Choosing the Right Drill Bit for Sheet Metal: A Guide

When it comes to drilling through sheet metal, selecting the right drill bit is essential. Sheet metal is a versatile material that is used in a wide range of applications, from automotive parts to home furnishings. However, it can be a challenge to find a drill bit that is capable of cutting through this material efficiently and effectively. In this guide, we will explore the different types of drill bits that are available and provide some tips on how to choose the right one for your sheet metal projects.

One of the first considerations when selecting a drill bit for sheet metal is the type of metal you will be working with. Different metals have different hardness levels, which can affect the performance of the drill bit. For example, stainless steel is a much harder material than aluminum, so you will need a drill bit that is specifically designed to handle the increased resistance. Similarly, softer metals like copper and brass require drill bits with sharper points to prevent them from getting stuck or causing damage to the material.

Another important factor to consider is the size of the hole you need to drill. Sheet metal comes in various thicknesses, and the size of the hole will dictate the type of drill bit you should use. For smaller holes, a twist drill bit is typically sufficient. These bits have a sharp point and angled flutes that allow for precise cutting. However, for larger holes, a step drill bit or a hole saw may be required. These bits have a series of stepped or circular teeth that gradually enlarge the hole as they cut through the metal.

Lastly, it is important to take into account the type of drill you will be using. Some drills are designed specifically for metalworking applications and offer features such as variable speed control and high torque. These drills are better suited for drilling through sheet metal as they can provide the necessary power and control required for the task. Additionally, using a drill with a metal-cutting lubricant can help to prolong the life of the drill bit and promote smoother cutting.

Choosing the right drill bit for sheet metal can make a significant difference in the final outcome of your project. By considering factors such as the type of metal, the size of the hole, and the type of drill, you can ensure that you have the right tool for the job. Whether you are a DIY enthusiast or a professional metalworker, investing in high-quality drill bits and taking the time to select the right one will result in cleaner, more precise cuts and a more successful project overall.

Sheet Metal: An Overview

Sheet metal refers to metal that has been formed into thin, flat pieces. It is commonly used in the manufacturing industry for a variety of applications due to its durability and versatility. Sheet metal can be made from various types of metals, including steel, aluminum, brass, and copper.

One of the main characteristics of sheet metal is its thickness, which is measured in gauge. The gauge of sheet metal ranges from very thin, such as 30 gauge, to thick, like 16 gauge. Thinner gauges are more flexible and often used for applications where weight and flexibility are important, such as in automotive body panels. Thicker gauges, on the other hand, are stronger and more suitable for applications that require durability, such as construction.

Properties of Sheet Metal

Sheet metal has several properties that make it an ideal material for various applications:

- Strength: Despite its thinness, sheet metal is surprisingly strong and can withstand significant amounts of pressure and force.

- Malleability: Sheet metal can be bent, stretched, and formed into different shapes without breaking or cracking, making it highly malleable.

- Ductility: Sheet metal has high ductility, meaning it can be stretched and deformed without losing its integrity or structural strength.

- Lightweight: Compared to other materials, sheet metal is relatively lightweight, making it easier to transport and handle.

- Corrosion resistance: Certain types of sheet metal, like stainless steel and aluminum, have a natural resistance to corrosion, making them suitable for outdoor applications.

Applications of Sheet Metal

Sheet metal is used in a wide range of industries and applications, including:

- Automotive: Sheet metal is used for making car body panels, chassis components, and structural support.

- Construction: Sheet metal is used for roofing, flashing, gutters, and ductwork in buildings.

- Appliances: Sheet metal is used for manufacturing household appliances like refrigerators, ovens, and washing machines.

- Aerospace: Sheet metal is used for aircraft components, such as wings, fuselages, and engine enclosures.

- Electronics: Sheet metal is used for manufacturing electronic enclosures, cabinets, and chassis for electronic devices.

Conclusion

Sheet metal is a versatile and widely used material in various industries. Its unique properties, such as strength, malleability, ductility, and corrosion resistance, make it an ideal choice for many applications. Whether it’s for automotive, construction, appliances, aerospace, or electronics, sheet metal offers a reliable and cost-effective solution for manufacturing needs.

Importance of Choosing the Right Drill Bit

Choosing the right drill bit is crucial when working with sheet metal. Using the wrong drill bit can result in damage to the material, inefficient drilling, and even safety hazards. Here are a few important reasons why choosing the right drill bit is essential:

- Efficiency: Using the correct drill bit for sheet metal ensures that the drilling process is efficient. The right bit will have a sharp cutting edge that can easily pierce through the metal, reducing the amount of time and effort required.

- Accuracy: Different drill bits are designed for specific tasks, such as creating pilot holes or enlarging existing holes. By using the right drill bit, you can achieve the desired hole size and shape with precision.

- Longevity: Choosing the right drill bit can also prolong the life of your drill. Using the wrong bit can cause excessive wear and tear on the drill’s motor, resulting in reduced performance and the need for frequent repairs or replacements.

- Safety: Using the wrong drill bit can be dangerous. For example, using a wood drill bit on sheet metal can cause the bit to slip, potentially leading to injuries. Selecting the appropriate drill bit for the material you are working with ensures a safer working environment.

With the wide variety of drill bits available for sheet metal, it’s important to understand the specific requirements of your project and choose the right bit accordingly. Consider factors such as the type of metal, the size of the holes needed, and the drilling technique you will be using. By investing in the right drill bit, you can achieve better results and make your drilling tasks easier and more efficient.

Types of Drill Bits for Sheet Metal

When it comes to drilling through sheet metal, using the right drill bit is essential. Here are some of the common types of drill bits that are commonly used for sheet metal:

- Twist Drill Bits: Twist drill bits are the most common type of drill bits used for sheet metal. They have a pointed end and spiral flutes that help to cut through the metal.

- Step Drill Bits: Step drill bits are designed with multiple cutting edges in the form of steps. They are ideal for drilling holes of different sizes in sheet metal.

- Unibit/Conical Bits: Unibit, also known as conical bits, are designed to create perfectly round, smooth holes in sheet metal. They are often used in electrical work and for creating holes for bolts and screws.

- Countersink Bits: Countersink bits are used to create a conical recess in sheet metal for a screw head. They help to ensure that the screw sits flush with the surface of the metal.

- Stepless Drill Bits: Stepless drill bits are specifically designed for drilling thin sheet metal without creating any burrs or distortions. They produce clean and precise holes with smooth edges.

It’s important to choose the right drill bit for the specific sheet metal project you are working on. Consider the thickness of the metal, the size of the hole needed, and the type of material you are drilling into. Taking these factors into account will help ensure that you select the appropriate drill bit for the job and achieve the best results.

Factors to Consider when Choosing a Drill Bit

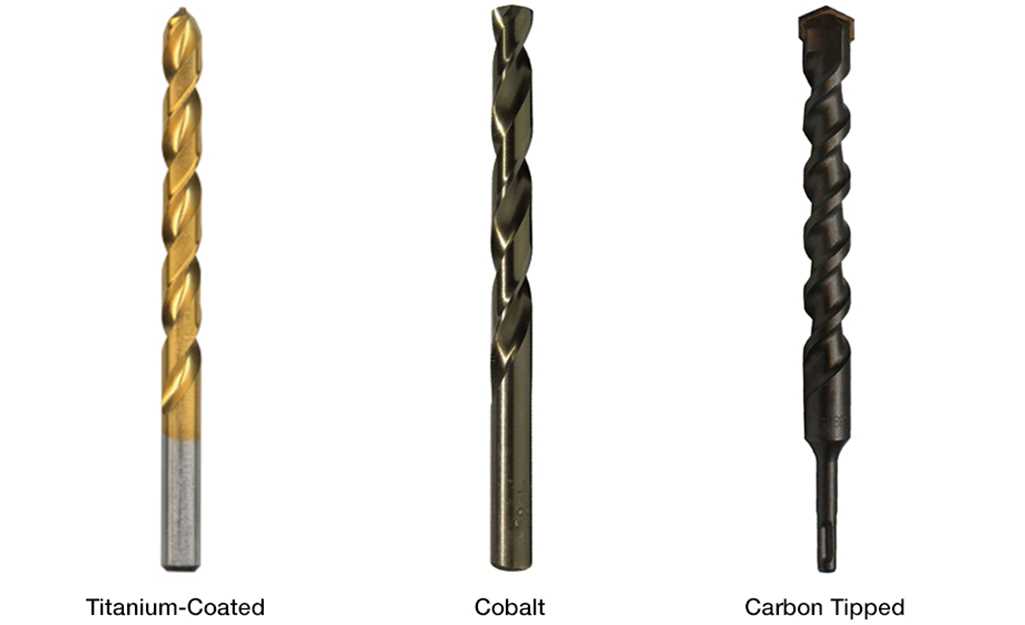

- Material: The material of the drill bit is an important factor to consider. Different materials, such as high-speed steel (HSS) or cobalt, have different levels of hardness and durability, which can affect the speed and efficiency of drilling through sheet metal.

- Diameter: The diameter of the drill bit determines the size of the hole that it will create in the sheet metal. It is important to choose a drill bit with the appropriate diameter for the specific task. If the hole is too small, it can cause unnecessary friction and heat buildup, while a hole that is too large may compromise the integrity of the sheet metal.

- Point Angle: The point angle of the drill bit refers to the angle formed by the cutting edges at the tip of the bit. Different point angles are suitable for different materials and applications. For sheet metal, a drill bit with a point angle of 118 degrees is commonly recommended.

- Coating: Some drill bits come with a coating that can provide additional protection and increase the lifespan of the bit. Titanium nitride (TiN) and black oxide coatings are commonly used in drill bits for sheet metal applications.

- Flute Design: The flute design of the drill bit affects its ability to remove chips and debris from the hole. For sheet metal, a drill bit with a spiral flute design is often preferred, as it helps to clear the chips efficiently and prevent clogging.

- Shank Type: The shank type of the drill bit refers to the part that is inserted into the drill chuck. Common shank types include round, hexagonal, and SDS. It is important to choose a drill bit with a shank type that is compatible with the drill being used.

By considering these factors, you can choose the right drill bit for your sheet metal drilling needs, ensuring efficient and precise results.

Step-by-Step Guide to Choosing the Right Drill Bit

1. Determine the Material of the Sheet Metal

Before choosing a drill bit, it is important to know the type of material you will be drilling through. Common sheet metal materials include aluminum, stainless steel, and mild steel. Different drill bits are designed for different materials, so identifying the material will help narrow down your options.

2. Consider the Thickness of the Sheet Metal

The thickness of the sheet metal will also impact the choice of drill bit. Thicker metals require more powerful and durable drill bits, whereas thinner metals can be drilled with lighter-duty bits. Make sure to check the specifications of the drill bit to ensure it is suitable for the thickness of the sheet metal.

3. Determine the Size of the Hole

Consider the size of the hole you need to drill in the sheet metal. Drill bits come in various sizes, and the size of the hole required will determine the diameter of the drill bit you need. Measure the diameter of the hole or refer to the specifications provided by the project or product requirements.

4. Choose the Right Drill Bit Type

There are several types of drill bits that can be used for sheet metal, including twist drill bits, step drill bits, and spade bits. Twist drill bits are the most common and versatile drill bits that can be used for various materials. Step drill bits are designed for drilling multiple hole sizes with a single bit. Spade bits are used for drilling large holes in wood or plastic and are not suitable for metal. Choose the drill bit type that is appropriate for your specific sheet metal application.

5. Consider the Coating or Material of the Drill Bit

Drill bits can have different coatings or be made from different materials to enhance their durability and performance. Some common coatings include black oxide, titanium nitride (TiN), and cobalt. These coatings can provide improved wear resistance, heat resistance, and lubricity. Choose a drill bit with a coating or material that is appropriate for the type of metal and the drilling conditions you will be working with.

6. Check Compatibility with Your Drill

Ensure that the selected drill bit is compatible with your drill. Check the drill’s chuck size and the shank size of the drill bit to make sure they match. Additionally, consider the drill’s speed settings and choose a drill bit that is suitable for the speed at which you will be drilling the sheet metal.

7. Read Reviews or Seek Expert Advice

If you are unsure about which drill bit to choose, read reviews from other users or seek advice from experts in the field. They may be able to provide recommendations based on their experience and expertise. Additionally, online forums or community groups can be valuable resources for gathering information and getting insights from others who have worked with similar materials and projects.

8. Purchase the Drill Bit

Once you have determined the appropriate type, size, coating, and compatibility of the drill bit, it is time to make the purchase. You can find drill bits at local hardware stores, home improvement centers, or online retailers. Compare prices and consider the quality of the drill bit before making your final decision.

By following these step-by-step guidelines, you can choose the right drill bit for your sheet metal project, ensuring accurate and efficient drilling.

Best Practices for Drilling Sheet Metal

1. Choose the Right Drill Bit

When drilling sheet metal, it’s important to choose the right drill bit for the job. Different types of drill bits are designed for specific materials, so using the correct bit will help you achieve clean and precise holes in the metal sheet.

2. Use a Center Punch

Before drilling, use a center punch to create a small indentation on the sheet metal. This will help guide the drill bit and prevent it from slipping off the surface. It’s best to place the center punch at the exact location where you want to drill the hole.

3. Clamp the Sheet Metal

Sheet metal can be thin and lightweight, making it prone to movement and vibrations during drilling. To prevent this, use clamps to securely hold the sheet metal in place. This will ensure more accurate drilling and avoid any unwanted damage.

4. Start with a Small Pilot Hole

When drilling sheet metal, it’s a good practice to start with a small pilot hole before drilling the final hole size. This will help guide the drill bit and make it easier to create a clean and precise hole. Once the pilot hole is established, you can gradually increase the size with larger drill bits.

5. Use Lubrication

To improve the drilling process and prolong the life of your drill bit, consider using a lubricant or cutting fluid. Applying lubrication to the drill bit while drilling sheet metal helps reduce friction, heat, and prevents the bit from dulling or breaking prematurely.

6. Take Breaks

Drilling sheet metal can generate heat, especially if you’re working with thicker or harder metals. To prevent overheating, it’s important to take breaks during the drilling process. This will give the metal and drill bit time to cool down and prevent any potential damage.

7. Use a Slow Speed Setting

When drilling sheet metal, it’s generally best to use a slow speed setting on your drill. This helps maintain control over the drilling process and reduces the risk of the bit getting stuck or causing damage to the metal. A slow drilling speed also allows for better precision.

8. Wear Safety Gear

When working with sheet metal and drilling, it’s essential to prioritize safety. Wear appropriate safety gear such as safety glasses, gloves, and ear protection. This will help protect you from any flying debris, sharp edges, and noise associated with the drilling process.

9. Practice on Scrap Metal

If you’re new to drilling sheet metal or trying out a different drilling technique, it’s a good idea to practice on a scrap piece of metal first. This allows you to get a feel for the drilling process, test different drill bits and speeds, and gain confidence before working on the actual project.

10. Clean and Deburr the Holes

After drilling the holes in the sheet metal, it’s important to clean and deburr them. Use a deburring tool or a file to remove any sharp edges or burrs around the holes. This will improve the overall appearance and safety of your sheet metal project.

By following these best practices, you can ensure successful drilling of sheet metal with clean, precise, and professional results.

FAQ:

What types of drill bits are suitable for sheet metal?

There are several types of drill bits that are suitable for sheet metal, including twist drill bits, step drill bits, and hole saws.

How do I choose the right size of drill bit for sheet metal?

To choose the right size of drill bit for sheet metal, you should consider the thickness of the metal and the size of the hole you want to drill. It is recommended to use a drill bit that is slightly smaller than the desired hole size.

What is the best way to drill a hole in sheet metal?

The best way to drill a hole in sheet metal is to start with a small pilot hole, and gradually increase the size of the hole using larger drill bits. This helps prevent the metal from cracking or getting distorted.

Can I use regular drill bits for sheet metal?

Regular drill bits can be used for sheet metal, but they are not the most effective option. It is recommended to use drill bits specifically designed for sheet metal, as they have a sharper cutting edge and are more efficient.

Video: