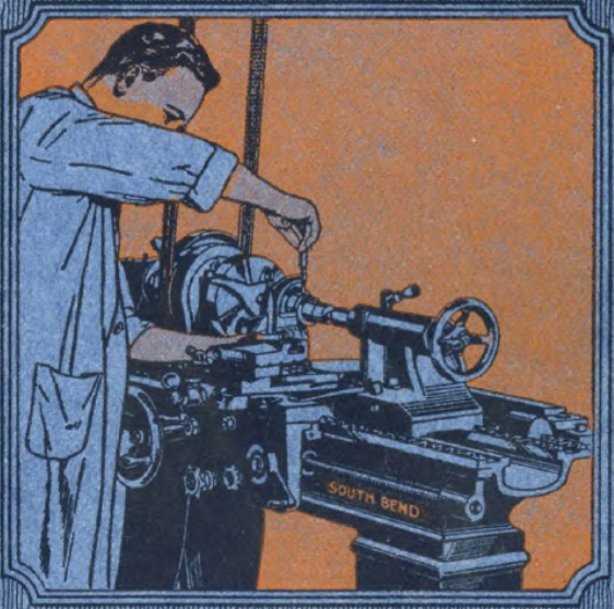

Learn How to Run a Lathe with South Bend PDF Guide

Running a lathe can be a daunting task, especially for beginners. However, with the help of the South Bend PDF Guide, you can learn the ins and outs of operating this versatile machine. Whether you’re a hobbyist looking to enhance your skills or a professional in need of a refresher, this guide will provide you with all the information you need to confidently use a lathe.

The South Bend PDF Guide covers everything from the basic components of a lathe to advanced techniques for machining. You’ll learn how to properly set up your lathe, select the right tools, and adjust the speed and direction of the spindle. The guide also provides step-by-step instructions for a variety of lathe operations, including turning, facing, threading, and boring. With this comprehensive resource, you’ll be able to tackle a wide range of projects with ease.

One of the great advantages of the South Bend PDF Guide is that it is accessible and easy to understand. The guide uses clear and concise language, accompanied by detailed illustrations and diagrams, to ensure that even the most complex concepts are explained in a straightforward manner. Whether you’re a visual learner or prefer to read instructions, this guide caters to your learning style.

Furthermore, the South Bend PDF Guide goes beyond the basics and provides valuable tips and tricks from experienced lathe operators. You’ll learn how to troubleshoot common issues, choose the right cutting tools for different materials, and achieve the highest level of precision in your work. With the help of this guide, you’ll gain the knowledge and confidence to take your lathe skills to the next level.

Whether you’re a beginner or an experienced lathe operator, the South Bend PDF Guide is an indispensable tool for mastering the art of running a lathe. With its comprehensive coverage of all aspects of lathe operation, this guide will help you become a more skilled and confident operator. Get your hands on the South Bend PDF Guide today and take your lathe skills to new heights!

The Basics of Running a Lathe

Introduction

Running a lathe is a fundamental skill for any machinist or metalworker. It is a versatile machine that can be used to shape and cut various materials such as wood, metal, and plastic. This guide will cover the basic steps and techniques to effectively run a lathe, using the South Bend lathe as an example. Whether you are a beginner or an experienced operator, this guide will provide valuable insights and tips to improve your lathe skills.

Safety Precautions

Before operating a lathe, it is important to ensure your safety. Here are some essential safety precautions to follow:

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection.

- Securely fasten your workpiece and wear an apron to protect yourself from flying chips and debris.

- Keep the lathe clean and free from clutter to prevent accidents and maintain optimal operation.

- Never leave the lathe unattended while it is running.

Parts of a Lathe

Before learning how to run a lathe, it is important to familiarize yourself with its different parts. Here are the main components of a lathe:

- Headstock: Contains the spindle and gears, which spin the workpiece.

- Tailstock: Provides support for the other end of the workpiece and can be used to hold tools and accessories.

- Carriage: Moves along the bed and houses the cutting tool.

- Cross slide: Allows the cutting tool to move across the workpiece vertically.

- Compound rest: Permits the cutting tool to make angled cuts.

- Chuck: Holds the workpiece securely in place.

Steps to Run a Lathe

Now let’s dive into the basic steps to run a lathe:

- Inspect the lathe and ensure it is in good working condition.

- Select the appropriate cutting tool for the desired operation.

- Securely mount the workpiece in the chuck or collet.

- Set the lathe to the desired speed and adjust the feed rate.

- Position the cutting tool at the desired starting point.

- Engage the lathe and slowly feed the cutting tool into the workpiece.

- Make precise and controlled cuts, adjusting the tool position and feed rate as necessary.

- Monitor the lathe and the cutting process, ensuring optimal performance.

- Once the desired shape or cut is achieved, disengage the lathe and safely remove the workpiece.

- Clean the lathe and the workspace, removing any chips or debris.

Tips and Tricks

Here are some additional tips and tricks to improve your lathe operation:

- Always use sharp cutting tools to achieve clean and accurate cuts.

- Take small cuts and gradually increase the depth of the cut for better control.

- Use cutting fluids to lubricate and cool the cutting tool and workpiece.

- Regularly check and maintain the lathe, ensuring proper alignment and lubrication.

- Practice proper tool positioning and feed rates to achieve the desired results.

- Seek guidance from experienced operators or attend training programs to enhance your lathe skills.

Conclusion

Running a lathe requires practice, knowledge, and attention to detail. By following the basic steps and safety precautions outlined in this guide, you will be able to effectively operate a lathe and produce high-quality work. Continuous learning and experience will further improve your lathe skills, enabling you to tackle more complex projects. So, get started and enjoy the endless possibilities of running a lathe with the South Bend PDF Guide.

Why Learn How to Run a Lathe?

There are several reasons why learning how to run a lathe is a valuable skill. Whether you are a DIY enthusiast, a professional machinist, or simply interested in learning a new skill, operating a lathe can provide numerous benefits.

1. Versatility and Efficiency

A lathe is a versatile and powerful machine that can shape, cut, and drill various materials such as wood, metal, and plastics. By learning how to operate a lathe, you gain the ability to create or repair a wide range of objects, from furniture and decorative items to machinery and tools. Using a lathe also allows you to achieve precise and accurate results, making your work more efficient.

2. Cost Savings

Knowing how to run a lathe can save you money in multiple ways. Firstly, being able to repair and maintain your own items can significantly reduce the costs of hiring a professional or buying new replacements. Secondly, if you are skilled enough, you can even create unique and customized objects instead of purchasing them. Additionally, the market for lathe work is highly in demand, so having this skill can potentially provide you with an additional source of income.

3. Creative Expression

Operating a lathe allows you to unleash your creativity and artistic side. Whether you enjoy woodworking or metalworking, a lathe can turn your ideas into reality. From crafting intricate designs and patterns to sculpting beautiful shapes, a lathe offers endless possibilities for expressing your unique style and vision.

4. Career Opportunities

Learning how to run a lathe opens up a variety of career opportunities in the machining and manufacturing industries. Skilled lathe operators are in high demand, and having this skill can make you a valuable asset to companies and organizations that rely on precision machining. Whether you are interested in starting your own business or working for established companies, knowing how to run a lathe can help you advance in your career.

5. Personal Growth and Learning

Lastly, learning how to run a lathe is an opportunity for personal growth and continuous learning. Mastering this skill requires patience, practice, and dedication. By developing these qualities, you can enhance your problem-solving abilities, attention to detail, and overall craftsmanship. Moreover, acquiring new skills and knowledge is intellectually stimulating and can boost your confidence and self-esteem.

Conclusion:

Whether your goal is to pursue a career in machining, save money on repairs, or simply enjoy the satisfaction of creating something with your own hands, learning how to run a lathe is a valuable and rewarding endeavor. It provides you with practical skills, cost-saving opportunities, creative outlets, and personal growth. So why wait? Start expanding your horizons and discover the world of lathe operation today!

Getting Started with South Bend Lathe

Introduction

Welcome to the beginner’s guide to using a South Bend Lathe. This guide will walk you through the necessary steps to get started with your lathe and provide you with some basic knowledge to help you successfully operate it.

Step 1: Familiarize Yourself with the Lathe

Before you start using the lathe, it’s important to familiarize yourself with its various parts and components. Take some time to study the lathe’s manual and understand its functions. Pay special attention to safety instructions to ensure you operate the lathe in a safe manner.

Step 2: Prepare the Lathe

Once you are comfortable with the lathe, ensure that it is properly set up and ready to use. Check the lathe for any loose parts or damage. Make sure the lathe is securely mounted on a stable work surface and the power supply is connected and functioning correctly.

Step 3: Select the Right Tooling

Choose the appropriate tooling for the job you wish to perform on the lathe. This includes selecting the correct cutting tools, tool holders, and workholding devices. Refer to the lathe’s manual for guidance on selecting the right tooling for your specific task.

Step 4: Set up the Workpiece

Securely mount the workpiece on the lathe’s chuck or collet. Ensure that the workpiece is properly aligned and centered to avoid any issues during machining. Use appropriate workholding devices, such as jaws or clamps, if necessary.

Step 5: Adjust the Lathe Settings

Adjust the lathe settings, such as spindle speed, feed rate, and depth of cut, according to the requirements of your machining task. Refer to the lathe’s manual for guidance on how to make these adjustments.

Step 6: Start Machining

With the lathe set up and the workpiece securely in place, you are ready to start machining. Begin the machining process by slowly feeding the cutting tool into the workpiece, making sure to maintain a consistent feed rate and depth of cut.

Step 7: Monitor the Machining Process

Continuously monitor the machining process to ensure that everything is running smoothly. Check for any abnormalities, such as excessive vibration or unusual sounds. Make any necessary adjustments to the lathe settings or tooling if needed.

Step 8: Complete the Machining

Once you have completed the machining process, carefully remove the workpiece from the lathe. Inspect the machined surface for any defects or errors. Use appropriate measuring tools to verify the dimensions and accuracy of the machined part.

Step 9: Clean and Maintain the Lathe

After each use, clean the lathe and make sure to remove any chips or debris. Regularly inspect and maintain the lathe to ensure its optimal performance. Refer to the lathe’s manual for specific maintenance instructions.

Conclusion

By following these steps and practicing regularly, you will gain confidence in operating a South Bend Lathe. Remember to always prioritize safety and never hesitate to seek assistance or further guidance if needed. Happy machining!

The Importance of a PDF Guide

A PDF guide is an essential tool for learning how to run a lathe with South Bend. It provides a comprehensive and easy-to-understand resource that allows users to quickly grasp the various concepts and techniques involved in operating a lathe.

Clear and Concise Instructions: A PDF guide offers step-by-step instructions with detailed explanations, making it easier for users to follow along and understand the process. This ensures that learners can quickly acquire the necessary skills to operate a lathe effectively.

Visual Representation: PDF guides often include visual representations such as diagrams, illustrations, and photographs. These visuals help learners visualize the different parts of the lathe, understand how they work together, and how to properly use them. Visual aids also make it easier to troubleshoot any issues that may arise during the lathe operation.

Comprehensive Content: A PDF guide for running a lathe with South Bend typically covers a wide range of topics, including safety precautions, lathe components, tool selection, setup, and cutting techniques. This comprehensive content ensures that users have access to all the necessary information for successful lathe operations.

Accessible Anytime, Anywhere: PDF guides are easily accessible on various devices, such as computers, tablets, and smartphones. This allows users to refer to the guide whenever and wherever they need, making it convenient for both beginners and experienced lathe operators to refresh their knowledge or seek guidance on specific topics.

Portable and Print-Friendly: Unlike online tutorials or videos, a PDF guide can be easily downloaded, saved, and printed. This makes it a portable resource that can be carried to the workshop or any other location. Additionally, learners can use the printed guide as a quick reference while operating the lathe, enhancing their efficiency and productivity.

Cost and Time Effective: Many PDF guides for running a lathe with South Bend are available for free or at a nominal cost. This makes them an affordable alternative to expensive training courses or workshops. Furthermore, learning with a PDF guide saves time that would otherwise be spent attending classes, allowing learners to progress at their own pace.

In conclusion, a PDF guide is an invaluable resource for anyone looking to learn how to run a lathe with South Bend. Its clear instructions, visual representation, comprehensive content, accessibility, portability, and cost-effectiveness make it a must-have tool for both beginners and experienced lathe operators.

Understanding Lathe Tools and Accessories

1. Cutting Tools

Cutting tools are one of the most essential accessories for a lathe machine. They are used to shape and cut the material being turned on the lathe. Some common types of cutting tools include:

- Turning Tools: These tools are used to remove material from the workpiece, creating various shapes and contours.

- Chamfering and Deburring Tools: These tools are used to remove sharp edges and burrs from the workpiece.

- Threading Tools: These tools are used to create threads on the workpiece, allowing for the attachment of nuts, bolts, or other threaded components.

2. Lathe Chucks

A lathe chuck is a device used to securely hold the workpiece in place while it is being turned. Chucks typically have jaws that can be adjusted to accommodate different sizes and shapes of workpieces. There are various types of lathe chucks, including:

- Three-Jaw Chuck: This type of chuck has three jaws that can be adjusted simultaneously, providing excellent gripping strength for round workpieces.

- Four-Jaw Chuck: This type of chuck has four independently adjustable jaws, allowing for more flexibility in gripping different shapes and sizes.

- Collet Chuck: A collet chuck uses a collet to hold the workpiece securely. It is commonly used for small and delicate workpieces.

3. Tool Holders

Tool holders are accessories that secure the cutting tools in place on the lathe machine. They provide stability and proper alignment for efficient and accurate machining. Some common types of tool holders include:

- Quick-Change Tool Post: This type of tool holder allows for the rapid change of cutting tools, minimizing downtime between operations.

- Turning Tool Holder: This holder is specifically designed to hold turning tools, allowing for precise and controlled cutting operations.

- Parting Tool Holder: This holder is used for parting off operations, where a groove or cut is made to separate the workpiece into two pieces.

4. Tailstock

The tailstock is a movable part of the lathe machine that supports the workpiece from the opposite end of the headstock. It helps to stabilize long workpieces and provides additional support during machining operations. The tailstock can be adjusted for different workpiece lengths and can be equipped with accessories such as live centers or drill chucks.

5. Centers

Centers are used in the tailstock for supporting the workpiece during turning operations. There are two main types of centers:

- Dead Center: A dead center is a stationary center that does not rotate with the workpiece. It provides support without adding rotation.

- Live Center: A live center has bearings that allow it to rotate with the workpiece, reducing friction and heat buildup.

6. Scales and Dials

Scales and dials on a lathe machine are used for accurate measurement and positioning. They help to ensure precise machining operations by providing feedback on the movement of the cutting tools and the workpiece. Some common scales and dials found on a lathe machine include:

- Compound Rest Dial: This dial is used to control the movement of the compound rest, allowing for precise angular adjustments.

- Carriage Stop Dial: This dial is used to set the position of the carriage stop, which limits the travel of the carriage during turning operations.

- Thread Dial: This dial is used to engage the leadscrew for threading operations, ensuring accurate pitch and thread depth.

7. Coolant System

A coolant system is often an essential accessory for lathe machines, especially when machining materials that generate heat or require lubrication. The coolant system helps to cool the workpiece and cutting tools, reducing friction, heat, and tool wear. It also helps to clear away chips and debris for a cleaner machining process.

Conclusion

Understanding the various tools and accessories available for lathe machines is crucial for efficient and accurate machining operations. By having a good knowledge of these tools, you can select the appropriate accessories for your specific machining needs and improve the overall performance of your lathe machine.

Step-by-Step Guide to Operating a Lathe

1. Familiarize Yourself with the Lathe

Before you start operating a lathe, it’s important to have a good understanding of the machine. Take the time to read the instruction manual and familiarize yourself with the different components and controls of the machine. This will help you operate the lathe safely and efficiently.

2. Wear Proper Safety Gear

Always wear the appropriate safety gear when operating a lathe. This includes safety glasses, ear protection, and gloves. Make sure your clothing is not loose and can’t get caught in the lathe’s moving parts.

3. Prepare the Lathe

Before turning on the lathe, make sure it is properly set up. Check that all the necessary tools and accessories are in place and that the lathe is clean and free of debris. Make any adjustments needed to ensure the lathe is properly aligned.

4. Secure the Workpiece

Place the workpiece securely in the lathe’s chuck or between centers, depending on the type of work being done. Make sure the workpiece is properly centered and tightened in place to prevent it from moving during operation.

5. Set the Speed and Feed Rate

Choose the appropriate speed and feed rate for the job. This will depend on the type of material being machined and the desired outcome. Refer to the lathe’s instruction manual or consult with an experienced operator for guidance on determining the correct settings.

6. Start the Lathe

Once everything is set up and ready to go, turn on the lathe. Make sure all the safety features are engaged, such as the emergency stop button and interlocks, before starting the machine.

7. Begin Machining

Use the lathe’s controls to guide the cutting tool along the workpiece. Take small, gradual cuts to remove material and create the desired shape or finish. Pay attention to the cutting tool’s position and the feed rate to ensure a smooth and accurate cut.

8. Monitor the Operation

Throughout the machining process, keep an eye on the lathe and the workpiece. Check for any signs of vibration, unusual noises, or excessive heat. Adjust the cutting parameters as needed to achieve the desired result and maintain optimal machine performance.

9. Complete the Machining

Once the machining is done, turn off the lathe and wait for it to come to a complete stop before removing the workpiece. Use proper techniques and tools to unclamp or unmount the workpiece, taking care not to damage it or injure yourself.

10. Clean Up and Maintenance

After using the lathe, clean up any chips, dust, or debris that may have accumulated. Lubricate the machine as necessary and perform any routine maintenance tasks recommended by the manufacturer. This will help keep the lathe in good working condition and prolong its lifespan.

Remember, practice makes perfect when it comes to operating a lathe. Take the time to gain experience and refine your skills, and always prioritize safety throughout the process.

Safety Measures while Running a Lathe

Introduction

Operating a lathe can be dangerous if proper safety measures are not followed. It is crucial to prioritize safety while working with this machinery to prevent accidents and injuries. This section outlines some essential safety measures that should be taken when running a lathe.

1. Wear Personal Protective Equipment (PPE)

Always wear appropriate Personal Protective Equipment (PPE) when operating a lathe. This typically includes safety glasses, ear protection, safety gloves, and a protective apron. PPE helps protect against flying debris, noise exposure, and potential contact with hot or sharp objects.

2. Secure the Workpiece

Before starting the lathe, ensure that the workpiece is securely clamped or held in a chuck. This helps prevent it from being dislodged during operation, reducing the risk of accidents caused by a loose or shifting workpiece.

3. Monitor the Speed and Power

Be aware of the speed and power settings on the lathe. Adjust them according to the specific requirements of the job being performed. Always start the lathe at a low speed and gradually increase it as needed, taking care to maintain control of the workpiece at all times.

4. Keep the Workspace Clean and Organized

Maintain a clean and organized workspace to minimize the risk of tripping or slipping. Remove any debris or clutter that could obstruct movement around the lathe. Keep all tools, equipment, and materials neatly organized to prevent accidents or injuries caused by stumbling or falling.

5. Avoid Loose Clothing and Jewelry

Avoid wearing loose clothing or jewelry that could get caught in the lathe’s moving parts. Loose clothing or accessories pose a significant risk of entanglement and can lead to severe injuries. It is essential to wear appropriate attire that fits close to the body and does not pose any hazards.

6. Stay Focused and Alert

Always remain focused and alert while operating a lathe. Avoid distractions and never operate the machinery while under the influence of drugs or alcohol. Pay attention to the task at hand and be aware of any unusual noises, vibrations, or signs of malfunction that may indicate a safety issue.

7. Use Tools Correctly

Use the correct tools for the job and handle them with care. Ensure all cutting tools are sharp and properly secured. Do not force tools or apply excessive pressure, as this can lead to tool breakage or the workpiece being thrown out of the lathe. Always follow the manufacturer’s recommendations for tool usage.

8. Know the Emergency Stops

Familiarize yourself with the emergency stop mechanisms of the lathe, including the location of the stop button and other safety features. In case of an emergency or if an accident is about to occur, quickly and confidently activate the emergency stop to halt the lathe’s operation.

9. Regular Maintenance and Inspection

Perform regular maintenance and inspection on the lathe to ensure it is in proper working condition. Check for any loose or damaged parts, abnormal noises, or signs of wear. Lubricate moving parts as recommended by the manufacturer. Keeping the lathe well-maintained helps prevent accidents caused by equipment failure or malfunction.

10. Receive Proper Training

Ensure you have received proper training on how to operate a lathe before attempting to use one. Familiarize yourself with the lathe’s features, controls, and safety precautions. If you are unsure about any aspect of operating the lathe, seek guidance from a professional or experienced operator.

By following these safety measures, you can minimize the risk of accidents while running a lathe and protect yourself from serious injuries. Safety should always be the top priority to ensure a safe and productive work environment.

Troubleshooting Common Lathe Issues

1. Lathe not turning on

If your lathe is not turning on, there are a few things you can check:

- Make sure the lathe is plugged in and the power switch is turned on.

- Check the fuse or circuit breaker to ensure it hasn’t tripped.

- Inspect the power cord for any damage, and replace if necessary.

- If everything appears to be in order, the motor may be faulty and should be inspected by a professional.

2. Poor surface finish

If you are getting a poor surface finish on your lathe, consider the following:

- Check the sharpness of your cutting tool. Dull tools can result in a rough finish.

- Ensure the workpiece is properly centered and aligned. Misalignment can cause vibrations and affect the surface finish.

- Check the lathe speed. Too high or too low of a speed can also affect the finish. Consult the lathe’s manual for recommended speeds.

- Inspect the tool’s cutting edge and make sure it is properly ground and sharpened.

3. Chatter or vibration

If your lathe is experiencing chatter or vibration, try the following troubleshooting steps:

- Check the workpiece and ensure it is secured properly. Loose workpieces can cause vibration.

- Inspect the lathe’s tool rest and make sure it is securely tightened in place.

- Check the lathe’s leveling and alignment. Adjust as necessary to eliminate any potential sources of vibration.

- Examine the cutting tool and make sure it is properly sharpened and balanced.

4. Excessive heat

If you notice excessive heat while using your lathe, follow these steps:

- Check the lubrication of the lathe. Insufficient lubrication can cause excessive heat.

- Ensure the workpiece is properly cooled during the machining process.

- Inspect the lathe’s cooling system and clean or replace any clogged filters or hoses.

- Check the lathe’s speed. Running the lathe at too high of a speed can generate excess heat.

5. Problems with threading

If you are experiencing issues with threading on your lathe, try the following:

- Check the lathe’s threading gears and make sure they are properly engaged and aligned.

- Inspect the thread cutting tool and make sure it is properly sharpened.

- Ensure the lathe is running at the correct speed for the thread pitch you are using.

- Check the alignment of the workpiece and make sure it is properly centered.

6. Strange noises

If your lathe is making strange noises, consider the following:

- Check for loose or damaged parts, such as belts, pulleys, or gears. Tighten or replace as necessary.

- Inspect the bearings and lubricate as needed.

- Ensure the lathe is properly leveled and aligned to prevent unnecessary vibrations.

- Check for any foreign objects or debris that may have become trapped in the lathe.

By troubleshooting these common lathe issues, you can help ensure smooth and accurate operation of your lathe.

Mastering Advanced Lathe Techniques

1. Taper Turning

To master the art of taper turning on a lathe, it is important to understand the concept of taper and the methods involved in achieving a desired taper. Taper turning can be accomplished using various techniques, such as offsetting the tailstock, using a taper turning attachment or compound slide, or by employing a taper turning fixture. Experiment with different methods to understand their advantages and limitations.

2. Thread Cutting

Thread cutting is a crucial skill in lathe operation, as it allows you to create threads on cylindrical workpieces. Different threading techniques, such as single-point threading and thread chasing, can be used depending on the desired thread type and pitch. It is essential to accurately calculate the pitch, depth, and helix angle of the threads to achieve the desired results. Practice thread cutting on various materials and thread sizes to enhance your proficiency.

3. Knurling

Knurling is a process of creating a pattern of diamond-shaped or straight impressions on a workpiece’s surface to improve grip or aesthetics. Mastering knurling techniques requires proper selection of knurling tools, including knurling wheels, the correct feed rate, and orientation. Experiment with different feed rates and orientations to achieve the desired knurling pattern and depth on various materials.

4. Boring

Boring is the process of enlarging an existing hole or creating a precise internal diameter on a workpiece. Advanced boring techniques involve setting up the workpiece on the lathe’s spindle, using various boring tools such as boring bars or boring heads, and properly aligning the boring tool with the workpiece’s axis. Take the time to understand the principles of boring and practice on different materials to achieve accurate and smooth bores.

5. Facing Off

Facing off is the process of creating a flat, square surface at the end of a workpiece. To master facing off techniques, ensure the lathe’s cutting tool is properly aligned perpendicular to the workpiece’s axis and adjust the feed rate accordingly. Practice facing off on different materials while maintaining consistent cutting depth and surface finish.

6. Parting

Parting is the process of cutting a workpiece to separate it into two or more parts. Mastering parting techniques requires accuracy and control over the cutting tools, feed rate, and depth of cut to prevent workpiece damage or tool breakage. Practice parting on various materials with different parting tools to achieve clean and precise cuts.

7. Drilling

Drilling on a lathe involves creating accurate and centered holes on a workpiece. Advanced drilling techniques include using a lathe chuck or drill chuck to hold the drill bit, proper alignment and centering, and controlling the feed rate and cutting speed. Experiment with different drill bit sizes, materials, and drilling depths to enhance your drilling skills on the lathe.

8. Advanced Tool Techniques

Mastering advanced lathe techniques also includes exploring different tool geometries, cutting angles, and tool materials to achieve optimal cutting performance and surface finishes. Experiment with different tool settings, such as rake angles, clearance angles, and cutting speeds, to achieve desired results on various materials. Additionally, explore the use of carbide inserts, indexable tools, and other tooling innovations to enhance your lathe skills.

9. Project-Based Learning

One of the best ways to master advanced lathe techniques is by engaging in project-based learning. Undertake challenging projects that require the application of multiple lathe techniques, such as creating complex shapes, detailed engravings, or precision assemblies. Project-based learning allows you to consolidate your lathe skills and apply them to real-world applications, pushing the boundaries of your knowledge and abilities.

Conclusion

Mastering advanced lathe techniques requires patience, practice, and a willingness to explore new possibilities. As you gain confidence and proficiency in these techniques, you will be able to tackle more complex projects and achieve precise and high-quality results on the lathe.

FAQ

What is the South Bend PDF Guide about?

The South Bend PDF Guide is about learning how to run a lathe machine using a South Bend lathe. It provides step-by-step instructions and illustrations to help beginners understand the basics of operating a lathe.

Is the South Bend PDF Guide suitable for beginners?

Yes, the South Bend PDF Guide is designed for beginners who have limited or no experience with operating a lathe. It provides comprehensive instructions and guidance to help them learn the necessary skills.

Can I learn how to run a lathe just by reading the PDF guide?

While reading the South Bend PDF Guide is a great starting point, it is recommended to also gain practical experience by actually operating a lathe. This will help you develop a better understanding of the process and improve your skills.

Are there any specific safety precautions mentioned in the South Bend guide?

Yes, the South Bend PDF Guide emphasizes the importance of safety when operating a lathe. It provides detailed instructions on how to use safety equipment, such as goggles and gloves, and outlines common safety practices to ensure the well-being of the operator.

Is the South Bend PDF Guide available for free?

Yes, the South Bend PDF Guide is available for free. It can be downloaded from the South Bend website or other online sources that provide educational resources on lathe operation.