Why is an allen wrench called an allen wrench

An allen wrench, also known as a hex key or hex wrench, is a versatile tool commonly used to tighten or loosen screws and bolts with hexagonal sockets. The allen wrench gets its name from the Allen Manufacturing Company, a prominent manufacturer of screws and bolts in the early 20th century. The Allen Manufacturing Company was founded by William G. Allen, who patented the hex socket drive system in 1910. This innovative drive system allowed for better torque transmission and increased efficiency in fastening applications.

The popularity and wide usage of the hex socket drive system led to the widespread adoption of the term “allen wrench” to refer to any tool with a hexagonal shape used for turning screws and bolts. Over time, the term “allen wrench” has become a genericized trademark, similar to how “Kleenex” is used to refer to any brand of facial tissue.

The allen wrench is an essential tool in many industries, including automotive, construction, and furniture assembly. Its compact size, ease of use, and ability to reach tight spaces make it a valuable tool for both professionals and DIY enthusiasts. The hexagonal shape of the wrench provides a secure grip and prevents slippage during use, ensuring effective fastening and minimizing the risk of damage.

Next time you reach for an allen wrench to assemble furniture or tighten a bolt, remember the origins of its name and the contributions of the Allen Manufacturing Company. The allen wrench, with its hexagonal shape and precision design, continues to be a reliable tool for all your fastening needs.

What is an allen wrench?

An allen wrench, also known as a hex key or hex wrench, is a small handheld tool used for driving bolts and screws with hexagonal socket heads. It is commonly used in assembling furniture, bicycles, machinery, and other appliances that have hexagonal socket fittings.

Design

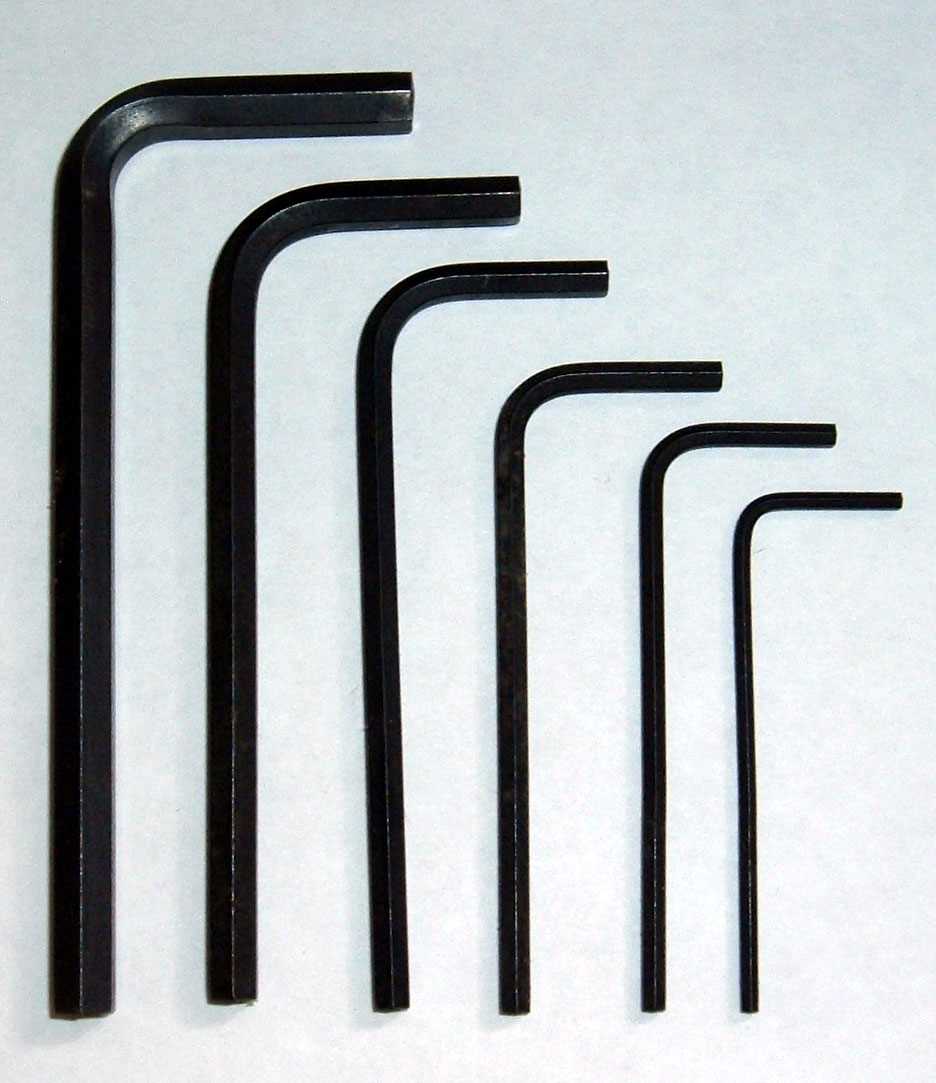

An allen wrench is typically L-shaped, with a hexagonal cross-section at one end and a handle at the other end. The hexagonal end of the wrench is designed to fit into the socket head of a bolt or screw, providing a secure grip for turning.

The wrench can come in different sizes, with the most common being 0.05 inches to 3/8 inches in diameter. Each size of the wrench corresponds to a specific socket size, ensuring a proper fit and preventing slippage during use.

Usage

To use an allen wrench, you simply insert the hexagonal end into the socket head of the bolt or screw and apply torque by turning the handle. The L-shape design of the wrench allows for increased leverage, making it easier to tighten or loosen fasteners with minimal effort.

Allen wrenches are commonly used in with socket head cap screws (SHCS), set screws, and other types of fasteners that have hexagonal heads. They are especially useful in situations where limited space makes it difficult to use traditional wrenches or screwdrivers.

Alternative names

An allen wrench is often referred to by different names depending on the region or manufacturer. Some common alternative names include:

- Hex key

- Hex wrench

- Allen key

- L-key

- Hexagon wrench

- Allen screwdriver

History

The allen wrench was invented by William G. Allen in the early 1900s. Allen was an engineer working for the Allen Manufacturing Company, which later became the Allen Manufacturing Division of the Apex Tool Group. The company patented the design of the wrench in 1910 and began producing and selling it under the Allen brand name.

Since then, the allen wrench has become a widely used tool and is now produced by various manufacturers around the world. Its simple yet effective design has made it a staple in many toolboxes and a valuable tool for countless DIY projects and professional applications.

Definition of an allen wrench

An allen wrench, also known as a hex key or a hexagon wrench, is a specialized tool used to tighten or loosen screws and bolts with a hexagonal socket. It consists of a small, L-shaped metal rod with a hexagonal tip at one or both ends. The hexagonal tip is designed to fit securely into the hexagonal socket of the screw or bolt.

The term “allen wrench” is derived from the Allen Manufacturing Company, which first introduced the tool in the early 20th century. The company, founded by William G. Allen, became known for their innovative design and manufacturing of hex socket screws and wrenches.

The allen wrench is commonly used in industries such as automotive, furniture assembly, and machinery. It is a versatile tool that can be found in various sizes, allowing it to be used with different-sized hexagonal sockets.

Types of allen wrenches

Allen wrenches come in different types and sizes to accommodate a wide range of applications. The most common types include:

- L-shaped allen wrench: This is the traditional type of allen wrench, with one short arm and one long arm forming an L-shape. It provides leverage and ease of use when tightening or loosening screws.

- T-handle allen wrench: This type of wrench has a longer handle in the shape of a T. It offers better grip and torque, making it suitable for heavy-duty applications.

- Folding allen wrench: This compact tool features multiple allen wrench sizes that can be folded into a single handle. It is portable and convenient for on-the-go repairs or maintenance.

Using an allen wrench

To use an allen wrench, follow these steps:

- Select the appropriate size of allen wrench that matches the hexagonal socket of the screw or bolt.

- Insert the hexagonal tip of the wrench into the hexagonal socket, ensuring a secure fit.

- Apply pressure in the desired direction (clockwise to tighten or counterclockwise to loosen) while holding the wrench at the handle.

- Continue turning until the screw or bolt is tightened or loosened to the desired level.

It is important to use the correct size of allen wrench to avoid damaging the screw or bolt and to ensure effective tightening or loosening.

| Advantages |

|---|

| Allows for more torque compared to standard screwdrivers |

| Provides a secure grip on hexagonal sockets |

| Compact and portable |

Origins of the term “allen wrench”

The term “allen wrench” originated from the Allen Manufacturing Company, a company that was founded in the early 20th century. The company, which later became known as the Allen Manufacturing Company, was founded by William G. Allen in the year 1910.

At the time, the company specialized in producing various tools and fasteners. One of their most notable inventions was a hexagonal socket wrench that had a unique design. This particular wrench had a hexagonal-shaped socket on one end, which allowed it to be used on screws and bolts with hexagonal heads.

The distinctive design of this wrench made it a popular and useful tool among mechanics and engineers. Due to its effectiveness and widespread use, the wrench became commonly referred to as the “Allen wrench” after the company’s founder, William G. Allen.

Over the years, the term “Allen wrench” became synonymous with any type of hex key or hexagonal socket wrench, regardless of the manufacturer. Today, it is still widely used to refer to these types of tools.

Historical use of allen wrenches

The history of the allen wrench, also known as the hex key or hex wrench, dates back to the early 20th century. The tool was first invented and patented by the American engineer William G. Allen in 1910.

Allen originally developed the hex key as a solution to a common issue in automobile manufacturing. At the time, traditional screw heads were prone to stripping and becoming damaged, especially when exposed to high levels of torque. This posed a significant problem in the assembly of automobiles, as stripped screws could result in faulty or insecure connections.

By designing a wrench with a hexagonal-shaped socket, Allen was able to create a tight and secure grip on screws, greatly reducing the risk of stripping. The hexagon shape provided more contact points between the tool and the screw, distributing the torque evenly and minimizing the likelihood of damage.

The early use of Allen’s wrench was predominantly in the automotive industry, where it quickly gained popularity due to its effectiveness and versatility. The design of the tool allowed for easy removal and replacement of fasteners in tight spaces, making it an invaluable asset in vehicle assembly and repair.

Over time, the use of the allen wrench expanded beyond the automotive sector and found its application in a wide range of industries. The tool became a staple in furniture manufacturing, electronics assembly, bicycle maintenance, and countless other fields where precise and reliable fastening was essential.

Today, allen wrenches are available in various sizes and are commonly sold as part of sets. They are generally made from steel or other durable materials and have a standard hexagonal shape on one end, with a handle on the other for ease of use. The versatility and effectiveness of the allen wrench continue to make it a popular and widely used tool around the world.

Types and sizes of allen wrenches

1. Hex Key Set

The most common type of allen wrench is the hex key set. It typically includes wrenches of various sizes, ranging from small to large. A hex key set usually consists of a set of short, L-shaped wrenches with a hexagonal-shaped tip on each end. The different sizes allow you to choose the right wrench for the job based on the size of the hexagonal socket or screw head you’re working on.

2. Folding Hex Key Set

Folding hex key sets are a convenient option for those who need to carry their allen wrenches around. These sets feature a set of hexagonal wrenches that fold neatly into a compact case or handle. The foldable design makes it easy to store and transport the wrenches, making them ideal for on-the-go repairs or maintenance tasks.

3. T-Handle Allen Wrench

T-handle allen wrenches are designed with a T-shaped handle for increased leverage and control. These wrenches are especially useful when working with stubborn hex screws or bolts. The T-handle design allows for a more comfortable grip and makes it easier to apply the necessary torque to remove or tighten hexagon fasteners.

4. Ball-End Allen Wrench

Ball-end allen wrenches have a unique design that allows for easier access to hex screws or bolts in tight or obstructed spaces. These wrenches feature a rounded tip instead of a hexagonal one, allowing them to be inserted at an angle. This design enables the user to work at different angles and positions while maintaining a secure grip on the fastener.

5. Tamper-Proof Allen Wrench

Tamper-proof allen wrenches are specifically designed to tighten or loosen tamper-resistant hex screws or bolts. These screws feature a pin or other obstruction in the middle of the hex socket, preventing a regular allen wrench from fitting properly. Tamper-proof allen wrenches feature a hollowed-out center that allows them to fit over the obstruction, providing the necessary leverage to engage the screw or bolt.

6. Security Allen Wrench Set

Security allen wrench sets are used to remove security fasteners that have unique or intricate screw heads. These sets include wrenches with specialized tips that can engage with the corresponding security screws. They are commonly used in situations where tampering or unauthorized access needs to be prevented, such as in high-security environments or with valuable equipment.

Overall, allen wrenches come in various types and sizes to suit different applications and requirements. Whether you need a set for general-purpose use or for specific tasks, there is a wide range of options available to meet your needs.

Popularity and common uses of allen wrenches

Introduction

The popularity of allen wrenches, also known as hex keys or hex wrenches, stems from their versatility and ease of use in various applications. These hexagonal tools are commonly used in both professional and household settings for a wide range of tasks.

Assembly of Furniture and Appliances

One of the most common uses of allen wrenches is in the assembly of furniture and appliances. Many manufacturers provide allen wrenches with their products, as these tools are often needed to tighten screws and bolts that hold various parts together. Whether it’s a desk, chair, shelf, or even a bed frame, allen wrenches are indispensable in ensuring the sturdiness and stability of the assembled items.

Bicycle Maintenance

Allen wrenches are widely used in bicycle maintenance due to the prevalence of hex bolts and screws on bicycles. From adjusting the seat height to tightening brake calipers or handlebars, allen wrenches play a crucial role in maintaining and repairing bicycles. Their compact size and ability to reach tight spaces make them a preferred tool among cyclists and bike mechanics.

Electronic Device Repair

In the world of electronics, many devices such as computers, smartphones, and gaming consoles rely on hex screws for assembling and securing components. Allen wrenches allow technicians and DIY enthusiasts to open and repair these devices without causing damage. Whether it’s replacing a hard drive or upgrading memory, having the right size allen wrench is often necessary for such tasks.

Machinery and Industrial Applications

Hex bolts and screws are commonly used in machinery and industrial equipment due to their resistance to vibrations and ability to support heavy loads. As a result, allen wrenches are frequently employed in mechanical and industrial settings for assembly, disassembly, and maintenance of machines, engines, and various equipment.

Conclusion

The popularity and common uses of allen wrenches can be attributed to their versatility, compact size, and effectiveness in tightening and loosening hex bolts and screws. Whether it’s assembling furniture, maintaining bicycles, repairing electronics, or working with machinery, allen wrenches have become an essential tool in various industries and households around the world.

Advantages of using allen wrenches

Allen wrenches, also known as hex keys, are widely used in various industries for a multitude of tasks. These simple yet effective tools offer several advantages that make them a preferred choice for many professionals and DIY enthusiasts. Here are some of the main advantages of using allen wrenches:

1. Versatility

One of the primary advantages of allen wrenches is their versatility. These tools come in various sizes, ranging from small and compact to larger sizes, allowing them to be used for different applications. Whether you need to tighten a small screw in intricate machinery or assemble furniture, an allen wrench can handle the job with ease.

2. Efficient Torque Transmission

Allen wrenches feature a hexagonal shape that provides excellent torque transmission. The design ensures a tight grip and minimizes the risk of slipping, allowing you to apply more force without worrying about damaging the screw or bolt. This efficient torque transmission makes allen wrenches particularly useful for tasks that require precise tightening, such as building electronic devices or tightening bike components.

3. Space-Saving Design

Another advantage of allen wrenches is their compact and space-saving design. The L-shaped or T-shaped handle makes it easy to access screws and bolts that are located in tight or hard-to-reach spots. This design allows you to work in cramped spaces, such as within machinery or behind furniture, without requiring a lot of room to maneuver.

4. Durable and Long-Lasting

Allen wrenches are typically made from high-quality materials, such as hardened steel or chrome vanadium, which enhances their strength and durability. The robust construction ensures that the wrenches can withstand heavy-duty use without breaking or wearing out easily. This durability makes them a reliable tool that can handle demanding tasks in various industries.

5. Cost-Effective

Compared to other types of wrenches or tools, allen wrenches are generally more affordable. Their simple design and production process make them cost-effective, making them an accessible choice for professionals and DIYers alike. Investing in a set of allen wrenches can save you money in the long run, as they can be used for multiple tasks and are built to last.

6. Enhanced Accuracy

Allen wrenches provide excellent control and precision, thanks to their compact size and design. This accuracy is crucial for tasks that require delicate adjustments or work in tight spaces. The ability to precisely fit into screws or bolts ensures that you can tighten or loosen them with minimal effort and achieve the desired result without damaging the surrounding components.

7. Wide Range of Applications

Allen wrenches find applications in a wide range of industries and tasks. From automotive repairs and electronic assembly to furniture assembly and plumbing work, these versatile tools can handle various jobs efficiently. Their compatibility with both metric and imperial sizes further expands their usage, making them a go-to tool for many professionals.

| Advantages of using allen wrenches | |||

|---|---|---|---|

| Versatility | Efficient Torque Transmission | Space-Saving Design | Durable and Long-Lasting |

| Cost-Effective | Enhanced Accuracy | Wide Range of Applications |

How to properly use an allen wrench

- Step 1: Choose the correct size allen wrench for the job. Allen wrenches come in various sizes, so it is important to use the right size for your specific task. Using the wrong size can damage the fastener or the wrench itself.

- Step 2: Insert the shorter end of the allen wrench into the corresponding hexagonal hole on the fastener. The hexagonal shape of the hole is designed to provide maximum grip and power transfer when turning the wrench.

- Step 3: Hold the longer end of the wrench firmly and apply steady pressure in the desired direction. Most allen wrenches are L-shaped, allowing you to easily grip and exert force on the fastener.

- Step 4: Turn the wrench clockwise to tighten the fastener or counterclockwise to loosen it. Make sure to turn the wrench in small increments to prevent overtightening or stripping the fastener.

- Step 5: If necessary, use the longer end of the wrench as a lever for additional torque. However, be cautious not to apply too much force, as it may cause the fastener or wrench to break.

- Step 6: Once the desired tightness or looseness is achieved, remove the wrench from the fastener by pulling it straight out.

Remember to always use an allen wrench that is in good condition and not worn out. Using a damaged wrench can lead to improper torque application, resulting in stripped fasteners or injuries.

Additionally, if you encounter resistance while turning the wrench, do not force it. Instead, check if the hexagonal hole or the fastener is damaged and address the issue before proceeding.

Overall, using an allen wrench properly requires selecting the right size, applying steady pressure, and using caution to avoid damage or injury. With proper technique and attention, you can effectively use an allen wrench to tighten or loosen various types of fasteners.

Tips and tricks for maintaining allen wrenches

Allen wrenches, also known as hex keys, are versatile tools that are commonly used for assembling and disassembling furniture, machinery, and other equipment. Proper maintenance of these tools is essential to ensure their longevity and effectiveness. Here are some helpful tips and tricks for maintaining allen wrenches:

- Keep them clean: After each use, make sure to wipe down your allen wrenches with a clean cloth to remove any dirt, grease, or debris. This will prevent the buildup of grime and ensure smooth operation.

- Store them properly: It is important to store your allen wrenches in a dry and organized manner. Consider using a tool chest or a designated tool roll to keep them together and protect them from moisture and damage.

- Avoid over-torquing: Over-tightening screws or bolts with an allen wrench can cause excessive stress on the tool and lead to premature wear. Use the appropriate size allen wrench for the job and apply steady, even pressure.

- Inspect for damage: Regularly inspect your allen wrenches for signs of wear or damage. Look for bent or rounded edges, as these can affect the tool’s ability to grip properly. Replace any worn-out or damaged wrenches to ensure safe and effective use.

- Apply lubrication: To keep your allen wrenches operating smoothly, apply a small amount of lubricant, such as silicone spray or light machine oil, to the moving parts. This will help reduce friction and prevent rust.

- Use the right technique: When using an allen wrench, make sure to align it properly with the screw or bolt. Apply force in a straight line to prevent slippage and potential injury. Consider using a T-handle allen wrench for better control and leverage.

- Protect the finish: If your allen wrenches have a colored or plated finish, take extra care to avoid scratching or chipping it. Use a soft cloth or non-abrasive cleaning agents when necessary.

By following these tips and tricks, you can extend the lifespan of your allen wrenches and ensure that they remain reliable tools in your arsenal. Remember to always use the right size and type of allen wrench for each task and handle them with care.

FAQ

What is an allen wrench?

An allen wrench is a type of tool used to tighten or loosen screws and bolts with hexagonal sockets.

Why is it called an allen wrench?

It is called an allen wrench because it was invented by the Allen Manufacturing Company in the early 20th century.

Who invented the allen wrench?

The allen wrench was invented by the Allen Manufacturing Company.

When was the allen wrench invented?

The allen wrench was invented in the early 20th century.

What are some alternative names for an allen wrench?

Some alternative names for an allen wrench are hex key, hex wrench, and hexagon key.

What materials are allen wrenches made of?

Allen wrenches are typically made of hardened steel or other durable materials.

What are some common uses for allen wrenches?

Allen wrenches are commonly used to assemble and disassemble furniture, bicycles, and other products with hexagonal fasteners.

Video