Understanding the SCFM Rating on an Air Compressor: What You Need to Know

When it comes to choosing an air compressor for your project or workshop, understanding the SCFM rating is essential. SCFM stands for Standard Cubic Feet per Minute, and it is a unit of measurement that indicates the volume of air delivered by the compressor. This rating is crucial because it determines the compressor’s ability to power tools and equipment effectively.

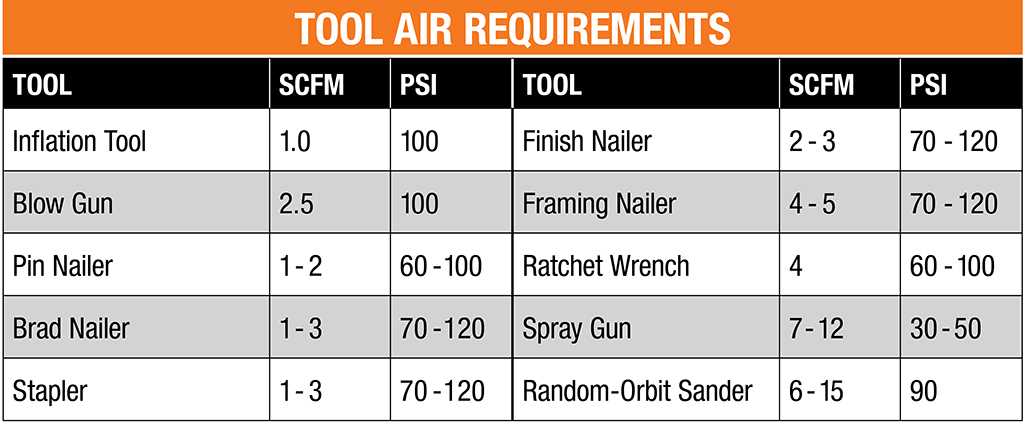

One of the key factors to consider when determining the appropriate SCFM rating is the type of tools you plan to use. Each tool requires a specific amount of air to operate efficiently, and the SCFM rating indicates whether the compressor can meet those requirements.

Another important aspect to consider is the duty cycle of the compressor. The duty cycle refers to the amount of time the compressor can run continuously before needing to cool down. Knowing the duty cycle of the compressor will help you determine if it can deliver a consistent SCFM rating throughout your project or if it may require breaks to cool down.

In addition to the SCFM rating, it’s essential to consider other factors such as tank size, horsepower, and pressure requirements. The tank size determines the amount of stored air available for use, while horsepower indicates the power output of the compressor. Pressure requirements are also crucial as different tools may require different levels of pressure to operate effectively.

Overall, understanding the SCFM rating on an air compressor is vital for selecting the right compressor for your needs. By considering factors such as the type of tools you plan to use, the duty cycle of the compressor, and other specifications, you can make an informed decision and ensure that you have the necessary air power to complete your projects efficiently.

What is an SCFM Rating?

The SCFM rating, which stands for Standard Cubic Feet per Minute, is a measurement that represents the volume of air that an air compressor can deliver at a specific pressure. It is an important specification to consider when choosing an air compressor for various applications, as it determines the compressor’s capability to power tools and equipment.

The SCFM rating takes into account the pressure at which the air is delivered and the temperature at which the measurement is made. This ensures that the air compressor’s performance is standardized and comparable across different conditions. It is typically measured at standard conditions of 14.7 psi (pound per square inch) and 68 degrees Fahrenheit.

When evaluating the SCFM rating of an air compressor, it is crucial to match it with the air requirements of the tools or equipment you plan to use. Different tools and equipment have varying SCFM needs to operate efficiently. It is necessary to ensure that the air compressor can meet or exceed the required SCFM for the desired application.

The SCFM rating can also be affected by factors such as the length and diameter of the air hoses used, as well as any pressure drops or restrictions in the system. It is important to consider the overall efficiency and performance of the entire compressed air system to ensure that the SCFM rating of the air compressor is effectively delivered to the tools or equipment.

Why is the SCFM Rating Important?

The SCFM (Standard Cubic Feet per Minute) rating is an important factor to consider when choosing an air compressor because it indicates the compressor’s ability to deliver a constant volume of air at a specific pressure. This rating helps determine whether the air compressor is suitable for your specific needs.

Matching the Air Compressor’s SCFM Rating to the Air Tools

One of the main reasons the SCFM rating is important is because it helps in matching the air compressor’s capacity to the air tools or equipment you plan to use. Different tools require different amounts of air flow to function properly, and if the air compressor cannot provide the required SCFM, the tools may not work efficiently or at all. Having an understanding of the SCFM rating allows you to properly match the air compressor to the tools and equipment you will be using.

Preventing Performance Issues

Another reason the SCFM rating is important is that it helps prevent performance issues with air tools. If you use an air compressor with a lower SCFM rating than what the tool requires, the tool may not receive sufficient air flow, resulting in reduced performance and potential damage to the tool. By choosing an air compressor with a sufficient SCFM rating, you can ensure that your air tools will operate optimally and efficiently.

Time and Efficiency

The SCFM rating also plays a role in the amount of time it takes to complete a task and the overall efficiency of your work. With a higher SCFM rating, the air compressor can deliver more air at a faster rate, which can speed up the work process and improve overall productivity. On the other hand, using an air compressor with a lower SCFM rating may result in slower work progress and may require more time and effort to complete tasks.

In conclusion, the SCFM rating is an important consideration when choosing an air compressor as it ensures that your tools and equipment receive the necessary air flow for efficient and optimal performance. Matching the SCFM rating of the air compressor to the requirements of your tools and equipment helps prevent performance issues and improves productivity and efficiency in your work.

How is the SCFM Rating Determined?

The SCFM (Standard Cubic Feet per Minute) rating of an air compressor is determined by several factors.

1. Compressor Size: The size of the compressor plays a significant role in determining the SCFM rating. A larger compressor generally has a higher SCFM rating as it can supply a larger volume of air.

2. Motor Power: The power of the motor also affects the SCFM rating. A more powerful motor can compress air at a higher rate, resulting in a higher SCFM rating.

3. Pump Efficiency: The efficiency of the compressor’s pump is another factor that determines the SCFM rating. A more efficient pump can compress air more effectively, resulting in a higher SCFM rating.

4. Tank Size: The size of the air tank plays a role in determining the SCFM rating as well. A larger tank can store more compressed air, allowing for a higher SCFM rating during peak usage.

5. Pressure Rating: The pressure rating of the compressor also affects the SCFM rating. Higher pressure compressors can supply more air in a given amount of time, resulting in a higher SCFM rating.

Manufacturers typically determine the SCFM rating through laboratory testing. They measure the airflow generated by the compressor at various pressures and record the results. These results are then used to calculate the SCFM rating, which is typically mentioned in the product specifications.

Factors that Affect the SCFM Rating

The SCFM (Standard Cubic Feet per Minute) rating of an air compressor is determined by several factors. These factors can have a significant impact on the performance and efficiency of the compressor.

1. Compressor Type: The type of air compressor, such as reciprocating, rotary screw, or centrifugal, can affect the SCFM rating. Each compressor type has its own design and capabilities, which can impact the volume and rate of airflow it can provide.

2. Size of the Compressor: The physical size of the compressor also plays a role in its SCFM rating. Larger compressors generally have a higher SCFM rating, as they have larger tanks and more powerful motors to generate higher airflow.

3. Motor Power: The power of the compressor’s motor directly affects its SCFM rating. A more powerful motor can generate higher airflow, resulting in a higher SCFM rating.

4. Tank Capacity: The size of the air tank on the compressor affects the SCFM rating. A larger tank can store more air, allowing for longer periods of continuous use without a drop in airflow.

5. Operating Pressure: The operating pressure of the compressor also influences its SCFM rating. Higher operating pressures require more airflow to maintain the desired pressure, resulting in a lower SCFM rating.

6. Ambient Temperature: The ambient temperature in which the compressor operates can affect its SCFM rating. High temperatures can cause the compressed air to heat up and decrease in density, resulting in a lower SCFM rating.

7. Air Quality: The quality of the air being compressed can impact the SCFM rating. If the air contains moisture or contaminants, it can affect the compressor’s performance and reduce the SCFM rating.

Understanding these factors is crucial when choosing an air compressor and determining its suitability for specific applications. It’s essential to consider the specific requirements and factors that may affect the SCFM rating to ensure optimal performance and efficiency.

Understanding the Difference between SCFM and CFM

When it comes to air compressors, two common terms that are often used are SCFM and CFM. While they may seem similar, they actually represent different concepts.

CFM stands for Cubic Feet per Minute and is a measurement of the volume of air that can be delivered by an air compressor. It indicates the rate at which the compressor can supply air. CFM is a measurement of the overall capacity of the compressor and is typically used to compare different models or sizes of compressors.

SCFM, on the other hand, stands for Standard Cubic Feet per Minute and takes into account standard conditions, such as temperature, pressure, and relative humidity, to provide a more accurate measurement of the actual air flow. SCFM is used to determine the performance of an air compressor in real-world applications.

It’s important to note that SCFM can be lower than CFM because it accounts for the specific conditions under which the compressor is operating. For example, if you have an air compressor that has a CFM rating of 10, it may have an SCFM rating of 8 under real-world conditions.

Understanding the difference between SCFM and CFM is crucial when selecting an air compressor for a specific application. If you need a compressor that can deliver a certain amount of air at a specific pressure, it’s important to consider the SCFM rating rather than just the CFM rating to ensure that it will meet your needs in real-world conditions.

How to Choose the Right Air Compressor based on SCFM Rating

When selecting an air compressor, it is important to consider the SCFM rating, which stands for Standard Cubic Feet per Minute. The SCFM rating represents the volume of air that the compressor can deliver at a specific pressure level.

Determine your specific needs: Before choosing an air compressor based on its SCFM rating, you should first understand your specific needs. Consider the tools or equipment you will be using with the compressor and their required SCFM rating.

Check the tool’s SCFM requirement: Each tool or equipment typically has a specified SCFM requirement, which indicates the amount of airflow needed for the tool to operate efficiently. Make sure to check the SCFM requirement of the tools you will be using most frequently.

Choose a compressor with a higher SCFM rating: To ensure that your air compressor can meet the demands of your tools and equipment, it is generally recommended to choose a compressor with a slightly higher SCFM rating than the highest SCFM requirement of your tools. This will allow for efficient operation and avoid any potential performance issues.

Consider the intended usage: If you are planning to use the air compressor for heavy-duty or continuous usage, it is recommended to choose a compressor with a higher SCFM rating to accommodate the increased air demands. On the other hand, if you will be using the compressor for light or occasional tasks, a compressor with a lower SCFM rating may be sufficient.

Compare different models: When selecting an air compressor, it is important to compare different models and their SCFM ratings. Look for reputable brands and read customer reviews to ensure that the compressor you choose will meet your requirements and provide reliable performance.

Consider other factors: While the SCFM rating is an important factor to consider, it is also essential to consider other factors such as tank size, horsepower, and noise level when choosing an air compressor. These factors can significantly impact the overall performance and usability of the compressor.

To summarize, choosing the right air compressor based on the SCFM rating involves understanding your specific needs, checking the SCFM requirement of your tools, choosing a compressor with a higher SCFM rating, considering the intended usage, comparing different models, and taking into account other relevant factors. By considering these factors, you can ensure that you select the most suitable air compressor for your needs.

Tips for Maximizing the SCFM Rating of Your Air Compressor

If you want to make the most of your air compressor and maximize its SCFM rating, there are a few key tips to keep in mind:

1. Choose the Right Tools

Using tools that have a low SCFM requirement can help you maximize the performance of your air compressor. When selecting tools, check their SCFM rating to ensure they are compatible with your compressor’s capabilities. Opt for tools with lower SCFM requirements whenever possible.

2. Monitor Your Air Pressure

Regularly checking and adjusting the air pressure in your compressor’s storage tank can help ensure optimal performance. Keep an eye on the pressure gauge and adjust it as needed to maintain the recommended levels. This will help prevent any drops in SCFM due to insufficient pressure.

3. Use the Right Air Hose

The type and size of the air hose you use can have a significant impact on the SCFM rating of your compressor. Opt for a larger diameter hose with minimal restrictions to allow for maximum airflow. This will help minimize pressure drop and maximize the SCFM output.

4. Properly Maintain Your Compressor

Regular maintenance and cleaning of your air compressor can go a long way in maximizing its SCFM rating. Clean or replace air filters as recommended, check for any leaks or damages, and lubricate moving parts regularly. A well-maintained compressor will operate more efficiently and deliver its maximum SCFM output.

5. Adjust the Run Time

Running your air compressor continuously for extended periods can lead to a decrease in its SCFM rating. To maximize performance, consider adjusting the run time to allow for occasional cool-down periods. This will help maintain consistent airflow and prevent overheating, ultimately maximizing the SCFM rating.

Overall, by following these tips and being mindful of your air compressor’s SCFM rating, you can ensure optimal performance and make the most of your investment.

FAQ:

What does SCFM stand for?

SCFM stands for Standard Cubic Feet per Minute.

Why is the SCFM rating important?

The SCFM rating is important because it indicates the air flow capacity of an air compressor, allowing you to determine if it can meet your specific needs.

How is the SCFM rating determined?

The SCFM rating is determined through standardized testing procedures that measure the amount of air an air compressor can deliver at a specific pressure.

What factors can affect the SCFM rating?

Factors that can affect the SCFM rating include the pressure setting of the air compressor and the temperature and humidity of the air being compressed.

Can I use an air compressor with a lower SCFM rating than required?

You can use an air compressor with a lower SCFM rating, but it may not be able to provide enough air flow for your intended applications, resulting in reduced performance.

What is the relationship between SCFM and PSI?

SCFM and PSI are two different measurements. SCFM measures the air flow rate, while PSI measures the pressure at which the air is delivered. However, the SCFM rating of an air compressor is often determined at a specific PSI setting.

How can I determine the SCFM requirement for my specific application?

To determine the SCFM requirement for your specific application, you will need to consider factors such as the air tools or equipment you will be using and their specific SCFM requirements. It is recommended to consult the manufacturer’s specifications or seek professional advice if you are unsure.

Video: