Choosing the Right PSI: What is a Good Air Compressor Pressure?

When it comes to choosing the right air compressor for your needs, one of the crucial factors to consider is the pressure it can produce. The air compressor pressure, measured in PSI (pounds per square inch), determines the power and efficiency of the machine in delivering compressed air for various applications.

Before deciding on the appropriate PSI for your air compressor, it is essential to understand what PSI represents. PSI is a unit of measurement that indicates the force exerted by the air compressor on the air it compresses. It affects the velocity and volume of the compressed air, influencing the performance and effectiveness of tools and equipment connected to the air compressor.

Choosing the right PSI for your air compressor depends on the specific application you intend to use it for. Different tools and tasks require different levels of pressure to operate optimally. For example, pneumatic tools such as nail guns or airbrushes typically require a lower PSI, around 90-120, while heavy-duty tools like sanders or grinders may need a higher PSI ranging from 120-150.

It is important to note that using a higher PSI than necessary can lead to excessive wear and tear on tools, decreased efficiency, and increased risk of accidents. On the other hand, using a lower PSI may result in tools not performing at their best, affecting the quality and productivity of your work. It is crucial to consult the manufacturer’s guidelines and requirements for each tool or equipment to determine the appropriate PSI for optimal performance and safety.

In conclusion, choosing the right PSI for your air compressor is essential for achieving efficient and productive results in your specific applications. Consider the recommended PSI range for the tools and equipment you will be using, ensuring they operate optimally without unnecessary strain or risk. By understanding the importance of PSI and selecting the appropriate pressure, you can maximize the performance and longevity of your air compressor and associated tools.

Why PSI Matters: Understanding Air Compressor Pressure

PSI, or pounds per square inch, is a key measurement when it comes to air compressors. It refers to the amount of pressure the compressor is able to generate to power tools or equipment. Understanding the importance of PSI is essential for determining the right air compressor for your needs and ensuring proper operation and performance.

Effective Tool Operation: PSI plays a crucial role in the proper functioning of pneumatic tools. Different tools require different PSI levels to operate efficiently. Using the wrong PSI can result in decreased productivity and reduced performance. For example, if a tool requires 90 PSI and the compressor is only delivering 60 PSI, the tool may not function properly or have enough power to complete the task at hand.

Safety Considerations: PSI also affects safety when working with air compressors and pneumatic tools. Too low of a PSI can cause a tool to malfunction, while too high of a PSI can lead to an increased risk of accidents or injury due to tools or equipment becoming overpressurized. It is important to understand the PSI requirements of the tools you are using and ensure that the air compressor is delivering the appropriate pressure.

Air Tool Compatibility: Different air tools have specific PSI requirements, and using an air compressor with the wrong PSI output can result in damage to the tool or decreased lifespan. Additionally, using an air tool with a higher PSI rating than the compressor can generate may cause strain on the compressor and result in decreased efficiency and durability. Always check the manufacturer’s specifications for both the air tool and the air compressor to ensure compatibility.

Performance and Efficiency: The correct PSI also affects the overall performance and efficiency of an air compressor. An air compressor operating at its recommended PSI will be able to provide the necessary power and airflow for tools to perform optimally. Using an air compressor with too low of a PSI may lead to increased energy consumption and longer operating times, while using one with too high of a PSI may result in unnecessary wear and tear on the compressor.

Understanding the importance of PSI and its impact on air compressor operation and tool performance is essential for anyone considering purchasing or using an air compressor. By selecting an air compressor with the appropriate PSI output and properly matching it to the tools being used, you can ensure safe and efficient operation, prolong the lifespan of your tools, and achieve desired results.

What is PSI and Why Does it Matter?

The term PSI stands for pounds per square inch, and it is a unit of measurement used to quantify the pressure exerted by an air compressor. PSI is an important factor to consider when choosing an air compressor, as it determines the power and effectiveness of the tool.

The right PSI level is crucial for a variety of reasons. Firstly, it directly affects the performance of pneumatic tools. Each tool has a recommended PSI range that enables it to work efficiently. If the PSI is too low, the tool may not function properly, while if it is too high, it can cause damage to the tool or even pose a safety risk.

Additionally, PSI is also important for tasks that require specific levels of pressure, such as inflating tires, powering airbrushes, or operating paint sprayers. These tasks often have specific PSI requirements, and using the correct pressure ensures optimal results and prevents damage to the equipment.

When selecting an air compressor, it is important to consider the PSI requirements of the tools and tasks you will be using it for. It is recommended to choose a compressor with a PSI rating that falls within the recommended range of your tools and applications. Some compressors have adjustable PSI settings, allowing you to customize the pressure based on your needs.

Choosing the Right PSI for Your Needs

When it comes to choosing the right PSI for your needs, it’s important to consider the specific applications you will be using your air compressor for. Different tasks require different levels of pressure, so it’s essential to determine the appropriate PSI range for your intended use.

Determining the PSI Range

To determine the PSI range that is suitable for your needs, you should first consider the equipment or tools you’ll be using. Each tool typically has a recommended PSI range that is necessary for optimal performance and safety. Consult the manufacturer’s guidelines or the tool’s user manual to identify the recommended pressure range.

It’s also important to consider the material you’ll be working with. For example, if you’ll be using your air compressor for painting, different types of paint may require different pressure levels. Consult the paint manufacturer’s recommendations to ensure you’re using the correct PSI for the specific paint you’re working with.

Finding the Right Balance

While it’s important to match the appropriate PSI range for your equipment and applications, it’s also crucial to find the right balance. Higher pressure doesn’t always mean better performance, as excessive pressure can lead to damage or accidents. On the other hand, insufficient pressure may result in ineffective operation.

Consider the specific task at hand and any potential safety concerns. If you’re unsure about the appropriate PSI for your needs, consider consulting with a professional or seeking advice from experienced users in forums or community groups.

Remember that it’s always better to err on the side of caution and choose a lower PSI, as you can always increase the pressure if necessary. Regularly monitor and adjust the PSI as needed to ensure optimal performance and safety.

Final Thoughts

Choosing the right PSI for your needs is essential for efficient and safe operation of your air compressor. Take into account the recommended PSI ranges provided by manufacturers and the specific requirements of your applications. Finding the right balance between pressure and performance will help you achieve the best results while protecting your equipment and ensuring your safety.

Factors to Consider When Determining PSI

When determining the appropriate PSI for an air compressor, there are several factors that need to be taken into consideration:

- Type of application: The type of application will greatly influence the PSI requirements. For example, a nail gun typically requires a lower PSI than a sandblaster. It is important to match the PSI to the specific application to ensure optimal performance.

- Tool requirements: Different tools have different PSI requirements. Before choosing a PSI setting, it is essential to check the manufacturer’s recommendation for the specific tool being used. This will help to prevent any damage to the tool or reduce the risk of accidents.

- Airflow capacity: The airflow capacity of an air compressor is another important consideration. The greater the airflow capacity, the higher the PSI the compressor can deliver. It is important to choose a compressor with adequate airflow capacity to meet the demands of the intended applications.

- Hose length: The length of the hose can affect the PSI delivered to the tool. Longer hoses can cause a drop in pressure, so it is important to factor in the hose length when determining the appropriate PSI setting.

- Environmental conditions: The environmental conditions in which the air compressor will be used should also be considered. Cold temperatures can affect the performance of an air compressor, so the PSI setting may need to be adjusted accordingly. Similarly, high altitude locations may require a higher PSI setting due to reduced air density.

By taking into account these factors when determining the PSI for an air compressor, you can ensure that you select the appropriate pressure for your specific needs. This will help to optimize performance, prolong the lifespan of tools, and ensure safety during operation.

PSI Requirements for Different Applications

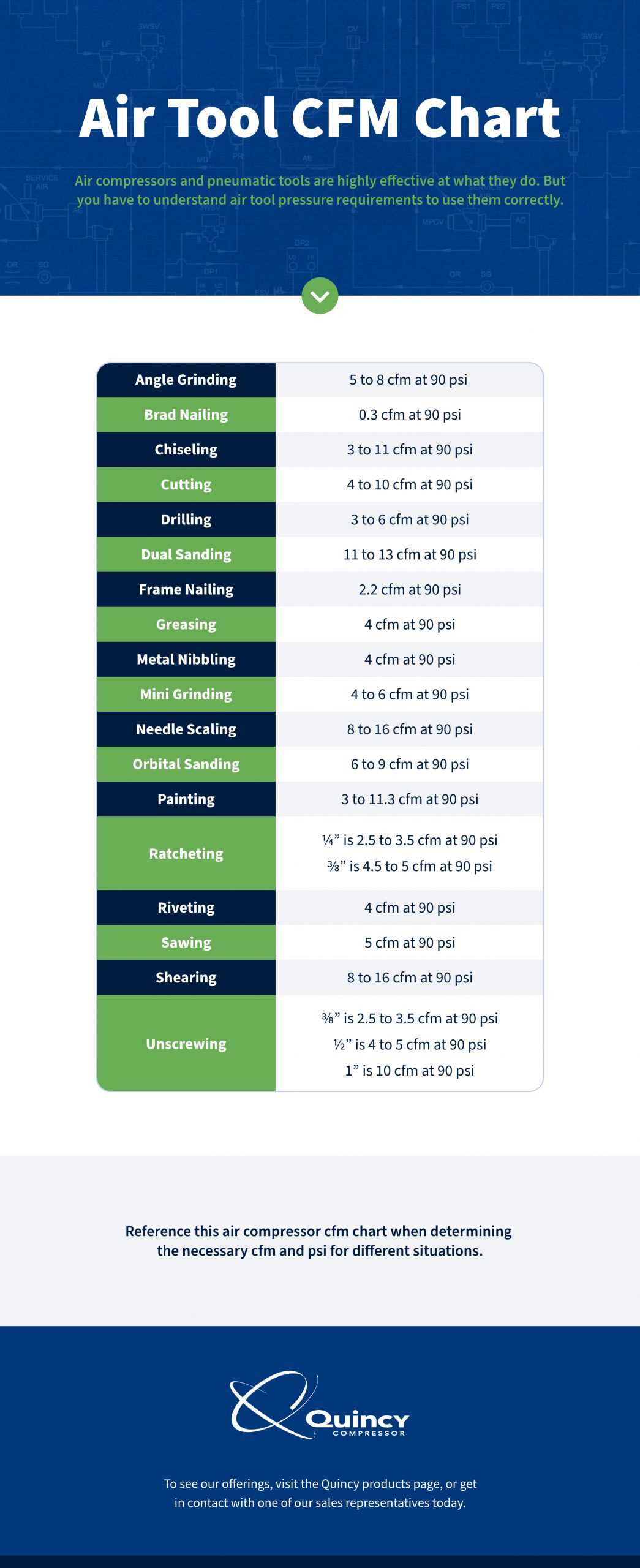

When choosing an air compressor, it is important to consider the specific PSI requirements of the application you will be using it for. Different tools and equipment have different PSI needs, and using the wrong pressure can result in inefficient or ineffective operation. Below are some common applications and their recommended PSI ranges:

Tire Inflation

When inflating tires, the PSI requirement will depend on the size and type of tire. Passenger car tires typically require a PSI between 30 and 40, while larger vehicle tires may require up to 100 PSI. It is important to check the recommended PSI for your specific tires and adjust the air compressor accordingly.

Painting

Painting is another application that requires specific PSI settings. Most paint guns have a recommended PSI range that should be followed for optimal results. Generally, for automotive painting, a PSI of around 20 to 30 is recommended, while for other painting tasks, a PSI between 30 and 50 may be more suitable. It is important to refer to the paint gun manufacturer’s guidelines for the exact PSI requirements.

Power Tools

Power tools such as nail guns, drills, and impact wrenches also have specific PSI requirements. These requirements can vary depending on the tool and the task at hand. For example, a typical nail gun may require a PSI between 70 and 100, while an impact wrench may require a PSI between 90 and 120. It is important to consult the tool’s user manual or manufacturer’s guidelines for the recommended PSI settings.

Spraying and Cleaning

Spraying and cleaning applications, such as pressure washers or spray guns, also have specific PSI requirements. For pressure washers, the recommended PSI can range from 1000 to 4000, depending on the task and the surface being cleaned. For spray guns used in cleaning or disinfecting applications, a PSI between 40 and 60 is often recommended. Again, it is important to refer to the manufacturer’s guidelines for the specific PSI requirements.

By understanding the specific PSI requirements for different applications, you can ensure that you choose an air compressor that is capable of delivering the necessary pressure. Always consult the tools or equipment manuals and guidelines to determine the recommended PSI settings for optimal performance and efficiency.

The Effects of Incorrect PSI Setting

Choosing the correct PSI setting for your air compressor is crucial to ensure optimal performance and safety. Setting the pressure too low or too high can have various negative effects.

- Inefficient operation: If the PSI setting is too low, the air compressor will struggle to deliver the required air volume for the tasks at hand. This can lead to decreased productivity and increased energy consumption.

- Poor tool performance: Incorrect PSI settings can lead to poor tool performance. If the pressure is too low, the tools may not have enough power to perform efficiently. On the other hand, if the pressure is too high, the tools may malfunction or even break due to excessive force.

- Increased risk of accidents: Improper PSI settings can increase the risk of accidents. If the pressure is too high, there is a higher risk of air hoses bursting or tools becoming uncontrollable. This can lead to injuries to the operator or those nearby.

- Damaged materials: Using the wrong PSI setting can also result in damaged materials. If the pressure is too high, delicate materials can be crushed or distorted. On the other hand, if the pressure is too low, materials may not be properly fastened or sealed, leading to leaks or structural failures.

It is important to carefully consider the PSI requirements of your specific applications and adjust the settings accordingly. Regularly check and maintain the air compressor to ensure it is operating within the recommended PSI range. By doing so, you can ensure efficient and safe operation, prolong the lifespan of your equipment, and achieve the desired results in your projects.

Maintaining Optimal PSI Levels

In order to prolong the lifespan of your air compressor and ensure optimal performance, it is crucial to maintain the appropriate PSI levels. Here are a few key steps to help you in this process:

1. Regularly Check and Adjust the PSI

It is important to regularly check the PSI levels of your air compressor to ensure they are within the recommended range. By using a reliable pressure gauge, you can easily monitor the pressure and make any necessary adjustments. Be sure to follow the manufacturer’s guidelines for the ideal PSI for your specific compressor model.

2. Keep an Eye on Air Leaks

Air leaks can cause a drop in PSI, leading to decreased performance and efficiency of your air compressor. Regularly inspect the hoses, fittings, and connections for any signs of leaks. If you detect any leaks, promptly repair or replace the affected parts to maintain the optimal PSI levels.

3. Clean and Replace Air Filters

Clogged or dirty air filters can restrict airflow and put additional strain on your air compressor. This can result in decreased PSI levels and reduced performance. Regularly clean or replace the air filters as recommended by the manufacturer to ensure proper airflow and maintain optimal PSI levels.

4. Keep the Compressor Properly Lubricated

Proper lubrication is essential for the smooth operation of your air compressor and maintaining the optimal PSI levels. Refer to the manufacturer’s instructions for the recommended lubrication schedule and use the appropriate lubricant. Be sure to check the oil level regularly and change it when necessary to prevent any issues with the compressor’s performance.

By following these steps and regularly maintaining the PSI levels of your air compressor, you can ensure efficient and reliable operation, prolong the lifespan of your equipment, and achieve the best results for your air-powered tools and applications.

Common Questions About Air Compressor Pressure

1. What is the optimal air compressor pressure for my tools?

Each tool has its own specific air pressure requirements, which are typically provided by the manufacturer. It is important to use the recommended air pressure for optimal tool performance and to prevent damage or malfunction. Using too high or too low pressure can lead to inefficiency and potential safety hazards.

2. How do I determine the correct air pressure for my air compressor?

To determine the correct air pressure for your air compressor, refer to the tool’s manual or packaging. The manufacturer will typically provide a recommended operating pressure range. It is important to use a pressure gauge to monitor and adjust the air pressure accordingly. Adjustments should be made based on the specific task or tool being used.

3. Can I use a higher or lower air pressure than recommended for my tools?

Using a higher air pressure than recommended can lead to excess strain on the tool, which can result in damage or reduced performance. On the other hand, using a lower air pressure than recommended may result in insufficient power to operate the tool effectively. It is best to stick to the recommended pressure range for optimal tool performance and longevity.

4. What are the safety considerations when working with air compressor pressure?

Working with air compressor pressure requires following certain safety guidelines. It is important to wear proper protective gear, such as safety glasses and ear protection, when operating air tools. Additionally, regular maintenance of the air compressor and its components is crucial to ensure safe operation. Always consult the manufacturer’s instructions and guidelines for specific safety measures.

5. Can I adjust the air pressure on my air compressor?

Most air compressors have an adjustable pressure setting that allows users to regulate the output according to their needs. This feature allows for flexibility when using a variety of tools with different pressure requirements. It is important to adjust the pressure within the recommended range for each specific tool to ensure optimal performance and avoid potential damage.

6. What are the consequences of using incorrect air compressor pressure?

Using incorrect air compressor pressure can have several negative consequences. Using too high pressure can lead to accelerated wear and tear on tools, increased risk of accidents, and decreased tool lifespan. Using too low pressure can result in diminished power and efficiency, potentially causing tasks to take longer or become more difficult. It is best to adhere to the recommended pressure range for each specific tool to avoid these issues.

Final Thoughts on Selecting the Right PSI

When it comes to choosing the right PSI for your air compressor, there are a few key factors to consider. First and foremost, you need to think about the type of work you will be doing with the compressor. Different tasks require different levels of pressure, so it’s important to match the PSI to your specific needs.

Another important factor to consider is the capacity of your air tools. Each tool has a recommended operating PSI range, and you want to make sure your compressor can meet those requirements. Using a compressor with a PSI that is too low or too high for your tools can result in inefficient performance and potential damage.

It’s also worth noting that higher PSI levels can lead to increased wear and tear on your air tools and compressor. If you’re using a compressor with a higher PSI than necessary, you may be putting unnecessary strain on your equipment. On the other hand, using a compressor with too low of a PSI can result in reduced tool performance and slower task completion.

Lastly, don’t forget to consider any future needs you may have. If you anticipate expanding your tool collection or taking on more demanding projects in the future, it’s a good idea to choose a compressor with a higher PSI capacity. This way, you’ll be prepared for any future tasks that require additional pressure.

In conclusion, selecting the right PSI for your air compressor is crucial for achieving optimal performance and efficiency. By considering factors such as your specific tasks, tool requirements, potential wear and tear, and future needs, you can make an informed decision that will ensure successful air compressor operation for years to come.

FAQ:

What does PSI mean in the context of air compressors?

PSI stands for pounds per square inch and it is the unit used to measure air compressor pressure.

What is the recommended PSI for most air compressors?

The recommended PSI for most air compressors is between 90 and 120 PSI. However, it is important to check the manufacturer’s specifications for your specific model.

Can I use a higher PSI than recommended for my air compressor?

No, it is not recommended to use a higher PSI than recommended for your air compressor. Doing so can put unnecessary strain on the compressor and may lead to damage or failure.

What can happen if the air compressor pressure is too low?

If the air compressor pressure is too low, it can lead to poor performance and inefficient operation. The tools and equipment connected to the compressor may not work properly and may require higher pressure to function effectively.

Video: