Understanding the Functioning of Rotary Screw Air Compressors

Rotary screw air compressors are a type of positive displacement compressor commonly used in various industrial applications. They play a crucial role in providing compressed air for power tools, manufacturing processes, and even medical equipment. Understanding how these compressors function can help in optimizing their performance and ensuring their reliable operation.

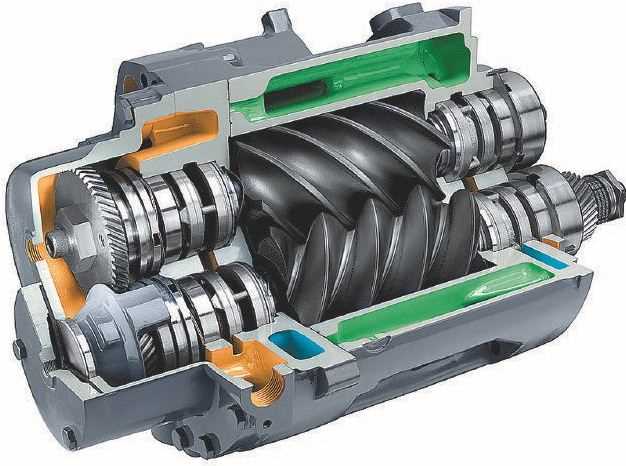

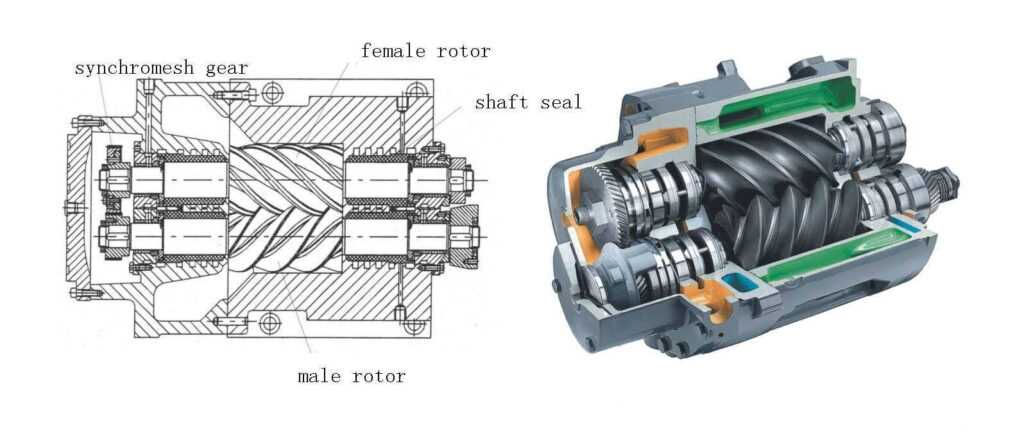

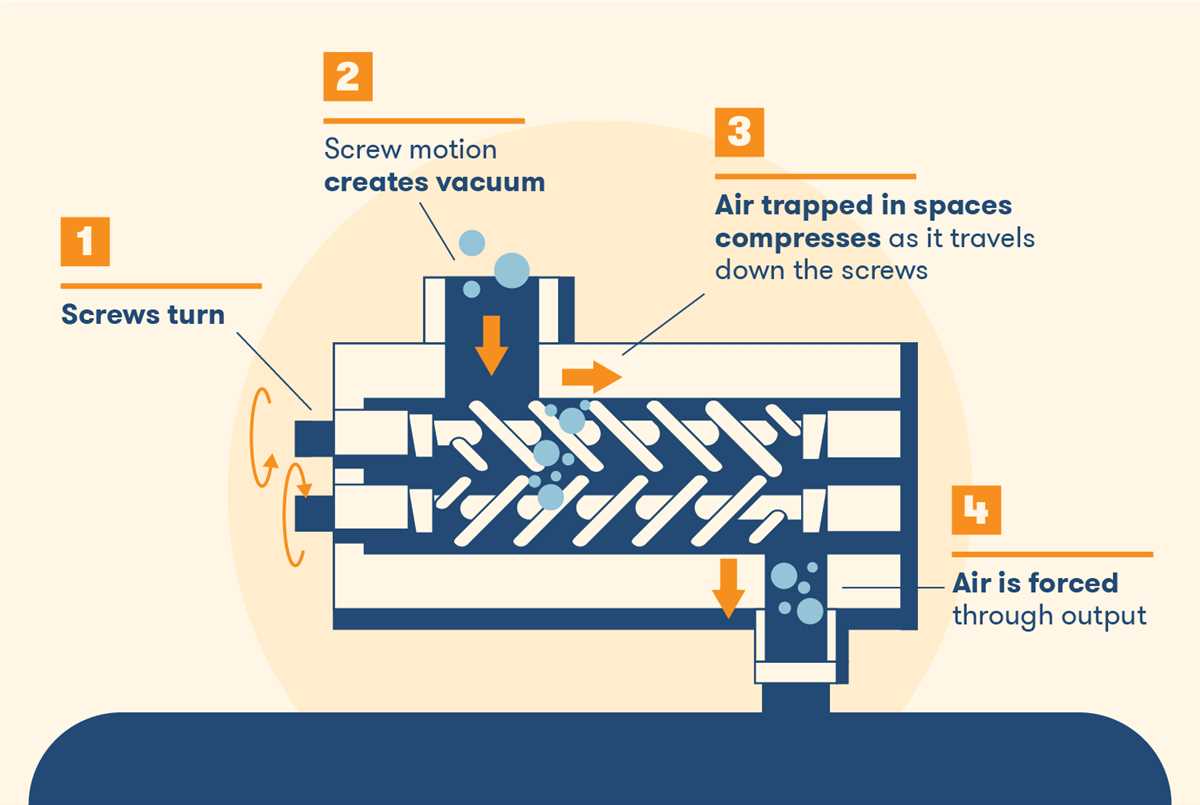

At the heart of a rotary screw air compressor is a pair of interlocking screws, known as rotors. These rotors rotate within a housing, and as they turn, air is drawn into the compressor through the inlet valve. The rotors compress the air by reducing the volume between the screws, resulting in an increase in pressure. The compressed air is then discharged through the outlet valve, ready for use in various applications.

One key advantage of rotary screw air compressors is their ability to deliver a continuous and steady supply of compressed air. Unlike reciprocating compressors that produce pulses of compressed air, screw compressors provide a smooth flow, making them suitable for applications that require a constant air supply. The design of the intermeshing rotors ensures a consistent compression process, minimizing pressure fluctuations and allowing for precise control of airflow.

Another noteworthy feature of rotary screw air compressors is their energy efficiency. The screw compressor design eliminates the need for excessive energy consumption during the compression process. The interlocking rotors create tight, leak-free seals that prevent air from escaping, maximizing the compressor’s efficiency. Additionally, screw compressors often incorporate advanced control systems that optimize power usage, further reducing energy consumption and operating costs.

Understanding Rotary Screw Air Compressors

Rotary screw air compressors are a type of air compressor that uses two rotors to compress air. These compressors are commonly used in industrial and commercial applications where a continuous supply of compressed air is required. The design of rotary screw compressors allows for efficient and reliable operation, making them widely used in various industries.

How do rotary screw air compressors work?

Rotary screw air compressors operate by trapping air between two rotating rotors. As the rotors rotate, the air is compressed and pushed out of the compressor. This process is continuous, ensuring a constant supply of compressed air. The rotors are designed with helical lobes that mesh together, creating a seal that prevents air from escaping. This efficient design allows for high compression ratios and minimal energy loss.

Advantages of rotary screw air compressors

There are several advantages to using rotary screw air compressors. First, they provide a continuous supply of compressed air, making them ideal for applications that require a constant air flow. Second, rotary screw compressors are energy efficient, as they can achieve high compression ratios with minimal energy loss. Third, these compressors are designed for quiet operation, reducing noise levels in the working environment. Additionally, rotary screw compressors are known for their reliability and long service life, making them a cost-effective choice for many industries.

- Continuous supply of compressed air

- Energy efficient

- Quiet operation

- Reliable and long service life

Applications of rotary screw air compressors

Rotary screw air compressors are used in a wide range of applications. They are commonly found in manufacturing plants, where they power various tools and machinery. They are also used in automotive and aerospace industries for powering pneumatic systems. In addition, rotary screw compressors are used in HVAC systems to provide compressed air for air conditioning and refrigeration. Their versatility and reliability make them a popular choice for many industries.

Working Principles of Rotary Screw Air Compressors

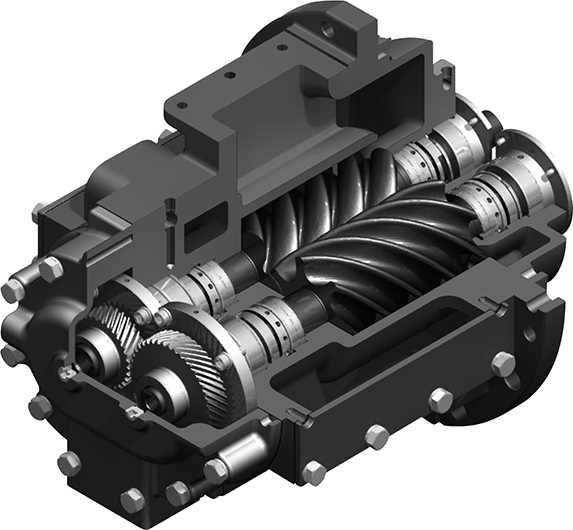

Gearing Mechanism

Rotary screw air compressors work on the principle of a gearing mechanism, where two rotors, typically shaped like screws, are meshed together. One rotor is the driving rotor, which is connected to a motor, and the other rotor is the driven rotor. As the driving rotor rotates, it transfers rotational energy to the driven rotor, causing it to rotate in the opposite direction.

Compression Process

The compression process in rotary screw air compressors involves the intake of atmospheric air through an inlet valve. This air is then trapped between the rotors and the compressor housing, forming compression chambers. As the rotors continue to rotate, the volume between the rotors and the compressor housing decreases, causing the air to be compressed.

It is important to note that the compression process in rotary screw air compressors is continuous, which means that they do not have intermittent compression cycles like reciprocating compressors.

Oil Injection

In order to ensure efficient operation and reduce wear on the rotors, rotary screw air compressors often incorporate an oil injection system. This system injects a controlled amount of oil into the compression chamber, which helps lubricate and cool the rotors. The oil also acts as a sealant, preventing air leakage between the rotors and the compressor housing.

The oil injection system is typically separate from the compression chamber, with an oil separator or filtration system used to separate the oil from the compressed air before it leaves the compressor.

Discharge of Compressed Air

Once the air is compressed to the desired pressure, it is discharged through an outlet valve and delivered to the required application or storage tank. Rotary screw air compressors can deliver a continuous flow of compressed air at a high volume, making them suitable for various industrial applications.

The pressure level of the discharged air can be adjusted using a pressure regulator, which allows for precise control of the compressed air output.

In summary, rotary screw air compressors operate on the principle of a gearing mechanism, with two rotors meshing together to compress the air. The compression process is continuous, and an oil injection system is often used to lubricate and cool the rotors. The compressed air is then discharged through an outlet valve for use in various applications.

Main Components of Rotary Screw Air Compressors

Rotary screw air compressors are powerful machines that are widely used in industrial applications. They work by compressing air and delivering it at high pressures to power various tools and equipment. These compressors consist of several key components that work together to ensure their efficient operation.

1. Air Intake

The air intake is the first component of a rotary screw air compressor. It is responsible for drawing in ambient air, which is then compressed by the compressor. The air intake is equipped with filters to remove impurities and dirt particles from the air, ensuring that only clean and filtered air enters the compressor.

2. Compressor Elements

The compressor elements are the heart of a rotary screw air compressor. These elements consist of two screws – a male rotor and a female rotor – that rotate in opposite directions. As the rotors rotate, air is trapped between them and compressed. The design of the screws allows for high efficiency and continuous compressed air flow.

3. Oil Seals

Oil seals are crucial components that prevent air leakage in a rotary screw air compressor. They are located at various points along the compressor housing, ensuring a tight seal between the rotating and stationary parts. The oil seals also help to maintain proper lubrication of the screws and bearings, reducing friction and extending the life of the compressor.

4. Oil Separator

Rotary screw air compressors use oil for lubrication and cooling purposes. The oil separator is responsible for separating the compressed air from the oil and returning the oil to the compressor for recirculation. This component ensures that only clean and dry compressed air is delivered to the tools or equipment.

5. Air Receiver Tank

The air receiver tank is an essential component that stores the compressed air before it is distributed to the tools or equipment. It acts as a buffer, allowing for a steady supply of compressed air even during peak demand. The air receiver tank also helps to reduce pressure fluctuations and allows for more efficient operation of the compressor.

In conclusion, the main components of rotary screw air compressors include the air intake, compressor elements, oil seals, oil separator, and air receiver tank. These components work together to ensure the efficient and reliable operation of the compressor, providing a steady supply of compressed air for industrial applications.

Advantages of Using Rotary Screw Air Compressors

1. Energy Efficiency:

Rotary screw air compressors are known for their high energy efficiency. Unlike reciprocating air compressors, which operate in a start-stop mode, rotary screw compressors operate continuously, allowing them to maintain a consistent airflow while minimizing energy consumption. This makes them more cost-effective and environmentally friendly.

2. High Output Capacity:

Rotary screw air compressors have a higher output capacity compared to other types of compressors. The screw mechanism allows for a larger volume of air to be compressed, resulting in a higher flow rate and greater output. This makes them ideal for industrial applications that require a constant supply of compressed air.

3. Quiet Operation:

One of the key advantages of rotary screw air compressors is their quiet operation. The screw mechanism ensures smooth and vibration-free operation, resulting in minimal noise. This makes them suitable for use in noise-sensitive environments, such as offices or hospitals, where noise pollution needs to be minimized.

4. Low Maintenance:

Rotary screw air compressors have a simple design and fewer moving parts compared to other compressors. This translates to lower maintenance requirements and less downtime. The absence of valves, pistons, and cylinders reduces the likelihood of mechanical failures and the need for frequent repairs.

5. Versatility:

Rotary screw air compressors are versatile and can be used for a wide range of applications. They can provide a steady supply of compressed air for tasks such as pneumatic tools, HVAC systems, manufacturing processes, and more. Their flexibility makes them suitable for various industries and settings.

In conclusion, rotary screw air compressors offer several advantages over other compressor types. Their energy efficiency, high output capacity, quiet operation, low maintenance requirements, and versatility make them a popular choice for many industrial applications. Whether you need a constant supply of compressed air for production lines or require a reliable air source for your HVAC system, a rotary screw air compressor can meet your needs effectively.

Applications of Rotary Screw Air Compressors

1. Industrial Applications

Rotary screw air compressors are widely used in various industrial applications. They are commonly used in manufacturing plants, where they provide a reliable and continuous supply of compressed air for powering pneumatic tools and equipment. The high efficiency and durability of rotary screw air compressors make them ideal for use in heavy-duty industrial settings.

2. Construction and Mining

Rotary screw air compressors are essential in the construction and mining industries. They are used to power jackhammers, rock drills, and other pneumatic tools that are commonly used in these fields. The portability of rotary screw air compressors makes them a preferred choice for construction and mining applications.

3. Food and Beverage Industry

In the food and beverage industry, rotary screw air compressors are used in a wide range of applications. They are used for pneumatic conveying of food ingredients, powering air-operated pumps and mixers, and in the packaging and labeling process. Moreover, the oil-free options of rotary screw air compressors make them suitable for use in food and beverage production, where air quality is critical.

4. Medical and Pharmaceutical

Rotary screw air compressors are also used in medical and pharmaceutical applications. They are used to provide clean, dry, and oil-free compressed air for various medical devices and equipment, such as ventilators, dental chairs, and laboratory instruments. The precise control and high efficiency of rotary screw air compressors make them suitable for use in these sensitive environments.

5. Automotive Industry

In the automotive industry, rotary screw air compressors are used for a variety of applications. They are used for providing compressed air for pneumatic tools and equipment in automotive manufacturing plants. They are also used for tire inflation in service stations and in automotive repair shops for powering pneumatic tools.

In conclusion, rotary screw air compressors have a wide range of applications in various industries. They are used for powering pneumatic tools, providing compressed air for manufacturing processes, and ensuring the reliability of critical equipment in industries such as construction, food and beverage, medical, and automotive. The versatility, efficiency, and durability of rotary screw air compressors make them an essential component in many industrial settings.

Factors to Consider When Choosing a Rotary Screw Air Compressor

When it comes to choosing a rotary screw air compressor, there are several important factors to consider. These factors will help ensure that you select the right compressor for your specific needs and applications.

1. Air Volume and Pressure Requirements

One of the first things to consider is the air volume and pressure requirements of your operations. You need to determine the amount of air flow (CFM) and the pressure (PSI) needed to power your tools or equipment. This information will help you choose a compressor with the appropriate capacity.

2. Power Source

Another important factor to consider is the power source available. Rotary screw air compressors can be powered by electricity or gasoline engines. You need to evaluate your power source options and choose a compressor that is compatible with your available power supply.

3. Duty Cycle

The duty cycle refers to the amount of time the compressor can operate before it needs to rest. It is crucial to choose a compressor with a duty cycle that aligns with your specific needs. Industries with continuous air demand require compressors with high-duty cycles, while intermittent usage may require a lower duty cycle.

4. Noise Level

Consider the noise level of the compressor, especially if it will be used in a noise-sensitive environment. Rotary screw compressors tend to be quieter than reciprocating compressors, but it’s still important to choose a model with a noise level that is acceptable for your workplace.

5. Maintenance Requirements

It is important to consider the maintenance requirements of the compressor you choose. Some models require regular oil changes and filter replacements, while others may have more complex maintenance procedures. Evaluate the maintenance needs and costs associated with each compressor before making a decision.

6. Price and Warranty

Price is always a consideration when purchasing equipment. Compare the prices of different rotary screw air compressors and consider the value they offer for your specific needs. Additionally, consider the warranty provided by the manufacturer to ensure you have adequate protection in case of any issues.

By considering these factors, you can make an informed decision when choosing a rotary screw air compressor that will meet your needs, provide reliable performance, and offer long-term value.

Maintenance and Troubleshooting of Rotary Screw Air Compressors

Regular maintenance

Regular maintenance is crucial for the efficient and reliable operation of rotary screw air compressors. It is recommended to follow a schedule for routine maintenance tasks, such as changing oil filters, checking and adjusting belt tension, and inspecting for any signs of leaks or damage.

One important maintenance task is checking and cleaning the air intake filter. A clogged filter can restrict airflow and decrease compressor performance. It should be cleaned or replaced regularly to ensure proper operation.

Oil level and quality should also be checked regularly. Low oil levels can cause excessive wear and damage to the compressor, while dirty or contaminated oil can lead to decreased efficiency and increased operating temperatures.

Troubleshooting common issues

When troubleshooting rotary screw air compressors, it is important to be aware of common issues that can affect their performance. One common issue is inadequate pressure output. This can be caused by a variety of factors, such as a worn-out compressor air end, a malfunctioning pressure regulator, or a leak in the system.

Another common issue is excessive noise or vibrations. This can be a sign of misaligned or worn-out belts, loose mounting bolts, or a failing compressor motor.

Leakage is also a common problem with rotary screw air compressors. It is important to inspect the system for any air or oil leaks regularly, as they can lead to decreased efficiency and increased operational costs.

If troubleshooting efforts do not resolve the issue, it is recommended to contact a professional technician with experience in rotary screw air compressors for further diagnosis and repair.

Preventive maintenance

In addition to regular maintenance tasks, preventive maintenance can help prevent unexpected breakdowns and extend the lifespan of rotary screw air compressors. This can include tasks such as inspecting and tightening all electrical connections, checking and adjusting drive belt tension, and lubricating moving parts as recommended by the manufacturer.

It is also important to keep the compressor room clean and free from debris, as dust and dirt can clog filters and reduce the efficiency of the system.

By following a regular maintenance and preventive maintenance schedule, operators can ensure the optimal performance and longevity of their rotary screw air compressors.

FAQ:

What is a rotary screw air compressor?

A rotary screw air compressor is a type of air compressor that uses two interlocking helical rotors to compress air. The rotors rotate in opposite directions, trapping air between them and reducing its volume.

How does a rotary screw air compressor work?

A rotary screw air compressor works by using two interlocking helical rotors to compress air. As the rotors rotate, they draw air into the chamber between them. As the air moves along the length of the rotors, it becomes compressed. The compressed air is then forced out of the compressor and into a storage tank or directly into a pneumatic system.

What are the advantages of rotary screw air compressors?

Rotary screw air compressors have several advantages over other types of air compressors. They are generally more efficient and provide a continuous supply of compressed air. They also have a longer lifespan and require less maintenance. Additionally, rotary screw air compressors are quieter and produce less vibration compared to reciprocating air compressors.

How do I choose the right rotary screw air compressor for my needs?

When choosing a rotary screw air compressor, consider factors such as the required air pressure and flow rate, the duty cycle (continuous or intermittent use), the power source (electric or diesel), and the size and portability of the compressor. It is also important to consider the specific applications and requirements of your business or project.

Video: