Mastering the Art of Using a Spray Gun with an Air Compressor

If you’re a DIY enthusiast or a professional painter, knowing how to use a spray gun with an air compressor can be a game-changer. Whether you’re working on a small project or a large-scale painting job, a spray gun allows you to achieve a smooth and even finish in a fraction of the time it would take with a brush or roller. However, using a spray gun with an air compressor requires some skill and practice to get the best results. In this article, we will explore the steps and techniques for mastering the art of using a spray gun with an air compressor.

One of the first things to consider when using a spray gun with an air compressor is the type of paint or finish you will be using. Different paints have different viscosities, and it’s essential to choose the right spray nozzle size and air pressure for the job. For thicker paints, you will need a larger nozzle size and higher air pressure to ensure proper atomization. On the other hand, for thinner paints, a smaller nozzle size and lower air pressure will provide better control and prevent overspray.

Another crucial factor in mastering the art of using a spray gun with an air compressor is the technique of spraying. It’s important to maintain a consistent distance between the spray gun and the surface being painted. Usually, a distance of around 6 to 8 inches works well, but it may vary depending on the type of paint and desired finish. Additionally, using smooth and even strokes, overlapping each pass by about 50%, will help prevent streaks and ensure a uniform application of paint.

Furthermore, adjusting the air pressure is key to achieving the desired spray pattern and atomization. Too much pressure can cause the paint to splatter or create a rough finish, while too little pressure may result in a thin and uneven coat. It’s recommended to start with a lower air pressure and gradually increase it until you find the right balance. Experimenting on a scrap piece of material before starting the actual painting project can help you determine the ideal air pressure for the specific paint and surface you’re working with.

In conclusion, using a spray gun with an air compressor can significantly enhance your painting projects. By choosing the right paint, practicing proper spraying techniques, and adjusting the air pressure accordingly, you can achieve professional-looking results. However, it’s important to note that mastering the art of using a spray gun with an air compressor takes time and patience. With practice and experience, you’ll be able to paint with precision and efficiency, turning any project into a masterpiece.

The Basics of Spray Gun and Air Compressor

Spray Gun

A spray gun is a device that uses compressed air to spray a liquid, such as paint, onto a surface. It is commonly used in industries such as automotive, construction, and manufacturing for applications such as painting, coating, and finishing. A spray gun consists of a nozzle, fluid container, and trigger mechanism.

There are different types of spray guns available, including gravity feed, siphon feed, and pressure feed. The choice of spray gun depends on the specific application and the type of material being sprayed. Different nozzles can also be used to achieve different spray patterns and coverage.

Air Compressor

An air compressor is a machine that converts power, typically from an electric motor or a gasoline engine, into compressed air. This compressed air can then be used to power various tools and equipment, including spray guns. The air compressor supplies the necessary pressure and volume of air for the spray gun to atomize and spray the liquid.

When using an air compressor with a spray gun, it is important to consider the air pressure and volume requirements of the spray gun. The air compressor should be capable of delivering the recommended air pressure and volume for optimal spray gun performance. Regular maintenance and proper adjustment of the air compressor are also essential to ensure consistent and reliable operation.

Tips for Using a Spray Gun with an Air Compressor

- Make sure the air compressor is properly connected and functioning before using the spray gun.

- Adjust the air pressure according to the manufacturer’s recommendations for the specific material and spray gun being used.

- Practice proper spraying techniques, such as maintaining the correct distance from the surface and moving the spray gun in a smooth and consistent motion.

- Clean the spray gun thoroughly after each use to prevent buildup of dried paint or other materials.

- Regularly check and replace any worn or damaged parts of the spray gun or air compressor to maintain optimal performance.

By understanding the basics of spray guns and air compressors, and following best practices for their use, you can achieve professional results and master the art of using a spray gun with an air compressor.

Choosing the Right Spray Gun for Your Project

When it comes to using a spray gun with an air compressor, choosing the right spray gun for your project is essential. The spray gun you select will greatly impact the quality and efficiency of your painting or finishing job. There are several factors to consider when choosing a spray gun, including the type of material you will be spraying, the size of the project, and your level of experience.

Type of Material

One of the first things to consider is the type of material you will be spraying. Different materials have different viscosities and require different spray guns. For example, if you are spraying thicker materials such as latex paint or epoxy, you will need a spray gun with a larger nozzle and higher fluid flow rate. On the other hand, if you are spraying thinner materials such as lacquer or stain, a spray gun with a smaller nozzle and lower fluid flow rate will be more suitable.

Size of Project

The size of your project will also influence the type of spray gun you need. For small projects, such as furniture or small parts, a gravity-fed spray gun may be sufficient. These spray guns have a small cup on top that holds the paint or finish, and gravity pulls the material down into the gun. For larger projects, such as walls or automobiles, a pressure-fed spray gun may be necessary. These spray guns are connected to a paint or finish supply container and use compressed air to push the material through the gun.

Experience Level

Your level of experience using a spray gun should also be taken into consideration. If you are a beginner, it is recommended to start with a more user-friendly spray gun that has adjustable settings and a comfortable grip. This will make it easier for you to control the spray pattern and fluid flow. As you gain more experience and confidence, you can upgrade to a more professional-grade spray gun with advanced features.

In summary, choosing the right spray gun for your project involves considering the type of material you will be spraying, the size of the project, and your level of experience. By selecting a spray gun that is appropriate for your specific needs, you can achieve optimal results and improve your overall painting or finishing process.

Selecting the Perfect Air Compressor

Factors to Consider

Choosing the right air compressor for spray gun applications is crucial to achieving optimal results. Several factors should be taken into consideration when selecting the perfect air compressor:

- Air pressure and volume: The air compressor should be able to provide a consistent and adequate supply of air pressure and volume to meet the requirements of the spray gun. The ideal pressure for a spray gun typically ranges from 20 to 30 pounds per square inch (psi), while the volume is measured in cubic feet per minute (CFM).

- Power source: Air compressors can be powered by electricity or gasoline. Electric models are more commonly used, as they are more convenient for indoor applications and offer quieter operation. Gasoline-powered compressors are typically more powerful and better suited for outdoor and heavy-duty use.

- Tank size: The tank size of the air compressor determines its capacity to store compressed air. A larger tank allows for longer continuous operation without needing to refill. For spray gun applications, a tank size of at least 20 gallons is recommended to ensure a steady supply of air.

- Portability: Consider the portability of the air compressor, especially if you need to move it around frequently. Smaller, compact compressors with wheels or handles are easier to transport, while larger ones may require additional equipment or assistance.

Types of Air Compressors

There are different types of air compressors available, each with its own advantages and limitations:

- Reciprocating air compressors: Also known as piston compressors, these are the most common type and suitable for most spray gun applications. They use a piston-driven system to compress air.

- Rotary screw air compressors: These are more efficient and durable than reciprocating compressors, making them ideal for industrial and continuous use. However, they are often more expensive.

- Portable air compressors: As the name suggests, portable compressors are designed for easy transportation. They are smaller in size and have limited tank capacities, making them suitable for smaller-scale projects or on-the-go applications.

Additional Considerations

In addition to the above factors, it is important to consider the noise level, maintenance requirements, and overall reliability of the air compressor. Noise levels can vary depending on the model, so if noise is a concern, look for compressors with lower decibel ratings. Regular maintenance, such as oil changes and filter replacements, is necessary to keep the compressor running smoothly and efficiently. Lastly, read customer reviews and consider reputable brands to ensure a reliable and durable air compressor.

Understanding the Proper Air Pressure

One important aspect of using a spray gun with an air compressor is understanding the proper air pressure to achieve the desired results. The air pressure is measured in pounds per square inch (psi) and can significantly affect the finish of your spray job.

Higher air pressure can cause overspray and excessive paint application. It can create a cloud of paint particles that don’t adhere well to the surface, leading to wastage and an uneven finish. On the other hand, lower air pressure may result in an insufficient amount of paint being sprayed onto the surface. This can lead to a thin, patchy application, requiring multiple coats and a longer drying time.

Factors influencing proper air pressure:

- Type of paint: Different types of paint require different air pressure settings. Thin materials like stains and lacquers typically require lower air pressure, while heavier materials like primers and automotive paints may require higher air pressure for proper atomization.

- Spray gun specifications: Each spray gun has recommended air pressure guidelines provided by the manufacturer. It is crucial to consult the user manual or product specifications to determine the optimal air pressure range for your specific spray gun model.

- Surface area: The size and nature of the surface being painted can also influence the ideal air pressure. Larger surfaces may require higher air pressure for better coverage, while smaller or intricate areas may benefit from lower air pressure for more precision.

To ensure the proper air pressure, it is recommended to perform a test spray on a scrap material before starting your project. Adjust the air pressure gradually, observing the spray pattern, and make any necessary adjustments until you achieve optimal atomization and coverage.

Overall, understanding the proper air pressure for your spray gun and air compressor is crucial in achieving a high-quality finish. It is essential to consider the type of paint, spray gun specifications, and surface area to determine the optimal air pressure range for your specific project.

Preparing Your Work Area and Safety Measures

Before starting any project with a spray gun and air compressor, it is important to properly prepare your work area to ensure safety and optimal results. Here are some steps you should follow:

Clean and Clear the Work Area

Make sure the area where you plan to use the spray gun is clean and clear of any debris or objects that could interfere with your work or pose a safety hazard. Remove any furniture, tools, or other items that are not necessary for your project. This will help you move around freely and reduce the risk of accidents.

Protect Surrounding Surfaces

Before you start spraying, take the time to protect any surfaces that you don’t want to get paint or other coatings on. Use drop cloths, plastic sheets, or masking tape and paper to cover floors, walls, windows, and other nearby objects. This will prevent unwanted overspray and make the cleanup process much easier.

Ventilation

Ensure that you have proper ventilation in your work area to avoid inhaling harmful fumes or particles from the paint or coating you are using. Open windows and doors if possible, or use fans and exhaust systems to keep the air circulating. If you are working in a closed space, consider wearing a respirator to protect your lungs.

Protective Clothing and Equipment

Always wear appropriate protective clothing and equipment when working with a spray gun and air compressor. This includes safety glasses or goggles to protect your eyes from splashes or debris, gloves to protect your hands, and a mask or respirator to protect against fumes and particles. Additionally, wear clothing that covers your skin to reduce the risk of skin irritation or contact with chemicals.

Check and Maintain Equipment

Before using the spray gun and air compressor, inspect them for any damages or defects. Ensure that all connections are secure and that there are no leaks. Follow the manufacturer’s instructions for cleaning and maintaining the equipment to keep it in good working condition. Regular maintenance will help prevent accidents and ensure consistent performance.

Following these safety measures and properly preparing your work area will help you achieve the best results with your spray gun and air compressor, while keeping yourself and others safe during the process. Remember to always read and follow the instructions provided by the equipment manufacturer for your specific model.

Mixing and Diluting Paint for Spray Gun Application

When using a spray gun with an air compressor, it is important to mix and dilute the paint properly for optimal application. The correct mixing ratio will ensure that the paint flows smoothly through the spray gun and onto the desired surface.

1. Read the Instructions: Before mixing the paint, be sure to read the instructions provided by the manufacturer. Different types of paint may have specific guidelines for mixing and dilution.

2. Choose the Right Thinner: Depending on the type of paint you are using, you may need to add a thinner to achieve the desired consistency. The type of thinner will vary based on the paint’s composition, so it is important to choose the right one for optimal results.

3. Mix Thoroughly: Use a stirring stick or paddle to mix the paint and thinner together. Ensure that the mixture is well-blended, with no lumps or clumps remaining. This will ensure that the paint will flow smoothly through the spray gun without clogging or splattering.

4. Test the Viscosity: To determine if the paint is properly mixed and diluted, perform a viscosity test. Dip a viscosity cup into the paint mixture and time how long it takes for the paint to flow through the cup. Adjust the paint’s viscosity by adding more thinner or paint until it reaches the desired flow rate.

5. Strain the Paint: Before pouring the paint into the spray gun, strain it through a fine mesh strainer. This will remove any impurities or particles that could cause blockages in the spray gun nozzle.

6. Dilute in Small Batches: It is best to mix and dilute the paint in small batches, especially if you are working with a large quantity. This will ensure that the paint remains at the desired consistency throughout the application process.

7. Keep Notes: It is helpful to keep notes on the mixing and dilution ratios used for different types of paint. This will help you create consistent results in the future and streamline the process.

By following these steps and taking the time to mix and dilute the paint properly, you will achieve better results when using a spray gun with an air compressor. Remember to always follow the manufacturer’s instructions and adjust the paint’s viscosity as needed for optimal application.

Mastering Techniques for Using a Spray Gun

1. Adjusting the Air Pressure

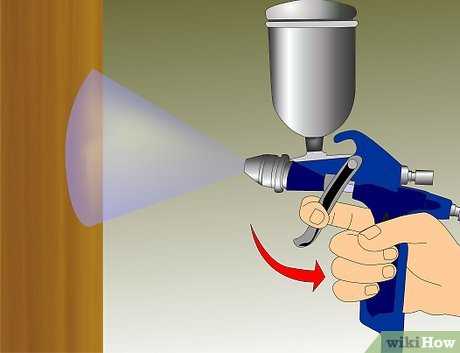

To achieve the best results with a spray gun, it is important to adjust the air pressure accordingly. This can be done by turning the air pressure regulator on the air compressor. Start with a low pressure setting and gradually increase it until the desired result is achieved. It is important to find the right balance, as too much pressure can cause the paint to splatter and too little pressure may result in an uneven finish.

2. Holding the Spray Gun

The way you hold the spray gun can greatly affect the outcome of your painting project. Hold the spray gun firmly, but not too tightly, with your dominant hand. Keep your wrist relaxed and move the gun using your entire arm, rather than just your wrist. This will help provide a smooth and even application of paint.

3. Maintaining the Proper Distance

It is crucial to maintain the proper distance between the spray gun and the surface being painted. Holding the gun too close may result in drips and uneven coverage, while holding it too far away can cause the paint to dry before it reaches the surface. Aim for a distance of about 6 to 8 inches, and adjust as needed based on the type of paint and desired finish.

4. Overlapping the Strokes

To prevent streaks and ensure even coverage, it is important to overlap each stroke when using a spray gun. Start each stroke slightly before the previous one ends, and continue the motion in a smooth and steady manner. This technique helps to blend the paint together and create a seamless finish.

5. Practicing Proper Cleanup and Maintenance

After using a spray gun, it is essential to clean it thoroughly to prevent clogs and ensure its longevity. Follow the manufacturer’s instructions for cleaning and maintenance, which may include disassembling the gun, flushing it with a cleaning solution, and lubricating the moving parts. Regular maintenance will help keep the spray gun in optimal condition for future use.

Cleaning and Maintenance of Your Spray Gun and Air Compressor

Proper cleaning and maintenance are essential for keeping your spray gun and air compressor in optimal condition. Regular cleaning will help prevent clogs and buildup, ensuring consistent performance and a longer lifespan for your equipment.

1. Cleaning the Spray Gun

After each use, it’s crucial to clean your spray gun thoroughly to remove any residual paint or coatings. Start by disconnecting the gun from the air compressor and removing the paint container. Carefully disassemble the gun and soak the individual parts in a solution of warm water and mild dish soap.

Use a soft brush to scrub away any paint residue, paying close attention to the nozzle and needle. Rinse each part thoroughly with clean water and allow them to air dry. Once dry, reassemble the spray gun and make sure all connections are tightened properly.

2. Maintaining the Air Compressor

To keep your air compressor running smoothly, regular maintenance is necessary. Start by checking the oil level and adding more if needed, following the manufacturer’s instructions. Change the oil regularly to ensure proper lubrication of the compressor’s moving parts.

Inspect the air filter and clean or replace it as necessary. Clogged or dirty filters can hinder the compressor’s performance and lead to overheating. Additionally, check for any leaks in the air compressor’s hoses and fittings. Repair or replace damaged components to maintain air pressure and prevent air loss.

It’s also important to drain the moisture from the air compressor’s tank regularly. Moisture buildup can lead to corrosion and damage the compressor. Open the drain valve located at the bottom of the tank and allow any accumulated water to drain completely. Close the valve tightly once the tank is empty.

Lastly, store your spray gun and air compressor in a clean, dry area to protect them from dust and debris. Covering them with a tarp or using a dedicated storage case can provide an extra layer of protection and help prolong their lifespan.

By following these cleaning and maintenance tips, you can ensure that your spray gun and air compressor are always ready for optimal performance. Regular upkeep will not only extend their lifespan but also help you achieve better results in your painting projects.

FAQ:

What is a spray gun and why is it used?

A spray gun is a device that uses compressed air from an air compressor to atomize and propel paint or other liquids onto a surface. It is used for various applications such as automotive painting, furniture refinishing, and DIY projects.

Can I use any type of spray gun with an air compressor?

No, not all spray guns are compatible with air compressors. It is important to choose a spray gun that is specifically designed for use with an air compressor. The spray gun should have the necessary air pressure and volume requirements to work effectively with the air compressor.

What are the benefits of using a spray gun with an air compressor?

Using a spray gun with an air compressor offers several benefits. It provides a smooth and even finish, allows for quick and efficient application of paint or other liquids, and is suitable for both large and small areas. Additionally, it reduces the risk of brush marks and provides better control over the flow and coverage of the material being sprayed.

How do I choose the right air compressor for a spray gun?

When choosing an air compressor for a spray gun, you need to consider the air pressure and volume requirements of the spray gun. Check the specifications of the spray gun to determine the minimum air pressure and volume it requires. Select an air compressor that meets or exceeds these requirements. It is also important to consider the size and portability of the air compressor based on your needs and workspace.

Video: