The Main Purpose of the Air Compressor

An air compressor is a versatile tool that is used in various industries and applications. Its main purpose is to convert power, usually from an electric motor or a diesel engine, into potential energy stored in pressurized air. This pressurized air can then be used to power a wide range of pneumatic tools and equipment.

One of the main uses of an air compressor is in manufacturing and construction. It is commonly used in factories and construction sites to power tools such as impact wrenches, nail guns, and paint sprayers. By using compressed air, these tools can perform tasks more efficiently and with greater precision.

Another important application of air compressors is in the automotive industry. Compressed air is used to power pneumatic tools for tasks such as tire inflation, engine cleaning, and brake repairs. It is also used in air suspension systems to control the height and firmness of the vehicle’s suspension.

In addition to industrial and automotive applications, air compressors are also used in household tasks and hobbies. They can be used to inflate tires, clean dust from difficult-to-reach areas, and operate hobbyist tools such as airbrushes and sanders. Overall, the main purpose of an air compressor is to provide a reliable source of compressed air for a wide range of tasks and applications.

The Versatility of Air Compressors

Air compressors are an extremely versatile tool that can be found in a wide range of industries and applications. From construction sites to manufacturing plants, the use of air compressors has become essential in many processes.

Industrial applications:

Air compressors are commonly used in industrial settings for a variety of purposes. They can power pneumatic tools such as drills, grinders, and impact wrenches, making them vital for construction projects and automotive repairs. Air compressors can also be used in manufacturing processes to operate machinery and control systems.

Home and DIY applications:

Air compressors are not only limited to industrial use, but they also have numerous applications in households and DIY projects. They are commonly used for tasks such as inflating tires, blowing debris or dust, and painting. With the right attachments, air compressors can power nail guns, staplers, and sanders, making them a versatile tool for homeowners and DIY enthusiasts.

Medical and dental applications:

Air compressors are essential in medical and dental settings. They can power dental drills, suction machines, and air-driven tools used in surgical procedures. Medical air compressors also play a crucial role in supplying clean and compressed air for respiratory support systems and anesthesia machines.

Commercial use:

Air compressors are widely used in commercial applications, such as the food and beverage industry. They can be used to power pneumatic systems that control production lines, packaging, and filling machines. Air compressors also play a vital role in refrigeration systems, providing compressed air for cooling and controlling temperature.

Other applications:

The versatility of air compressors extends to various other applications. They can be used in spray painting, sandblasting, and cleaning tasks. In the agricultural industry, air compressors are used for tasks such as operating pneumatic seeders, inflating tractor tires, and powering livestock equipment.

In conclusion, air compressors have a wide range of applications and are used in various industries. From industrial settings to household tasks, air compressors provide the necessary power for a multitude of tasks, making them an incredibly versatile tool.

The Mechanism Behind Air Compressors and Their Importance

Introduction

An air compressor is a mechanical device that converts power, usually from an electric motor or a diesel engine, into potential energy stored in compressed air. This compressed air can then be used in various applications and industries, making air compressors an essential tool in many settings.

The Working Principle

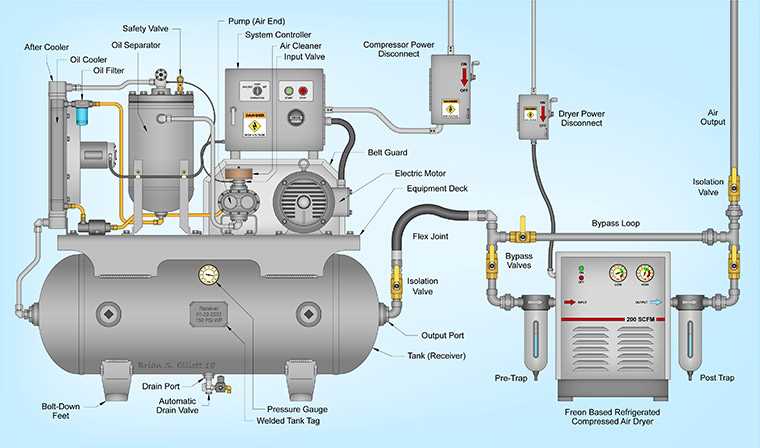

The basic principle of an air compressor involves the use of a piston or a rotating impeller to compress and pressurize the air. In a reciprocating air compressor, the piston moves back and forth within a cylinder, drawing in and compressing the air. On the other hand, a rotary-screw compressor uses two interlocking helical screws to compress the air as it is passed through the rotating mechanism.

The compressed air is stored in a tank, commonly known as an air receiver, which acts as a reservoir. This allows for continuous and stable airflow when the air is released for use. The air compressor is equipped with various components such as valves, pressure switches, and gauges to regulate the pressure and ensure safe operation.

The Importance of Air Compressors

Air compressors have wide-ranging applications across various industries, including construction, manufacturing, automotive, and electronics. They are used to power pneumatic tools like pneumatic drills, grinders, and impact wrenches, making them essential for construction and mechanical work. Air compressors also play a crucial role in spray painting, sandblasting, and cleaning operations, providing a steady stream of compressed air.

Furthermore, air compressors are commonly used in refrigeration and HVAC systems, where they help in cooling and maintaining the desired temperature. They are also vital in medical settings, powering respiratory devices like ventilators and anesthesia machines. In addition, air compressors find applications in power generation, with large-scale air compressors being used in gas turbine power plants.

In conclusion, air compressors are mechanical devices that compress and store air for various industrial applications. They operate on the principle of converting power into potential energy stored in compressed air. With their ability to power pneumatic tools, assist in cooling systems, and support critical medical devices, air compressors play a crucial role in numerous industries and are an essential tool in any industrial setup.

Applications in Construction and Industrial Sectors

Powering Tools and Equipment

Air compressors are widely used in the construction and industrial sectors to power various tools and equipment. These compressors provide a reliable and efficient source of compressed air that can be used to operate pneumatic tools such as nail guns, jackhammers, and impact wrenches. The compressed air generated by the air compressor allows these tools to achieve high levels of power and precision, making them essential for construction and industrial tasks.

Painting and Sandblasting

In construction and industrial sectors, air compressors are also used for painting and sandblasting applications. The compressed air can be used to power paint sprayers, allowing for faster and more efficient paint application on large surfaces such as walls, floors, and vehicles. Additionally, air compressors are used in sandblasting operations to propel abrasive materials at high speeds for cleaning, paint removal, and surface preparation.

Pneumatic Systems

Air compressors play a crucial role in powering pneumatic systems in construction and industrial settings. These systems use compressed air to operate various components, such as valves, cylinders, and actuators. Pneumatic systems are commonly found in manufacturing plants, assembly lines, and construction sites, where they are used to control machinery, move heavy loads, and perform repetitive tasks efficiently.

Material Conveying

In construction and industrial sectors, air compressors are utilized for material conveying applications. Compressed air can be used to transport materials such as cement, sand, and aggregate through pipelines, making it easier and faster to move these heavy materials on construction sites. This saves time and labor compared to manual handling, making air compressors an essential tool for material conveying tasks.

Industrial Cleaning

Air compressors are also commonly used for industrial cleaning purposes. The compressed air can be used to blow away dust, debris, and other contaminants from surfaces, machinery, and equipment. It is an efficient and effective method for cleaning hard-to-reach areas and maintaining the cleanliness of industrial facilities. Air compressors with specialized attachments such as air guns and air blowers are often used for this purpose.

In conclusion, air compressors have various applications in the construction and industrial sectors. They are used to power tools and equipment, facilitate painting and sandblasting, operate pneumatic systems, convey materials, and perform industrial cleaning tasks. The versatility and efficiency of air compressors make them indispensable in these sectors, improving productivity and enabling the completion of tasks more effectively.

Efficiency in Automotive and Manufacturing Industries

Increased Productivity

An air compressor plays a crucial role in enhancing efficiency in automotive and manufacturing industries. Its ability to provide a continuous supply of compressed air enables various tools and equipment to operate smoothly and without interruption. This results in increased productivity as workers can complete tasks more quickly and effectively.

Streamlined Operations

The use of air compressors allows for the automation of many manufacturing processes in the automotive industry. Compressed air powers pneumatic systems that operate machinery, control valves, and perform assembly line tasks. This automation streamlines operations, reducing the need for manual labor and minimizing the risk of human error. As a result, the production process becomes more efficient and reliable.

Energy Savings

Air compressors are designed to be energy-efficient, offering cost savings for both automotive and manufacturing industries. They convert electrical power into kinetic energy stored in compressed air, which can then be used to power various tools and equipment. Since compressed air can be stored, excess energy can be saved for later use. This energy-saving feature helps reduce electricity consumption and lowers operating costs in the long run.

Improved Product Quality

Compressed air is widely used in automotive and manufacturing industries to ensure high product quality. For example, air compressors power paint sprayers used in automotive painting, resulting in a smooth and even finish. Compressed air is also essential for cleaning and removing debris from parts, ensuring that they meet the required specifications. These quality control measures enhance the overall efficiency of the production process by minimizing defects and reworks.

Versatility and Flexibility

Air compressors are highly versatile and can be used for a wide range of applications in automotive and manufacturing industries. They can power tools such as impact wrenches, pneumatic drills, and sanders, making them essential for various tasks, including assembly, fabrication, and maintenance. The flexibility of air compressors allows for easy integration into existing setups, providing businesses with the ability to adapt and expand their operations as needed.

In conclusion, air compressors are indispensable tools for enhancing efficiency in automotive and manufacturing industries. They enable increased productivity, streamlined operations, energy savings, improved product quality, and offer versatility and flexibility in various applications. Utilizing air compressors in these industries not only improves overall efficiency but also contributes to cost savings and higher-quality products.

The Versatility and Benefits of Portable Air Compressors

Portable air compressors are versatile tools that can be used in a variety of applications. Whether you need to inflate tires, power your pneumatic tools, or even clean surfaces, a portable air compressor can get the job done efficiently and conveniently.

One of the key benefits of portable air compressors is their convenient size and mobility. These compact machines are designed to be easily transported from one location to another, making them ideal for both professional and personal use. Whether you’re working in the garage, on a construction site, or even in your own backyard, a portable air compressor can be easily moved around to reach your desired workspace.

Another advantage of portable air compressors is their ability to provide a continuous supply of pressurized air. This is particularly useful when using pneumatic tools, as it ensures consistent power and performance. Whether you’re using an air impact wrench, a nail gun, or a spray gun, a portable air compressor can provide the necessary pressure to operate these tools effectively.

Additionally, portable air compressors can be used for a variety of other tasks, such as inflating sports equipment, cleaning dust and debris from hard-to-reach areas, or even powering airbrushes for artistic projects. The versatility of portable air compressors makes them a valuable tool to have on hand for a wide range of applications.

When choosing a portable air compressor, it’s important to consider factors such as the maximum pressure output, the tank size, and the noise level. These specifications will determine the compressor’s suitability for different tasks and environments. It’s also worth considering additional features such as built-in air pressure gauges, adjustable pressure settings, and auto-shutoff functionality for added convenience and ease of use.

In conclusion, portable air compressors offer versatility and a wide range of benefits for various applications. Their compact size, mobility, and ability to provide a continuous supply of pressurized air make them an essential tool for professionals and DIY enthusiasts alike.

Enhancing Efficiency in Air Tools and Equipment

Introduction

Air tools and equipment have become essential in various industries, including automotive, construction, and manufacturing. These tools offer numerous advantages over traditional electric and manual tools, including increased power, versatility, and portability. However, to fully maximize the efficiency of air tools and equipment, it is important to have a reliable air compressor.

The Role of Air Compressors

Air compressors play a crucial role in enhancing the efficiency of air tools and equipment. These devices convert power from an electrical or gasoline-driven motor into potential energy stored in compressed air. The compressed air can then be used to power pneumatic tools and equipment, allowing for smoother operation and increased productivity.

1. Regulated Air Pressure: Air compressors provide regulated air pressure, ensuring consistent performance of air tools and equipment. This allows for precise and accurate results, especially in applications that require a specific level of force or pressure.

2. Quick and Continuous Operation: Air compressors enable quick and continuous operation of air tools and equipment. By providing a constant supply of compressed air, the downtime between tasks is minimized, resulting in improved efficiency and productivity.

Main Features of Air Compressors

To enhance the efficiency of air tools and equipment, it is important to choose an air compressor with the right features:

- 1. Tank Capacity: A larger tank capacity allows for a longer continuous operation of air tools without the need for the compressor to constantly run and refill the tank.

- 2. Pressure Regulator: A pressure regulator allows for precise control of the air pressure, making it easier to adapt to different applications and tools.

- 3. Oil-Free Design: An oil-free air compressor eliminates the risk of oil contamination in sensitive applications, ensuring cleaner and higher quality results.

- 4. Portability: Portable air compressors are ideal for applications that require mobility and flexibility. They allow for easy transportation between job sites and offer versatility in various work environments.

Conclusion

Overall, air compressors play a vital role in enhancing the efficiency of air tools and equipment. They provide regulated air pressure, promote quick and continuous operation, and offer various features that cater to specific requirements. By choosing the right air compressor and ensuring proper maintenance, industries can maximize the productivity and effectiveness of their air tools and equipment.

The Role of Air Compressors in HVAC and Refrigeration Systems

Air compressors play a crucial role in HVAC (heating, ventilation, and air conditioning) and refrigeration systems. They are used to generate the high-pressure air required for various tasks within these systems, such as air conditioning, refrigeration, and ventilation.

Air Conditioning

In air conditioning systems, air compressors are responsible for compressing the refrigerant gas. This compressed gas then passes through the condenser coil, where it releases heat and turns into a liquid. The liquid refrigerant then expands in the evaporator coil, absorbing heat from the surrounding air and cooling it. The compressor plays a vital role in this process by maintaining the necessary pressure levels to ensure efficient heat transfer and cooling.

Refrigeration

In refrigeration systems, air compressors are used to compress the refrigerant, which allows it to absorb heat from the refrigerator or freezer compartment. This compressed refrigerant then passes through the condenser, releasing the absorbed heat to the surrounding environment. The cooled refrigerant then expands in the evaporator coil, cooling the interior of the refrigerator or freezer. The compressor plays a critical role in maintaining the necessary pressure levels and ensuring the proper functioning of the refrigeration system.

Ventilation

Air compressors also play a role in ventilation systems by providing the necessary pressurized air for air-driven equipment. For example, air compressors can power pneumatic actuators that control the opening and closing of dampers, allowing the proper amount of fresh air to enter a building. Compressed air can also be used to power ventilation fans or air-handling units, ensuring the efficient movement of air within a building.

In conclusion, air compressors are essential components of HVAC and refrigeration systems. They are responsible for compressing the refrigerant gas, maintaining the necessary pressure levels, and enabling the efficient transfer of heat. Without air compressors, these systems would not be able to provide the cooling, refrigeration, and ventilation required for comfort and proper functioning.

Utilizing Air Compressors in Cleaning and Painting Applications

Air Compressors for Cleaning

When it comes to cleaning, air compressors are highly versatile and efficient tools. They can be used in a wide range of cleaning applications, from dusting off surfaces to removing stubborn dirt and debris. Air compressors are commonly used in industries such as automotive, manufacturing, and construction for cleaning tasks.

Dusting: Air compressors are perfect for dusting off hard-to-reach areas, such as machinery, electronics, and ventilation systems. The compressed air can quickly blow away accumulated dust, ensuring a clean and well-maintained environment.

Pressure Washing: Air compressors can be used in conjunction with pressure washing equipment to provide a powerful cleaning solution. The compressed air helps generate the required pressure to remove dirt, grime, and stains from various surfaces.

Sandblasting: Air compressors are essential for sandblasting operations. The compressed air propels abrasive material, such as sand or glass beads, to remove rust, paint, or corrosion from surfaces. Sandblasting is commonly used in industries like automotive, construction, and metalworking.

Air Compressors for Painting

Air compressors play a crucial role in painting applications, ensuring a smooth and efficient painting process.

Spray Painting: Air compressors power spray guns used in spray painting applications. The compressed air atomizes the paint, breaking it into tiny droplets and enabling an even and smooth application. This technique is widely used in automotive painting, furniture refinishing, and industrial coatings.

Airbrushing: Air compressors are also used in airbrushing, a technique that allows for precise and detailed painting. Airbrushing is commonly used in artistic and hobby applications, as well as in automotive customization and sign painting.

Paint Mixing: Air compressors can also be used to power paint mixers, ensuring a uniform consistency of the paint mixture. This is important for achieving consistent results and avoiding any issues with paint application.

Overall, air compressors are indispensable tools for cleaning and painting applications. They provide the necessary power and versatility to tackle a wide range of tasks, making them a valuable asset in various industries.

Environmental Benefits of Using Air Compressors for Power Generation

One of the key environmental benefits of using air compressors for power generation is their energy efficiency. Air compressors are known for their high energy efficiency compared to other power generation methods. This is because they convert electricity into compressed air, allowing for minimal energy waste during the conversion process. As a result, air compressors can help reduce overall energy consumption and lower carbon emissions.

Another environmental benefit of using air compressors is their ability to reduce noise pollution. Traditional power generation methods, such as combustion engines or turbines, can produce high levels of noise during operation. In contrast, air compressors operate with less noise, making them a more eco-friendly option for power generation. This can be particularly advantageous in urban areas or locations where noise restrictions are in place.

In addition to energy efficiency and noise reduction, air compressors also offer a more sustainable power generation alternative. Unlike fossil fuel-powered generators, air compressors do not rely on non-renewable resources for operation. Air, which is the primary input for compressors, is a readily available resource that can be replenished naturally through the atmosphere. By utilizing air as a power source, air compressors contribute to a more sustainable and environmentally friendly power generation system.

Furthermore, air compressors help to reduce greenhouse gas emissions. The combustion of fossil fuels in traditional power generation methods releases carbon dioxide and other harmful greenhouse gases into the atmosphere, contributing to global warming and climate change. By utilizing air compressors, which do not involve combustion but instead use electricity to produce compressed air, these emissions can be significantly reduced, helping to mitigate the adverse effects of climate change.

In conclusion, air compressors offer several environmental benefits when used for power generation. They are energy-efficient, reducing overall energy consumption. They produce less noise pollution compared to traditional power generation methods. They rely on a sustainable resource, air, and do not contribute to the depletion of non-renewable resources. Additionally, they help reduce greenhouse gas emissions, promoting a more sustainable and environmentally friendly power generation system.

FAQ:

What is an air compressor used for?

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air. It is commonly used for various purposes, such as inflating tires, powering pneumatic tools, supplying clean and compressed air for industrial processes, and operating air-powered machinery.

Why would someone need an air compressor?

There are several reasons why someone would need an air compressor. It can be used for inflating tires or sporting equipment, powering pneumatic tools like nail guns or impact wrenches, supplying compressed air for spray painting or sandblasting, and operating machinery in industries like manufacturing, construction, and automotive. It is a versatile tool that provides a reliable and efficient source of compressed air.

How does an air compressor work?

An air compressor works by drawing in air from the surroundings and compressing it using a piston, rotary screw, or centrifugal force. The compressed air is then stored in a tank or delivered directly to the point of use. The compressor is powered by an electric motor, diesel or gasoline engine, which creates the energy needed to compress the air. The stored compressed air can be released in controlled bursts to power pneumatic tools or provide a clean and compressed air supply.

What are the benefits of using an air compressor?

Using an air compressor offers several benefits. Firstly, it provides a portable and readily available source of compressed air for various applications. It is also cost-effective and energy-efficient compared to other power sources. Additionally, it allows for precise control and adjustment of air pressure, making it suitable for delicate tasks or heavy-duty applications. Moreover, compressed air is clean and free from contaminants, ensuring a reliable and consistent power supply.

Video: