How to Choose the Right Drill Bit: A Comprehensive Guide

Choosing the right drill bit can make a significant difference in the success of your project. Whether you’re a DIY enthusiast or a professional contractor, having the right drill bit is essential for achieving precise and clean holes. With the wide variety of drill bits available on the market, it can be overwhelming to know which one is the best fit for your needs.

This comprehensive guide will walk you through the key factors to consider when selecting a drill bit. From the material you’re working with to the type of hole you need to create, we’ll cover everything you need to know to make an informed decision. By understanding the different types of drill bits and their applications, you’ll be able to choose the right tool for the job, saving you time and effort in the long run.

Throughout this guide, we’ll also provide tips and recommendations based on our expertise and industry experience. We’ll discuss the importance of quality materials, the benefits of different coatings, and the importance of selecting the appropriate size and shape. Whether you’re working with wood, metal, or masonry, we’ll help you navigate the complex world of drill bits, ensuring that you have the right tools to tackle any project.

Remember, investing the time and effort into choosing the right drill bit will pay off in the long run. Not only will you achieve better results, but you’ll also prolong the lifespan of your drill and significantly reduce the risk of accidents or damage to your workpiece. So let’s get started and learn how to choose the right drill bit for your next project!

Understanding Drill Bit Materials

When it comes to choosing the right drill bit for your project, understanding the different materials used in drill bits is crucial. The material of the drill bit can greatly affect its performance, durability, and suitability for specific applications.

High-Speed Steel (HSS)

High-speed steel is one of the most common materials used for drill bits. It is known for its versatility and affordability. HSS drill bits are made from a combination of carbon steel and other alloys, which enhances their strength and hardness. These drill bits are suitable for drilling into wood, plastic, and soft metals.

Cobalt

Cobalt drill bits are made from a mixture of cobalt and steel. They are known for their high heat resistance and durability. Cobalt drill bits are ideal for drilling in stainless steel, cast iron, and other hard metals. They retain their hardness even at high temperatures, making them suitable for heavy-duty applications.

Carbide-Tipped

Carbide-tipped drill bits are designed for drilling into hard materials such as masonry, brick, and concrete. The tip of the drill bit is made from carbide, a compound of carbon and other elements. Carbide-tipped drill bits provide excellent longevity and cutting performance in tough materials.

Diamond

Diamond drill bits are used for drilling through extremely hard materials like glass, ceramic, and tile. The cutting edge of these drill bits is embedded with tiny diamond particles, which make them extremely hard and effective for precision drilling.

Coating

In addition to the different materials used in drill bits, they can also have various coatings to enhance their performance. Common coatings include titanium nitride (TiN), black oxide, and cobalt. These coatings help reduce friction, increase hardness, and improve overall performance and longevity of the drill bit.

| Material | Applications |

|---|---|

| High-Speed Steel (HSS) | Wood, plastic, soft metals |

| Cobalt | Stainless steel, cast iron, hard metals |

| Carbide-Tipped | Masonry, brick, concrete |

| Diamond | Glass, ceramic, tile |

When choosing a drill bit, consider the material you will be drilling into and select a drill bit made from a compatible material. This will ensure optimal performance and longevity for your drilling project.

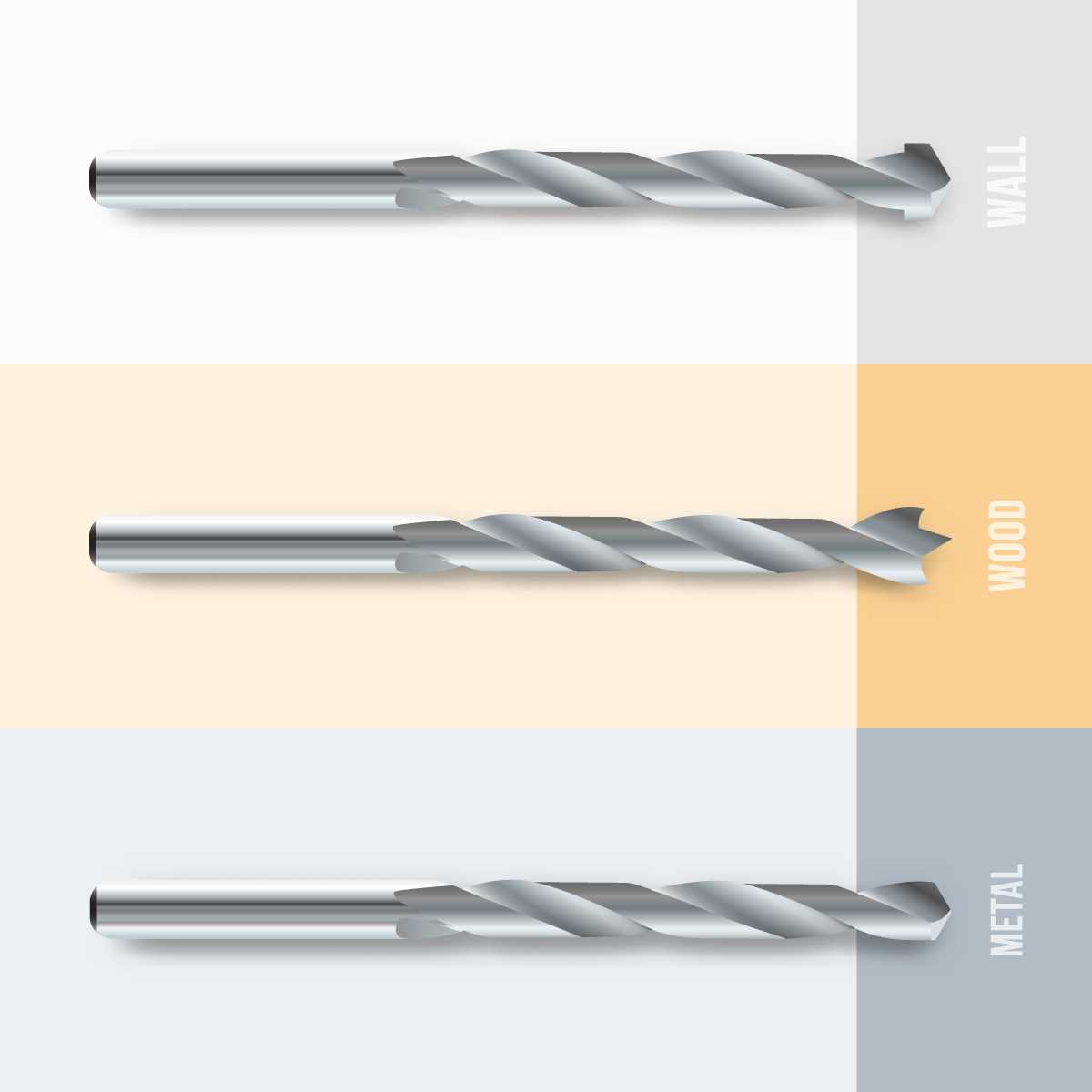

Matching Drill Bits to Materials

Choosing the right drill bit for your project is essential in achieving accurate and efficient results. Different materials require different types of drill bits to ensure clean holes and prevent damage to the workpiece. Here are some common materials and the corresponding drill bits that are best suited for each:

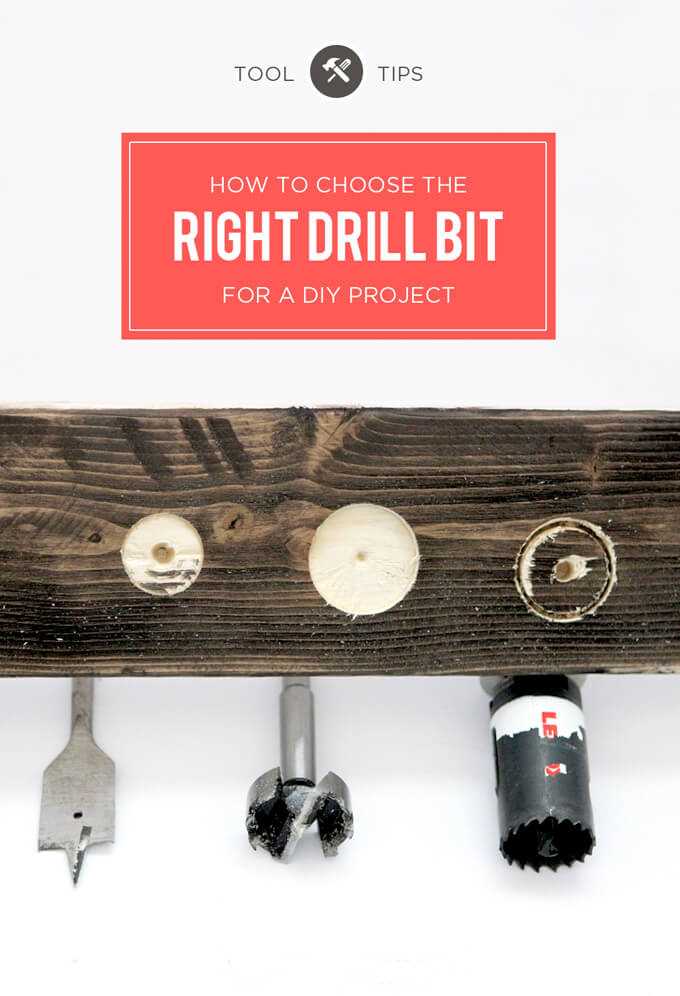

Wood

- Spade bit: Ideal for drilling large holes in wood. The flat, paddle-shaped tip helps to create clean holes without splintering.

- Brad point bit: Designed for precision drilling in wood. The sharp point helps to keep the bit centered, while the fluted edges help to remove chips.

- Forstner bit: Perfect for drilling flat-bottomed holes in wood. The circular rim helps to create clean and precise holes without tear-out.

Metal

- Twist bit: The most commonly used drill bit for metal. Its spiral shape allows for efficient chip removal and provides good control for precise drilling.

- Step bit: Ideal for drilling holes of various sizes in thin metal sheets. The stepped design allows for gradual drilling, minimizing the risk of bit breakage.

- Countersink bit: Used to create a conical hole to accommodate screws. It helps to create a flush surface when attaching metal pieces together.

Concrete and Masonry

- Masonry bit: Designed specifically for drilling into concrete, brick, and stone. Made of a carbide tip, it offers excellent durability and can withstand the hardness of these materials.

- Hammer drill bit: Similar to a masonry bit but specifically designed for use in a hammer drill. The hammering action helps to break through tough materials more effectively.

- Tile bit: Used for drilling through ceramic or porcelain tiles. The spear-shaped carbide tip helps to prevent cracking and chipping.

Glass and Tile

- Diamond bit: Specifically designed for drilling into glass, ceramic, and porcelain tiles. The diamond-embedded tip ensures precise and clean holes without causing damage or breakage.

- Glass and tile bit with a spear point: Similar to a diamond bit but with a spear-shaped carbide tip. It provides more control and is ideal for drilling small holes.

Remember to always wear appropriate safety gear when drilling and follow the manufacturer’s guidelines for the specific drill bit being used. Proper selection and use of drill bits will not only ensure a successful project but also guarantee the longevity of your tools.

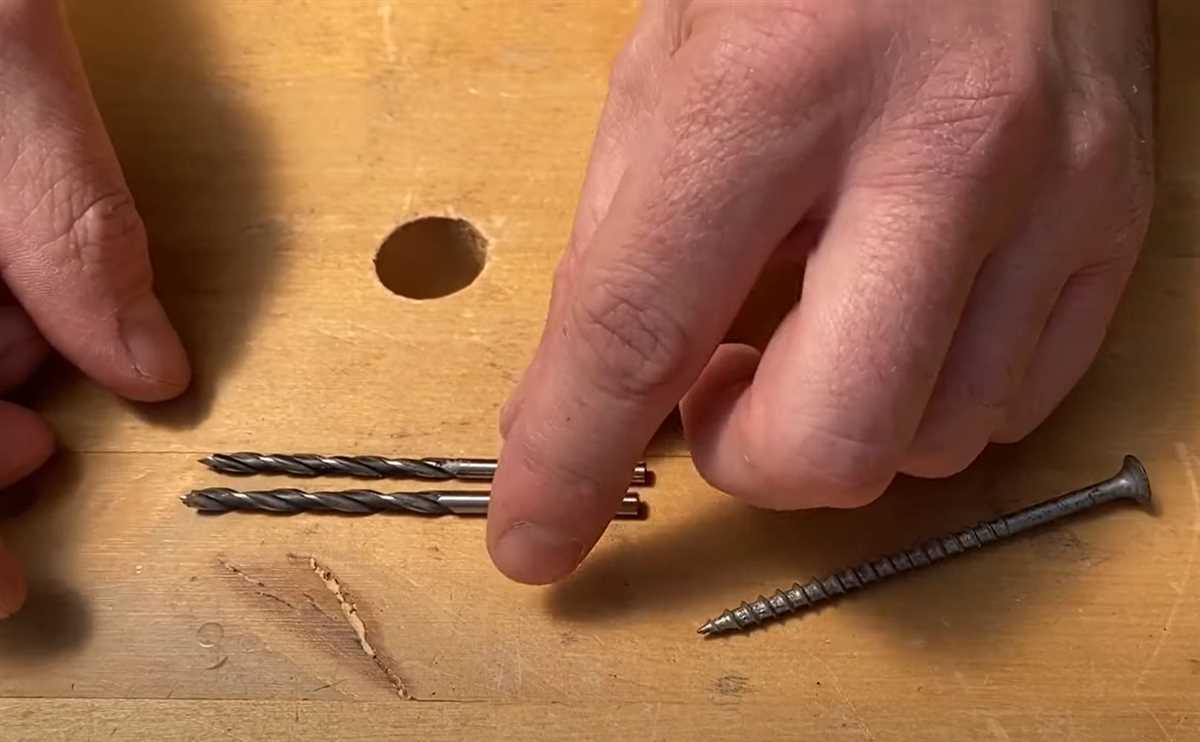

Choosing the Right Drill Bit Size

When it comes to drilling, choosing the right drill bit size is essential for achieving the desired results. The drill bit size determines the diameter of the hole that will be drilled, and it can vary based on the specific project or material being worked on. Here are some factors to consider when selecting the right drill bit size:

1. Material

The type of material being drilled is a crucial factor in determining the appropriate drill bit size. Different materials require different types and sizes of drill bits. For example, drilling into wood will require a different bit size compared to drilling into metal or masonry. It is important to choose a drill bit size that matches the hardness and density of the material.

2. Project Requirements

The specific requirements of the project also play a role in determining the right drill bit size. Consider the depth and diameter of the hole needed for the project. If precision is required, it may be necessary to use a drill bit with a smaller diameter. On the other hand, larger holes may require drill bits with bigger diameters. Make sure to measure and mark the desired hole size before selecting the appropriate drill bit.

3. Compatibility with the Drill

It is important to choose a drill bit size that is compatible with the drill being used. Check the drill’s chuck size and capacity to ensure that it can accommodate the chosen drill bit. Using a drill bit that is too large or too small for the drill can result in poor performance or potential damage to the drill.

4. Drill Bit Types

Consider the different types of drill bits available for the specific project. Twist bits, spade bits, and hole saws are just a few examples of the various types of drill bits that come in different sizes. Each type of drill bit has its own set of advantages and disadvantages, so it is important to choose the right type and size for the job at hand.

5. Safety Considerations

Lastly, it is essential to consider safety when choosing the right drill bit size. Always wear appropriate safety gear, including safety glasses or goggles, when drilling. Using the correct drill bit size for the project will help ensure a cleaner and safer drilling experience.

In conclusion, choosing the right drill bit size is crucial for achieving accurate and efficient drilling results. By considering factors such as the material, project requirements, compatibility with the drill, drill bit types, and safety considerations, you can select the appropriate size drill bit for your specific project or application.

Selecting the Appropriate Drill Bit Type

Choosing the right drill bit type is crucial for ensuring accurate and efficient drilling. With a variety of drill bits available, each designed for specific materials and drilling applications, it’s important to select the appropriate bit type for your project. Here are some key factors to consider when choosing the right drill bit type:

1. Material Compatibility

The first factor to consider is the material you will be drilling into. Different drill bits are designed to work with specific materials such as wood, metal, concrete, or tile. Using the wrong drill bit can result in poor performance, damaged materials, or even broken bits. Refer to the manufacturer’s recommendations or consult a professional to ensure you are selecting a drill bit that is compatible with the material you are working with.

2. Drill Bit Size

The size of the hole you need to drill will determine the appropriate drill bit size. Drill bits come in various diameters, ranging from small pilot holes to larger holes for pipe fittings or wiring. It’s essential to choose a drill bit that matches the desired hole size to achieve accurate and clean drilling results.

3. Drill Bit Shape

The shape of the drill bit is another important consideration. Common drill bit shapes include twist bits, spade bits, hole saws, and masonry bits. Each shape is designed for specific drilling tasks. Twist bits are versatile and suitable for general-purpose drilling, while spade bits are ideal for drilling large holes in wood. Hole saws are great for creating larger holes in various materials, and masonry bits are specifically designed for drilling into concrete or brick.

4. Drilling Application

Consider the specific drilling application when choosing a drill bit type. For example, if you are drilling into a hard material like metal or concrete, you may need a carbide-tipped or cobalt drill bit that offers increased durability and heat resistance. If you are drilling into wood, a standard high-speed steel twist bit may be sufficient.

5. Project Budget

Lastly, consider your project budget when selecting a drill bit type. Different drill bits vary in price, with more specialized or premium options often costing more. While it’s important to invest in high-quality bits for durability and performance, you should also consider your budget constraints and choose a drill bit type that offers the best value for your specific project.

By considering these factors and selecting the appropriate drill bit type for your specific needs, you can ensure accurate, efficient, and successful drilling results.

Considering the Shank Type

When choosing a drill bit, one important factor to consider is the shank type. The shank is the part of the bit that is inserted into the drill chuck. There are several different shank types available, each with its own advantages and uses.

1. Round Shank

The round shank is the most common type of shank and is used in most standard drill bits. It is compatible with most drills and offers good stability and grip in the chuck. Round shank drill bits are versatile and can be used for a wide range of applications.

2. Hex Shank

The hex shank, as the name suggests, has a hexagonal shape. This type of shank is commonly used in impact drills and allows for quick and easy bit changes. The six-sided design provides increased grip and reduces the chance of slippage during use.

3. SDS Shank

The SDS shank is a specialized shank type that is used in rotary hammer drills. It features two open grooves on the sides that allow the bit to slide and move in a hammering motion. This shank type is specifically designed for heavy-duty drilling and offers increased drilling speed and efficiency.

4. Morse Taper Shank

The morse taper shank is typically used in larger drill bits and is common in metalworking applications. It features a tapered design that allows for easy insertion and removal of the bit from the drill chuck. The morse taper shank provides a secure grip and helps to prevent the bit from slipping during use.

5. Reduced Shank

The reduced shank, also known as a “black oxide” or “silver and deming” shank, is used when drilling larger holes with a smaller drill. The shank is larger in diameter than the drill bit itself, allowing it to be inserted into a standard drill chuck. Reduced shank drill bits are often used in drilling applications that require the drilling of large holes in metal or wood.

Conclusion

Considering the shank type is important when choosing the right drill bit for your specific application. Each shank type offers its own advantages and uses, so it’s important to choose the one that is best suited for your needs. Whether you’re using a standard drill, impact drill, or rotary hammer drill, there is a shank type that is perfect for the job.

Assessing Drill Bit Coatings

Drill bit coatings play a crucial role in the performance and durability of the tool. They provide protection against wear, corrosion, and excessive heat that can damage the bit and reduce its effectiveness. When choosing a drill bit, it is important to assess the different types of coatings available and understand their benefits and limitations.

Types of Drill Bit Coatings

There are several common types of coatings used in drill bits:

- Titanium Nitride (TiN): TiN coatings are known for their excellent hardness and high resistance to wear. They provide a smooth surface that reduces friction and heat buildup, allowing the bit to last longer.

- Black Oxide: Black oxide coatings provide a protective layer against corrosion and also help to reduce friction. They are commonly used in general-purpose drill bits and are cost-effective.

- Cobalt: Cobalt coatings are ideal for drilling through hard materials like stainless steel and cast iron. They enhance the hardness and heat resistance of the bit, making it durable and efficient.

- Diamond: Diamond coatings are extremely hard and are commonly used in specialized drilling applications. They are ideal for drilling through glass, stone, and other hard materials.

Factors to Consider

When assessing drill bit coatings, consider the following factors:

- Material to be drilled: The type of material you will be drilling will determine the coating that is best suited for the task. Different coatings have different levels of hardness, heat resistance, and durability.

- Drilling speed: If you frequently drill at high speeds, you will need a coating that can withstand the heat generated. Coatings like titanium nitride and cobalt are recommended for high-speed drilling.

- Budget: Some coatings, like diamond, are more expensive than others. Consider your budget and the expected lifespan of the drill bit when choosing a coating.

Conclusion

Assessing drill bit coatings is an important step in choosing the right drill bit for your needs. Consider the type of material to be drilled, the drilling speed, and your budget when making a decision. By choosing the appropriate coating, you can ensure the longevity and effectiveness of your drill bit.

Reviewing Drill Bit Brands and Quality

When it comes to choosing the right drill bit, the brand and quality of the bit are important factors to consider. Different brands offer different levels of performance and durability, so it’s essential to review and compare the various options available in the market.

Top Drill Bit Brands

There are several well-known brands in the drill bit industry that have built a reputation for manufacturing high-quality and reliable products. Some of the top brands to consider include:

- DeWalt: DeWalt is known for producing drill bits that are both durable and efficient. They offer a wide range of bits for different applications and materials.

- Bosch: Bosch is another trusted brand that offers drill bits with excellent performance and long-lasting durability. Their bits are designed to withstand heavy use and deliver precise drilling results.

- Makita: Makita drill bits are known for their superior quality and versatility. They are made from high-quality materials and are suitable for both professional and DIY use.

- Irwin: Irwin drill bits are renowned for their durability and strength. They are designed to handle tough drilling tasks and are ideal for heavy-duty applications.

Factors to Consider for Quality

When reviewing drill bit brands, there are several factors to consider that determine the quality of the bit:

- Material: The type of material used in the drill bit affects its strength and durability. High-speed steel (HSS), cobalt, and carbide are commonly used materials in drill bits.

- Coating: Some drill bits have a coating that enhances their performance and prolongs their lifespan. Titanium nitride (TiN) and black oxide coatings are popular options.

- Design: The design of the drill bit plays a crucial role in its effectiveness. Features like flutes, point angles, and helix angles are designed for specific drilling applications.

- Manufacturing process: The manufacturing process determines the precision and reliability of the drill bit. Look for bits that are made using advanced manufacturing techniques.

Comparison and Recommendations

It is essential to compare the different drill bit brands based on their features, performance, and user reviews. Reading customer feedback and expert recommendations can help you make an informed decision.

Based on extensive research and customer feedback, we recommend considering DeWalt and Bosch as top choices for drill bits. These brands consistently receive high praise for their durable construction, excellent performance, and wide range of options for different drilling needs.

| Brand | Key Features | Customer Rating |

|---|---|---|

| DeWalt | Durable, efficient, wide range of options | 4.5/5 |

| Bosch | High performance, long-lasting durability | 4.3/5 |

| Makita | Superior quality, versatile | 4.1/5 |

| Irwin | Durable, suitable for heavy-duty | 4.0/5 |

Ultimately, the right drill bit brand will depend on your specific needs and budget. Consider the factors mentioned above and choose a brand that offers the best combination of quality, performance, and value for money.

Tips for Proper Drill Bit Maintenance

Regularly Clean and Inspect Drill Bits

- Clean drill bits after each use to remove any debris or excess material that may affect their performance.

- Inspect the drill bits for any signs of wear, damage, or dullness. Replace any bits that are no longer in optimal condition.

Store Drill Bits Properly

- Store drill bits in a clean and dry place to prevent rust and damage.

- Use a drill bit organizer or case to keep the bits organized and protected. This will also make it easier to find the right bit when needed.

Sharpen Drill Bits when Dull

- If a drill bit becomes dull, it’s important to sharpen it for optimal performance.

- Use a drill bit sharpener or a bench grinder to sharpen the cutting edges of the bit.

- Follow the manufacturer’s instructions and take necessary safety precautions when sharpening drill bits.

Use Proper Speed and Pressure

- Always use the recommended speed for the specific type of drill bit and material being drilled.

- Avoid applying excessive pressure while drilling, as this can lead to overheating and damage to the drill bit.

Replace Worn-out Drill Bits

- As drill bits are used over time, they will naturally wear out and become less effective.

- Replace any drill bits that are no longer cutting cleanly or are causing excessive heat or vibrations.

Properly Secure Drill Bits

- Ensure that drill bits are securely tightened in the drill chuck before use.

- Check the drill bits periodically during use to make sure they are still tightly secured.

Protect Drill Bits during Transport

- When transporting drill bits, use a suitable case or container to prevent damage.

- Avoid dropping or mishandling the drill bits, as this can cause them to become dull or damaged.

Follow Manufacturer’s Recommendations

- Always refer to the manufacturer’s recommendations and guidelines for proper drill bit maintenance.

- Follow any specific instructions provided by the manufacturer for cleaning, sharpening, and storing drill bits.

By following these tips and taking proper care of your drill bits, you can ensure that they remain in optimal condition and provide reliable performance for a longer period of time.

FAQ:

What are the different types of drill bits?

The different types of drill bits include twist drill bits, masonry drill bits, spade drill bits, hole saw drill bits, countersink drill bits, and step drill bits.

How do I choose the right drill bit for metal?

To choose the right drill bit for metal, you should consider the type of metal you’re working with (ferrous or non-ferrous), the thickness of the metal, and the size of the hole you need. High-speed steel (HSS) drill bits are generally suitable for drilling into most metals.

What should I consider when choosing a masonry drill bit?

When choosing a masonry drill bit, you should consider the type of masonry material you’re drilling into (concrete, brick, or stone), the size of the hole you need, and the type of drill you’ll be using (hammer drill or rotary drill).

What are some tips for maintaining drill bits?

Some tips for maintaining drill bits include keeping them sharp by regularly sharpening or replacing them, using cutting fluid or lubricant while drilling, and storing them properly in a clean and dry environment.

Video: