Mastering the Art of Drilling Through Titanium

Drilling through titanium can be a challenging task even for experienced craftsmen. Titanium is known for its remarkable strength and toughness, making it one of the most sought-after metals in various industries. However, its high resistance to drilling poses a unique set of obstacles that require specialized techniques and tools.

To successfully drill through titanium, it is crucial to understand the characteristics of the metal. Titanium has a low thermal conductivity, which means that it tends to hold onto heat generated by the drilling process. This can lead to an increase in temperature, potentially causing the titanium to overheat and become brittle. Therefore, cooling methods, such as using a constant flow of coolant or lubricating the drill bit with cutting oil, are essential to prevent heat accumulation and maintain the integrity of the material.

Another challenge when drilling through titanium is its tendency to work harden. As the drill bit penetrates the material, it creates friction and heat, which can cause the titanium to harden and become even more difficult to drill through. To avoid this, it is recommended to use carbide-tipped or cobalt drill bits, as they have a higher resistance to heat and can withstand the hardening effect of titanium. Additionally, using a slow drilling speed and applying consistent pressure can help prevent work hardening while maintaining control over the drilling process.

“Proper chip evacuation is crucial when drilling through titanium. The chips produced during drilling can be sharp and hot, posing a safety hazard if not removed efficiently. Therefore, using high-pressure coolant or compressed air to blow away the chips is highly recommended.”

Mastering the art of drilling through titanium requires a combination of knowledge, experience, and the right tools. By understanding the unique properties of titanium, implementing proper cooling methods, using appropriate drill bits, and ensuring efficient chip evacuation, craftsmen can overcome the challenges associated with drilling through this resilient metal and achieve precise and successful results.

Understanding the Importance of Drilling Titanium

When it comes to drilling through titanium, it is important to understand the unique characteristics of this material and the challenges it presents. Titanium is a strong and lightweight metal that is highly resistant to corrosion, making it a popular choice in industries such as aerospace, automotive, and medical. However, drilling through titanium requires specialized techniques and tools due to its hardness and heat resistance.

1. Hardness

Titanium is known for its high strength and hardness. In fact, it is one of the hardest known metals. This makes drilling through titanium a difficult and time-consuming process. Standard drill bits are not sufficient for drilling through titanium as they can quickly wear down or break. Specialized carbide or cobalt drill bits, designed specifically for drilling through hard materials like titanium, are required to ensure efficient and effective drilling.

2. Heat Resistance

Another challenge when drilling through titanium is its high heat resistance. As the drill bit cuts through the metal, it generates heat. If not effectively managed, this heat can cause the drill bit to overheat and become dull, resulting in poor drilling performance. To overcome this challenge, it is important to use cutting fluids or coolants to lubricate and cool the drill bit during the drilling process. This helps to dissipate heat and prolong the life of the drill bit.

3. Material Fracturing

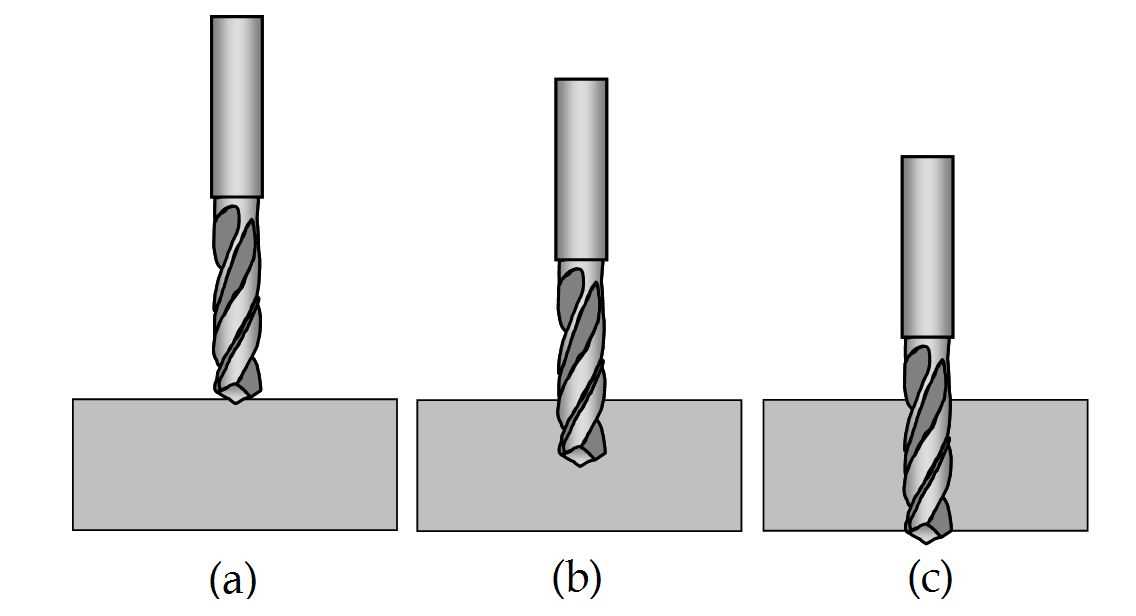

Due to its high hardness, titanium is prone to material fracturing during the drilling process. This can result in burrs or rough edges that may affect the quality and integrity of the hole. To minimize material fracturing, it is crucial to use the correct drilling speed and apply steady and consistent pressure. Additionally, using a pecking technique – drilling in short bursts and retracting the drill bit periodically – can help prevent material build-up and reduce the risk of fracturing.

4. Tool Selection

Choosing the right tools for drilling through titanium is essential. As mentioned earlier, carbide or cobalt drill bits are recommended for their hardness and durability. Additionally, using a drill press or a rigid setup to stabilize the workpiece can help maintain accuracy and prevent the drill bit from wandering off course. It is also important to select the appropriate cutting speed and feed rate for the specific titanium alloy being drilled to achieve optimal results.

In conclusion, understanding the importance of drilling titanium is essential to ensure successful and efficient drilling operations. By considering the hardness, heat resistance, material fracturing, and tool selection associated with titanium drilling, you can overcome the challenges and achieve high-quality results in drilling through this remarkable metal.

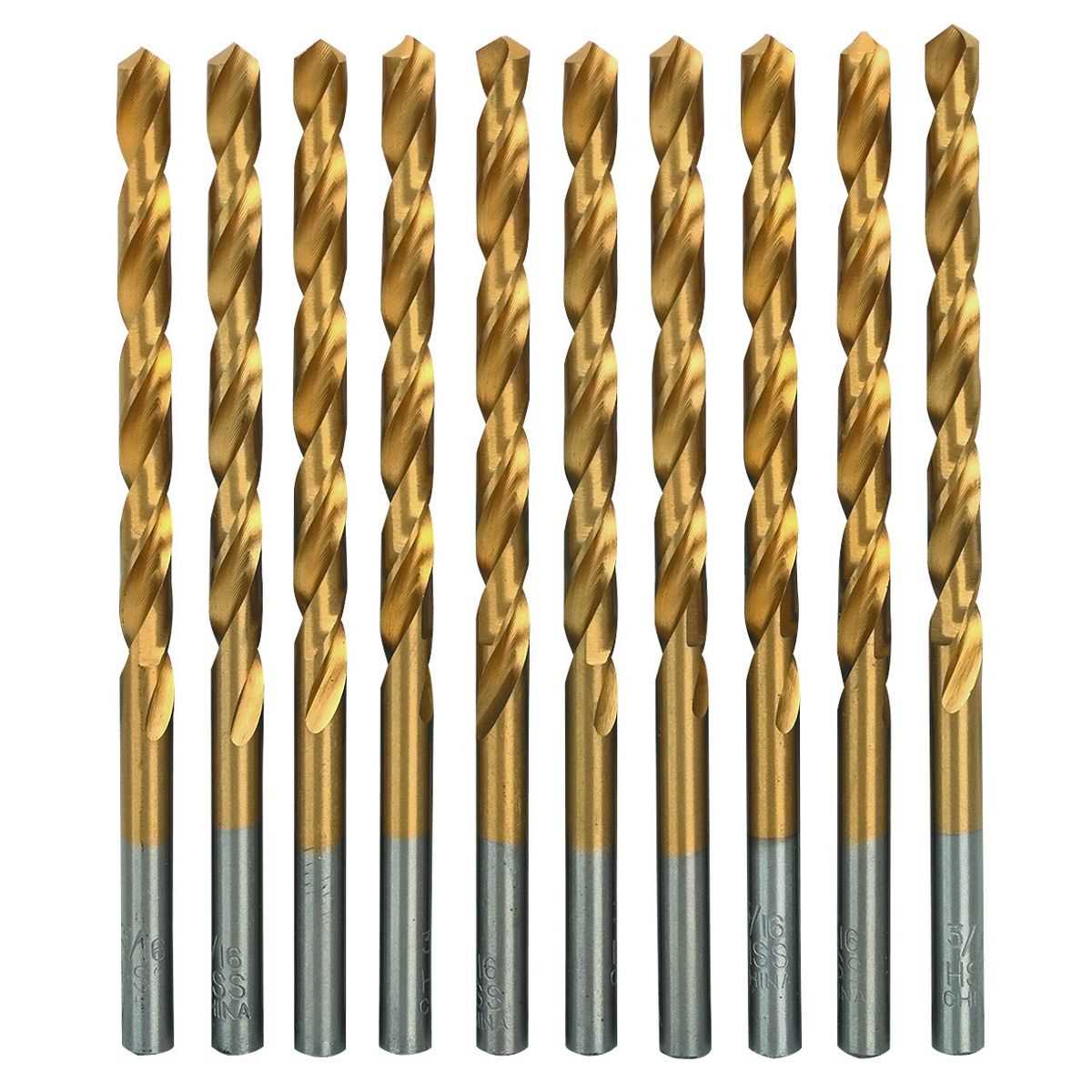

Choosing the Right Drill Bit

When it comes to drilling through titanium, choosing the right drill bit is crucial. Titanium is a strong and durable metal that can be difficult to drill through without the proper tools. Here are some factors to consider when selecting a drill bit for titanium:

1. Material

The material of the drill bit is an important factor to consider. For drilling titanium, high-speed steel (HSS) drill bits or cobalt drill bits are recommended. These materials are known for their hardness and heat resistance, making them suitable for drilling through tough materials like titanium.

2. Coating

Coated drill bits are designed to reduce friction and increase durability. For drilling titanium, it is best to choose a drill bit with a coating such as titanium nitride (TiN), titanium carbonitride (TiCN), or titanium aluminum nitride (TiAlN). These coatings help to prolong the life of the drill bit by reducing heat and friction during drilling.

3. Point Angle

The point angle of the drill bit plays a crucial role in drilling through titanium. A sharper point angle is generally recommended for drilling harder materials like titanium. A point angle between 135 and 140 degrees is ideal for titanium drilling, as it provides better cutting action and decreases the chance of the drill bit wandering or slipping.

4. Flute Design

The flute design of the drill bit affects chip ejection and helps in cooling the drill bit during drilling. For drilling titanium, a parabolic flute design or a twisted flute design is recommended. These designs help in efficient chip removal and reduce heat buildup, increasing the drill bit’s lifespan.

5. Size

The size of the drill bit depends on the hole diameter you need to drill. It is important to choose the appropriate size to ensure precise and accurate drilling. Select a drill bit with the desired diameter and length to meet the requirements of your project.

6. Speed and Feed Rate

When drilling through titanium, it is important to use the appropriate speed and feed rate to prevent overheating and premature dulling of the drill bit. Consult the manufacturer’s guidelines or conduct tests to determine the optimal speed and feed rate for your specific drill bit and titanium material.

By considering these factors and selecting the right drill bit, you can enhance your drilling performance and achieve precise results when working with titanium.

Finding the Ideal Drill Bit Material and Coating

When drilling through titanium, finding the ideal drill bit material and coating is crucial for successful drilling operations. Titanium is a strong and hard metal, which makes it challenging to drill through without the proper tools.

Choosing the Right Drill Bit Material

When selecting the drill bit material for titanium drilling, it is important to consider hardness, heat resistance, and durability. Some of the commonly used materials for drill bits that work well with titanium include:

- High-Speed Steel (HSS): HSS drill bits are a popular choice for drilling titanium. They offer good heat resistance and are relatively affordable. However, they may wear out faster compared to other materials.

- Cobalt: Cobalt drill bits are another excellent choice for drilling titanium. They have superior heat resistance and are more durable than HSS bits. Cobalt bits are ideal for high-speed drilling and can withstand the heat generated during the drilling process.

- Carbide: Carbide drill bits are known for their exceptional hardness and wear resistance. They are suitable for drilling through hard materials like titanium. However, carbide bits are more expensive compared to HSS and cobalt bits.

Understanding Drill Bit Coatings

In addition to the drill bit material, choosing the right coating can significantly enhance the drilling performance when working with titanium. The coatings improve the hardness, lubricity, and heat resistance of the drill bits. Some common coatings for titanium drilling include:

- Titanium Nitride (TiN): TiN coating offers excellent wear resistance and helps reduce friction during drilling. It can handle high-heat conditions and extend the lifespan of the drill bit.

- Titanium Carbonitride (TiCN): TiCN coating provides similar benefits to TiN but offers even greater resistance to wear and heat. It is an excellent choice for drilling titanium.

- Titanium Aluminum Nitride (TiAlN): TiAlN coating is known for its extreme hardness and enhanced performance in high-heat environments. It has excellent wear resistance and can extend the lifespan of the drill bit.

Conclusion

Choosing the ideal drill bit material and coating is essential for successful drilling through titanium. Consider the hardness, heat resistance, and durability of the drill bit material and select a coating that enhances performance. With the right tools, drilling through titanium can be more efficient and effective.

Selecting the Appropriate Speed and Pressure

When drilling through titanium, it is crucial to select the appropriate speed and pressure to ensure the best results. Titanium is a strong and tough material, so it requires a different approach compared to drilling through other metals.

Speed

When drilling through titanium, it is recommended to use a lower speed compared to drilling through softer metals such as aluminum or mild steel. This is because high speed can generate excess heat, which can lead to tool wear and reduce the efficiency of the drilling process. Therefore, it is important to select a speed that allows for efficient cutting without generating excessive heat.

Pressure

Applying the right amount of pressure is essential when drilling through titanium. Too much pressure can cause the drill bit to wander or break, while too little pressure can result in a slow drilling process and poor quality holes. The key is to find the balance between applying enough pressure to maintain cutting efficiency and avoiding excessive pressure that can damage the tool or workpiece.

Lubrication

Using appropriate lubrication is crucial when drilling through titanium. Lubricants, such as cutting oil or coolant, help to reduce heat generation and friction during the drilling process. They also help in prolonging the life of the drill bit by reducing wear and tear. It is important to apply lubrication consistently during the drilling process to ensure smooth operation and good results.

Overall, selecting the appropriate speed and pressure when drilling through titanium is crucial for achieving efficient and high-quality results. By using a lower speed, applying the right amount of pressure, and using proper lubrication, you can ensure a successful drilling operation on this tough material.

Optimizing the Drilling Speed for Titanium

Introduction

Drilling through titanium can be a challenging task due to its high strength and low thermal conductivity. To ensure efficient drilling, it is important to optimize the drilling speed for titanium.

Factors Affecting Drilling Speed

There are several factors that can affect the drilling speed for titanium:

- Feed rate: The speed at which the drill bit advances into the material.

- Spindle speed: The rotational speed of the drill bit.

- Cutting tools: The type and quality of the drill bit used.

- Coolant: The use of a coolant during drilling to reduce heat and friction.

Optimization Techniques

Here are some techniques that can help optimize the drilling speed for titanium:

- Use a high-quality drill bit: Investing in a high-quality drill bit specifically designed for drilling titanium can significantly improve drilling speed. These drill bits typically have special coatings that reduce friction and increase cutting efficiency.

- Optimize the feed rate and spindle speed: Finding the right combination of feed rate and spindle speed is crucial for efficient drilling. A higher feed rate and spindle speed can help increase drilling speed, but excessive speeds can also lead to tool wear or tool failure.

- Use a coolant: Titanium has poor thermal conductivity, which means it can quickly become hot during drilling. Using a coolant can help dissipate the heat and reduce friction, improving drilling speed and prolonging tool life.

- Consider peck drilling: Peck drilling involves drilling in short, interrupted cycles to remove chips and prevent heat build-up. This technique can help optimize drilling speed and reduce the risk of tool failure.

Conclusion

Optimizing the drilling speed is essential for efficient drilling through titanium. By using high-quality drill bits, optimizing the feed rate and spindle speed, using a coolant, and considering peck drilling, the drilling speed for titanium can be significantly improved, resulting in faster and more reliable drilling operations.

Cooling and Lubricating the Drilling Process

When drilling through titanium, it is essential to properly cool and lubricate the drilling process. Titanium has a tendency to heat up quickly during the drilling process, which can cause damage to both the material being drilled and the drilling tool itself. Cooling and lubricating the drilling process helps to dissipate heat, reduce friction, and prolong the life of the drilling tool.

Cooling

Cooling the drilling process involves the use of a coolant or cutting fluid. The coolant is usually applied directly to the cutting edge of the drill bit or to the titanium surface being drilled. The purpose of the coolant is to dissipate heat by lowering the drill bit’s temperature and preventing the titanium from overheating. This cooling effect reduces the risk of thermal damage to the titanium and also helps to prolong the tool’s lifespan.

There are various types of coolants available for drilling titanium, including water-based coolants, oil-based coolants, and synthetic coolants. Water-based coolants are commonly used due to their affordability and effectiveness. They can be applied by using a spray bottle, a coolant pump system, or through the use of flood coolant. Oil-based coolants provide better lubrication and cooling for demanding drilling applications but are typically more expensive. Synthetic coolants offer a balance between water-based and oil-based coolants, providing both effective cooling and lubrication.

Lubrication

Lubricating the drilling process is crucial for reducing friction and preventing the build-up of metal chips on the drill bit. Without proper lubrication, the drill bit can overheat and wear out quickly. The lubricant creates a protective barrier between the drill bit and the titanium, reducing the friction generated during the drilling process.

Common lubricants used for drilling titanium include oil-based lubricants, cutting oils, and synthetic lubricants. These lubricants can be applied directly to the cutting edge of the drill bit or to the surface being drilled. It is important to use the appropriate lubricant for the specific drilling operation and to follow the manufacturer’s recommendations for application and usage.

Tips for Effective Cooling and Lubrication

- Choose the right coolant and lubricant based on the type of drilling operation and the specific requirements.

- Apply the coolant and lubricant directly to the cutting edge of the drill bit or to the titanium surface being drilled.

- Monitor the coolant and lubricant levels during the drilling process and replenish as needed.

- Use flood coolant systems or coolant pumps for large-scale drilling operations to ensure consistent and sufficient cooling.

- Clean the drill bit and remove any built-up metal chips regularly to maintain proper cooling and lubrication.

- Follow the manufacturer’s recommendations and guidelines for coolant and lubricant usage, concentration, and disposal.

By implementing proper cooling and lubrication techniques, the drilling process can be optimized for drilling through titanium. This not only improves productivity but also helps to protect the integrity of the titanium and extend the lifespan of the drilling tool.

Preventing Overheating and Extending the Tool Life

Drilling through titanium can generate a significant amount of heat. This heat not only affects the quality of the hole but also reduces the lifespan of the drilling tool. To prevent overheating and extend the tool life, several key strategies can be employed:

Coolant

Using a coolant during the drilling process is crucial in preventing overheating. The coolant helps to lubricate the drilling tool, reducing friction and heat generation. It also helps to flush away chips and debris, ensuring a clean drilling environment. Coolants can be oil-based, water-based, or synthetic, depending on the specific drilling requirements.

Proper Cutting Speed and Feed Rate

Optimizing the cutting speed and feed rate is essential in preventing overheating. High cutting speeds and feed rates generate excessive heat, leading to tool wear. On the other hand, low cutting speeds and feed rates can cause rubbing and galling, resulting in poor hole quality. Finding the right balance for the specific drilling operation is crucial.

Quality Drill Bits

Investing in high-quality drill bits is essential for reducing heat generation and extending tool life. Inferior drill bits can chip or wear down quickly, leading to increased friction and overheating. High-quality drill bits, made from materials such as cobalt or carbide, offer increased durability and heat resistance, resulting in a longer tool life.

Proper Chip Control

Effective chip control is key in preventing heat buildup. Accumulated chips can act as an insulating layer, trapping heat and increasing the temperature in the cutting zone. Proper chip evacuation through the use of chip breakers or peck drilling techniques helps to remove chips and reduce heat buildup.

Cutting Fluid Management

Regularly monitoring and managing the cutting fluid is important in preventing overheating. Over time, cutting fluids can become contaminated with chips and debris, reducing their effectiveness. Regularly replacing or filtering the cutting fluid ensures its ability to dissipate heat and lubricate the drilling process.

Tool Coating

Applying a suitable tool coating can significantly extend tool life and reduce heat generation. Coatings such as titanium nitride or diamond-like carbon increase the hardness of the drilling tool, reducing friction and heat. They also provide better chip evacuation, resulting in a cooler drilling process.

Proper Tool Maintenance

Maintaining the drilling tool properly is crucial in preventing overheating. Regularly inspecting and sharpening drill bits helps to ensure proper cutting performance and reduces heat generation. Additionally, using the correct drilling parameters and avoiding excessive tool wear can help prevent overheating and extend tool life.

By implementing these strategies, drillers can prevent overheating and extend the tool life when drilling through titanium. This not only improves hole quality but also reduces production downtime and costs associated with tool replacement.

Proper Clamping and Stability

When drilling through titanium, proper clamping and stability are crucial for achieving accurate and precise results. Titanium is a challenging material to work with due to its strength and hardness, so it is important to ensure that the workpiece is securely clamped in place to prevent any movement during the drilling process.

There are several factors to consider when clamping titanium:

1. Clamping Method

Choose a clamping method that provides a strong and secure grip on the workpiece. This can be achieved through the use of vices, clamps, or specialized fixtures designed for titanium drilling. The clamping method should be able to hold the workpiece tightly in position without applying excessive pressure that could damage or deform the material.

2. Clamping Points

Ensure that the workpiece is clamped at multiple points to distribute the clamping force evenly. This helps to prevent any distortion or warping of the material and ensures stability during the drilling process. Pay attention to the location and number of clamping points to maximize stability and avoid any shifting or movement of the workpiece.

3. Clamping Jaws

Check the condition and alignment of the clamping jaws to ensure proper contact with the workpiece. The jaws should be clean, free from debris, and properly aligned to provide a secure grip. Misaligned or damaged jaws can lead to uneven clamping pressure and instability, resulting in inaccurate drilling and potential damage to the workpiece.

4. Clamping Force

Apply the appropriate clamping force based on the size and thickness of the workpiece. The clamping force should be sufficient to hold the workpiece securely in place without causing deformation or damage. It is important to strike a balance between a strong grip and avoiding excessive force that could lead to workpiece distortion or material failure.

By ensuring proper clamping and stability, you can minimize the risk of errors and achieve accurate drilling results when working with titanium. Taking the time to set up and secure the workpiece correctly will ultimately contribute to the success of your drilling operations.

Securing the Titanium Workpiece for Precise Drilling

When drilling through titanium, it is crucial to properly secure the workpiece to ensure precise drilling and avoid any potential hazards. Titanium is a hard and tough material that requires a stable and secure setup to achieve accurate results.

Here are some essential steps to follow when securing a titanium workpiece for drilling:

- Clean the workpiece: Before securing the titanium workpiece, thoroughly clean it to remove any dirt, debris, or oil residues. This will ensure a clean surface for the drilling operation.

- Choose the right workholding method: Consider the size, shape, and weight of the titanium workpiece to select the appropriate workholding method. Common options include vise grips, clamps, or fixtures.

- Use a stable work surface: Place the workpiece on a stable and flat surface, such as a workbench or machine table. This will minimize vibrations during drilling and provide better control over the drilling process.

- Secure with the appropriate force: Apply the necessary force to secure the workpiece in place. Make sure not to overtighten, as it may deform or damage the titanium material.

- Consider using a sacrificial backing plate: For delicate or thin titanium workpieces, it is advisable to use a sacrificial backing plate. This plate can prevent the workpiece from bending or vibrating excessively during drilling.

- Utilize a center punch: To ensure accuracy and prevent the drill bit from wandering, use a center punch to create a small indentation as a drilling guide. This will help maintain the desired location and angle for the hole.

- Select the appropriate drill bit: Choose a high-quality drill bit specifically designed for drilling titanium. Carbide or cobalt drill bits are commonly recommended for their hardness and heat resistance.

Following these steps and investing time in setting up a secure workpiece will enhance the drilling process, reduce the risk of damage, and increase the precision of the drilled holes in titanium.

Mastering the Feeding Technique

Understanding the Importance of the Feeding Technique

The feeding technique is a crucial aspect of drilling through titanium. It determines how the cutting tool interacts with the material, affects the efficiency of drilling, and influences the overall quality of the hole produced. Mastering the feeding technique is essential for successful drilling operations in titanium.

Tips to Improve Feeding Technique

- Use a Constant Feed Rate: Maintaining a constant and appropriate feed rate is essential for drilling through titanium. A consistent feed rate ensures a smooth and steady drilling process, preventing issues such as tool wear and overheating.

- Monitor the Chip Size: Monitoring the size of the chips produced during drilling can provide valuable insights into the feeding technique. Proper chip formation indicates that the cutting tool is applying the correct amount of pressure and feed rate, ensuring efficient material removal.

- Implement Proper Lubrication: Lubrication plays a crucial role in the feeding technique for drilling through titanium. Using the right lubricant helps reduce friction, heat, and tool wear, resulting in improved drilling performance and hole quality.

- Ensure Sufficient Cooling: Titanium drilling generates significant heat, which can negatively affect the cutting tool and the workpiece. Proper cooling techniques, such as using coolant or air blast, help dissipate heat and maintain the integrity of the drilling process.

- Optimize Cutting Parameters: Adjusting the cutting parameters, such as feed rate, RPM, and depth of cut, can significantly impact the feeding technique. Finding the optimal combination of these parameters ensures efficient material removal and minimizes the chances of tool failure.

Conclusion

Mastering the feeding technique is essential for successful drilling through titanium. By maintaining a constant feed rate, monitoring chip size, implementing proper lubrication, ensuring sufficient cooling, and optimizing cutting parameters, professionals can achieve efficient and high-quality drilling operations in titanium.

FAQ:

What are the challenges of drilling through titanium?

Drilling through titanium can be challenging due to its high strength and low thermal conductivity. The material is known for its toughness, which can make it difficult to cut through. Additionally, titanium has a low thermal conductivity, which means that heat generated during the drilling process tends to be concentrated in a small area, leading to increased tool wear and reduced machining efficiency.

How can drilling through titanium be made easier?

To make drilling through titanium easier, it is important to select the right cutting tools and parameters. High-performance carbide or diamond-coated drills are commonly used for titanium drilling, as they provide better wear resistance and chip evacuation. Using the proper cutting speed, feed rate, and coolant can also help to reduce heat buildup and improve the drilling process.

What are the recommended cutting speeds for drilling titanium?

The recommended cutting speeds for drilling titanium depend on the specific grade and thickness of the material, as well as the type of cutting tool being used. In general, the cutting speed for drilling titanium can range from 30 to 60 meters per minute. It is crucial to consult the tool manufacturer or reference technical resources to determine the optimal cutting speeds for a given application.

What types of coolant are suitable for drilling through titanium?

When drilling through titanium, it is important to use a suitable coolant to reduce heat buildup and improve tool life. Synthetic coolants, such as soluble oil or semi-synthetic coolant, are commonly used for titanium drilling. These coolants provide good lubrication and cooling properties, helping to reduce friction and heat generation during the drilling process.

How should the feed rate be adjusted when drilling titanium?

The feed rate for drilling titanium should be adjusted based on the specific cutting conditions and tool being used. It is generally recommended to use a lower feed rate compared to drilling other materials. This helps to reduce the amount of heat generated and prevent tool wear. It is important to balance the feed rate with the cutting speed and ensure proper chip evacuation during the drilling process.

What are some common mistakes to avoid when drilling through titanium?

When drilling through titanium, it is important to avoid common mistakes that can lead to poor results or tool damage. Some common mistakes include using improper cutting tools, using excessive cutting speeds or feed rates, inadequate cooling or lubrication, and improper chip evacuation. It is crucial to carefully select the right tools and cutting parameters, and to monitor the drilling process for any signs of tool wear or overheating.

Are there any specific safety precautions to take when drilling titanium?

Yes, there are specific safety precautions to take when drilling through titanium. It is important to wear appropriate personal protective equipment, such as safety glasses, gloves, and a face shield, to protect against flying chips and debris. Additionally, the drilling area should be properly ventilated to avoid inhaling any fumes or dust generated during the drilling process. Following proper safety guidelines and procedures is crucial to ensure a safe drilling operation.

Video: