Choosing the Right Drill Bit Size for a Number 8 Screw

When it comes to choosing the right drill bit size for a number 8 screw, there are a few important factors to consider. The size of the drill bit will determine the size of the hole you need to drill, which in turn will ensure a secure and tight fit for your screw. Using a drill bit that is too small can result in a loose fit, while using a drill bit that is too large can cause the wood or material to split. To find the perfect drill bit size for your number 8 screw, you need to take into account the type of material you are working with and the specific requirements of your project.

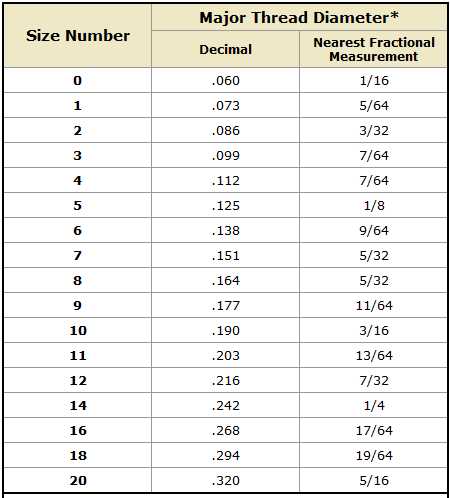

The first step in choosing the right drill bit size is to determine the diameter of your number 8 screw. A number 8 screw typically has a diameter of 0.164 inches or 4.17 millimeters. This information will help you select a drill bit that matches or closely matches the diameter of your screw. It is important to note that drill bit sizes are usually measured in fractions of an inch or in millimeters, so you may need to convert the size of your screw into the appropriate unit of measurement.

Once you know the diameter of your number 8 screw, you can select a drill bit size that is slightly smaller than the screw. This will allow for a snug fit and ensure that the screw holds tightly in place. In general, a drill bit that is 1/64 to 1/32 of an inch smaller than the diameter of the screw is a good choice. For a number 8 screw, a drill bit size between 0.148 to 0.156 inches or 3.76 to 3.96 millimeters would be suitable. However, it is always a good idea to test the drill bit size on a scrap piece of material before drilling into your project to ensure the best fit.

When drilling, it is important to use proper technique and apply steady pressure to avoid damaging the material. Using a drill with variable speed control can also help ensure a clean and precise hole. Remember to always wear safety glasses and work in a well-ventilated area when drilling. By choosing the right drill bit size for your number 8 screw and taking the proper precautions, you can ensure a successful and secure installation for your project.

Understanding the Importance of Drill Bit Size

When it comes to drilling holes, choosing the right drill bit is essential. One of the key factors to consider is the drill bit size. The size of the drill bit you choose will directly impact the size of the hole you create, and ultimately, the success of your project. Understanding the importance of drill bit size is crucial for achieving precise and accurate results.

1. Hole Size

The most obvious impact of drill bit size is the size of the hole it creates. If you use a drill bit that is too small, the hole will be too tight, and the screw or fastener may not fit properly. On the other hand, if the drill bit is too large, the hole may be too loose, which can weaken the structure or cause the screw to wobble.

2. Screw Stability

Another critical factor impacted by drill bit size is the stability of the screw. When a screw is inserted into a hole, it relies on the surrounding material to provide support and prevent it from coming loose. Using the right drill bit size ensures that the hole is the perfect fit for the screw, creating a secure and stable connection.

3. Ease of Drilling

Choosing the correct drill bit size also affects the ease of drilling. Using a smaller drill bit than necessary can make the drilling process more difficult, requiring more effort and potentially damaging the material. Conversely, a larger drill bit may remove excess material too quickly, leading to rough edges or even causing the material to crack.

4. Material Compatibility

Drill bit size selection is also crucial for ensuring compatibility with the material being drilled. Different materials require different drill bit sizes to achieve optimal results. Using the wrong size can result in poor drilling performance, overheating, or even damage to the drill bit.

5. Project Precision

Lastly, drill bit size plays a significant role in achieving project precision. Whether you are working on woodworking, metalworking, or any other DIY project, using the right drill bit size will help you achieve the desired accuracy and precision. It ensures that the holes are the correct size and alignment, allowing for smooth and seamless assembly.

In conclusion, understanding the importance of drill bit size is crucial for successful drilling and achieving precise results. By selecting the right drill bit size, you can ensure proper hole size, screw stability, ease of drilling, material compatibility, and overall project precision.

Drill Bit Size and Screw Compatibility

When it comes to choosing the right drill bit size for a number 8 screw, it is important to consider screw compatibility. Using the correct drill bit size ensures that the screw will fit properly and securely into the material.

Using the wrong drill bit size can lead to a variety of issues, including stripped screws, weak connections, and damage to the material being drilled into. To avoid these issues, it is important to match the drill bit size to the screw size.

Understanding Screw Sizes and Drill Bit Sizes

Screws are typically identified by a number, such as number 8. This number represents the diameter of the screw’s body in inches. Drill bit sizes are also identified by a number, which corresponds to the diameter of the bit in fractions of an inch.

For a number 8 screw, the ideal drill bit size is 11/64 inches. This ensures that the screw will fit snugly into the hole, allowing for a strong and secure connection.

Choosing the Right Drill Bit Size

When selecting a drill bit size for a number 8 screw, it is important to consider the material being drilled into. Different materials may require different drill bit sizes to ensure a proper fit.

- For softwoods, such as pine or cedar, a slightly smaller drill bit size may be used to allow the screw to bite into the material more easily.

- For hardwoods, such as oak or maple, a slightly larger drill bit size may be used to accommodate the density of the material.

- For metal or plastic materials, a drill bit size may need to be selected based on the specific material being used.

Additional Considerations

In addition to selecting the correct drill bit size, there are a few other factors to consider when drilling a hole for a number 8 screw:

- Make sure to use a drill bit that is sharp and in good condition. Dull or damaged drill bits can lead to poor results.

- Use a drill that is set to the appropriate speed for the material being drilled. Using too high of a speed can cause the drill bit to overheat and damage the material.

- Drill a pilot hole before inserting the screw. This helps to ensure that the screw goes in smoothly and prevents the material from splitting.

By taking these considerations into account and selecting the correct drill bit size, you can ensure that your number 8 screw fits securely and provides a strong connection in the material being drilled into.

Factors to Consider when Selecting a Drill Bit Size

Selecting the right drill bit size is crucial for the success of any drilling project. The appropriate drill bit size will ensure that the screw fits securely and the hole is correctly sized for optimal performance. Here are some factors to consider when selecting a drill bit size:

1. Screw Size

One of the most important considerations when choosing a drill bit size is the size of the screw that will be used. Different screw sizes require different drill bit sizes to ensure a proper fit. The drill bit size should match the diameter of the screw, allowing it to pass through the hole with ease.

2. Material Being Drilled

Consider the material you will be drilling into. Different materials require different drill bit sizes to achieve the desired results. For example, drilling into softwood may require a different drill bit size compared to drilling into metal. The hardness and density of the material will affect the drill bit size needed.

3. Hole Depth

The depth of the hole you need to drill is another factor to consider when selecting a drill bit size. If you need to drill a shallow hole, a shorter drill bit may be sufficient. However, if you require a deeper hole, you will need a longer drill bit that can reach the desired depth.

4. Type of Drill Bit

Consider the type of drill bit you will be using. Different types of drill bits have different cutting abilities and may require specific drill bit sizes. For example, a twist drill bit is commonly used for general drilling purposes, while a spade drill bit is ideal for drilling large holes. Make sure to choose a drill bit size that is appropriate for the type of bit you will be using.

5. Pilot Holes

In some cases, you may need to create a pilot hole before drilling the final hole. A pilot hole is a smaller hole that guides the drill bit into the correct position. The size of the pilot hole will depend on the screw size and the material being drilled. Ensure that the drill bit size for the pilot hole is appropriate to avoid any issues during the final drilling.

6. Manufacturer’s Recommendations

When in doubt, always refer to the manufacturer’s recommendations for the drill bit size. The manufacturer’s guidelines will provide specific information on the drill bit size required for their screws or materials. Following these recommendations will help ensure a successful and accurate drilling project.

By considering these factors and taking the necessary measurements, you can confidently select the right drill bit size for your project, ensuring a secure and properly sized hole for your screws. Remember to always wear safety goggles and follow proper drilling techniques to avoid accidents and injuries.

Measuring the Screw Size

Before choosing the right drill bit size for a number 8 screw, it is important to accurately measure the size of the screw. The size of a screw is typically determined by its diameter, length, and thread pitch.

Diameter

The diameter of a screw refers to the thickness of the shaft. To measure the diameter, you can use a caliper or a screw size gauge. Place the screw on a flat surface and align the measuring tool with the widest part of the screw shaft. Take the measurement and note the diameter.

Length

The length of a screw is measured from the tip of the screw to the end of the shaft. A ruler or a tape measure can be used to measure the length of the screw. Place the measuring tool against the tip of the screw and align it with the end of the shaft. Take the measurement and note the length.

Thread Pitch

The thread pitch refers to the distance between two thread peaks on a screw. To measure the thread pitch, you can use a thread pitch gauge or count the number of threads within a one-inch span. The thread pitch is important for determining the compatibility of the screw with the corresponding nut or threaded hole.

Overall Size

After measuring the diameter, length, and thread pitch, you can determine the overall size of the screw. The size is typically indicated by a number, such as a number 8 screw. This number corresponds to a specific range of screw sizes and is used to select the appropriate drill bit size for drilling pilot holes.

By accurately measuring the screw size, you can ensure a proper fit and avoid damaging the screw or the material in which it is being used.

Determining the Proper Drill Bit Diameter

When it comes to choosing the right drill bit for a number 8 screw, one of the most important factors to consider is the diameter of the hole. The diameter of the hole should match the diameter of the screw shaft, allowing the screw to properly grip the material without being too loose or too tight.

Method 1: Using a Screw Gauge

One easy way to determine the proper drill bit diameter is by using a screw gauge. A screw gauge is a small tool that measures the diameter or size of screws and other fasteners. It usually consists of a set of holes with labeled sizes. To determine the proper drill bit diameter using a screw gauge, simply place the screw on the gauge and find the hole that matches the diameter of the screw shaft. The size label on that hole indicates the proper drill bit diameter to use.

Method 2: Using a Drill Bit Size Chart

If you don’t have a screw gauge, you can also determine the proper drill bit diameter by using a drill bit size chart. A drill bit size chart provides a list of drill bit sizes and their corresponding screw sizes. To use a drill bit size chart, find the screw size you are using (in this case, number 8) and look for the corresponding drill bit diameter. The chart will usually have the drill bit diameters listed in both metric and imperial measurements.

Method 3: Matching the Screw Shaft Thickness

If you don’t have a screw gauge or a drill bit size chart, you can still determine the proper drill bit diameter by matching the thickness of the screw shaft. Measure the diameter of the screw shaft using a caliper or a ruler, and select a drill bit with a diameter that matches the thickness. It’s important to note that the diameter of the screw shaft may not always match the official screw size designation, so measuring the shaft directly can be a more accurate method.

Regardless of the method you choose, it’s important to select a drill bit diameter that matches the screw size to ensure a secure and tight fit. Using a drill bit that is too small may result in a loose connection, while using a drill bit that is too large may cause the material to split or the screw to strip.

Matching the Drill Bit Shank Size

Once you have determined the appropriate drill bit size for a number 8 screw, it is important to also consider the shank size of the drill bit. The shank is the straight part of the bit that goes into the drill chuck. Choosing the right shank size is crucial for a successful drilling operation.

Types of Shank Sizes

There are generally two types of shank sizes for drill bits: straight shank and hex shank. Each type has its own advantages and ideal uses.

- Straight Shank: This type of shank is cylindrical in shape and is compatible with most drills. Straight shank bits have a smooth surface and are held in place with the help of a chuck. They are commonly used with drill presses and hand drills.

- Hex Shank: This type of shank has a hexagonal shape and is primarily used with impact drivers and screwdrivers. Hex shank bits are designed to provide a better grip and reduce slipping, making them ideal for fastening screws and driving bolts.

Choosing the Right Shank Size

When choosing the shank size for your drill bit, it is important to consider the type of drill or driver you will be using. Match the shank size of the drill bit to the chuck size of your drill or driver. This will ensure a secure fit and prevent the bit from slipping or wobbling during the drilling process.

If you are uncertain about the chuck size of your drill or driver, consult the user manual or check the specifications provided by the manufacturer. It is always better to be precise when choosing the shank size to ensure optimal performance and safety.

In Summary

Matching the drill bit shank size is just as important as choosing the right bit size for a number 8 screw. Consider the type of shank (straight or hex) and ensure it matches the chuck size of your drill or driver. This will ensure a secure fit and enhance the effectiveness of your drilling operation.

Choosing the Right Drill Bit Material

When it comes to choosing the right drill bit for your project, the material of the drill bit is an important factor to consider. The material of the drill bit can affect its durability, performance, and lifespan. Here are some common materials used for drill bits:

1. High-Speed Steel (HSS)

High-speed steel is one of the most common materials used for drill bits. It is a type of tool steel that contains a high concentration of carbon and other elements to enhance its hardness and heat resistance. HSS drill bits are suitable for drilling into wood, plastic, and soft metals.

2. Cobalt

Cobalt drill bits are made from a mix of cobalt and high-speed steel. The addition of cobalt increases the drill bit’s hardness and heat resistance, making it suitable for drilling through tough materials like stainless steel and cast iron. Cobalt drill bits are also known for their long lifespan.

3. Carbide Tipped

Carbide-tipped drill bits have a carbide tip welded onto the cutting edge of the drill bit. Carbide is an extremely hard material made from a combination of tungsten and carbon. Carbide tipped drill bits are ideal for drilling into hard materials like concrete, masonry, and stone.

4. Titanium

Titanium drill bits have a titanium coating that provides additional hardness and heat resistance. Titanium drill bits are known for their durability and ability to stay sharp for a longer period of time. They are suitable for drilling into wood, plastic, and soft metals.

5. Diamond

Diamond drill bits are the hardest and most durable type of drill bits. They are designed for drilling through hard materials like glass, ceramic, and porcelain. Diamond drill bits are typically used with a drill press or rotary tool to ensure precision and control.

When choosing the right drill bit material, consider the type of material you will be drilling into and the desired outcome of your project. It’s also important to match the drill bit material with the appropriate drilling speed and pressure to achieve the best results.

Using a Drill Bit Size Guide

When it comes to drilling holes for screws, it’s essential to choose the right drill bit size to ensure a secure and tight fit. To determine the appropriate drill bit size, you can rely on a drill bit size guide. This guide provides information on the recommended drill bit size for various screw sizes.

Step 1: Identify the Screw Size

Before using a drill bit size guide, you need to know the size of the screw you will be using. The most common method is to refer to the screw’s gauge number, which indicates its diameter. For example, a number 8 screw has a diameter of 0.164 inches.

Step 2: Consult the Drill Bit Size Guide

Once you have identified the screw size, you can consult a drill bit size guide to find the recommended drill bit size. These guides often come in the form of tables that provide corresponding drill bit sizes for different screw gauges. For a number 8 screw, the recommended drill bit size is usually 11/64 inches or 4.37 mm.

Step 3: Use the Recommended Drill Bit Size

After determining the recommended drill bit size, you can proceed with drilling the hole. Attach the appropriate drill bit to your drill, making sure it matches the recommended size. It’s crucial to use a drill bit that matches the recommended size precisely to achieve the best results.

Tips:

- Double-check the recommended drill bit size to ensure accuracy.

- If you don’t have access to a drill bit size guide, you can find general guidelines online or consult a hardware store for assistance.

- When in doubt, it’s better to choose a slightly smaller drill bit size and gradually widen the hole if needed, rather than using a larger drill bit and risk damaging the screw’s grip.

Tips for a Successful Drilling Experience

1. Choose the right drill bit

Using the correct drill bit is crucial for a successful drilling experience. Consider the material you are drilling into and the size of the hole needed. Different drill bits are designed for specific materials such as wood, metal, or masonry. Additionally, ensure that the drill bit size matches the screw or anchor you plan to use.

2. Use the right drill for the job

There are various types of drills available, including cordless drills, electric drills, and hammer drills. Each drill has its own unique features and capabilities. For general drilling tasks, a cordless drill is often sufficient. However, for more demanding projects or drilling masonry, a hammer drill may be necessary. Choose the right drill for the specific job to ensure better results.

3. Secure your workpiece

Before drilling, make sure your workpiece is securely clamped or held in place. This will prevent it from moving or spinning during drilling, which can lead to inaccurate holes or accidents. Use clamps, vices, or other suitable methods to hold your workpiece firmly in place.

4. Start with a pilot hole

When drilling into wood or other materials, it’s often helpful to start with a pilot hole. A pilot hole is a small initial hole that serves as a guide for the larger drill bit. It helps prevent the wood from splitting or the drill bit from wandering off course. Start with a smaller drill bit, then enlarge the hole with the desired size bit.

5. Use a suitable drilling speed

Drilling at the right speed is essential for achieving clean and accurate holes. Different materials and drill bit sizes require different speeds. Consult the drill bit manufacturer’s guidelines or experiment on scrap material to determine the optimal drilling speed for your specific situation.

6. Apply steady and consistent pressure

While drilling, apply steady and consistent pressure to the drill. You don’t want to force the drill through the material, but you also don’t want to let up on the pressure. Maintain control of the drill and keep it perpendicular to the surface for a straight hole.

7. Use lubrication for metal drilling

When drilling into metal, it’s advisable to use a lubricant to reduce friction and prevent overheating. Apply a small amount of cutting oil or lubricating spray to the drill bit and the area being drilled. This will help improve drilling performance and prolong the life of the drill bit.

8. Clear away debris

During the drilling process, debris and dust can accumulate in the hole and around the drill bit. Clear away the debris regularly to keep the hole clean and prevent clogging. This will improve drilling efficiency and help maintain accuracy.

9. Take breaks when needed

Drilling can be physically demanding, especially for larger or more prolonged projects. Take regular breaks to rest and prevent fatigue. This will not only help you maintain accuracy but also reduce the risk of accidents due to tiredness.

10. Practice safety precautions

Always prioritize safety when drilling. Wear appropriate protective gear such as safety glasses, gloves, and ear protection. Keep your work area tidy and free from clutter. Familiarize yourself with the drill’s safety features and follow the manufacturer’s instructions for safe operation.

By following these tips, you can ensure a successful drilling experience and achieve accurate and clean holes for your projects.

FAQ:

What size drill bit should I use for a number 8 screw?

The recommended drill bit size for a number 8 screw is 11/64 inch.

Can I use a different size drill bit for a number 8 screw?

While it is possible to use a slightly different size drill bit for a number 8 screw, it is recommended to use the recommended size of 11/64 inch to ensure proper fit and avoid splitting the wood.

What happens if I use a drill bit that is too small for a number 8 screw?

If you use a drill bit that is too small for a number 8 screw, it may not provide enough space for the screw to properly grip the wood, resulting in a weak connection and potential for the screw to loosen over time.

What happens if I use a drill bit that is too large for a number 8 screw?

If you use a drill bit that is too large for a number 8 screw, the screw may not have enough material to bite into, resulting in a loose connection that may not hold securely.

Can I use a pilot hole instead of a drill bit for a number 8 screw?

Using a pilot hole is a good practice when installing a number 8 screw. The pilot hole should be slightly smaller in diameter than the screw to ensure proper grip and prevent splitting the wood.

Video: