Choosing the Right Drill Bit for 1/4-20 Threaded Inserts

When it comes to installing threaded inserts, choosing the right drill bit is crucial for a successful outcome. Threaded inserts are commonly used in woodworking, metalworking, and other applications where a strong threaded connection is needed. The 1/4-20 threaded insert is one of the most popular types, as it provides a versatile solution for a wide range of projects.

One of the first considerations when choosing a drill bit for 1/4-20 threaded inserts is the size. The 1/4-20 refers to the thread size, with 1/4″ indicating the outer diameter of the insert and 20 indicating the number of threads per inch. The ideal drill bit size for this type of insert is typically slightly smaller than the outer diameter, allowing for a secure and stable fit.

In addition to size, the material of the drill bit is another important factor to consider. For drilling into wood, a standard high-speed steel (HSS) drill bit is often sufficient. However, when drilling into harder materials like metal or plastic, a carbide drill bit is recommended for its superior strength and durability. It’s worth investing in a quality drill bit that will last longer and provide cleaner, more precise holes.

It’s also essential to use the correct drilling technique when working with 1/4-20 threaded inserts. To prevent splitting or cracking, it’s best to use a center punch to mark the center of the hole before drilling. Then, start drilling at a low speed and gradually increase the speed as you go. Apply gentle pressure, letting the drill bit do the work, and use coolant or lubricant to keep the bit cool and reduce friction.

Overall, selecting the right drill bit for 1/4-20 threaded inserts involves considering the size, material, and drilling technique. By taking these factors into account, you can ensure a secure and reliable connection that will stand up to the demands of your project.

Understanding the Basic Concepts

Before choosing the right drill bit for 1/4-20 threaded inserts, it is important to understand some basic concepts related to these inserts and their installation process.

Threaded Inserts

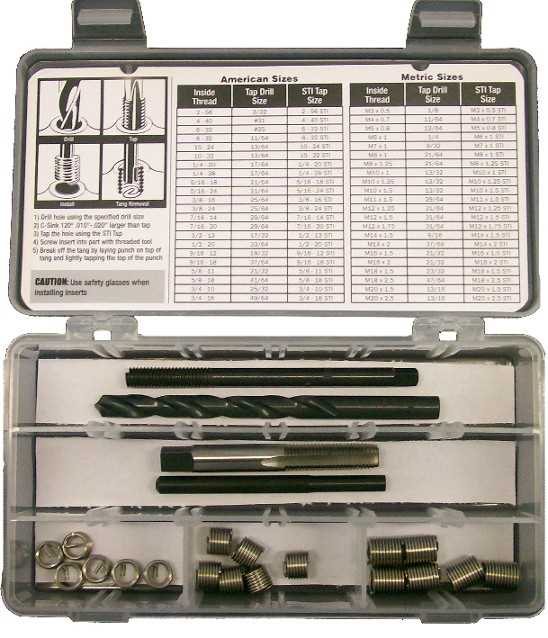

Threaded inserts are small metal fasteners that are designed to provide a strong threaded connection in materials like wood, plastic, or metal. They consist of an outer body with internal threads and are typically installed by being pressed or screwed into a pre-drilled hole.

1/4-20 Threaded Inserts

The term “1/4-20” refers to the size and thread pitch of the threaded insert. In this case, the insert has a 1/4-inch outer diameter and a 20 threads per inch pitch. This specific size is commonly used in woodworking and metalworking applications.

Drill Bit Selection

Choosing the right drill bit for installing 1/4-20 threaded inserts is crucial for achieving a proper fit and preventing any damage to the workpiece. The drill bit should have the same diameter as the outer body of the insert to create a snug fit and allow the threads to engage properly.

It is recommended to use a drill bit specifically designed for drilling holes for threaded inserts. These drill bits typically have a stepped design, with a smaller diameter at the tip to create a pilot hole and a larger diameter further up the bit to accommodate the outer body of the insert.

When selecting a drill bit, consider the material of the workpiece and the type of insert being used. Different materials require different drill bits to ensure clean and accurate holes. Additionally, if the threaded insert has any special features or requirements, such as a flange or specific depth, make sure to choose a drill bit that can accommodate those features.

It is always a good idea to refer to the manufacturer’s guidelines or consult with a knowledgeable professional to ensure the correct drill bit size and type for installing 1/4-20 threaded inserts.

What Are 1/4-20 Threaded Inserts?

Threaded inserts are small metal or plastic pieces designed to provide a threaded hole in a material that doesn’t have its own internal threads. They are commonly used in woodworking, furniture making, and other applications where a strong, secure connection is needed.

1/4-20 threaded inserts are a specific type of threaded insert that have a 1/4 inch diameter and 20 threads per inch. The 1/4-20 thread size is one of the most common thread sizes used for threaded inserts.

These inserts are typically made from materials such as brass, stainless steel, or zinc alloy. They come in various shapes and sizes, but the most common form is a cylindrical shape with an external thread on the outside and a threaded hole on the inside.

1/4-20 threaded inserts are often used to provide a strong threaded connection in materials such as wood, plastic, and composite materials. They can be installed by drilling a hole slightly smaller than the outer diameter of the insert, then using a threaded insert installation tool or a threaded insert driver to screw the insert into place.

Once installed, 1/4-20 threaded inserts allow for the use of bolts or screws with matching threads to securely fasten objects to the material. This makes them a versatile and reliable choice for a wide range of applications.

Why is Choosing the Right Drill Bit Important?

Choosing the right drill bit is crucial when it comes to using threaded inserts, such as 1/4-20 threaded inserts. The drill bit you choose will ultimately determine the size of the hole you create, which can have a significant impact on the overall success and durability of your project.

Accuracy and Precision: Using the right drill bit ensures that you can accurately and precisely create the hole needed for the threaded insert. If the hole is too small, the threaded insert may not fit properly, leading to loose or unstable connections. On the other hand, if the hole is too large, the threaded insert may not be securely held in place, reducing its effectiveness.

Strength and Stability: The drill bit you choose also affects the strength and stability of the threaded insert. A properly sized hole allows the threaded insert to be securely embedded in the material, providing a strong and stable connection. This is especially important when working with materials that may be subjected to heavy loads or vibrations.

Efficiency and Time: Using the right drill bit can also help improve efficiency and save time. A drill bit that matches the size of the threaded insert allows for quick and easy installation. It reduces the need for excessive drilling or modifying the hole, helping you complete your project faster and more efficiently.

Longevity and Durability: By using the correct drill bit, you can enhance the longevity and durability of your project. A properly sized hole, in combination with a well-fitting threaded insert, creates a strong and reliable connection. This increases the overall durability of the project, reducing the risk of damage or failure over time.

Overall, choosing the right drill bit is essential when working with threaded inserts like 1/4-20 inserts. It ensures accuracy, strength, efficiency, and longevity, ultimately leading to a successful and long-lasting project.

Factors to Consider

1. Material of the Workpiece

One of the most important factors to consider when choosing a drill bit for 1/4-20 threaded inserts is the material of the workpiece. Different materials require different types of drill bits to achieve the best results. For example, if you are working with wood, you will need a drill bit specifically designed for wood. On the other hand, if you are working with metal, you will need a drill bit that can handle the hardness of the metal without dulling or breaking.

2. Size of the Threaded Insert

The size of the threaded insert you are using will also play a role in determining the right drill bit to use. The drill bit should be able to create a hole that matches the size of the threaded insert. It is important to measure the diameter of the threaded insert before selecting the drill bit.

3. Depth of the Hole

The depth of the hole you need to drill for the threaded insert is another factor to consider. The drill bit should be able to create a hole that is deep enough to accommodate the entire length of the threaded insert. It is important to measure the length of the threaded insert before selecting the drill bit.

4. Type of Shank

The type of shank on the drill bit is another important consideration. The shank should be compatible with the type of drill you are using. There are different types of shanks, such as hex shanks, round shanks, and SDS shanks. It is important to select a drill bit with a shank that can be securely held by the drill.

5. Drill Bit Material

The material of the drill bit itself is also an important factor to consider. Drill bits are made from various materials, such as high-speed steel (HSS), cobalt, and carbide. The material of the drill bit should be able to withstand the heat and friction generated during drilling. It is important to select a drill bit that is suitable for the type of material you are working with.

6. Point Angle

The point angle of the drill bit refers to the angle at the tip of the bit. Different point angles are suitable for different materials. For example, a point angle of 118 degrees is often used for general-purpose drilling in soft materials, while a point angle of 135 degrees is often used for drilling in harder materials.

7. Speed and Feed Rate

The speed and feed rate at which you operate the drill bit will also affect the performance and life of the drill bit. It is important to follow the manufacturer’s recommendations for the specific drill bit you are using. Using the correct speed and feed rate will help prevent overheating, dulling, or breaking of the drill bit.

8. Other Factors

In addition to the factors mentioned above, there may be other factors to consider depending on the specific application, such as the type of drill press or power drill being used and any special requirements or limitations of the project.

Selecting the Appropriate Drill Bit

Choosing the right drill bit is essential for successfully installing 1/4-20 threaded inserts. The proper drill bit will ensure that the hole is the correct size and shape for the insert and will allow for a secure and durable connection.

Considerations for Selecting a Drill Bit

When selecting a drill bit for installing 1/4-20 threaded inserts, there are several factors to consider:

- Material: The type of material you will be drilling into will determine the type of drill bit you need. For most materials, a high-speed steel (HSS) drill bit will suffice. However, if you are drilling into harder materials such as metal or hardwood, a carbide drill bit may be necessary.

- Size: The drill bit size should match the diameter of the insert you are using. In the case of 1/4-20 threaded inserts, a 1/4″ drill bit is typically used. It is important to use the exact matching size to ensure a proper fit.

- Coating: Some drill bits come with coatings that can enhance their performance. For example, a titanium nitride (TiN) coating can increase the hardness and temperature resistance of the drill bit, making it more durable and longer-lasting.

- Length: The length of the drill bit should be sufficient to drill into the material to the desired depth for the insert. It is important to avoid drill bits that are too short, as they may not be able to reach the required depth.

Drill Bit Selection Guide

Here is a general drill bit selection guide for installing 1/4-20 threaded inserts:

| Material | Drill Bit Type | Drill Bit Size | Coating | Length |

|---|---|---|---|---|

| Metal | High-speed steel (HSS) | 1/4″ | Titanium nitride (TiN) | Equal to or slightly longer than the length of the insert |

| Wood | High-speed steel (HSS) or brad point | 1/4″ | N/A | Equal to or slightly longer than the length of the insert |

| Plastic | High-speed steel (HSS) | 1/4″ | N/A | Equal to or slightly longer than the length of the insert |

It is important to note that these recommendations are general guidelines and may vary depending on the specific application and materials involved. Always refer to the manufacturer’s instructions and guidelines for the inserts you are using.

Size and Material of the Threaded Inserts

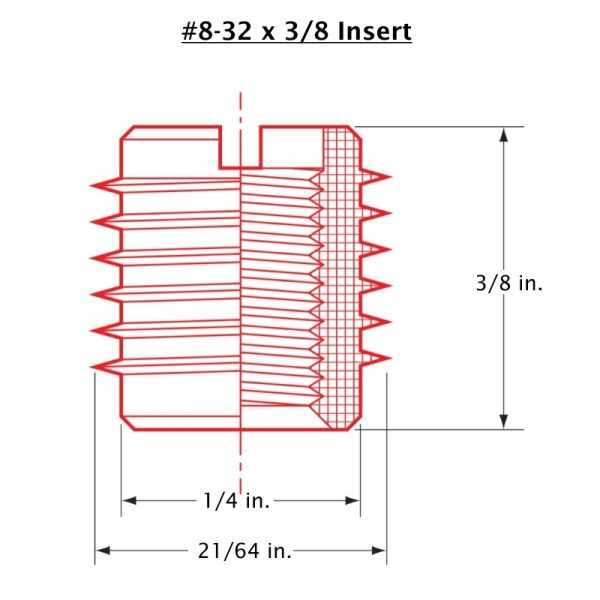

The size and material of the threaded inserts are important factors to consider when choosing the right drill bit. The size of the threaded insert refers to its dimensions, such as the internal and external thread sizes, as well as the length and diameter of the insert itself. The material of the threaded insert refers to the type of material used to make it, which can vary depending on the application and desired strength.

Size of the Threaded Inserts

The size of the threaded inserts is determined by the thread size, which is usually specified in inches or millimeters. The most common thread size for 1/4-20 threaded inserts is 1/4″, referring to the diameter of the external thread. The 20 in 1/4-20 refers to the number of threads per inch.

In addition to the thread size, the length and diameter of the threaded insert should also be considered. The length of the insert should be chosen based on the thickness of the material being drilled into, ensuring that there is enough thread engagement for a secure hold. The diameter of the insert should match the size of the hole being drilled, allowing for a proper fit.

Material of the Threaded Inserts

The material of the threaded insert can vary depending on the application and desired strength. Common materials used for threaded inserts include brass, stainless steel, and zinc alloy. The choice of material should be based on factors such as corrosion resistance, load-bearing capacity, and cost.

Brass threaded inserts are often used in applications where corrosion resistance is required, such as outdoor furniture or marine applications. They are also known for their strength and durability. Stainless steel threaded inserts are ideal for applications that require high strength and resistance to corrosion, such as automotive or aerospace industries. Zinc alloy threaded inserts are a cost-effective option for applications that do not require high strength or corrosion resistance.

It is important to choose the right size and material of the threaded insert to ensure a secure and long-lasting connection. Consider the requirements of your specific application and consult the manufacturer’s guidelines for further guidance on choosing the appropriate size and material for your threaded inserts.

Drill Bit Types

When it comes to choosing the right drill bit for 1/4-20 threaded inserts, there are several options available. Each type of drill bit has its own advantages and limitations, so it’s important to understand the differences between them.

1. Twist Drill Bit

The twist drill bit is the most common type of drill bit and is suitable for most general drilling tasks. It has a cylindrical shape with spiral flutes that help to remove material as the bit rotates. Twist drill bits come in various sizes and can be used on different materials, including metal, wood, and plastic.

2. Step Drill Bit

A step drill bit, also known as a step bit or a unibit, is designed for drilling holes of different sizes. It has a conical shape with multiple steps that allow you to drill holes with different diameters using a single bit. Step drill bits are often used for drilling holes in thin materials, such as sheet metal, but they can also be used on other materials.

3. Brad Point Drill Bit

A brad point drill bit is a specialized type of bit that has a sharp, pointed tip and flat cutting edges. It is commonly used for drilling clean and accurate holes in wood, as the sharp point helps to prevent the bit from wandering. Brad point drill bits are available in various sizes and are ideal for woodworking projects.

4. Countersink Drill Bit

A countersink drill bit is used to create a conical recess at the surface of a material. It is often used in conjunction with 1/4-20 threaded inserts to create a recess for the insert. Countersink drill bits come in different sizes and angles, allowing you to choose the one that best suits your needs.

5. Forstner Drill Bit

A Forstner drill bit is a specialized bit designed for drilling holes with flat bottoms. It has a cylindrical shape with a small point in the center and sharp outer edges. Forstner drill bits are commonly used for woodworking projects that require precise and clean-cut holes.

These are just some of the drill bit types that are available for drilling holes for 1/4-20 threaded inserts. Each type has its own advantages and can be used for different materials and applications. It’s important to choose the right drill bit for your specific needs to ensure accurate and clean holes.

Matching Drill Bit Size to Thread Size

When it comes to choosing the right drill bit for 1/4-20 threaded inserts, it is important to match the drill bit size to the thread size. This ensures that the threaded insert will fit securely and properly in the drilled hole.

The 1/4-20 thread size refers to a 1/4-inch diameter screw with 20 threads per inch. To drill a hole for a 1/4-20 threaded insert, you will need to use a drill bit that matches the outer diameter of the insert. In this case, a 1/4-inch drill bit will be required.

Using a drill bit that is slightly larger or smaller than the insert’s outer diameter can result in a loose or tight fit, respectively. It is important to use the correct size drill bit to ensure a proper fit and avoid any issues with the threaded insert.

Before drilling the hole, it is recommended to mark the desired location on the surface where the threaded insert will be installed. This will serve as a guide for drilling the hole at the correct depth and position.

When drilling the hole, make sure to use a drill bit that is sharp and in good condition. Dull or worn-out drill bits may cause the hole to be uneven or oversized, resulting in a poor fit for the threaded insert.

Once the hole is drilled, it is important to clean out any debris or dust from the hole using a blow gun or a brush. This will ensure that the threaded insert can be inserted smoothly into the hole without any obstructions.

It is also worth noting that different materials may require different drill bit sizes. For example, drilling a hole in wood may require a different size drill bit compared to drilling a hole in metal. It is important to consider the material you are working with and choose the appropriate drill bit size accordingly.

Matching the drill bit size to the thread size is essential when working with 1/4-20 threaded inserts. Taking the time to choose the correct drill bit size will result in a secure and proper fit for the threaded insert, ensuring the success of your project.

Drilling Techniques

When drilling holes for 1/4-20 threaded inserts, it is important to use the correct techniques to ensure proper installation. Here are some drilling techniques to consider:

1. Marking the Hole Location

Before drilling, it is important to mark the exact location where the hole needs to be drilled. This can be done by using a center punch to create a small divot in the material. The divot will serve as a guide for the drill bit.

Tip: Use a measuring tape or ruler to ensure that the hole is marked in the correct location.

2. Selecting the Right Drill Bit

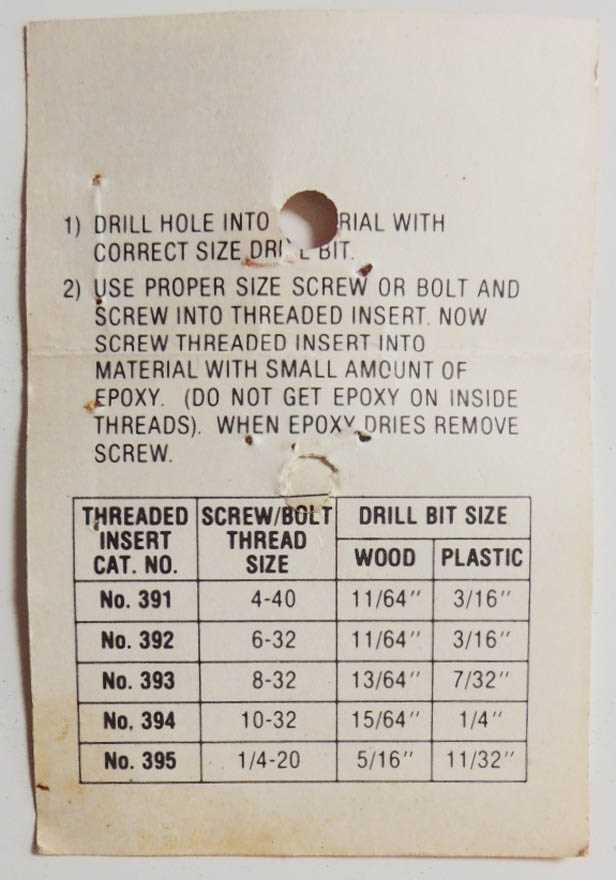

Choosing the right drill bit is crucial for successful installation of threaded inserts. For 1/4-20 threaded inserts, a drill bit with a 13/64″ diameter is typically used. This size allows for the proper fit of the insert.

Tip: It is always a good idea to double-check the specifications of the threaded inserts you are using to ensure that you are using the correct drill bit size.

3. Using Proper Drilling Speed

When drilling holes for threaded inserts, it is important to use the correct drilling speed. Using a high-speed setting on the drill can cause the material to heat up and potentially crack or become damaged. It is recommended to use a medium speed setting and apply consistent pressure while drilling.

Tip: If you notice that the material is getting too hot or the drill bit is becoming dull, take a break and allow the drill bit to cool down before continuing.

4. Maintaining a Proper Drilling Angle

When drilling the hole for the threaded insert, it is important to maintain a proper drilling angle. A slight tilt or angle can cause the hole to be off-center, resulting in difficulty during the installation of the insert. It is recommended to drill the hole perpendicular to the surface of the material.

5. Drilling Depth

Finally, it is important to consider the drilling depth when drilling holes for threaded inserts. The hole should be deep enough to accommodate the entire length of the insert, but not too deep that it goes through the material. Using a depth stop on the drill or marking the drill bit with tape can help ensure the proper drilling depth.

Tip: Test the depth of the hole by inserting the threaded insert and ensuring that it sits flush with the surface of the material.

By following these drilling techniques, you can ensure that your 1/4-20 threaded inserts are installed correctly and securely. Proper drilling techniques are essential for the success of any threaded insert installation project.

Using a Drill Press vs. Handheld Drill

Overview

When it comes to drilling holes for 1/4-20 threaded inserts, you have two main options: using a drill press or a handheld drill. Each of these tools has its advantages and disadvantages, and the choice between them depends on various factors, including the type of material you are working with and the level of precision you require.

Drill Press

A drill press is a stationary tool that typically consists of a base, a column, a spindle, and a drill head. It is designed to provide precision and stability during drilling operations. Here are some key features and benefits of using a drill press:

- Accuracy: The drill press allows for precise and consistent drilling due to its fixed position and controlled drilling speed.

- Stability: The drill press is firmly mounted to a work surface, providing greater stability and reducing the risk of error or accidents.

- Adjustability: Most drill presses have adjustable tables and depth stops, allowing you to set the drilling depth and angle with ease.

- Power: Drill presses are generally more powerful than handheld drills, making them suitable for drilling through tough materials.

Handheld Drill

A handheld drill, also known as a power drill or cordless drill, is a portable tool that can be held by hand during drilling operations. While it may not offer the same level of precision and stability as a drill press, it has its own advantages:

- Portability: Handheld drills are lightweight and easy to carry, allowing you to work in various locations and positions.

- Convenience: With a handheld drill, you are not limited by the size or weight of the material you are drilling, as you can move around freely.

- Versatility: Handheld drills can be used for a wide range of drilling tasks, not just for drilling holes for threaded inserts.

- Cost: Handheld drills are generally more affordable than drill presses, making them a budget-friendly option for occasional use.

Choosing the Right Tool

The choice between a drill press and a handheld drill depends on the specific requirements of your project. If you need precise and consistent drilling in heavy-duty materials, a drill press is the better option. On the other hand, if you value portability and versatility, a handheld drill may be more suitable. It’s worth considering factors such as budget, available space, and frequency of use before making a decision.

| Tool | Accuracy | Stability | Adjustability | Power | Portability | Versatility | Cost |

|---|---|---|---|---|---|---|---|

| Drill Press | High | High | High | High | Low | Low | High |

| Handheld Drill | Medium | Medium | Medium | Medium | High | High | Low |

Ultimately, the choice between a drill press and a handheld drill comes down to your personal preferences and the specific requirements of your project. Both tools have their advantages and can be useful in different situations, so it’s worth considering which one aligns best with your needs.

FAQ:

What is a 1/4-20 threaded insert?

A 1/4-20 threaded insert is a type of fastener that is commonly used to create a strong and reliable threaded connection in materials such as wood, plastic, and metal. The “1/4-20” refers to the size and thread pitch of the insert, with 1/4 inch being the diameter and 20 threads per inch.

Why is it important to choose the right drill bit for 1/4-20 threaded inserts?

Choosing the right drill bit is important because it ensures that the threaded insert fits properly and securely in the material. Using the wrong drill bit can result in a loose or weak connection, causing the insert to pull out or become damaged over time.

What factors should be considered when selecting a drill bit for 1/4-20 threaded inserts?

When selecting a drill bit for 1/4-20 threaded inserts, it is important to consider the type of material being used, the length of the insert, and the specific requirements of the project. For softer materials, a regular twist drill bit may be sufficient, while harder materials may require a carbide tip or stepped drill bit.

What are some common drill bit sizes for 1/4-20 threaded inserts?

Common drill bit sizes for 1/4-20 threaded inserts include 13/64 inch, 7/32 inch, and 15/64 inch. These sizes are recommended for creating pilot holes that allow the insert to be securely installed in the material. It is important to choose a drill bit size that matches the diameter of the threaded insert.

Can any type of drill bit be used for 1/4-20 threaded inserts?

No, not any type of drill bit can be used for 1/4-20 threaded inserts. It is recommended to use a drill bit specifically designed for creating pilot holes for threaded inserts. These drill bits often have a specific angle and shape, allowing for clean and accurate drilling without damaging the material or the insert.

Video: