Choosing the Right Drill Bit Size for Electrical Wire Installation

Installing electrical wires requires precise measurements and the right tools to ensure a safe and efficient installation. One key tool in this process is the drill bit, which is used to create holes for routing the wires.

When choosing the drill bit size for electrical wire installation, there are several factors to consider. The most important factor is the size of the wire itself. Different wire gauges have different diameters, and the drill bit size needs to match the diameter of the wire.

In general, it is recommended to choose a drill bit size that is slightly larger than the diameter of the wire. This allows for easy passage of the wire through the hole without any risk of damage. The exact size of the drill bit will depend on the specific wire gauge being used.

It is also important to consider the type of material being drilled. Different materials require different drill bit sizes and types. For example, drilling through wood requires a different drill bit size than drilling through metal or concrete.

Tip: It is always a good idea to consult the manufacturer’s instructions or a professional electrician for guidance on choosing the right drill bit size for a specific wire installation.

Thickness of the Wire

The thickness, or gauge, of electrical wire is an important factor to consider when choosing the right drill bit size for installation. Electrical wires come in a range of thicknesses, and the drill bit size should be selected to match the wire’s gauge.

The American Wire Gauge (AWG) system is commonly used to determine the thickness of electrical wire. The AWG system assigns a numerical value to each gauge, with lower numbers indicating thicker wires. For example, a 12-gauge wire is thicker than a 20-gauge wire.

When installing electrical wires, it is important to use the correct drill bit size to accommodate the wire’s thickness. Using a drill bit that is too small can cause damage to the wire and make it difficult to thread through the hole. On the other hand, using a drill bit that is too large can result in a loose fit, which may affect the wire’s stability.

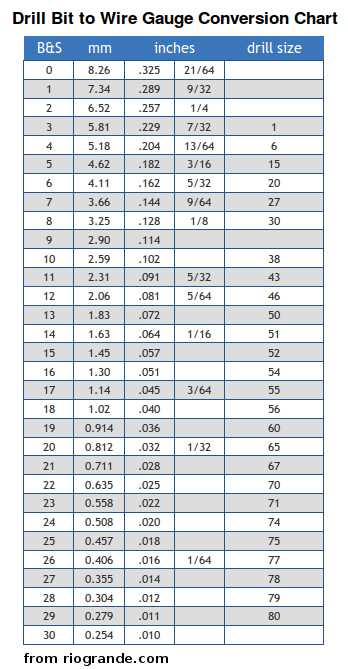

To determine the appropriate drill bit size for a specific wire gauge, it is helpful to consult a drill bit size chart. These charts provide the recommended drill bit sizes for various wire gauges. It is important to note that the drill bit size may vary depending on the type of material being drilled into, so it is always best to double-check with a chart or consult a professional if you are unsure.

| Wire Gauge | Drill Bit Size |

|---|---|

| 12 | 3/16 inch |

| 14 | 5/32 inch |

| 16 | 9/64 inch |

| 18 | 7/64 inch |

As shown in the example table above, a 12-gauge wire typically requires a 3/16 inch drill bit, while a 14-gauge wire would require a 5/32 inch drill bit. It is important to select the appropriate drill bit size to ensure a secure and proper fit for the wire.

By taking into account the thickness of the wire and using the correct drill bit size, you can ensure a successful electrical wire installation that is safe and secure.

Type of Drill Bit Material

When selecting a drill bit for electrical wire installation, it is important to consider the material from which the drill bit is made. Different materials offer varying levels of durability, sharpness, and resistance to wear. Here are some of the most common types of drill bit materials:

- High-Speed Steel (HSS): HSS drill bits are made from a combination of steel and other elements, such as tungsten or vanadium. They are durable, heat-resistant, and suitable for drilling into a variety of materials, including wood, plastic, and metal.

- Cobalt: Cobalt drill bits are made from high-speed steel with a higher percentage of cobalt. They are designed to withstand higher temperatures and are ideal for drilling into hard materials like stainless steel and cast iron.

- Carbide: Carbide drill bits are made from a combination of carbide (a compound of carbon and tungsten) and cobalt. They are extremely hard and can drill into the toughest materials, such as concrete, ceramic, and masonry. However, they are more brittle than other drill bit materials and should be used with care.

- Titanium: Titanium drill bits are made from high-speed steel coated with a layer of titanium nitride. This coating increases the hardness and lubricity of the drill bit, allowing for faster drilling and improved wear resistance. They are suitable for drilling into various materials, including wood, plastic, and metal.

When choosing the right drill bit material for electrical wire installation, consider the type of material you will be drilling into and the level of durability and heat resistance required. It is also important to use the correct size drill bit for the wire you are installing to ensure a clean and secure installation.

Diameter of the Hole

The diameter of the hole is an important factor to consider when choosing the right drill bit size for electrical wire installation. The hole must be large enough to allow the wire to pass through easily, but not so large that it becomes loose or creates a safety hazard.

The diameter of the hole will depend on the size of the wire being installed. In general, the hole should be slightly larger than the diameter of the wire. This allows for easy threading of the wire through the hole while also ensuring a snug fit to prevent any movement or damage to the wire.

When determining the diameter of the hole, it is important to consider the insulation on the wire. The insulation adds thickness to the wire, so the hole should be sized to accommodate both the wire and the insulation. The diameter of the hole should be slightly larger than the total diameter of the wire and its insulation.

It is recommended to refer to a wire gauge chart to determine the appropriate hole size for different wire gauges. The chart will provide the recommended hole size based on the gauge of the wire being used. It is important to always measure the wire thickness accurately and select the corresponding drill bit size accordingly.

Using a drill bit that is too small can make it difficult to thread the wire through the hole, while using a drill bit that is too large can create a loose fit, which can lead to wire damage or potential safety hazards. Therefore, it is crucial to select the right drill bit size to ensure a secure and safe wire installation.

Compatibility with the Electrical Box

When choosing the right drill bit size for electrical wire installation, it is important to consider the compatibility with the electrical box. The electrical box houses the wires and provides protection, so it is crucial to ensure that the drill bit size aligns with the box dimensions.

Firstly, you need to determine the size of the electrical box. Electrical boxes come in various sizes, including standard sizes such as 2×4 inches, 4×4 inches, and 4×6 inches. The size of the electrical box will determine the size of the hole that needs to be drilled to accommodate the wires.

Once you know the size of the electrical box, you can choose the appropriate drill bit size. The drill bit should be slightly larger than the diameter of the wire to allow for easy installation without damaging the wire insulation. It is recommended to use a drill bit that is 1/4 inch larger than the wire diameter.

For example, if you are installing 12-gauge wire, which has a diameter of approximately 0.081 inches, you would need a drill bit that is 1/4 inch larger, such as a 5/16 inch drill bit.

It is important to note that using a drill bit that is too large can result in an oversized hole, which may affect the stability and security of the electrical box. On the other hand, using a drill bit that is too small can make it difficult to insert the wires into the box.

Additionally, when drilling the hole, it is crucial to pay attention to the depth. The hole should be deep enough to accommodate the wires comfortably but not too deep to avoid damaging the internal components of the electrical box.

In conclusion, when choosing the right drill bit size for electrical wire installation, it is essential to consider the compatibility with the electrical box. By selecting a drill bit that aligns with the box dimensions and provides the necessary space for the wires, you can ensure a secure and proper installation.

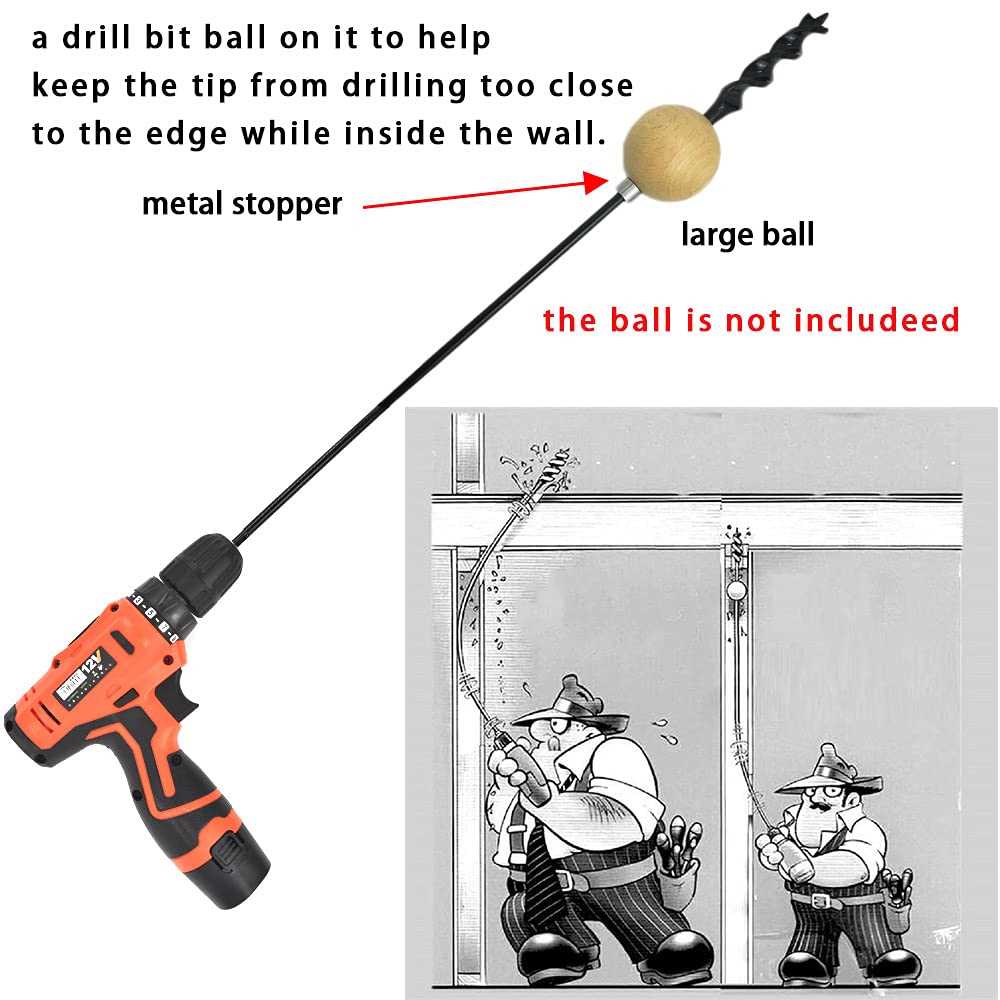

Length of the Drill Bit

When choosing a drill bit for electrical wire installation, it is important to consider the length of the drill bit. The length of the drill bit will determine how deep you can drill into the wall or surface to accommodate the electrical wire.

It is generally recommended to choose a drill bit that is longer than the expected depth of the hole. This ensures that you have enough room to feed the electrical wire through the hole without any difficulty. Furthermore, a longer drill bit can provide better stability and control while drilling.

Before selecting the length of the drill bit, it is important to determine the thickness of the wall or surface you will be drilling into. This will help you choose a drill bit that is long enough to reach the desired depth.

If you are unsure about the thickness of the wall or surface, you can use a stud finder or probe the area with a small nail to get an idea of the depth. Remember to always exercise caution when drilling into walls to avoid damaging any electrical or plumbing lines behind the surface.

Additionally, it is important to consider if you will be drilling horizontally or vertically. If you are drilling horizontally, a longer drill bit may be necessary as the wire will need to travel a longer distance through the wall.

It is also worth noting that some drill bits come with markings or indicators that can help you determine the depth of your hole. These markings can be particularly useful when drilling precise holes for electrical wire installation.

In summary, when choosing the length of the drill bit for electrical wire installation, consider the thickness of the wall or surface, the direction of the hole (horizontal or vertical), and the desired depth. Choosing a drill bit that is longer than the expected depth can provide better stability and control while drilling, and make it easier to feed the electrical wire through the hole.

