Choosing the Right Size Air Compressor for HVLP Spray Gun: A Comprehensive Guide

When it comes to achieving a flawless finish in spray painting, having the right air compressor is essential. For those using HVLP (High Volume Low Pressure) spray guns, choosing the correct size air compressor is crucial for achieving optimal performance and efficiency. In this comprehensive guide, we will explore the factors to consider when selecting the right size air compressor for your HVLP spray gun.

One of the main factors to consider when choosing the size of your air compressor is the air volume, also known as the CFM (Cubic Feet per Minute) rating. CFM refers to the amount of air that the compressor can provide per minute, and it directly affects the performance of your HVLP spray gun. It is important to choose an air compressor with a CFM rating that meets or exceeds the requirements of your spray gun.

Another crucial factor to consider is the air pressure, measured in PSI (Pounds per Square Inch). Different HVLP spray guns have different PSI requirements, and the air compressor you choose should be able to deliver the required pressure consistently. It is recommended to choose an air compressor with a higher PSI rating than the maximum requirement of your spray gun to ensure a steady and consistent output.

Additionally, it is important to consider the tank size of the air compressor. The tank size determines the amount of compressed air that can be stored and used before the compressor needs to refill. A larger tank size can provide a more consistent and continuous supply of compressed air, which is particularly important for longer painting sessions. However, it is also important to consider the portability and space limitations when choosing the tank size.

By considering these factors and understanding the specific requirements of your HVLP spray gun, you can choose the right size air compressor that will provide you with the necessary air volume, pressure, and storage capacity for a flawless and efficient spraying experience.

Choosing the Perfect Air Compressor Size for Your HVLP Spray Gun

Finding the right air compressor size for your High Volume Low Pressure (HVLP) spray gun is crucial to achieving high-quality results in your paint projects. The size of your air compressor directly affects the performance and efficiency of your spray gun, so it’s important to choose wisely.

To determine the perfect air compressor size for your HVLP spray gun, you need to consider two main factors: the air consumption requirements of your spray gun and the duty cycle of your air compressor.

Air Consumption Requirements of Your Spray Gun

The air consumption requirements of your HVLP spray gun are typically measured in cubic feet per minute (CFM). This refers to the amount of air that is required to properly atomize the paint and deliver a consistent spray pattern. Each HVLP spray gun model typically has a specific CFM rating that you need to take into account when choosing an air compressor.

To determine the CFM requirements of your spray gun, refer to the manufacturer’s specifications or consult the manual. It’s important to choose an air compressor with a CFM rating that matches or exceeds the requirements of your spray gun to ensure optimal performance.

Duty Cycle of Your Air Compressor

The duty cycle of your air compressor is another important factor to consider. The duty cycle refers to the amount of time the air compressor can operate continuously in a given time frame. If you plan on using your HVLP spray gun for extended periods of time, you will need an air compressor with a higher duty cycle to ensure it can keep up with the demand.

The duty cycle is usually expressed as a percentage, such as 50% or 100%. For example, a 50% duty cycle means that the air compressor can run for 30 minutes and then needs 30 minutes of rest to cool down. It’s important to choose an air compressor with a duty cycle that suits your painting needs.

Conclusion

Choosing the perfect air compressor size for your HVLP spray gun requires careful consideration of the air consumption requirements of your spray gun and the duty cycle of your air compressor. It’s important to select an air compressor with a CFM rating that meets or exceeds the requirements of your spray gun, as well as a duty cycle that can handle the demands of your painting projects. Taking these factors into account will ensure that you achieve optimal performance and efficiency with your HVLP spray gun.

The Importance of Correct Air Compressor Size

Choosing the right size air compressor is crucial when it comes to using an HVLP spray gun. The air compressor provides the necessary air pressure for the spray gun to atomize the paint or coating, allowing for a smooth and even application.

Using an air compressor that is too small for the job can result in inadequate air pressure, which can lead to poor paint atomization and a streaky or uneven finish. On the other hand, using an air compressor that is too large for the spray gun can be inefficient and wasteful, as it may consume more energy than necessary.

One of the key factors in determining the correct air compressor size for an HVLP spray gun is the required CFM (cubic feet per minute) rating. The CFM rating indicates the amount of air that the spray gun requires to function properly.

It is essential to match the CFM rating of the spray gun with the CFM output of the air compressor. If the air compressor cannot provide enough CFM, it will struggle to maintain the necessary air pressure, resulting in an inadequate spray pattern.

In addition to the CFM rating, it is also important to consider the tank size and the duty cycle of the air compressor. A larger tank size can provide a reserve of compressed air, allowing for consistent spraying without interruption. The duty cycle indicates the amount of time the air compressor can run continuously before it needs to rest. A higher duty cycle is desirable for prolonged use.

Overall, using the correct air compressor size for an HVLP spray gun is essential for achieving professional-quality results. It ensures proper paint atomization, consistent air pressure, and efficient operation. Taking the time to research and choose the right air compressor size can make a significant difference in the quality of your spray painting projects.

Understanding HVLP Spray Guns

When it comes to applying paint or other coatings to various surfaces, HVLP spray guns are a popular choice among professionals and DIY enthusiasts. HVLP stands for High Volume Low Pressure, which refers to the method of atomizing the paint and delivering it to the surface. This technology has gained popularity due to its efficiency, reduced overspray, and ability to produce a smooth and high-quality finish.

One of the key features of HVLP spray guns is the low pressure at which the paint is delivered. Unlike traditional spray guns that operate at higher pressures, HVLP guns operate at around 10 PSI (pounds per square inch) or less. This helps minimize overspray and allows for better control over the application process.

Another important aspect of HVLP spray guns is the high volume of air they use to atomize the paint. This is achieved through the use of a large air compressor that can supply a constant flow of air. The high volume of air helps to break up the paint into fine particles, ensuring a smooth and even application.

HVLP spray guns also come with a range of nozzle sizes, which can be selected based on the type of coating being used and the desired finish. Different nozzle sizes allow for different levels of control and coverage. Larger nozzles are suitable for larger areas and thicker coatings, while smaller nozzles are better suited for finer details and thinner coatings.

It is important to understand the capabilities and limitations of HVLP spray guns before choosing the right size air compressor. Factors such as the type of coating, surface area to be covered, and desired finish will influence the air compressor size and capacity needed for optimal performance. Understanding HVLP spray guns is crucial for achieving professional results and ensuring efficient and effective paint application.

Factors to Consider when Selecting Air Compressor Size

Type of HVLP Spray Gun

The type of HVLP spray gun you are using will play a significant role in determining the size of air compressor you need. Different spray guns require different amounts of air volume and pressure to operate effectively. It is important to consult the manufacturer’s specifications for your specific spray gun to determine the recommended air compressor size.

Air Volume Requirements

One of the main factors to consider when selecting the size of an air compressor for an HVLP spray gun is the air volume requirements. HVLP spray guns typically have a specified CFM (cubic feet per minute) rating. This rating indicates how much air volume the spray gun requires to operate optimally. It is crucial to choose an air compressor that can provide the necessary CFM for your spray gun.

Pressure Requirements

In addition to air volume, the pressure requirements of your HVLP spray gun are also important to consider. The spray gun will have a specified PSI (pounds per square inch) rating that indicates the amount of pressure needed to atomize the paint or finish. Your air compressor should be capable of delivering the necessary PSI to meet the requirements of the spray gun.

Tank Size

The size of the air compressor tank can affect the overall performance of your HVLP spray gun. A larger tank size allows for a more consistent air supply and can help prevent interruptions in the painting process. If you are using your spray gun for extended periods or on larger surfaces, a larger tank size may be beneficial to avoid frequent refills and maintain a steady air pressure.

Duty Cycle

The duty cycle of an air compressor refers to the amount of time it can operate continuously before needing to cool down. Depending on the size of your project and how often you plan to use the HVLP sprayer, it is important to choose an air compressor with an appropriate duty cycle. A compressor with a higher duty cycle will be able to handle longer periods of operation without overheating.

Considering these factors will help you determine the right size air compressor for your HVLP spray gun and ensure optimal performance in your painting projects.

Calculating the Required Air Volume

When selecting an air compressor for an HVLP spray gun, it is important to calculate the required air volume to ensure that the compressor can meet the needs of the gun. The air volume is typically measured in cubic feet per minute (CFM).

To calculate the required air volume, you need to know the air consumption of the HVLP spray gun. This information is usually provided by the manufacturer and can be found in the gun’s specifications or user manual.

Once you have the air consumption rate in CFM, you can then determine the minimum CFM rating for the air compressor. It is recommended to select a compressor that can deliver at least the same CFM as the gun’s air consumption rate, if not slightly higher.

Additionally, it is important to consider any other air tools or equipment that may be used simultaneously with the HVLP spray gun. If you plan to use multiple tools at once, you will need to add up the individual air consumption rates to calculate the total required CFM for the compressor.

It is worth noting that the required air volume may also depend on the size of the project and the desired spraying speed. Larger projects or faster spraying speeds may require a higher CFM rating to ensure sufficient air supply.

Matching Air Compressor CFM to HVLP Spray Gun Requirements

When choosing an air compressor for an HVLP spray gun, it is important to match the CFM (cubic feet per minute) of the air compressor to the requirements of the spray gun. CFM is a measure of the volume of air that the compressor can deliver per minute, and it is crucial to have enough CFM to properly power the spray gun.

Each HVLP spray gun has its own CFM requirement, which is typically specified by the manufacturer. It is important to check the CFM requirement of your specific spray gun before selecting an air compressor. Using an air compressor with too low CFM can result in insufficient air flow, leading to poor atomization and application of the paint or finish.

When it comes to selecting an air compressor, it is generally recommended to choose one that has a slightly higher CFM rating than the requirement of the spray gun. This is because some air will be lost due to factors such as air hoses, fittings, and filters. Having a higher CFM rating ensures that enough air will reach the spray gun, even with some loss along the way.

It is also important to consider the type of projects you will be working on with the HVLP spray gun. Larger projects that require continuous spraying may benefit from an air compressor with a higher CFM rating, as it will be able to supply a consistent flow of air. On the other hand, smaller projects may be better suited with a lower CFM rating, as long periods of continuous spraying are not required.

Overall, matching the air compressor CFM to the HVLP spray gun requirements is crucial for achieving optimal performance and results. Taking the time to research and select the right air compressor will ensure that your painting or finishing projects are done efficiently and effectively.

Common Air Compressor Sizes for HVLP Spray Guns

1. 30 Gallon Air Compressor

An air compressor with a 30-gallon tank is a common size for HVLP spray guns. This size provides enough air storage capacity to support continuous spraying without frequent interruptions for the compressor to refill. It can supply air to the spray gun at a consistent pressure, ensuring a smooth and even application of paint or coating.

A 30-gallon air compressor is suitable for small to medium-sized painting projects, such as automotive touch-ups, furniture refinishing, or cabinet painting. It is also a popular choice for hobbyist painters or DIY enthusiasts who want a reliable and versatile compressor for various household projects.

2. 60 Gallon Air Compressor

A 60-gallon air compressor is a step up in size and capacity from the 30-gallon model. It provides even more air storage, allowing for longer periods of continuous spray painting without needing to wait for the compressor to catch up. This size is ideal for larger painting projects that require a higher volume of air, such as repainting a car or tackling a large-scale home improvement project.

With its increased capacity, a 60-gallon air compressor can handle the demands of a HVLP spray gun with ease. It can deliver a consistent flow of air at the required pressure, ensuring optimal atomization and a professional finish. This size is popular among professional painters and contractors who require a reliable and powerful compressor for their work.

3. 80 Gallon Air Compressor

An 80-gallon air compressor is the largest size commonly used for HVLP spray guns. It offers the highest air storage capacity, allowing for extended periods of continuous painting without the need for the compressor to cycle on and off frequently. This size is typically reserved for heavy-duty commercial or industrial applications where large volumes of air are required.

The 80-gallon air compressor is capable of delivering a high flow rate and maintaining a stable air pressure, making it suitable for demanding spray painting jobs. It can support multiple spray guns operating simultaneously, making it a popular choice for automotive painting shops or large manufacturing facilities. This size ensures consistent performance and minimizes any potential loss in pressure during prolonged use.

In summary, the common air compressor sizes for HVLP spray guns include the 30-gallon, 60-gallon, and 80-gallon models. The choice of size depends on the scale and demands of the painting project, with smaller sizes suitable for small to medium-sized jobs and larger sizes preferred for heavy-duty or industrial applications.

Other Considerations for Air Compressor Selection

While the size of the air compressor is a crucial factor to consider when choosing one for an HVLP spray gun, there are other considerations to keep in mind as well:

Type of Spray Gun

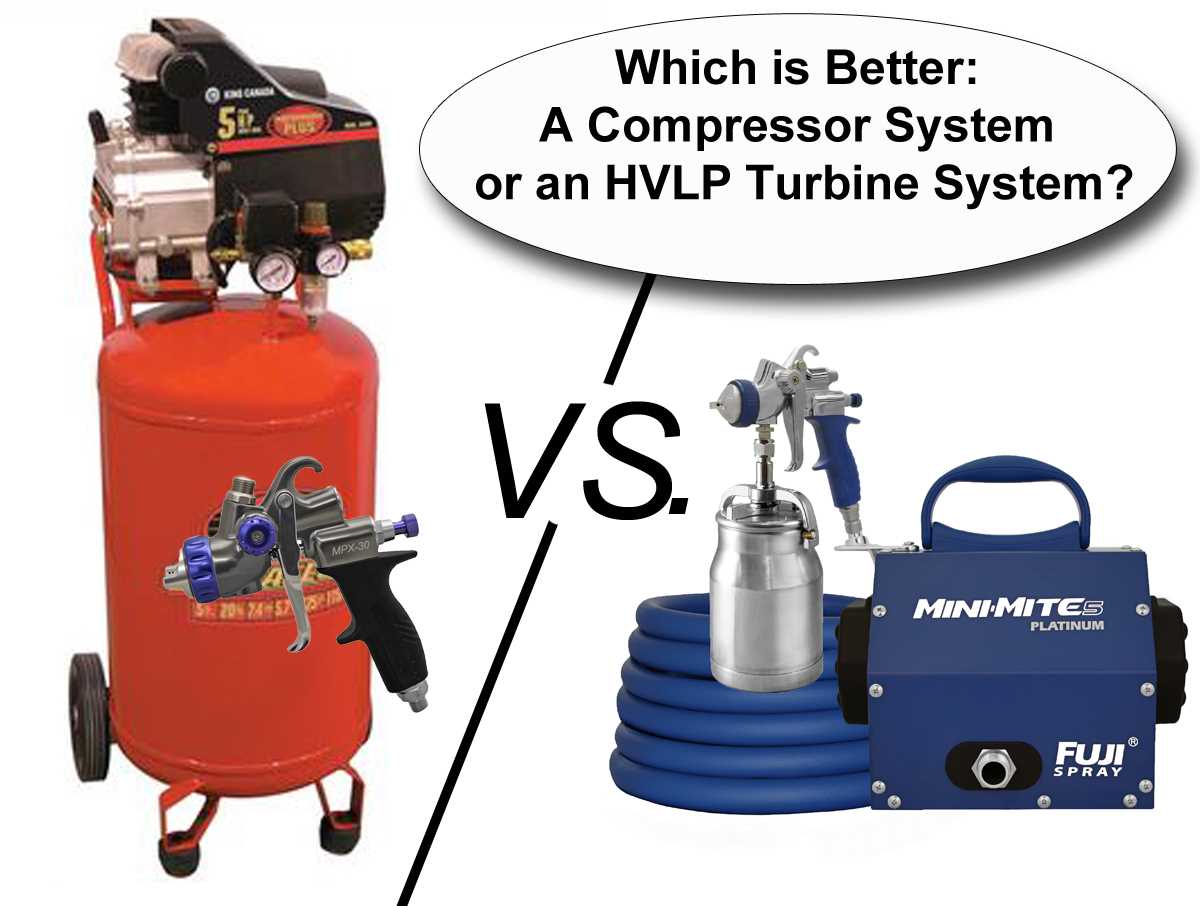

The type of spray gun you are using will affect the air compressor requirements. HVLP spray guns require less pressure and volume compared to conventional spray guns, so you may be able to use a smaller air compressor with an HVLP gun.

CFM and PSI Requirements

Pay attention to the CFM (cubic feet per minute) and PSI (pound-force per square inch) requirements of your spray gun. Make sure that the air compressor you choose can meet or exceed these requirements.

Tank Size

The size of the air compressor tank can also affect its performance. A larger tank will allow for longer periods of continuous spraying before the compressor needs to kick in and refill the tank with compressed air.

Portability

If you plan on using your air compressor in different locations or need to move it around frequently, consider the portability of the compressor. Look for models with built-in handles or wheels for easier transportation.

Noise Level

Some air compressors can be quite loud, which can be a significant factor to consider if you will be working in an enclosed space or if noise is a concern. Look for models with lower decibel ratings (dB) for a quieter working environment.

By taking these considerations into account along with the size of the air compressor, you can ensure that you choose the right air compressor for your HVLP spray gun that meets all of your specific needs.

FAQ:

What is an HVLP spray gun?

An HVLP spray gun is a type of paint sprayer that uses high-volume, low-pressure technology to atomize the paint and create a fine finish.

How does an HVLP spray gun work?

An HVLP spray gun works by using a high-volume of air at a low pressure to atomize the paint particles, creating a fine spray that can be easily controlled and applied to a surface.

What factors should be considered when choosing the right size air compressor for an HVLP spray gun?

When choosing the right size air compressor for an HVLP spray gun, you should consider factors such as the air consumption of the spray gun, the maximum pressure required, and the air storage capacity of the compressor.

How can I determine the air consumption of an HVLP spray gun?

You can determine the air consumption of an HVLP spray gun by checking the specifications provided by the manufacturer. Typically, the air consumption is measured in terms of cubic feet per minute (CFM).

What happens if the air compressor is too small for the HVLP spray gun?

If the air compressor is too small for the HVLP spray gun, it may not be able to supply enough air volume or maintain the required pressure. This can result in a poor quality finish, uneven application of paint, and an overall inefficient spraying process.

What is the recommended air pressure for an HVLP spray gun?

The recommended air pressure for an HVLP spray gun is typically between 10 and 20 psi (pounds per square inch). However, it is important to refer to the specific recommendations provided by the spray gun manufacturer.

Video: