How to Turn On a Husky Air Compressor

If you’re new to using a Husky air compressor, you may be wondering how to turn it on and get it running. Whether you’re using it for your personal DIY projects or for professional work, knowing how to properly start up your air compressor is essential for its function and longevity.

First, make sure the air compressor is placed on a stable surface and securely connected to a power source. Check that the power cord is in good condition and there are no exposed wires. If any issues are found, have them addressed properly before proceeding.

Next, locate the on/off switch or button on the air compressor. It is typically labeled with a power symbol, such as a circle with a vertical line in the middle. Once found, switch it to the “on” position. You may need to press and hold the switch for a few seconds for the compressor to start.

After turning on the air compressor, you should hear the motor running and see the pressure gauge start to rise. Depending on the model, there may be an automatic shut-off feature that stops the motor when the desired pressure is reached. In this case, you can proceed with your work knowing that the compressor will maintain the correct pressure level.

What is a Husky Air Compressor?

A Husky air compressor is a type of portable and versatile equipment used for powering pneumatic tools and machinery. It is commonly used in various industries such as construction, automotive, and woodworking. The Husky air compressor is designed to generate compressed air, which is then stored in a tank for future use. This compressed air can be utilized to operate a wide range of tools, including nail guns, paint sprayers, airbrushes, and impact wrenches.

The Husky air compressor is known for its reliability and durability. It is built with high-quality materials and components, ensuring its longevity and ability to withstand heavy-duty use. The compressor is equipped with a powerful motor that drives a piston or a rotary screw, depending on the model. This creates a compression cycle that results in the generation of pressurized air.

One of the key features of a Husky air compressor is its portability. It is designed to be compact and lightweight, making it easy to transport and move around job sites. This allows for greater flexibility and convenience, as it can be easily taken to different locations as needed.

In addition, Husky air compressors are known for their user-friendly design. They are equipped with easy-to-use controls and gauges, allowing users to adjust the pressure and monitor the performance of the compressor. Some models also come with built-in safety features, such as thermal overload protection, to prevent damage and ensure safe operation.

Overall, a Husky air compressor is a reliable and efficient tool that can be used for a wide range of applications. Whether it’s for professional use or DIY projects, the Husky air compressor provides the necessary power and versatility to get the job done. With proper maintenance and care, it can last for years and deliver consistent performance.

Why Turn On a Husky Air Compressor?

If you own a Husky air compressor, you may be wondering why you should bother turning it on. Well, there are several reasons why you might need to turn on your Husky air compressor. Here are a few:

1. Inflating Tires

One of the most common uses for an air compressor is to inflate tires. Whether you need to add some air to your car or bike tires, or if you’re inflating the tires on a trailer or other equipment, a Husky air compressor can make the job quick and easy. With the right attachment, you can easily connect the air compressor to the tire valve and fill it up in no time.

2. Powering Tools

Another reason to turn on a Husky air compressor is to power tools. Many power tools, such as nail guns, spray guns, and impact wrenches, require compressed air to function properly. By turning on your Husky air compressor and connecting it to the tool, you can ensure that you have a constant supply of compressed air to power your tools.

3. Cleaning and Dusting

A Husky air compressor can also be used for cleaning and dusting purposes. By attaching a blow gun or air nozzle to the compressor, you can blow away dust and debris from hard-to-reach areas. This is particularly useful for cleaning out workshops, garages, and other areas where dirt and dust tend to accumulate.

4. Operating Machinery

If you have any machinery or equipment that requires compressed air to operate, then you’ll need to turn on your Husky air compressor. This could include things like air pumps, air compressors, or pneumatic systems. By turning on the air compressor, you can ensure that your machinery has the necessary supply of compressed air to function properly.

In summary, there are several reasons why you might need to turn on a Husky air compressor. From inflating tires to powering tools, cleaning and dusting, and operating machinery, a Husky air compressor can provide a versatile source of compressed air for a variety of tasks and applications.

Step 1: Read the Manual

Before attempting to turn on your Husky Air Compressor, it is essential to familiarize yourself with the user manual. The manual provides important information about the specific model of the compressor, including safety precautions, proper usage instructions, and troubleshooting tips. Reading the manual ensures that you understand how to operate the compressor correctly and avoids any potential accidents or malfunctions.

Why read the manual?

Reading the manual is crucial because it provides important details about the different components of the Husky Air Compressor and the steps required to turn it on safely. The manual outlines specific instructions, such as how to connect the power cord, how to turn on the compressor, and what to do in case of an emergency. By reading the manual, you can avoid any potential hazards and ensure a smooth start-up process.

Where to find the manual?

The user manual for your Husky Air Compressor can typically be found inside the packaging or can be downloaded from the manufacturer’s website. Make sure to store the manual in a safe place for future reference and share it with other individuals who may need to operate the compressor.

Step 2: Prepare the Compressor

Before turning on the Husky air compressor, it is important to make sure that the compressor is properly prepared. Follow these steps to prepare the compressor:

- Check the oil level: Locate the oil sight glass or oil dipstick on the compressor and ensure that the oil level is between the minimum and maximum marks. If the oil level is low, add the appropriate type of oil as recommended by the manufacturer.

- Inspect the air filter: Locate the air filter on the compressor and remove it for inspection. If the air filter appears dirty or clogged, clean or replace it as necessary to ensure proper air flow.

- Check for any leaks: Inspect the hoses, fittings, and connections of the compressor for any signs of leaks. Tighten any loose fittings or replace any damaged parts to prevent air leakage during operation.

- Ensure proper ventilation: Make sure the compressor is positioned in a well-ventilated area to allow for proper air circulation and prevent overheating. Keep the compressor at least a few feet away from walls or other obstructions to allow for adequate airflow.

- Verify the pressure settings: Check the pressure settings on the compressor to ensure they are set according to your desired operating pressure. Adjust the pressure regulator as needed to achieve the desired pressure.

By properly preparing the Husky air compressor before turning it on, you can ensure its optimal performance and prolong its lifespan. Following these steps will help you get your compressor ready for use.

Step 3: Check the Power Supply

Before turning on the Husky air compressor, it is important to check the power supply to ensure that it is properly connected and functioning. Follow these steps to check the power supply:

- Inspect the power cord for any visible damage, such as frayed wires or broken plugs. If there is any damage, do not attempt to use the compressor and contact a professional for repairs or replacement.

- Check that the power cord is securely plugged into a functioning electrical outlet. Ensure that the outlet is providing power by plugging in another device and confirming that it turns on.

- If the compressor is equipped with a power switch, make sure it is in the “off” position before plugging in the power cord.

- For compressors with a pressure switch, ensure that the pressure switch is set to the desired pressure level. Some compressors may have an adjustable pressure switch that can be set to different levels.

- If the compressor is equipped with a circuit breaker, check if it is tripped. If the circuit breaker has tripped, reset it by switching it off and then on again.

- Refer to the user manual or manufacturer’s instructions for any specific power supply requirements for your particular Husky air compressor model.

By thoroughly checking the power supply and ensuring it is properly connected and functioning, you can help prevent electrical issues and ensure the safe operation of your Husky air compressor.

Step 4: Turn On the Compressor

To turn on the Husky air compressor, follow these steps:

- Make sure the power switch on the Husky air compressor is in the “off” position.

- Check the oil level in the compressor and make sure it is at the appropriate level. Refer to the owner’s manual for specific instructions on checking and adding oil, if needed.

- If the compressor is electric-powered, ensure that it is plugged into a properly grounded electrical outlet.

- If the compressor is gas-powered, check the fuel level and ensure it has enough fuel to operate.

- If the compressor has a pressure regulator, set it to the desired pressure level for your specific task. Refer to the owner’s manual for instructions on how to adjust the pressure regulator.

- Flip the power switch on the compressor to the “on” position.

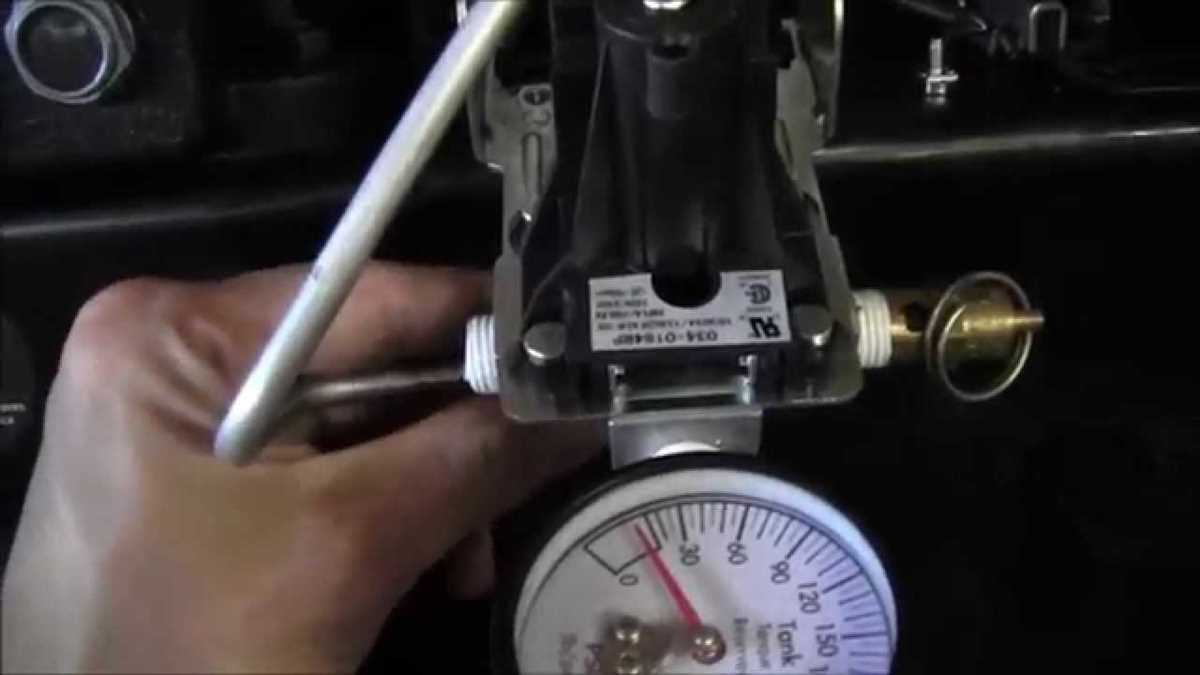

- Listen for the compressor motor to start running. You should also see the pressure gauge on the compressor start to rise.

- Wait for the compressor to reach the desired pressure level, which will depend on the specific task you are using it for.

- Once the compressor has reached the desired pressure level, you can begin using it for your intended task.

Note: Always refer to the owner’s manual for specific instructions and safety guidelines when operating any equipment, including the Husky air compressor.

Step 5: Monitor the Pressure

Once you have successfully turned on your Husky air compressor, it is important to monitor the pressure to ensure that it is operating correctly and within the desired range.

Firstly, locate the pressure gauge on the compressor. This gauge displays the current pressure inside the tank. It is usually located on the front of the compressor and is marked with numerical values that indicate the pressure in pounds per square inch (PSI).

While the compressor is running, keep an eye on the pressure gauge and make sure it remains within the recommended range for your specific task. Different tools and applications require different pressure settings, so refer to the user manual or guidelines provided by the manufacturer.

If the pressure goes below the desired range, the compressor may not be providing enough air for your needs. In this case, you may need to adjust the pressure regulator on the compressor by turning the knob clockwise to increase the pressure or counterclockwise to decrease it.

On the other hand, if the pressure exceeds the recommended range, it could put unnecessary strain on the compressor and potentially lead to malfunctions or damage. If this happens, you may need to adjust the pressure regulator accordingly to bring the pressure back within the desired range.

Continuously monitoring the pressure while the compressor is in use will help ensure its optimal performance and prevent any potential issues from arising.

Step 6: Adjust the Pressure

Once the Husky air compressor is turned on and running, you may need to adjust the pressure to match the requirements of the task at hand. Adjusting the pressure is a simple process that can be done using the pressure regulator knob located on the front of the compressor.

First, locate the pressure regulator knob. It is typically labeled and can be found near the gauges on the front of the compressor. The pressure regulator knob allows you to increase or decrease the pressure output of the compressor.

To adjust the pressure, turn the knob clockwise to increase the pressure and counterclockwise to decrease it. Start by setting the pressure regulator knob to the desired output pressure for your specific task. It is important to consult the manual or the manufacturer’s guidelines to determine the appropriate pressure settings for your particular task.

After setting the desired pressure, give the compressor a few moments to adjust and stabilize at the new pressure before starting your task. The compressor will automatically adjust and maintain the set pressure as long as it is running.

During your task, it may be necessary to make further adjustments to the pressure. If you find that the pressure is too high or too low, simply turn the pressure regulator knob accordingly to achieve the desired pressure. Remember to make small adjustments and allow the compressor to stabilize before making any additional changes.

It is important to regularly monitor and adjust the pressure as needed during your task to ensure optimal performance and safety. By adjusting the pressure to the appropriate level, you can ensure that your Husky air compressor is operating efficiently and effectively for your specific needs.

Step 7: Turn Off the Compressor

Once you have finished using the Husky air compressor, it is important to turn it off properly to ensure safety and prolong the lifespan of the unit. Follow these steps to turn off the compressor:

- Release the Pressure: Before turning off the compressor, release the pressure in the tank. This can be done by turning the pressure release valve counterclockwise to allow the air to escape slowly. Do not attempt to release the pressure too quickly, as this can be dangerous.

- Disconnect the Power: Once the pressure has been released, unplug the power cord from the power source or turn off the switch if it is connected to a circuit breaker.

- Secure the Accessories: If you have any air tools or accessories connected to the compressor, make sure to detach them and store them properly. This will prevent any potential damage to the tools and keep your workspace clean and organized.

- Clean the Compressor: After turning off the compressor, take a few minutes to clean the unit. Wipe down the exterior with a clean cloth and remove any dust or debris that may have accumulated. This will help maintain the performance and appearance of the compressor.

- Store the Compressor: Finally, find a suitable location to store the Husky air compressor. Choose a dry and well-ventilated area, away from any moisture or extreme temperatures. Make sure to follow the manufacturer’s instructions for proper storage to prevent any damage.

By following these steps, you can safely and effectively turn off the Husky air compressor after each use, ensuring its longevity and reliable performance for future projects.

FAQ:

What is a Husky Air Compressor?

A Husky air compressor is a powerful tool that is used to convert power into potential energy stored in pressurized air. It is commonly used in various industries and for household tasks.

How do I turn on a Husky air compressor?

To turn on a Husky air compressor, locate the power switch or knob on the device and flip it to the “on” position. Make sure that the compressor is connected to a power source and that all necessary hoses and fittings are properly attached.

Are there any safety precautions to keep in mind while turning on a Husky air compressor?

Yes, there are a few safety precautions to consider. Before turning on the compressor, make sure that you are wearing appropriate safety gear, such as safety goggles and ear protection. Additionally, ensure that the compressor is placed on a stable surface to avoid tipping.

Can I adjust the pressure of a Husky air compressor?

Yes, you can adjust the pressure of a Husky air compressor. Most models have a pressure regulator knob that you can turn to increase or decrease the pressure output. It is important to refer to the user manual for specific instructions on how to adjust the pressure for your particular model.

What are some common uses for a Husky air compressor?

A Husky air compressor can be used for a variety of tasks. Some common uses include powering pneumatic tools, such as nail guns and impact wrenches, inflating tires and sports equipment, and painting or staining projects. It is a versatile tool that can be used in both professional and DIY settings.

Can I use a Husky air compressor for painting?

Yes, a Husky air compressor can be used for painting. However, it is important to ensure that you have the necessary attachments and accessories for painting, such as a paint gun and appropriate filters. Additionally, it is recommended to follow proper painting techniques and use the recommended air pressure for your specific paint job.

How do I properly maintain a Husky air compressor?

To properly maintain a Husky air compressor, you should regularly check and change the oil, clean or replace the air filter, inspect and tighten any loose fittings, and drain the moisture from the tank. It is also important to follow the manufacturer’s guidelines for maintenance and storage to ensure the longevity of the compressor.

Video: