How to Adjust Unloader Valve on Air Compressor

One of the crucial parts of an air compressor is the unloader valve. This valve helps to regulate the pressure inside the compressor and protects it from overloading. Over time, however, the unloader valve may need to be adjusted to ensure optimal performance.

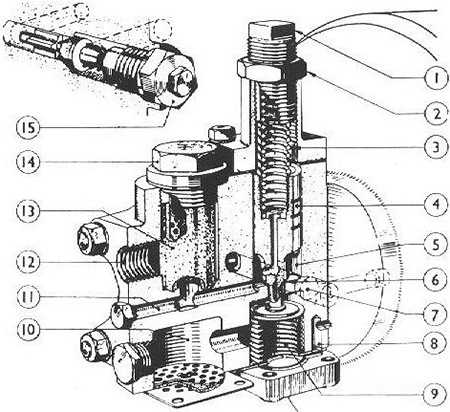

Adjusting the unloader valve on an air compressor can be a simple task, but it requires careful attention to detail. The first step is to identify the location of the valve. Typically, it can be found near the pressure switch or on the side of the compressor.

Once you have located the unloader valve, it is important to shut off the air compressor and release all the air pressure from the tank. This can be done by opening the drain valve or simply waiting for the pressure to dissipate. It is crucial to ensure that there is no pressure in the tank before attempting to adjust the unloader valve to avoid accidents or damage to the compressor.

After releasing the pressure, the next step is to adjust the unloader valve. This can be done by turning the adjusting screw, usually located on the top of the valve, using a screwdriver or a wrench. The direction to turn the screw may vary depending on the specific model of the air compressor, so it is essential to consult the manufacturer’s instructions or the user manual.

Understanding the Unloader Valve

The unloader valve is an essential component of an air compressor that helps to regulate the pressure build-up and release in the compressor. It plays a crucial role in preventing the compressor from stalling and helps to ensure smooth and efficient operation.

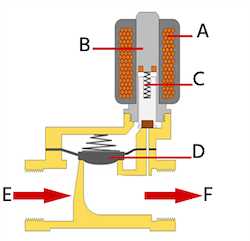

Function: The primary function of the unloader valve is to release the air pressure that remains in the compressor head and discharge line after the compressor stops. This prevents the motor from facing excessive starting load and also allows for an easier start-up when the compressor is turned on again.

Types: There are two main types of unloader valves commonly used in air compressors: continuous run unloader valves and pressure switch actuated unloader valves. Continuous run unloader valves release air pressure constantly while the compressor is running, ensuring a constant release of pressure. Pressure switch actuated unloader valves, on the other hand, are connected to the compressor’s pressure switch and release air pressure only when the switch signals the compressor to stop.

Adjustment: Adjusting the unloader valve is necessary if you notice any issues with the compressor’s pressure build-up or release. This can be done by following specific instructions provided by the manufacturer. It usually involves adjusting the tension on the unloader valve spring or turning a screw to increase or decrease the amount of pressure released.

Maintenance: Regular maintenance of the unloader valve is important to ensure its proper functioning. This includes cleaning the valve, checking for any signs of wear or damage, and lubricating moving parts if necessary. It is also essential to monitor the valve’s performance and address any issues promptly to prevent further damage to the compressor.

Conclusion: Understanding the unloader valve and its role in an air compressor is crucial for maintaining the compressor’s efficiency and preventing potential issues. Regular maintenance and proper adjustment are key to ensure the valve’s optimal performance and to prolong the lifespan of the compressor.

Signs of an Unloader Valve Problem

If you are experiencing issues with your air compressor, one possible culprit could be a problem with the unloader valve. The unloader valve is responsible for releasing pressure in the compressor tank when the motor shuts off, preventing the compressor from starting under load. Here are a few signs that indicate you may have a problem with the unloader valve:

- High cycling frequency: If your air compressor seems to be cycling on and off more frequently than usual, it could be a sign of an unloader valve problem. When the valve fails to release pressure properly, the motor will have a hard time starting, leading to more frequent cycling.

- Difficulty starting: Another common sign of an unloader valve problem is difficulty getting the air compressor motor to start. This is often caused by excessive pressure build-up in the compressor tank, which can make it hard for the motor to overcome the load and initiate the start-up process.

- Air leaks: A malfunctioning unloader valve may also result in air leaks around the compressor. These leaks can occur at the valve itself or other areas of the system where pressure escapes when the motor shuts off. If you notice hissing or air escaping when the compressor is not running, it’s likely due to a faulty unloader valve.

- Pressure fluctuations: An unloader valve problem can also cause pressure fluctuations in the compressor tank. If you notice that the pressure gauge jumps up and down rapidly or that the pressure is not consistent, it could be an indication of an issue with the unloader valve.

If you encounter any of these signs, it’s important to address the unloader valve problem promptly. Not only can a faulty valve affect the performance of your air compressor, but it can also put unnecessary strain on the motor and other components, potentially leading to further damage if left unattended.

Tools Needed for Adjusting the Unloader Valve

Adjusting the unloader valve on an air compressor may require a few specific tools to ensure the process is done correctly. Here are some tools that you may need:

Pressure Gauge

A pressure gauge is an essential tool for adjusting the unloader valve. It allows you to measure the pressure inside the air compressor tank accurately. This is necessary because the unloader valve is designed to release excess pressure from the tank when it reaches a certain level.

Adjustable Wrench

An adjustable wrench is another important tool for adjusting the unloader valve. It allows you to tighten or loosen the unloader valve as needed. Make sure to choose an adjustable wrench that fits the specific size of the unloader valve on your air compressor.

Pliers

Pliers can come in handy when adjusting the unloader valve. They can be used to hold certain parts in place or to provide a better grip while making adjustments. It’s a good idea to have a set of pliers with different sizes and types to ensure versatility.

Thread Seal Tape

Thread seal tape is a helpful tool when adjusting the unloader valve. It can be used to create a tight seal between the valve and other connecting parts. This helps to prevent air leaks and ensures proper functioning of the unloader valve.

These are some of the tools that you may need when adjusting the unloader valve on your air compressor. It’s important to have the right tools on hand to ensure a successful adjustment process. Remember to always refer to the manufacturer’s instructions and take necessary safety precautions when working with an air compressor.

Step-by-Step Guide to Adjusting the Unloader Valve

Step 1: Turn off the Air Compressor

Before adjusting the unloader valve on your air compressor, make sure to turn off the machine and unplug it from the power source for safety.

Step 2: Locate the Unloader Valve

Find the unloader valve on your air compressor. It is usually located near the pressure switch or the pressure regulator. The valve may have a lever or knob that you can adjust to control the pressure release.

Step 3: Release the Pressure

To adjust the unloader valve, you first need to release the pressure in the air tank. This can be done by opening the drain valve on the bottom of the tank or by slowly turning the pressure adjustment knob counterclockwise until you hear the air escaping.

Step 4: Adjust the Unloader Valve

Once the pressure is released, you can now adjust the unloader valve. Turn the adjustment knob or lever clockwise to increase the pressure setting, or counterclockwise to decrease it. Make small adjustments at a time and test the compressor to ensure it operates within the desired pressure range.

Step 5: Test the Air Compressor

After making the adjustments, turn on the air compressor and monitor the pressure gauge. Listen for any abnormal sounds or vibrations that may indicate a problem. If everything seems to be working properly, you have successfully adjusted the unloader valve on your air compressor.

Remember to always follow the manufacturer’s instructions when adjusting the unloader valve or performing any maintenance tasks on your air compressor. Improper adjustments can cause damage to the machine or compromise its performance.

Troubleshooting Tips

1. Check for Leaks

One common issue with air compressors is air leakage. If you notice that the pressure drops quickly after reaching the desired level, there may be a leak in the system. Start by inspecting all the connections, hoses, and fittings for any visible signs of leakage. Tighten any loose connections or replace damaged components. If the leak persists, you may need to apply a soapy water solution to identify the exact source of the leak.

2. Inspect the Unloader Valve

The unloader valve plays a crucial role in the operation of an air compressor. It releases the excess pressure in the compressor head when the motor shuts off, preventing a backflow of air into the system. If the unloader valve is not functioning correctly, it can lead to various issues, including difficulty in starting the compressor or excessive noise. Inspect the valve for any clogs or damage. Clean or replace the valve if necessary to ensure proper functioning.

3. Check the Pressure Switch

The pressure switch is responsible for automatically turning on and off the compressor based on the desired pressure level. If the switch is faulty, it may not accurately detect the pressure or fail to shut off the compressor when the desired level is reached. Check the pressure switch for any signs of damage or loose connections. You may need to replace the pressure switch if it is not functioning correctly.

4. Clean or Replace Air Filters

Clogged or dirty air filters can restrict the airflow to the compressor, leading to decreased performance and potential overheating. Regularly check and clean the air filters to ensure they are free from dust and debris. If the filters are damaged or excessively dirty, consider replacing them to maintain optimal air flow and prevent potential issues.

5. Regular Maintenance

Performing regular maintenance on your air compressor can help prevent future problems and extend its lifespan. This includes checking and tightening all connections, lubricating moving parts, draining condensation from the tank, and inspecting the overall condition of the compressor. Follow the manufacturer’s recommendations for maintenance intervals and procedures to keep your air compressor running smoothly.

By following these troubleshooting tips, you can address common issues with air compressors and ensure their proper functioning. If you are unsure about any repairs or maintenance tasks, it is recommended to consult a professional or refer to the manufacturer’s guidelines for assistance.

Maintaining the Unloader Valve

Proper maintenance of the unloader valve is crucial to ensure the efficient operation of your air compressor. Regular upkeep will help prevent potential issues and extend the lifespan of the valve.

Clean the Valve

To maintain the unloader valve, it is important to keep it clean and free from debris. Use a clean cloth or compressed air to remove any dirt or particles that may have accumulated on the valve. This will help prevent clogs and ensure smooth operation.

Check for Leaks

Periodically inspect the unloader valve for any leaks. A leaking valve can cause a drop in air pressure and reduce the performance of your air compressor. Use a soap and water solution to identify any leaks. If you notice any bubbles or hissing sounds, it may be an indication that the valve needs to be repaired or replaced.

Adjust the Pressure

It is important to adjust the pressure on the unloader valve to match the requirements of your air compressor. Refer to the manufacturer’s instructions or user manual for the correct pressure setting. Use a pressure gauge to measure the air pressure and make any necessary adjustments.

Replace Worn Parts

If you notice any signs of wear or damage on the unloader valve, it is important to replace the worn parts. This will help maintain the proper functioning of the valve and prevent any potential problems. Refer to the manufacturer’s instructions or consult a professional if you are unsure about replacing the parts.

Monitor Performance

Regularly monitor the performance of your air compressor to ensure that the unloader valve is working effectively. Pay attention to any unusual noises or changes in air pressure. If you notice any issues, it is important to address them promptly to prevent further damage to the valve or the compressor.

By following these maintenance tips, you can effectively maintain the unloader valve on your air compressor and ensure its optimal performance for years to come.

FAQ:

What is an unloader valve on an air compressor?

An unloader valve is a mechanism that releases pressure from the compressor’s pump head when the compressor stops. It helps prevent the compressor from starting under load and allows for an easier start-up.

Why would I need to adjust the unloader valve on my air compressor?

There are a few reasons why you might need to adjust the unloader valve on your air compressor. If the compressor is not starting properly, or if you are experiencing excessive pressure buildup in the tank, adjusting the unloader valve can help fix these issues.

How do I adjust the unloader valve on my air compressor?

The process for adjusting the unloader valve can vary depending on the specific air compressor model. However, in general, you will need to locate the unloader valve and use a wrench or other appropriate tool to make the necessary adjustments. It’s best to consult the manufacturer’s manual for specific instructions on adjusting the valve for your particular model.

What are some signs that the unloader valve on my air compressor may need adjustment?

If you notice that the compressor is struggling to start or if there is excessive pressure buildup in the tank, these may be signs that the unloader valve needs adjustment. Additionally, if you hear a hissing sound coming from the unloader valve when the compressor is not running, this could also indicate that adjustment is needed.

Video: