Understanding the Inner Workings of a Hammer Drill: The Ultimate Guide

When it comes to construction and DIY projects, having the right tools is essential. One tool that often comes in handy is the hammer drill. With its powerful impact mechanism, the hammer drill can make quick work of drilling into concrete, brick, and other hard surfaces that a regular drill simply can’t handle. But what exactly makes a hammer drill different from a regular drill?

The secret lies in the internal workings of the hammer drill. While both a regular drill and a hammer drill use a rotating motion to drill into materials, a hammer drill also incorporates a hammering action. This hammering action is what sets the hammer drill apart and allows it to easily penetrate hard materials.

Inside the hammer drill, there is a special mechanism that generates this hammering action. This mechanism consists of an anvil and a hammer. As the drill rotates, the hammer moves back and forth against the anvil, creating a hammering effect. This hammering effect helps to break up the material being drilled into, making it easier for the drill bit to penetrate.

In addition to the hammering mechanism, hammer drills often have a switch or setting that allows them to function as a regular drill as well. This versatility makes them a valuable tool to have in your arsenal. Whether you need to drill into concrete, wood, or metal, a hammer drill can handle the job.

In this ultimate guide, we will explore the inner workings of a hammer drill in more detail, including how the hammering mechanism works, the different types of hammer drills available, and tips for using a hammer drill effectively. With this knowledge, you’ll be able to confidently tackle any project that requires drilling into hard materials.

How Does a Hammer Drill Work?

A hammer drill is a powerful tool that combines the rotational motion of a drill with a forward hammering action to create a drilling force that can easily penetrate hard materials such as concrete, stone, and masonry. Understanding how a hammer drill works is essential if you want to make the most out of this versatile tool.

1. Electric Motor: A hammer drill is powered by an electric motor that generates the rotational force required for drilling. This motor is typically located at the back of the drill and is connected to the drill bit through a series of gears.

2. Drill Bit: The drill bit is the part of the hammer drill that actually does the drilling. It is usually made of high-speed steel or tungsten carbide and is available in various sizes and shapes to suit different applications. The drill bit is securely attached to the drill’s chuck, which holds it in place during operation.

3. Hammer Mechanism: The key feature of a hammer drill is its hammering action, which allows it to penetrate tough materials. Inside the drill, there is a mechanism that converts the rotational force from the electric motor into a hammering motion. This mechanism typically consists of two metal disks with scalloped edges called cam plates. As the motor rotates, these cam plates push against each other, creating a back-and-forth hammering motion.

4. Impact Control: Many modern hammer drills come with adjustable impact control, which allows the user to vary the force of the hammering action. This feature is especially useful when working with delicate materials or when drilling shallow holes.

5. Drill Modes: Hammer drills often have multiple drilling modes, including drilling only, hammer drilling, and hammering only. These modes can be selected using a switch or a control dial on the drill. The ability to switch between modes makes the hammer drill a versatile tool that can be used for various applications.

6. Accessories: Hammer drills can be used with various accessories, such as chisels and brushes, to perform tasks other than drilling. These accessories can enhance the versatility of the hammer drill and make it suitable for tasks such as chiseling, scraping, and cleaning.

7. Safety Measures: As with any power tool, it is important to follow safety guidelines when using a hammer drill. This includes wearing appropriate safety gear, such as protective eyewear and gloves, and using the tool in a well-ventilated area. It is also important to ensure that the drill is turned off and unplugged before changing drill bits or making any adjustments.

In conclusion, a hammer drill works by combining rotational motion with a hammering action to create a powerful drilling force. Understanding how this tool functions will help you use it effectively and safely for a wide range of applications.

Understanding the Different Types of Hammer Drills

1. Standard Hammer Drills

The standard hammer drill is the most common type of hammer drill. It is designed to drill into materials such as concrete, brick, and stone. It uses a combination of rotational force and repeated hammering action to create the hole. The chuck on a standard hammer drill typically accepts drill bits with a shank size of 1/2 inch or less.

2. SDS Hammer Drills

SDS hammer drills are commonly used in construction and masonry work. They have a special chuck system called SDS, which stands for Special Direct System. This chuck allows for quick and easy bit changes without the need for a key. SDS drills come in different sizes, with the most common ones being SDS-Plus and SDS-Max. The SDS-Max drills are larger and more powerful, suitable for heavy-duty drilling.

3. Rotary Hammer Drills

Rotary hammer drills are similar to standard hammer drills but with a few key differences. They have a dedicated hammering mechanism that provides more power and impact force, making them suitable for tougher materials and larger drilling tasks. Rotary hammer drills often feature three modes: drilling, hammer drilling, and chiseling. They are versatile tools commonly used in construction and demolition work.

4. Cordless Hammer Drills

Cordless hammer drills are powered by rechargeable batteries, making them portable and convenient to use in different locations. They offer the same functionality as standard hammer drills but without the need for a power cord. Cordless hammer drills come in different voltages, with higher voltages generally offering more power and longer battery life.

5. Combination Hammer Drills

Combination hammer drills, also known as combi drills, are versatile tools that combine the functionality of a hammer drill and an impact driver. They can be used for drilling into various materials as well as for driving screws and fasteners. Combination hammer drills are popular among DIY enthusiasts and professionals due to their versatility and convenience.

| Type | Chuck System | Power Source | Common Applications |

|---|---|---|---|

| Standard Hammer Drills | Keyed | Electric | Concrete, brick, stone |

| SDS Hammer Drills | SDS (keyless) | Electric | Construction, masonry |

| Rotary Hammer Drills | Keyed or SDS | Electric | Construction, demolition |

| Cordless Hammer Drills | Keyless | Rechargeable battery | Versatile |

| Combination Hammer Drills | Keyless | Electric or rechargeable battery | Drilling, screwdriving |

Choosing the Right Hammer Drill for Your Project

Choosing the right hammer drill for your project is essential to ensure the best results. There are several factors you need to consider when making your selection.

1. Power

One of the most important factors to consider is the power of the hammer drill. The power of the drill is measured in watts or volts, and it determines how fast and efficiently the drill can penetrate various materials. If you’re working on heavy-duty projects that involve drilling into tough materials like concrete or masonry, you’ll need a high-powered hammer drill that can deliver enough force to get the job done.

2. Speed

The speed of the hammer drill is another crucial factor to consider. Most hammer drills offer variable speed settings, allowing you to adjust the speed according to the specific task at hand. For example, when drilling into softer materials like wood or plastic, you’ll want to use a lower speed setting to prevent damage, while drilling into harder materials might require a higher speed setting for faster and more efficient drilling.

3. Chuck Size

The chuck size is an important consideration when choosing a hammer drill. The chuck is the part of the drill that holds the drill bit in place. Common chuck sizes for hammer drills are 1/2 inch and 3/8 inch. The larger the chuck size, the larger the drill bit it can accommodate. If you’re planning to use larger drill bits for your project, make sure to choose a hammer drill with a larger chuck size.

4. Features

Consider the features that are important for your specific projects. Some hammer drills come with a built-in level or LED light to improve accuracy and visibility. Others offer a hammer-only mode, which allows you to use the drill as a regular hammer for tasks like chiseling. Additionally, look for a hammer drill with a comfortable grip and ergonomic design to reduce fatigue during long drilling sessions.

5. Price

Finally, consider your budget when choosing a hammer drill. There are hammer drills available at various price points, so it’s important to find a balance between quality and affordability. Do some research to compare prices and read customer reviews to make sure you’re getting the best value for your money.

By considering factors such as power, speed, chuck size, features, and price, you’ll be able to choose the right hammer drill that meets your project needs and delivers exceptional results.

The Importance of Drill Bits in a Hammer Drill

When it comes to using a hammer drill, one of the most important components is the drill bit. Choosing the right drill bit for the task at hand can greatly impact the effectiveness and efficiency of the drilling process. Here are a few reasons why drill bits are so important in a hammer drill:

1. Compatibility

Drill bits are designed to be compatible with specific materials and drilling tasks. Different drill bits are suited for drilling into wood, metal, concrete, or masonry. Using the wrong drill bit for a particular material can result in inefficient drilling, damage to the drill bit or the material being drilled, and potential safety hazards.

2. Durability

Drill bits are subjected to intense pressure and friction during the drilling process, especially when used with a hammer drill. It is important to choose drill bits that are durable and can withstand the high speeds and impact forces generated by a hammer drill. High-quality drill bits made from materials such as carbide or cobalt are more resistant to wear and can last longer, resulting in cost savings and improved drilling performance.

3. Precision

The design and quality of the drill bit can greatly affect the precision and accuracy of the drilling process. A dull or misaligned drill bit can result in holes that are off-center or not the correct size. This can cause issues when installing screws, anchors, or other fasteners, and may require additional time and effort to correct the mistakes.

4. Efficiency

Using the right drill bit can significantly improve drilling efficiency. A drill bit designed for a specific material will have the appropriate cutting edges and flutes to remove material efficiently, reducing the drilling time and effort required. In contrast, using an inadequate drill bit may result in slower progress, increased heat generation, and premature wearing of the drill bit.

5. Safety

Choosing the right drill bit is crucial for safety reasons. Using an unsuitable drill bit can lead to increased vibrations, kickbacks, or the drill bit breaking during operation. This can pose a risk to the operator and anyone in the vicinity. Additionally, a dull or damaged drill bit can cause the drill to become unstable, increasing the chances of accidents or injury.

In conclusion, drill bits play a pivotal role in the performance and safety of a hammer drill. It is important to select the appropriate drill bit for the material being drilled to ensure compatibility, durability, precision, efficiency, and safety.

Tips for Using a Hammer Drill Safely and Efficiently

1. Read the User Manual

Before using a hammer drill, it is important to read the user manual provided by the manufacturer. The manual will provide detailed instructions on how to operate the drill safely and efficiently. It will also include information on maintenance and troubleshooting.

2. Wear Protective Gear

When using a hammer drill, it is crucial to wear the appropriate protective gear. This includes safety glasses or a face shield to protect your eyes from flying debris, as well as earplugs or earmuffs to protect your hearing from the loud noise produced by the drill.

3. Choose the Right Drill Bit

Selecting the correct drill bit is essential for both safety and efficiency. The wrong drill bit can cause damage to the material you are drilling into and even result in injury. Make sure to choose a drill bit that is suitable for the material you are working with, such as masonry, wood, or metal.

4. Secure the Workpiece

Before drilling, it is important to secure the workpiece to prevent it from moving or spinning. This can be done using clamps or by securing it against a stable surface, such as a workbench or wall. This will ensure that the drill stays steady and prevents any accidents or mistakes.

5. Start Slowly

When using a hammer drill, it is recommended to start at a low speed and gradually increase the speed as needed. This will help you maintain control over the drill and avoid any sudden movements or jerks. It is also important to maintain a firm grip on the drill at all times.

6. Use Proper Technique

To ensure safe and efficient drilling, it is important to use the proper drilling technique. This includes applying gentle pressure while drilling, allowing the hammer action of the drill to do the work, and avoiding excessive force or leaning on the drill. It is also important to keep the drill perpendicular to the surface being drilled to prevent any damage or accidents.

7. Use Water for Cooling

If you are drilling into masonry or concrete, it is recommended to use water for cooling. This will help prevent the drill bit from overheating and prolong its lifespan. Simply place a sponge soaked in water near the drilling area and periodically wet the drill bit as needed.

8. Clean and Lubricate Regularly

After each use, it is important to clean and lubricate the hammer drill to ensure its optimal performance and longevity. Use a damp cloth to remove any debris or dust from the drill, especially the drill chuck and motor vents. Apply a small amount of lubricating oil to the moving parts to prevent rust and ensure smooth operation.

9. Store Properly

When not in use, it is important to store the hammer drill in a safe and secure place. Keep it in a dry environment to prevent moisture damage and store it in a protective case or toolbox to avoid any accidental damage or mishandling.

By following these tips, you can use a hammer drill safely and efficiently, allowing you to complete your drilling tasks with ease and confidence.

Common Applications for Hammer Drills

Hammer drills are versatile power tools that are commonly used in the construction and home improvement industry. They are suitable for various applications that involve drilling into hard materials such as concrete, masonry, and stone. Here are some common applications where hammer drills are often used:

- Drilling holes in concrete: Hammer drills are specially designed to efficiently drill holes in tough materials like concrete. They have a hammering action that applies a forceful impact along with the rotation to break through the hard surface. This makes them perfect for tasks like installing anchors, concrete screws, and bolts.

- Removal of stubborn materials: Sometimes, there may be a need to remove old tiles, plaster, or other stubborn materials from a surface. Hammer drills with a chisel function can be used for chipping away at these materials, making the removal process faster and more efficient.

- Creating channels and openings: When working on electrical or plumbing installations, you may need to create channels or openings in walls or floors. Hammer drills can be used to make precise and controlled cuts, allowing for the installation of cables, pipes, or conduit.

- Breaking up concrete or masonry: In certain construction or demolition projects, it may be necessary to break up large sections of concrete or masonry. Hammer drills with a dedicated demolition function can deliver powerful blows to break up these materials effectively.

These are just a few examples of the common applications for hammer drills. Their versatility and ability to handle tough materials make them an essential tool for many construction and home improvement projects.

Maintenance and Care for Your Hammer Drill

Cleaning

Regular cleaning is essential to keep your hammer drill in good working condition. After each use, wipe down the exterior of the drill with a clean, dry cloth to remove any dust or debris. Use a small brush or a can of compressed air to clean out the vents and any hard-to-reach areas.

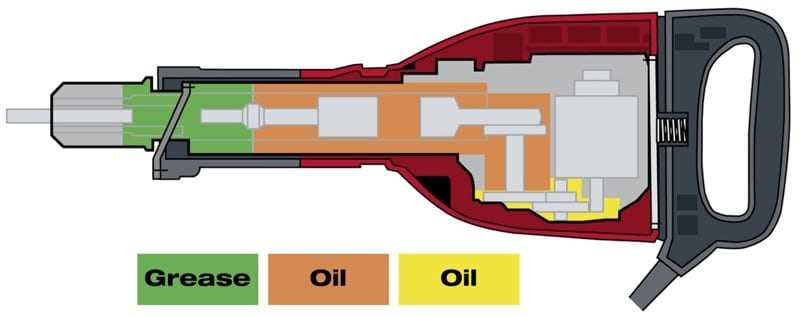

Lubrication

Proper lubrication is necessary to keep the moving parts of your hammer drill operating smoothly. Check the manufacturer’s instructions for the recommended lubricant, and apply it to the necessary areas according to the specified intervals.

Inspect for Damage

Regularly inspect your hammer drill for any signs of damage. Check the power cord for fraying or exposed wires, and replace it if necessary. Examine the chuck and chuck key for any wear or damage, and replace them if needed. Inspect the drill bit for any signs of wear or dullness, and replace it if it is no longer effective.

Battery Care

If your hammer drill is battery-operated, it is important to properly care for the battery. Avoid overcharging the battery, as this can shorten its lifespan. Store the battery in a cool, dry place when not in use, and avoid exposing it to extreme temperatures.

Storage

When storing your hammer drill, make sure it is in a clean, dry area where it will not be subject to moisture or extreme temperatures. Use a secure storage case or box to protect it from dust and debris. Additionally, consider removing the battery if the drill will not be used for an extended period of time.

Regular Maintenance

In addition to the above care and maintenance tasks, it is important to follow the manufacturer’s recommended maintenance schedule. This may include tasks such as replacing worn parts, cleaning or replacing the brushes, and checking the motor brushes for proper alignment and function.

Consult the Manual

If you have any questions or concerns about the care and maintenance of your hammer drill, consult the manufacturer’s manual. The manual will provide specific instructions for your particular model and can help you ensure that you are properly caring for your tool.

FAQ:

What is a hammer drill and how does it work?

A hammer drill is a power tool that combines a regular drill with a hammering action. It works by using a mechanical hammering mechanism that generates a pounding force to help break through hard materials, such as concrete or stone.

What are the key components of a hammer drill?

The main components of a hammer drill include the motor, hammering mechanism, chuck, drill bit, handle, and switch. The motor provides power, the hammering mechanism generates the hammering action, the chuck holds the drill bit in place, and the handle and switch allow for control of the tool.

What are the main uses of a hammer drill?

A hammer drill is commonly used for drilling holes in hard surfaces like concrete, masonry, or stone. It is also useful for tasks such as installing anchors, driving screws into tough materials, and chiseling away at concrete or tile.

What are the differences between a regular drill and a hammer drill?

A regular drill is designed for drilling holes in wood, metal, or plastic, while a hammer drill is specifically designed for tougher materials like concrete or stone. The main difference is that a hammer drill has a hammering action, which helps to break through these hard surfaces.

How do you select the right drill bit for a hammer drill?

When selecting a drill bit for a hammer drill, consider the material you are drilling into. For concrete, use a masonry bit. For metal, use a metal bit. For wood, use a wood bit. It is important to choose the correct bit as using the wrong one can result in damage to the bit and potentially the hammer drill.

What are the safety precautions to follow when using a hammer drill?

When using a hammer drill, it is important to wear safety goggles to protect your eyes from flying debris. It is also recommended to wear a dust mask to avoid inhaling any dust particles. Additionally, always grip the handle firmly and keep a stable stance.

Can a hammer drill be used as a regular drill?

Yes, a hammer drill can be used as a regular drill if the hammering action is turned off. Most hammer drills have a switch or button that allows you to disable the hammering mechanism, making it function like a regular drill.