Common Reasons Your Air Compressor is Not Turning On and How to Fix Them

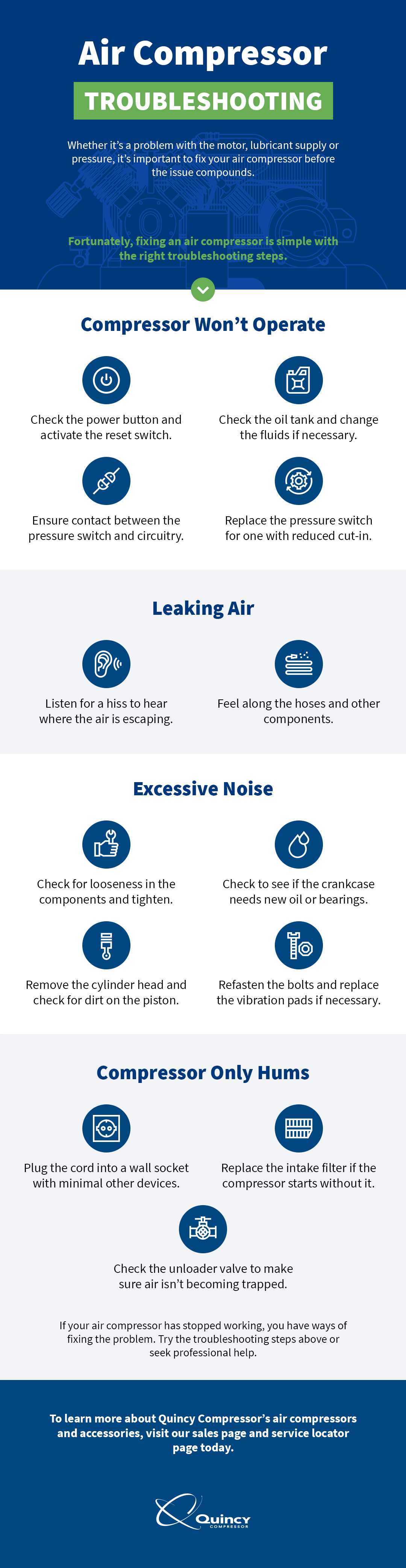

Having an air compressor that won’t turn on can be frustrating, especially when you need it for a project or task. There can be several reasons why your air compressor is not turning on, and understanding these common issues can help you troubleshoot and fix the problem.

One of the most common reasons for an air compressor not turning on is a lack of power. Make sure that the power cord is properly plugged in and that the outlet is functioning. Additionally, check the circuit breaker or fuse box to ensure that the circuit is not tripped or the fuse is not blown.

Another possible reason for a non-functioning air compressor is a faulty pressure switch. The pressure switch is a device that senses the air pressure in the compressor tank and controls the on/off function. If the pressure switch is faulty or not adjusted correctly, it may prevent the compressor from turning on. Try adjusting the pressure switch or replacing it if necessary.

A clogged or dirty air filter can also cause an air compressor to not turn on. The air filter is responsible for filtering out dust and debris from entering the compressor’s system. If the air filter is clogged, it can restrict the airflow and cause the compressor to shut off. Cleaning or replacing the air filter may solve the issue.

Finally, a malfunctioning motor or capacitor could be the reason why your air compressor is not turning on. The motor and capacitor work together to provide the necessary power for the compressor to operate. If either of these components is faulty or damaged, the compressor may fail to start. In this case, professional repair or replacement may be necessary.

Overall, troubleshooting and fixing an air compressor that won’t turn on can involve checking the power supply, inspecting the pressure switch, cleaning or replacing the air filter, and addressing any motor or capacitor issues. By identifying and resolving these common problems, you can ensure that your air compressor operates reliably and efficiently.

Power Supply

1. Check the power source

Before troubleshooting any other issues, the first thing you should check is if the air compressor is properly connected to a power source. Make sure the power cord is securely plugged into a functioning outlet or power supply. If possible, try connecting a different device to the same outlet to ensure there is power available.

2. Inspect the power cord

If the air compressor is properly connected but still not turning on, inspect the power cord for any signs of damage or wear. Look for frayed wires, cuts, or loose connections. If you notice any issues with the power cord, it may need to be replaced. It’s important to use a power cord that is specifically designed for your air compressor and meets the necessary electrical requirements.

3. Test the power switch

If the power cord appears to be in good condition, the next step is to test the power switch. Use a multimeter to check for continuity across the switch when it is in the “on” position. If there is no continuity, the power switch may be faulty and will need to be replaced. Consult the air compressor’s manual or contact the manufacturer for guidance on replacing the power switch.

4. Check the circuit breaker

If the power switch is functioning correctly but the air compressor still does not turn on, it’s possible that the circuit breaker has been tripped. Locate the circuit breaker that controls the power supply to the air compressor and check if it has been switched to the “off” position. If it has, switch it back on and try turning on the air compressor again. If the circuit breaker continues to trip, there may be an electrical problem that requires professional assistance.

By following these troubleshooting steps, you can identify and resolve power supply issues that may be preventing your air compressor from turning on. Always prioritize safety and consult a professional if you are unsure about any electrical repairs or replacements.

Electrical Connections

One common reason why an air compressor may not turn on is due to issues with its electrical connections. This can be caused by a variety of factors, such as loose or corroded wires, faulty switches, or blown fuses. It is important to check all of the electrical connections to ensure they are secure and free from damage.

Check for loose or corroded wires: Inspect the wires connecting the power source to the compressor motor. If any wires are loose or corroded, they may need to be tightened or replaced. A visual inspection can often help identify any obvious issues.

Test the switch: The switch on the compressor is responsible for turning it on and off. If the switch is faulty or damaged, it may not be sending the proper electrical signal to start the motor. Test the switch using a multimeter to determine if it is working correctly. If not, it may need to be replaced.

Check the fuse: A blown fuse can prevent an air compressor from turning on. Locate the fuse box or circuit breaker panel that corresponds to the compressor’s power source and check for any blown fuses or tripped circuit breakers. Replace or reset as necessary.

Inspect the capacitor: The capacitor is a component that helps start the compressor motor. If the capacitor is faulty or damaged, it can prevent the motor from turning on. Inspect the capacitor for any signs of damage, such as bulging or leaking. If there are any issues, the capacitor may need to be replaced.

Test the power source: If all of the above steps fail to resolve the issue, it may be necessary to test the power source itself. Use a multimeter to check the voltage at the outlet or power supply that the compressor is connected to. If there is no voltage, there may be a problem with the power source that needs to be addressed.

By checking and addressing any issues with the electrical connections, you can help ensure that your air compressor turns on and operates properly. Regular maintenance and inspections of all electrical components are recommended to prevent future issues.

Pressure Switch

The pressure switch is a crucial component of an air compressor as it controls when the compressor turns on and off based on the desired pressure level. If the pressure switch is not functioning properly, it can prevent the compressor from turning on.

One common issue with the pressure switch is a faulty electrical connection. Check the wiring connections to ensure they are secure and free from any damage. If there are any loose or damaged wires, they should be repaired or replaced.

Another potential problem with the pressure switch is a malfunctioning pressure sensor. This sensor measures the air pressure inside the tank and signals the switch to turn on or off accordingly. If the sensor is not working correctly, it may not accurately detect the pressure, causing the switch to fail.

If you suspect a problem with the pressure switch, it can be tested using a multimeter. Follow the manufacturer’s instructions to properly test the switch and determine if it needs to be replaced.

In some cases, the pressure switch may simply need to be adjusted. There are usually adjustable screws or knobs that can be used to set the desired pressure level. Consult the user manual or manufacturer’s instructions for guidance on how to adjust the pressure switch correctly.

If none of these solutions work, it may be necessary to replace the pressure switch altogether. Make sure to purchase a compatible switch for your specific air compressor model. Installation instructions should be provided with the new switch, or you may need to consult a professional for assistance.

Motor Overload

If your air compressor is not turning on, one common reason could be a motor overload. This occurs when the motor draws too much current, causing a safety device called an overload protector to trip and shut off power to the motor. Motor overload can happen due to a variety of reasons:

1. Overheating

One possible cause of motor overload is overheating. If the motor gets too hot, it can increase the resistance and cause the current to exceed the designated limits. Overheating can be caused by factors such as a lack of proper ventilation, operating the compressor for extended periods without allowing it to cool down, or excessive ambient temperatures. To fix this issue, ensure that your compressor has adequate ventilation and avoid continuous operation for extended periods.

2. Worn out motor bearings

Another reason for motor overload could be worn out motor bearings. Over time, the bearings in the motor can wear out and cause the motor to work harder than usual, leading to increased current draw. Regular maintenance and lubrication of the motor bearings can help prevent this issue. If the bearings are already worn out, they may need to be replaced.

3. Faulty start capacitor

A faulty start capacitor can also lead to motor overload. The start capacitor provides an extra boost of power to help the motor start up. If the capacitor fails, the motor may struggle to start, drawing more current and causing the overload protector to trip. In this case, the start capacitor will need to be tested and replaced if necessary.

To fix motor overload issues, you should first inspect the compressor for any signs of overheating or worn out motor bearings. Clean and/or replace any parts as needed. If the problem persists, it may be best to consult a professional technician who can diagnose and repair the motor overload issue.

Faulty Control Panel

A faulty control panel can be a common reason why your air compressor is not turning on. The control panel is responsible for regulating the operation of the compressor and ensuring that it starts and stops properly.

If you notice that the control panel is not functioning correctly, there are a few potential issues that could be causing the problem. First, check the power supply to the control panel. Make sure that the power is turned on and that there are no loose connections or blown fuses.

Another common issue is a malfunctioning control switch. If the switch is not working properly, it may not be sending the signal to start the compressor. You can test the switch using a multimeter to check for continuity. If you find that the switch is faulty, it will need to be replaced.

In some cases, the control panel itself may be the problem. Over time, the control panel can become worn or damaged, leading to issues with starting the compressor. If you suspect that the control panel is faulty, it is best to consult a professional for repairs or replacement.

Faulty Pressure Regulator

A faulty pressure regulator can prevent your air compressor from turning on. The pressure regulator is responsible for controlling the amount of air pressure in the system. If it is not functioning properly, it may not allow the air compressor to start.

There are a few signs that can indicate a faulty pressure regulator. One common sign is if the pressure gauge on your air compressor is not reading the correct pressure. This can mean that the pressure regulator is not accurately controlling the pressure in the system.

Another sign of a faulty pressure regulator is if there is a leak or hissing sound coming from the regulator. This can mean that the regulator is not closing properly and is allowing air to escape from the system.

To fix a faulty pressure regulator, you can try a few troubleshooting steps. First, check for any leaks in the regulator or in the air lines. Tighten any loose connections and replace any damaged parts. You can also try adjusting the pressure regulator to see if that resolves the issue.

If troubleshooting does not fix the problem, you may need to replace the pressure regulator. Consult the manufacturer’s instructions or contact a professional for guidance on how to safely replace the regulator.

Air Pressure Tank

The air pressure tank plays a crucial role in the functioning of an air compressor. It is a storage tank that holds compressed air, which can then be used for various applications. The tank is typically made of steel and is designed to withstand high pressure.

One common issue that can prevent an air compressor from turning on is a problem with the air pressure tank. If the tank is not holding pressure properly, it can cause the compressor to not start or run efficiently.

There are several possible reasons why the air pressure tank may be causing issues with the compressor. One possibility is that there is a leak in the tank or in the connections between the tank and the compressor. This can result in a loss of pressure and prevent the compressor from turning on.

Another potential issue with the air pressure tank is that it may have too much water or condensation inside. Excessive moisture can lead to rust and corrosion, which can affect the tank’s ability to hold pressure. Regular maintenance, such as draining the tank and using a moisture trap, can help prevent this problem.

In some cases, the air pressure switch, which controls the operation of the compressor, may be faulty. This switch is typically located near the tank and can become stuck or malfunction over time. Checking and replacing the air pressure switch if necessary can help resolve issues with the compressor not turning on.

Overall, the air pressure tank is an essential component of an air compressor system. Understanding the common problems that can occur with the tank and how to fix them can help ensure that your compressor operates efficiently and reliably.

Motor Failure

Motor failure is a common reason why an air compressor may not turn on. The motor is the main component that powers the compressor and if it fails, the machine will not work. There are several potential causes of motor failure.

Overheating

One possible cause of motor failure is overheating. If the motor gets too hot, it can cause the internal components to expand and fail. This can be caused by a lack of proper ventilation or running the compressor for extended periods of time without giving it a chance to cool down. To prevent overheating, make sure the compressor is located in a well-ventilated area and give it breaks between heavy usage.

Faulty Start Capacitor

Another common cause of motor failure is a faulty start capacitor. The start capacitor is responsible for providing an extra boost of power to start the motor. If the capacitor is not working properly, the motor may not have enough power to turn on. This can be fixed by replacing the faulty capacitor with a new one.

Wiring Issues

Motor failure can also be caused by wiring issues. Loose or damaged wires can prevent the motor from receiving the necessary power to turn on. Check all wiring connections for any signs of damage or looseness and repair or replace as needed.

FAQ:

What are the common reasons why an air compressor does not turn on?

There are several common reasons why an air compressor may not turn on. One possible reason is a power issue, such as a blown fuse or a tripped circuit breaker. Another reason could be a faulty pressure switch or a defective motor. It is also possible that there is an issue with the compressor’s wiring or a problem with the on/off switch.

How can I fix a power issue with my air compressor?

To fix a power issue with your air compressor, start by checking the fuse or circuit breaker. If the fuse is blown or the circuit breaker is tripped, replace the fuse or reset the circuit breaker. If that doesn’t solve the problem, you may need to check the power supply and make sure it is delivering the correct voltage to the compressor. If the power supply is functioning properly, you may need to replace the pressure switch or motor.

What should I do if the pressure switch in my air compressor is faulty?

If the pressure switch in your air compressor is faulty, it will need to be replaced. To do this, you will first need to disconnect the power to the compressor. Then, remove the cover of the pressure switch and disconnect the wires. Next, unscrew the pressure switch from the compressor. Install the new pressure switch and reconnect the wires. Finally, reapply power to the compressor and test it to make sure it is functioning correctly.

How do I know if the motor in my air compressor is defective?

If the motor in your air compressor is defective, the first thing to check is whether it is receiving power. You can do this by testing the power supply with a multimeter. If the motor is receiving power but not running, it may be burnt out or have a faulty capacitor. In this case, you will need to replace the motor. If the motor is not receiving power, there may be an issue with the wiring or the on/off switch.

What are the signs of a problem with the wiring in an air compressor?

Signs of a problem with the wiring in an air compressor can include intermittent operation, flickering lights, or a burning smell. If you suspect there is a wiring issue, you will need to inspect the wires for any damage or loose connections. If you find any damage or loose connections, they will need to be repaired or replaced. It is also a good idea to check the on/off switch to make sure it is functioning properly.

What should I do if my air compressor’s on/off switch is not working?

If your air compressor’s on/off switch is not working, you can try cleaning it to remove any dirt or debris that may be preventing it from functioning properly. If cleaning doesn’t solve the problem, you will likely need to replace the switch. This will involve disconnecting the power to the compressor, removing the faulty switch, and installing a new one. Once the new switch is installed, reconnect the power and test the compressor to make sure it is turning on and off correctly.

Video: