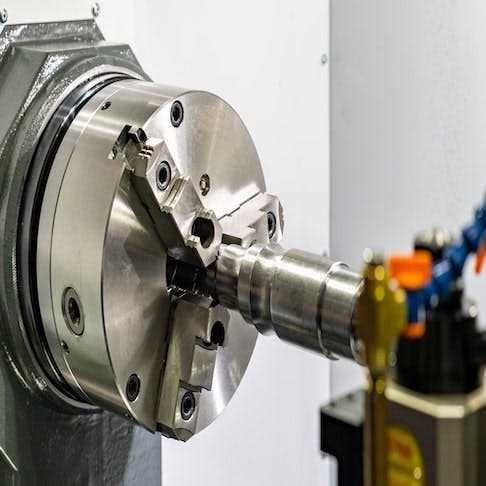

CNC lathe turning parts refer to components that are made using a lathe machine controlled by computer numerical control (CNC). These parts are typically cylindrical in shape and are turned on a lathe to achieve the desired dimensions and surface finish. CNC lathe turning is a precise and efficient manufacturing process that allows for the production of complex and intricate parts.

These parts are commonly used in various industries, including automotive, aerospace, electronics, and machinery. They are essential components in the manufacturing of products such as shafts, pins, rods, bushings, and connectors. CNC lathe turning parts are made from a wide range of materials, including metals like steel, aluminum, and brass, as well as plastics and composites.

During the CNC lathe turning process, the lathe machine holds the workpiece securely in place and rotates it while a cutting tool moves along the length of the part, removing material and shaping it according to the programmed design. The CNC control system directs the movements of the machine, ensuring high precision and repeatability. This automation enables the production of parts with tight tolerances and complex geometries.

The advantages of CNC lathe turning parts include faster production times, improved accuracy, and the ability to create complex designs. The use of computer control eliminates the need for manual adjustments, reducing human error and increasing efficiency. CNC lathe turning also allows for the customization of parts to meet specific requirements, making it a versatile and cost-effective manufacturing method.

In conclusion, CNC lathe turning parts are components made using a computer-controlled lathe machine. They are used in various industries and are made from a wide range of materials. CNC lathe turning is a precise and efficient manufacturing process that offers advantages such as faster production times and the ability to produce complex designs.

How to choose the best CNC lathe turning parts?

When selecting CNC lathe turning parts, it is important to consider several key factors to ensure the highest quality and most efficient performance. These parts play a crucial role in the overall functionality and accuracy of the lathe, so making the right choice is essential.

1. Material: The material used in CNC lathe turning parts should be carefully considered. Different materials have varying properties, such as hardness and heat resistance, which can impact the performance and longevity of the parts. It is important to choose a material that is suitable for the specific application and can withstand the required conditions.

2. Precision: Precision is a critical aspect of CNC lathe turning parts. The parts need to be manufactured to precise tolerances to ensure accurate and consistent performance. Look for parts that are manufactured using advanced machining techniques and technologies, such as computer numerical control (CNC) machining, to ensure the highest level of precision.

3. Compatibility: When choosing CNC lathe turning parts, it is essential to consider compatibility with the specific lathe model. Not all parts are universal, and using incompatible parts can lead to poor performance or even damage to the lathe. Therefore, it is important to verify the compatibility of the parts with the lathe’s specifications before making a purchase.

4. Reputation of the manufacturer: The reputation of the manufacturer should also be taken into consideration when selecting CNC lathe turning parts. Look for manufacturers with a proven track record of producing high-quality and reliable parts. Reading customer reviews and testimonials can provide insights into the manufacturer’s reputation and the quality of their products.

Overall, choosing the best CNC lathe turning parts involves considering the material, precision, compatibility, and reputation of the manufacturer. By carefully evaluating these factors, you can select parts that will enhance the performance and durability of your CNC lathe.

Factors to consider when selecting CNC lathe turning parts

When selecting CNC lathe turning parts, there are several factors that should be taken into consideration. These factors can greatly impact the overall performance and quality of the parts, so it is important to carefully evaluate each one before making a decision.

Material: One of the most important factors to consider is the material of the CNC lathe turning parts. Different materials have different properties and characteristics, which can affect the durability and functionality of the parts. It is important to choose a material that is suitable for the specific application and can withstand the required conditions.

Precision: Another important factor to consider is the precision of the CNC lathe turning parts. Precision plays a crucial role in the accuracy and consistency of the parts, especially in applications that require high levels of precision. It is important to select parts that are manufactured with tight tolerances and have a high level of precision to ensure optimal performance.

Cost: Cost is also a significant factor to consider when selecting CNC lathe turning parts. The cost of the parts can vary depending on factors such as material, complexity, and quantity. It is important to consider the budget and cost constraints while also ensuring that the selected parts meet the required quality standards.

Supplier: The choice of supplier is another important factor to consider. It is crucial to select a reliable and reputable supplier who can provide high-quality CNC lathe turning parts. The supplier should have a proven track record, experience in the industry, and a strong reputation for delivering quality products.

In conclusion, selecting the right CNC lathe turning parts requires careful consideration of factors such as material, precision, cost, and supplier. By evaluating these factors and making informed decisions, it is possible to choose parts that meet the specific requirements and ensure optimal performance.

Benefits of Using CNC Lathe Turning Parts

Using CNC lathe turning parts offers several benefits that make it a popular choice in various industries. One of the key advantages is the high level of precision and accuracy that can be achieved. CNC lathe turning parts are programmed to follow specific instructions, ensuring consistent and reliable performance. This level of precision is especially crucial in industries such as aerospace and automotive, where tight tolerances are required for the optimal functioning of the parts.

Another benefit of using CNC lathe turning parts is the increased efficiency and productivity they bring to the manufacturing process. These parts can be programmed to perform a wide range of complex tasks, eliminating the need for manual labor and reducing the possibility of human error. This automation not only speeds up the production process but also improves the overall quality of the finished products.

- Cost-effectiveness: CNC lathe turning parts can save costs in the long run as they reduce the need for manual labor and minimize material wastage. The precise and accurate nature of these parts also reduces the chances of errors and rework, further saving money on additional production time and costs.

- Versatility: CNC lathe turning parts can handle a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for various industries, from automotive to electronics. The ability to work with different materials expands the possibilities for product design and customization.

- Quick Turnaround: The automated nature of CNC lathe turning parts allows for faster production turnaround times. With the ability to run continuously and without breaks, these machines can produce a large number of parts in a relatively short period. This is especially beneficial when there is a need to meet tight production deadlines.

- Consistency and Quality: CNC lathe turning parts ensure consistent and high-quality results. Once the program is set, the machines can replicate the same actions repeatedly, producing identical parts with minimal variation. This consistency is crucial in industries where precision and quality are paramount.

In conclusion, CNC lathe turning parts offer numerous advantages, including increased precision, efficiency, cost-effectiveness, versatility, quick turnaround, and consistent quality. These benefits make CNC lathe turning parts a preferred choice in various industries, enabling manufacturers to produce high-quality products with minimal error and increased productivity.

5 Best cnc lathe turning parts quotes

Features

| Size | MT3 |

Features

| Part Number | VSW8522820982477LQ |

Features

| Part Number | JUSTPENGHUI |

| Color | Multi-colored |

Features

| Part Number | Walfrontzg1gdxf65v |

Question-answer:

What are the benefits of using CNC lathe turning parts?

The benefits of using CNC lathe turning parts include higher precision and accuracy in the manufacturing process, faster production times, increased efficiency and productivity, the ability to create complex shapes and designs, and improved consistency and quality control.

How does using CNC lathe turning parts improve precision and accuracy?

CNC lathe turning parts use computer-controlled systems to precisely guide the cutting tool, resulting in higher precision and accuracy in the manufacturing process compared to manual methods. This leads to better-finished products and reduced scrap or wastage.

Why are faster production times a benefit of using CNC lathe turning parts?

CNC lathes are able to perform multiple operations simultaneously, reducing the time required for each part. Additionally, the computer-controlled systems can operate at high speeds with consistent accuracy, resulting in faster production times and increased output.

How does using CNC lathe turning parts increase efficiency and productivity?

CNC lathes eliminate the need for manual intervention, reducing the time and effort required to produce parts. They also allow for continuous operation with minimal downtime, maximizing productivity. Additionally, the automation provided by CNC lathes frees up operators to focus on other tasks, further increasing efficiency.

Why is the ability to create complex shapes and designs a benefit of using CNC lathe turning parts?

CNC lathes use computer-aided design (CAD) software to guide the cutting tool, allowing for the creation of intricate and complex shapes and designs that would be difficult or impossible to achieve with manual methods. This opens up new possibilities for innovative and unique products.

Conclusion

In conclusion, the use of CNC lathe turning parts offers numerous benefits for businesses and industries. These parts provide precision and accuracy in manufacturing, leading to high-quality products. The use of CNC lathe turning parts also increases efficiency and productivity by reducing human error and speeding up production cycles. Additionally, these parts offer versatility, allowing for the creation of complex and intricate designs. Moreover, CNC lathe turning parts can contribute to cost savings in the long run due to their durability and reliability. Overall, integrating CNC lathe turning parts into manufacturing processes can greatly improve the quality and efficiency of production, making it a valuable investment for any business.