Type of Electrical Wire Insulation

1. PVC Insulation

PVC (Polyvinyl Chloride) is one of the most commonly used insulation materials for electrical wires. It is durable, flexible, and provides excellent resistance to heat and moisture. PVC insulation is also flame retardant, making it a safe choice for electrical installations.

2. Nylon Insulation

Nylon insulation is often used for high-temperature applications. It has a high melting point and can withstand extreme temperatures. Nylon-insulated wires are also resistant to oil, chemicals, and abrasion.

3. Teflon Insulation

Teflon, also known as PTFE (Polytetrafluoroethylene), is a type of insulation material with excellent electrical insulation properties. It has a high resistance to heat, chemicals, and moisture. Teflon-insulated wires are commonly used in applications where high temperature and chemical resistance are required.

4. Rubber Insulation

Rubber insulation is known for its excellent electrical insulation properties and flexibility. It provides good resistance to heat, oil, and abrasion. Rubber-insulated wires are commonly used in industrial applications.

5. Fiberglass Insulation

Fiberglass insulation is a tough and durable insulation material that can withstand high temperatures. It is resistant to heat, chemicals, and moisture. Fiberglass-insulated wires are commonly used in high-temperature applications.

6. Silicone Insulation

Silicone insulation is a type of insulation material known for its flexibility and high-temperature resistance. It can withstand extreme temperatures and is resistant to moisture and chemicals. Silicone-insulated wires are often used in high-temperature and harsh environment applications.

7. Paper Insulation

Paper insulation is one of the oldest types of insulation materials used for electrical wires. It is made from high-quality cellulose fibers and is highly economical. However, paper-insulated wires are not as durable or moisture-resistant as other types of insulation materials.

8. Enamel Insulation

Enamel insulation is a type of insulation material commonly used for magnet wire and small-gauge wires. It provides excellent electrical insulation, heat resistance, and durability. Enamel-insulated wires are often used in electrical motors and transformers.

9. Polyethylene Insulation

Polyethylene insulation is a type of insulation material with good electrical and thermal insulation properties. It is resistant to chemicals, moisture, and sunlight. Polyethylene-insulated wires are commonly used in outdoor applications.

10. Cross-linked Polyethylene (XLPE) Insulation

Cross-linked polyethylene (XLPE) insulation is a type of insulation material known for its excellent electrical and mechanical properties. It has a higher temperature rating and improved resistance to abrasion, moisture, and chemicals compared to traditional polyethylene insulation. XLPE-insulated wires are commonly used in high-voltage and industrial applications.

Desired Wire Routing

1. Concealed wiring

Concealed wiring is a popular choice for residential and commercial buildings as it hides all the electrical wires behind the walls, ceilings, or floors. This not only provides a neat and clean appearance but also reduces the risk of accidental damage or tripping hazards.

To achieve concealed wiring, the drill bit size should be chosen based on the thickness of the wall, ceiling, or floor. It is important to select a drill bit that is slightly larger than the diameter of the electrical wire to allow easy passage. Make sure to avoid drilling into any existing wiring, pipes, or other utilities to prevent damage.

2. Surface-mounted wiring

Surface-mounted wiring is often used in situations where concealing the wires behind the walls is not possible or practical. This method involves running the electrical wires along the surface of the walls, ceilings, or floors, using conduit or wire moldings to protect and hide the wires.

When using surface-mounted wiring, it is important to choose a drill bit size that can create a hole large enough to accommodate the conduit or wire moldings. The size of the drill bit will vary depending on the size of the conduit or wire moldings being used. Ensure that the drill bit does not damage the underlying structure or any existing wiring.

3. Through-holes

In some cases, it may be necessary to create through-holes to pass electrical wires from one area to another. Through-holes can be used for vertical wire routing or for connecting wires between different floors or walls.

When creating through-holes, the drill bit size should be chosen based on the size of the wires being installed. It is important to choose a drill bit that is slightly larger than the diameter of the wires to allow for easy passage. Take caution to avoid drilling into any existing wiring, pipes, or other utilities.

4. Wire protection

Regardless of the wire routing method chosen, it is important to ensure that the electrical wires are properly protected to prevent damage or accidents. This can be achieved by using conduit, wire moldings, or other protective devices. The size and type of wire protection will depend on the specific installation requirements and local electrical codes.

Before drilling any holes or installing any electrical wires, consult a licensed electrician or refer to local electrical codes to ensure compliance with safety regulations.

Safety Precautions

- Wear protective gear such as gloves, safety glasses, and a dust mask to protect yourself from debris, dust, and particles while drilling.

- Ensure that the power supply is turned off before starting any drilling work to avoid the risk of electric shock.

- Inspect the drill and drill bit for any damage or defects before use. Replace any worn or damaged parts to ensure safe operation.

- Use a drill with a properly functioning safety guard to prevent accidental contact with the drill bit.

- Secure the workpiece firmly using clamps or a vice to minimize movement and prevent accidents.

- Make sure the drill bit is securely locked in place before drilling to avoid any mishaps.

- Take caution when drilling near walls, beams, or any other hidden electrical components to avoid damaging electrical wiring or other infrastructure.

- Work in a well-ventilated area or use appropriate ventilation equipment when drilling to avoid inhaling dust or fumes.

- Keep the work area clean and free from clutter to reduce the risk of accidents or tripping hazards.

- Avoid wearing loose clothing or jewelry that could get caught in the drill, potentially causing injury.

FAQ:

What is the importance of choosing the right drill bit size for electrical wire installation?

Choosing the right drill bit size for electrical wire installation is crucial because it ensures that the hole in the wall or any other surface is the correct size for the wire you are running. Using the wrong size can result in loose or tight connections, which can lead to electrical hazards or damage to the wire insulation during installation.

How do I determine the right drill bit size for electrical wire installation?

To determine the right drill bit size for electrical wire installation, you need to consider the diameter of the wire and the type of anchor or fastener you will be using. The general rule of thumb is to choose a drill bit that is slightly larger than the diameter of the wire to allow for a snug fit without damaging the wire insulation.

What happens if I use a drill bit that is too small for electrical wire installation?

If you use a drill bit that is too small for electrical wire installation, the wire may not fit through the hole properly. This can result in a loose connection, which can be hazardous and may cause electrical malfunctions. Additionally, forcing the wire through a small hole can damage the insulation, leaving the wire exposed and increasing the risk of electrical shock.

What are the risks of using a drill bit that is too large for electrical wire installation?

Using a drill bit that is too large for electrical wire installation can result in a hole that is too big for the wire. This can lead to a loose connection, which can cause electrical hazards and malfunctions. In addition, if the hole is too large, the wire may not be properly secured, increasing the risk of the wire becoming loose or disconnected over time.

Can I use a universal drill bit for all types of electrical wire installations?

While a universal drill bit may be suitable for some general electrical wire installations, it is not recommended for all types. It is best to choose a drill bit size that is specific to the diameter of the wire you are working with to ensure a proper and secure fit. Using a universal drill bit may result in loose connections or damage to the wire insulation during installation.

Are there any standard drill bit sizes for electrical wire installation?

There are no specific standard drill bit sizes for electrical wire installation as it depends on the diameter of the wire you are working with. However, there are commonly used drill bit sizes such as 1/4 inch, 3/8 inch, and 1/2 inch that are often used for running electrical wires. It is important to choose a drill bit that is slightly larger than the diameter of the wire to ensure a proper fit.

Can I use a drill bit size smaller than the diameter of the wire for electrical wire installation?

It is generally not recommended to use a drill bit size smaller than the diameter of the wire for electrical wire installation. Using a smaller drill bit can result in a hole that is too tight for the wire, making it difficult to feed the wire through without damaging the insulation. It is best to choose a drill bit that is slightly larger than the wire diameter to ensure a proper and secure fit.

Video: