Drilling into sheet metal: Tips and Techniques

Drilling into sheet metal can be a challenging task, but with the right tips and techniques, it can be done effectively and safely. Whether you are a DIY enthusiast or a professional, knowing how to drill into sheet metal is a valuable skill to have.

One of the most important things to consider when drilling into sheet metal is the type of drill bit you use. A high-speed steel or cobalt drill bit is recommended for drilling into sheet metal. These drill bits are designed to withstand the demands of drilling through metal and provide a clean and precise hole.

Another important factor to consider is the speed and pressure at which you drill. Too high of a speed can cause the metal to heat up and become damaged, while too much pressure can cause the drill bit to break or create a jagged hole. It is important to find the right balance between speed and pressure for the best results.

Using lubrication or cooling agents can also help to prolong the life of your drill bit and prevent overheating of the metal. Applying a few drops of cutting oil or using a lubricant spray can reduce friction and make the drilling process smoother.

Choosing the Right Drill Bit for Sheet Metal Drilling

When it comes to drilling into sheet metal, using the right drill bit is crucial. The type of drill bit you choose can greatly impact the efficiency and effectiveness of your drilling operation. Here are some tips to help you choose the right drill bit for sheet metal drilling:

1. Consider the Material

The first thing you need to consider when choosing a drill bit for sheet metal drilling is the material of the sheet metal you are working with. Different materials have different hardness levels, and you’ll need a drill bit that is capable of cutting through the specific material you are working with.

2. Choose the Right Size

Another important factor to consider is the size of the hole you need to drill. Make sure to choose a drill bit that is the right size for the hole you want to create. If the drill bit is too small, it may not be able to cut through the metal properly. On the other hand, if the drill bit is too large, it may cause the metal to distort or even break.

3. Look for a High-Speed Steel (HSS) Drill Bit

For general sheet metal drilling, a high-speed steel (HSS) drill bit is a good choice. HSS drill bits are made from a combination of steel and other metals, making them strong and durable. They can handle the high heat generated during drilling and are capable of cutting through most types of sheet metal.

4. Consider Cobalt Drill Bits for Stainless Steel

If you are drilling into stainless steel sheet metal, consider using cobalt drill bits. Cobalt drill bits are made from a blend of cobalt and high-speed steel, making them ideal for drilling through tough materials like stainless steel. They are more resistant to heat and can produce clean holes in stainless steel without damaging the drill bit.

5. Use a Step Drill Bit for Enlarging Holes

If you need to enlarge an existing hole in sheet metal, a step drill bit is a great tool to use. Step drill bits have a cone-shaped design with multiple stepped sizes. They allow you to gradually enlarge the hole without the need for multiple drill bits.

6. Always Use Lubrication

When drilling into sheet metal, it’s important to use lubrication to reduce friction and heat. Lubricants like cutting oil or even regular household oil can help to prolong the life of the drill bit and improve the drilling process.

7. Safety First

Lastly, always prioritize safety when drilling into sheet metal. Wear safety goggles to protect your eyes from metal shavings, and consider wearing work gloves to protect your hands from any sharp edges. Additionally, ensure that the sheet metal is properly secured before drilling to prevent any accidents.

By considering the material, size, and type of drill bit, you can ensure that your sheet metal drilling operation is successful and efficient. Choose the right drill bit, follow safety guidelines, and your drilling project will be completed with ease.

Preparing the Sheet Metal Surface for Drilling

Before drilling into sheet metal, it is important to properly prepare the surface to ensure accuracy and prevent damage to the material. The following tips and techniques will help you prepare the sheet metal surface for drilling:

1. Clean the surface

Start by cleaning the sheet metal surface thoroughly. Remove any dirt, dust, oils, or debris that may be present. Use a degreaser or solvent to effectively clean the surface. This will ensure better adhesion of the drill bit to the metal.

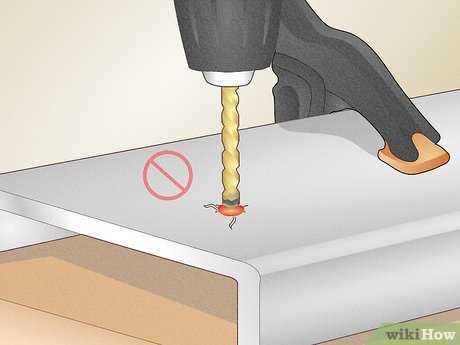

2. Mark the drilling location

Next, mark the location where you want to drill on the sheet metal. Use a center punch or a nail to make a small indentation at the center of the drilling spot. This will help the drill bit to stay in place and prevent it from slipping during drilling.

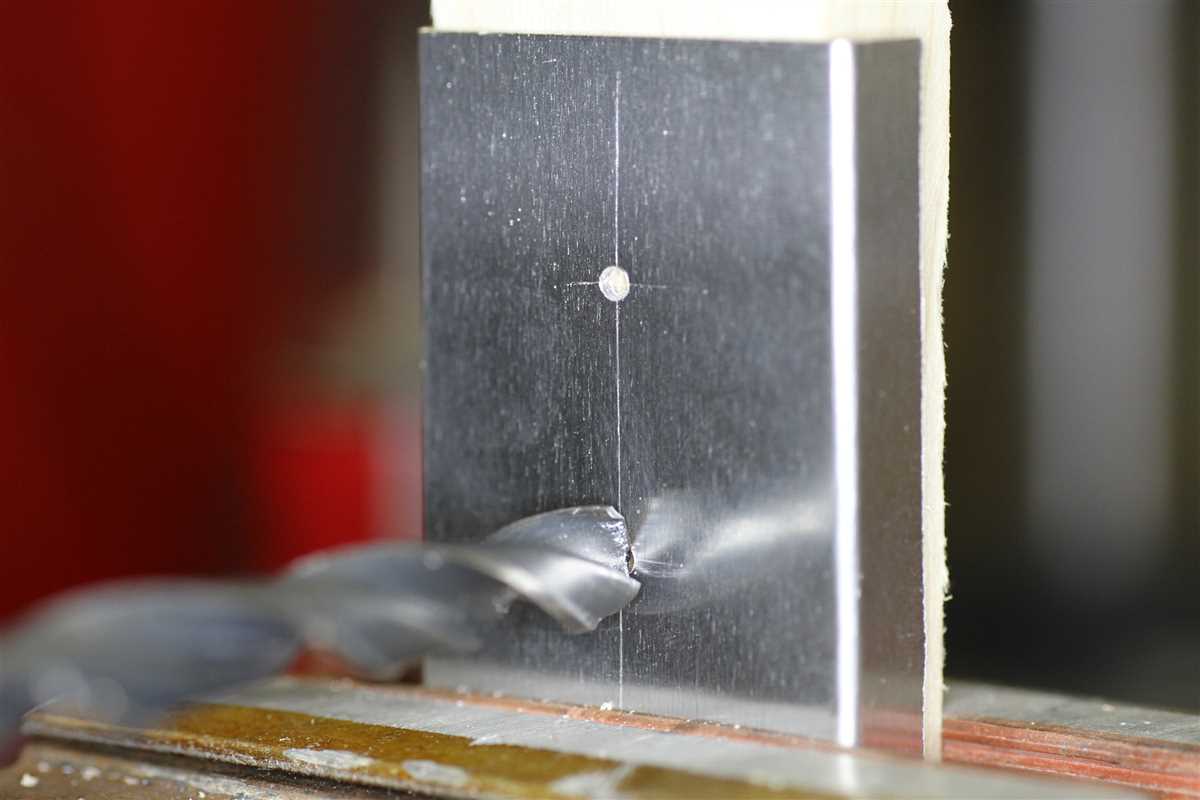

3. Use a pilot hole

If you are drilling a larger hole, it is recommended to start with a pilot hole. A pilot hole is a small hole that serves as a guide for the larger drill bit. It helps to prevent the drill bit from wandering and ensures a more accurate drilling position.

4. Secure the sheet metal

Before drilling, make sure to securely hold the sheet metal in place. You can use clamps or other types of fixtures to prevent the metal from moving or vibrating during drilling. This will help to maintain stability and improve drilling accuracy.

5. Use the correct drill bit

Choose the appropriate drill bit for the type of sheet metal you are working with. Different metals require different types of drill bits. Consult a drilling guide or seek professional advice to ensure you are using the right tool for the job.

6. Apply cutting fluid

When drilling into sheet metal, it is highly recommended to use cutting fluid or lubricant. Apply a small amount of cutting fluid to the drilling area to reduce friction and heat. This will prevent the drill bit from overheating and prolong its lifespan.

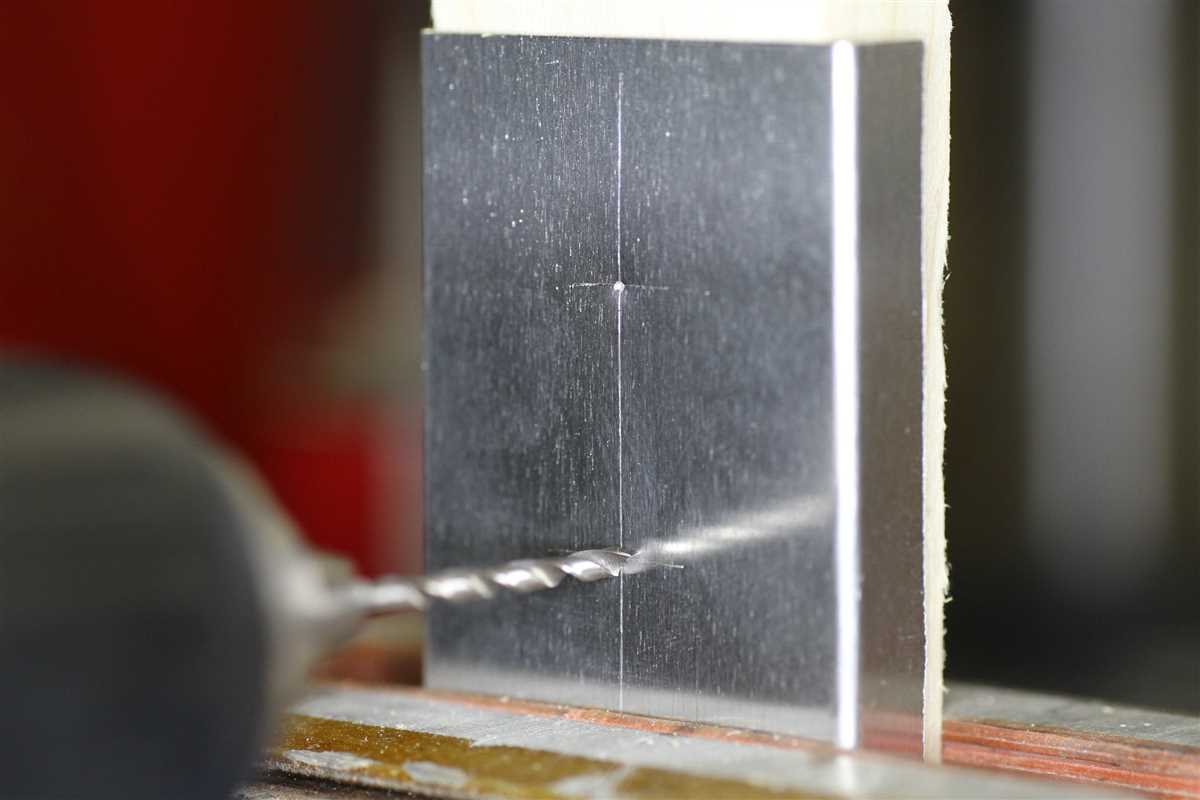

7. Start drilling slowly

Begin drilling at a slow speed to allow the drill bit to penetrate the sheet metal gradually. This will help to prevent the drill bit from skidding or damaging the surface. Increase the drilling speed as you go, but be careful not to apply excessive pressure.

By following these tips and techniques, you can effectively prepare the sheet metal surface for drilling. Remember to work in a well-ventilated area and wear appropriate safety gear to protect yourself from any potential hazards.

Positioning and Clamping the Sheet Metal

Before drilling into sheet metal, it is important to properly position and clamp the metal to ensure accurate and safe drilling. Here are some tips and techniques for positioning and clamping sheet metal:

1. Mark the drilling spots

Start by marking the spots where you want to drill on the sheet metal. Use a permanent marker or a center punch to create a small indentation that will serve as a guide for the drill bit. This will help you drill in the exact spots you want.

2. Use clamps

Clamps are essential for securely holding the sheet metal in place while drilling. Use a variety of clamps, such as C-clamps or quick-release clamps, to hold the metal firmly in place. Position the clamps strategically to provide stability and prevent the metal from shifting or vibrating during drilling.

3. Use scrap wood or backing material

If drilling through thin sheet metal, it is beneficial to place a piece of scrap wood or backing material underneath the metal. This will help prevent the metal from bending or warping as the drill bit goes through it. It also provides support and reduces the risk of the drill bit snagging or damaging the work surface below.

4. Consider using a vise

If you have access to a vise, it can provide an additional level of stability when drilling into sheet metal. Attach the metal securely in the vise, making sure it is firmly held in place. This will minimize any movement or vibrations during drilling.

5. Position the sheet metal at a comfortable height

When drilling into sheet metal, it is important to position the metal at a comfortable height. This will ensure that you have optimal control and visibility while drilling. Adjust your workbench or use a stand to bring the metal to a convenient height, reducing strain on your arms and back.

6. Use proper safety precautions

Always wear appropriate safety gear, such as safety goggles and gloves, when drilling into sheet metal. This will protect your eyes from flying metal chips and your hands from sharp edges. Additionally, make sure to secure loose clothing and tie back long hair to avoid entanglement with the drilling equipment.

By following these tips and techniques, you can position and clamp sheet metal effectively, ensuring accurate and safe drilling. Remember to take your time and work carefully to achieve the desired results.

Applying Proper Speed and Pressure for Drilling

Introduction

Drilling into sheet metal requires the proper combination of speed and pressure to achieve clean and accurate holes. Too much pressure can cause the drill bit to grab onto the metal and potentially break, while too little pressure can result in a slow and inefficient drilling process. This article provides tips and techniques for applying the right speed and pressure when drilling into sheet metal.

Choosing the Right Drill Bit

Before drilling, it is important to select the appropriate drill bit for the type of sheet metal being worked with. Consider the thickness and hardness of the metal, as different metals may require different types of drill bits. Carbide or cobalt drill bits are often recommended for drilling into sheet metal due to their durability and ability to withstand high speeds.

Setting the Drill Speed

When drilling into sheet metal, it is generally recommended to use high speeds. Higher speeds help to prevent the drill bit from grabbing onto the metal and creating burrs or irregular holes. However, it is important to note that excessive speeds can generate excessive heat, which can lead to warping or discoloration of the metal. As a general rule of thumb, start with a higher speed setting and adjust as necessary depending on the specific metal and thickness.

Applying Pressure

Applying the right amount of pressure is crucial when drilling into sheet metal. Too much pressure can cause the drill bit to grab onto the metal and potentially break, while too little pressure can result in a slow and inefficient drilling process. A steady and firm pressure is recommended, allowing the drill bit to cut through the metal without forcing it. Take breaks to clear away metal chips and cool down the drill bit if necessary.

Using Lubrication

Using a lubricant can help reduce friction and heat build-up when drilling into sheet metal. Apply a small amount of cutting fluid or oil onto the drill bit to improve the drilling process and prolong the life of the drill bit. This is especially important when drilling into harder metals or when using high-speed settings.

Conclusion

Applying the proper speed and pressure when drilling into sheet metal is essential for achieving clean and accurate holes. By choosing the right drill bit, setting the appropriate drill speed, applying the correct amount of pressure, and using lubrication when necessary, you can ensure a successful drilling process and avoid damaging the sheet metal. Remember to always prioritize safety and wear protective gear, such as safety goggles and gloves, when drilling into sheet metal.

Using Lubricants and Coolants for Sheet Metal Drilling

Drilling through sheet metal can be a challenging task, especially if the metal is thick or of a harder material. To make the drilling process easier and more efficient, it is recommended to use lubricants and coolants. These fluids help to reduce friction, dissipate heat, and prolong the life of both the drill bit and the sheet metal.

Lubricants

- Cutting Oil: Cutting oils are commonly used lubricants for drilling through sheet metal. They are specifically designed to reduce friction and heat during the drilling process. Cutting oils come in various types, such as mineral-based oils, synthetic oils, and water-based oils. It is important to choose the right cutting oil for the type of sheet metal and drilling operation.

- Vegetable Oil: In some cases, vegetable oil can be used as a lubricant for sheet metal drilling. It is a natural and environmentally friendly option that works well for softer metals.

- WD-40: WD-40 is a multi-purpose penetrating oil that can be used as a lubricant for sheet metal drilling. Its low viscosity allows it to penetrate into tight spaces and reduce friction.

Coolants

- Cutting Fluid: Cutting fluids, also known as coolants, are used to dissipate heat generated during the drilling process. They come in various forms, such as water-based emulsions, synthetics, and semi-synthetics. Cutting fluids not only cool down the drill bit and sheet metal but also flush away chips and debris.

- Air Blasts: Compressed air can be used as a coolant for sheet metal drilling. It helps to blow away chips and keep the drill bit and sheet metal cool. Air blasts are commonly used in combination with other lubricants and coolants.

When using lubricants and coolants for sheet metal drilling, it is important to follow the manufacturer’s recommendations and safety guidelines. Proper application of these fluids will result in improved drilling performance, enhanced tool life, and better quality drilled holes.

Preventing Chip Build-up and Breakage

To prevent chip build-up and breakage when drilling into sheet metal, there are several tips and techniques that can be employed. By following these guidelines, you can ensure a smoother and more efficient drilling process.

1. Choose the Right Drill Bit

Choosing the right drill bit is crucial for preventing chip build-up and breakage. For drilling into sheet metal, it is recommended to use a high-speed steel (HSS) drill bit or a cobalt drill bit. These types of drill bits are designed to handle the high-speed drilling required for sheet metal and have a higher heat resistance.

2. Use Cutting Fluid

Applying cutting fluid to the drill bit and workpiece can help reduce heat buildup and prevent chip build-up. Cutting fluid lubricates the drilling process and keeps the drill bit cool, reducing the risk of breakage. Apply the cutting fluid directly to the drill bit and workpiece before starting the drilling process.

3. Start with a Pilot Hole

When drilling into sheet metal, it is advisable to start with a pilot hole. A pilot hole serves as a guide for the larger drill bit and helps prevent the drill bit from wandering or slipping. It also reduces the chances of chip build-up and breakage by gradually removing material and minimizing the strain on the drill bit.

4. Use Proper Speed and Pressure

To prevent chip build-up and breakage, it is important to use the correct drilling speed and pressure. High speeds and excessive pressure can cause the drill bit to overheat and break. Start with a lower drilling speed and gradually increase it as needed. Apply steady and even pressure to maintain control and prevent chip build-up.

5. Clear Chips Regularly

Clearing chips regularly during the drilling process is essential for preventing chip build-up and breakage. Chip build-up can cause the drill bit to become stuck or break. Use a brush or compressed air to remove chips from the drill bit and workpiece. This will help maintain a clear drilling path and improve drilling efficiency.

6. Use a Backing Material

When drilling through thin sheet metal, it can be beneficial to use a backing material. Place a piece of scrap wood or a block of metal behind the workpiece to provide support and prevent chip breakout on the backside. This can help prevent chip build-up and breakage by reducing vibration and increasing stability during the drilling process.

By incorporating these tips and techniques when drilling into sheet metal, you can prevent chip build-up and breakage, ensuring a successful and efficient drilling process.

Countersinking and Deburring Sheet Metal Holes

When drilling holes in sheet metal, it is important to not only create clean, accurate holes, but also to ensure that the edges of the holes are smooth and free of burrs. Countersinking and deburring are two techniques that can help achieve this.

Countersinking

Countersinking is the process of creating a conical recess around a hole to allow for the flush seating of a screw or fastener. This can help prevent the screw from protruding above the surface of the sheet metal, which can cause interference or damage to other components.

To countersink a hole in sheet metal, follow these steps:

- Drill the hole to the desired size using a regular drill bit.

- Select a countersink bit that matches the angle and diameter of the screw or fastener you will be using.

- Insert the countersink bit into the hole and apply gentle pressure.

- Slowly rotate the countersink bit to create the conical recess around the hole.

- Remove any metal shavings or debris.

Deburring

Deburring is the process of removing any sharp or uneven edges from the holes in sheet metal. This helps to prevent cuts or injuries and improves the overall appearance of the metal.

To deburr a hole in sheet metal, you can use the following methods:

- Hand File: Use a file to gently file away any burrs or rough edges around the hole.

- Deburring Tool: A deburring tool is a specialized tool that can quickly and easily remove burrs from holes in sheet metal.

- Counterbore Tool: A counterbore tool can be used to both countersink and deburr holes in sheet metal.

Regardless of the method you choose, it is important to take your time and work carefully to ensure that the edges of the holes are smooth and free of burrs.

Conclusion

Countersinking and deburring sheet metal holes are essential steps in achieving clean and professional results. By following the techniques outlined above, you can ensure that your holes are not only accurate, but also safe and aesthetically pleasing.

Safety Precautions for Drilling into Sheet Metal

1. Wear Protective Gear

Before you start drilling into sheet metal, make sure to properly equip yourself with the necessary protective gear. This includes safety goggles or a face shield to protect your eyes from flying debris and metal shards. Additionally, wear heavy-duty gloves to protect your hands from sharp edges and a dust mask to avoid inhaling any particles.

2. Prepare the Work Area

Prior to drilling, ensure that the work area is clean and free from any clutter or obstructions. This will help prevent accidents and ensure that you have enough space to operate the drill safely. Remove any loose objects, such as tools or materials, that may interfere with your drilling process.

3. Use Proper Clamping

Sheet metal can be slippery, so it’s important to securely clamp it down before drilling. This will prevent the metal from shifting or moving while you work, reducing the risk of accidents. Choose a suitable clamping method, such as using a vice or clamps, to hold the sheet metal in place.

4. Choose the Right Drill Bit

Selecting the correct drill bit is crucial for drilling into sheet metal. Choose a bit specifically designed for metal drilling to ensure optimal performance and reduce the risk of damage. Avoid using dull or worn-out drill bits, as they can cause the drill to slip and increase the likelihood of accidents.

5. Start with a Pilot Hole

When drilling into sheet metal, it’s often beneficial to start with a pilot hole. This smaller hole helps guide the drill bit and prevents it from wandering off course. Additionally, it reduces the chances of the metal sheet from cracking or deforming, providing more control during the drilling process.

6. Control the Drill Speed

Controlling the speed of your drill is important when drilling into sheet metal. Too high of a speed can cause the drill bit to overheat and potentially damage the metal, while too low of a speed may result in a poor-quality hole. Find the appropriate speed setting for your specific sheet metal and adjust accordingly.

7. Apply Proper Pressure

When drilling, apply consistent and moderate pressure on the drill. Using too much force can cause the drill to slip and potentially injure you. Conversely, applying too little pressure may result in an ineffective drill and slower progress. Maintain a balance and steady pressure throughout the drilling process.

8. Keep the Work Area Clean

Regularly clean the work area while drilling into sheet metal. Clear away any metal shavings or debris to prevent them from causing accidents or interfering with the drilling process. Use a brush or vacuum to remove the debris and maintain a clean and safe workspace.

9. Take Breaks

Drilling into sheet metal can be physically demanding, so it’s essential to take regular breaks. This allows you to rest, maintain focus, and prevent fatigue-related accidents. Avoid rushing through the process and listen to your body’s needs.

10. Seek Professional Help if Needed

If you are uncertain about drilling into sheet metal or are faced with a complex task, it’s best to seek assistance from a professional. They have the experience and knowledge to handle the job safely and efficiently. Don’t hesitate to ask for help when necessary.

FAQ:

What is sheet metal drilling?

Sheet metal drilling is the process of creating holes in thin sheets of metal. It is commonly used in various industries for a wide range of applications.

What are some tips for drilling into sheet metal?

Some tips for drilling into sheet metal include using a center punch to create a starting point, using a drill bit specifically designed for metal, using a slow drilling speed, and using lubrication to reduce friction.

What types of drill bits are recommended for sheet metal drilling?

For sheet metal drilling, it is recommended to use drill bits made from high-speed steel or cobalt. These drill bits are harder and can withstand the high temperatures generated during the drilling process.

What are the advantages of drilling into sheet metal?

Drilling into sheet metal offers several advantages, including the ability to create precise holes of various sizes, the ability to join sheet metal pieces together, and the ability to install hardware or fasteners.

What safety precautions should be taken when drilling into sheet metal?

When drilling into sheet metal, it is important to wear safety goggles to protect the eyes from flying debris. It is also recommended to use clamps or a vise to secure the sheet metal and to keep hands and fingers away from the drill bit during the drilling process.

Video: