What to do if your allen wrench is stripped – Tips and solutions

Allen wrenches, also known as hex keys, are handy tools used for tightening or loosening screws and bolts with hexagonal socket heads. However, over time, the hexagonal shape of the wrench can become worn or stripped, making it difficult or even impossible to use. If you find yourself in this frustrating situation, there are several tips and solutions you can try to salvage your allen wrench and get the job done.

One solution is to use a rubber band or a piece of thick cloth. Simply place the rubber band or cloth between the stripped wrench and the screw or bolt head, and apply pressure while turning. The rubber or cloth can provide enough grip to allow the wrench to catch on the edges of the screw or bolt, enabling you to loosen or tighten it.

Another option is to use a power drill with a matching allen wrench bit. Power drills can apply stronger and more consistent torque than manual wrenches, making it easier to turn stripped screws or bolts. To use this method, select the appropriate allen wrench bit for your power drill, secure it in place, and carefully apply pressure while turning.

If all else fails, you may need to resort to more drastic measures, such as using a pair of pliers or vice grips to grip the stripped allen wrench. This method requires caution and precision to avoid damaging the screw or bolt head or injuring yourself. Gradually apply pressure while turning the wrench with the pliers or vice grips, and be prepared to make small adjustments as necessary.

Remember, prevention is always better than a cure. To avoid future issues with stripped allen wrenches, be sure to select the correct size wrench for the screw or bolt head, and use it with care. Avoid applying excessive force or using worn or damaged wrenches, as this can cause stripping. With proper maintenance and usage, your allen wrenches can serve you well for many projects to come.

Identify the problem

Before you can find a solution for a stripped allen wrench, it is important to properly identify the problem. Here are some steps to help you identify the issue:

- Visual examination: Inspect the allen wrench to determine if the hexagonal shape is damaged or worn down. Look for signs of rounding or smoothing of the edges.

- Difficulty turning: Attempt to turn the allen wrench in the corresponding screw or bolt. If you encounter resistance or the wrench slips, it is likely that the hexagonal hole is stripped.

- Inspect the screw or bolt: Examine the screw or bolt that the allen wrench is supposed to fit into. Look for signs of wear, damage, or rounding on the inside walls of the hexagonal hole.

- Test with another wrench: If available, try using another allen wrench or a different size that is known to be in good condition. If the second wrench also slips or has difficulty turning, it confirms that the problem lies with the screw or bolt.

By carefully examining the allen wrench and the screw or bolt, you should be able to accurately determine if the wrench is stripped or if the problem lies with the screw or bolt.

Use a rubber band

If your allen wrench is stripped and you can’t get a good grip on it, one simple solution is to use a rubber band.

Here’s how:

- Take a rubber band, preferably a thick one, and loop it over the end of the allen wrench.

- Make sure the rubber band is secure and tightly wrapped around the allen wrench.

- Insert the allen wrench into the stripped screw or bolt and apply pressure while turning.

- The rubber band will provide extra grip and help you turn the allen wrench even if the head is stripped.

This method works because the rubber band creates friction between the allen wrench and the stripped fastener, allowing you to apply more force without the wrench slipping.

Note: If your allen wrench is too small for a rubber band, you can use a small piece of adhesive tape or even a small square of sandpaper to create traction.

Try a larger size

If you’re finding it difficult to use your stripped allen wrench, one solution is to try a larger size. While it may seem counterintuitive, using a larger wrench can sometimes provide a better grip on the stripped area.

Here is a step-by-step guide on how to try a larger size:

- First, determine the size of the allen wrench that you are currently using. This can usually be found on the wrench itself or in the product manual.

- Visit a hardware or tool store to find a set of allen wrenches with a larger size. These sets often come in a variety of sizes, so you should be able to find one that is larger than your current wrench.

- Select the larger size allen wrench from the set and insert it into the stripped area. Make sure it fits securely before attempting to turn the screw or bolt.

- Apply steady pressure while turning the wrench to loosen or tighten the screw or bolt. Be careful not to apply too much force, as this can cause damage to the fastener or the wrench.

- If the larger size wrench does not work, you may need to consider alternative solutions such as using pliers or a screw extractor tool.

Remember to always use the correct size allen wrench for the job to prevent further damage to the fastener or the wrench itself. If you are unsure about the correct size to use, consult a professional or refer to the product manual.

By trying a larger size allen wrench, you may be able to overcome the difficulties posed by a stripped wrench and successfully complete your desired task.

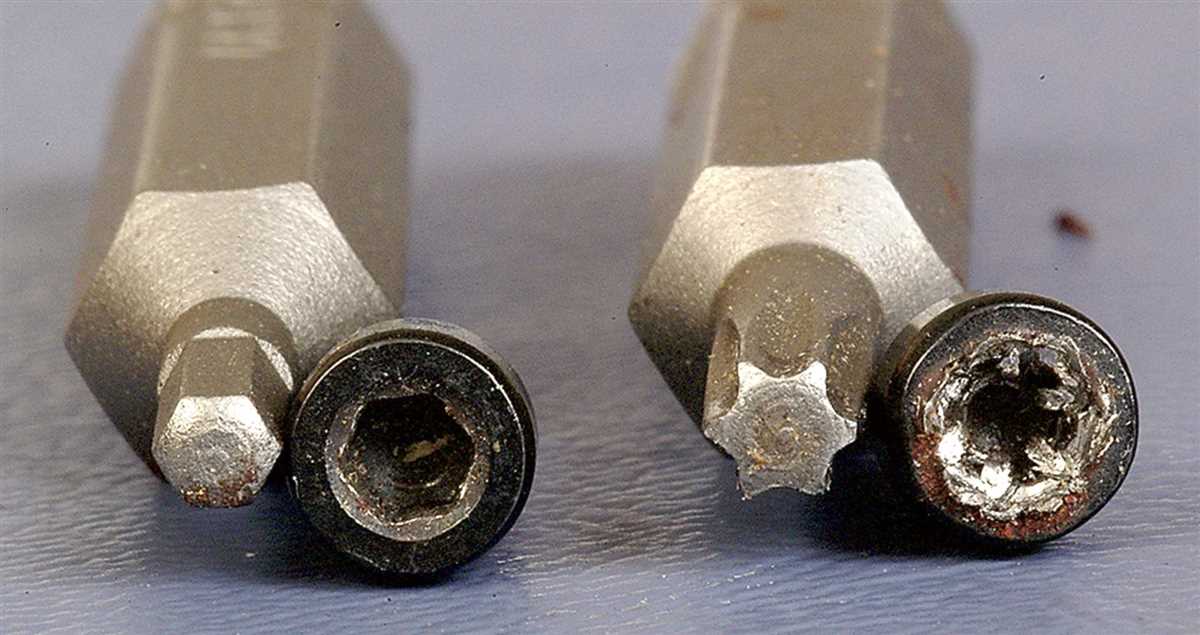

Use a torx driver

If your allen wrench is stripped, another option you can try is using a torx driver. Torx drivers are designed with a star-shaped head that provides better grip and reduces the chances of stripping your fasteners.

To use a torx driver, follow these steps:

-

Identify the appropriate torx driver size for your fastener. Torx drivers come in various sizes, so make sure you select the correct size for your needs.

-

Insert the torx driver into the fastener and apply firm pressure. Make sure the driver fits securely into the fastener head.

-

Slowly rotate the torx driver counterclockwise to loosen the fastener. Apply steady pressure to avoid slipping and further damaging the fastener.

-

Once the fastener is loosened, continue rotating the torx driver to remove it completely.

Using a torx driver can be an effective solution if your allen wrench is stripped. Make sure to select the correct torx driver size to ensure a secure fit and prevent any further damage to the fastener.

Apply heat

If your allen wrench is stripped, one solution is to apply heat to the fastener. The heat can help expand the metal and loosen the stripped allen wrench, making it easier to remove.

Materials needed:

- Heat source (e.g. blowtorch, heat gun)

- Protective gloves and goggles

- Fire extinguisher (as a safety precaution)

Steps to apply heat:

- Ensure you have a safe working area without any flammable materials nearby.

- Put on your protective gloves and goggles to protect yourself from heat and potential sparks.

- Prepare your heat source (e.g. blowtorch or heat gun) according to the manufacturer’s instructions.

- Aim the heat source directly at the stripped allen wrench and apply steady heat to the fastener.

- Move the heat source around in a circular motion to evenly distribute the heat and help expand the metal.

- Continue applying heat for a few minutes or until you feel the fastener starting to loosen.

- Once the fastener has loosened, carefully use another tool (such as pliers or vice grips) to remove it from the stripped allen wrench.

- After removal, allow the fastener and allen wrench to cool down before handling.

Note: Be cautious when using heat sources as they can cause burns and start fires. Keep a fire extinguisher nearby as a safety precaution.

Use a hammer and chisel

If your allen wrench is stripped and you cannot remove a screw or bolt, you can try using a hammer and chisel as an alternative method.

Materials needed:

- Hammer

- Chisel

Step 1: Position the chisel

Place the chisel at an angle on one side of the stripped allen wrench head. Make sure the chisel is securely positioned.

Step 2: Hammer the chisel

Using the hammer, hit the chisel firmly and carefully to create a notch on the stripped allen wrench head. The force from the hammer should help loosen the screw or bolt.

Step 3: Turn the allen wrench

Once you have created a notch on the stripped allen wrench head, try turning the wrench with a pair of pliers or an adjustable wrench. The notch should provide enough grip to loosen and remove the screw or bolt.

Important note:

Using a hammer and chisel method may cause damage to the allen wrench or the screw/bolt head. Only use this method if you are unable to remove the stripped allen wrench using other techniques, and be cautious when applying force with the hammer.

Using a hammer and chisel as a solution for a stripped allen wrench is a last resort method. If this method does not work or causes further damage, it is recommended to seek professional assistance or replace the stripped allen wrench.

Cut a new notch

If your allen wrench is stripped and you don’t have a replacement on hand, you can try cutting a new notch into the wrench. Here’s how:

- Gather the necessary tools – You will need a rotary tool or a metal file, a pair of safety goggles, and a pair of gloves.

- Put on safety gear – Before you start cutting, make sure to put on your safety goggles and gloves to protect yourself from any flying debris.

- Choose the correct size – Select the appropriate size cutting tool or metal file that matches the size of the stripped allen wrench.

- Align the tool – Place the cutting tool or metal file on the side of the allen wrench that is opposite the stripped side. Make sure the tool is aligned perpendicular to the wrench.

- Apply pressure – Apply gentle pressure to the tool while moving it back and forth in a sawing motion. This will gradually cut a new groove or notch into the wrench.

- Test the new notch – Once you have created a new groove, try fitting the wrench into the screw or bolt you were working on. If it fits securely, you can proceed with using the wrench. If not, you may need to repeat the process or consider alternative solutions.

Please note that cutting a new notch into a stripped allen wrench should be seen as a temporary solution. It is recommended to replace the wrench as soon as possible to avoid further damage or frustration.

Seek professional help

If you have tried all the above tips and solutions and still can’t remove the stripped allen wrench bolt, it may be time to seek professional help. A trained technician or mechanic will have the necessary tools and expertise to safely and effectively remove the bolt without causing any further damage.

Here are a few options for seeking professional help:

- Visit a hardware store: Most hardware stores have knowledgeable staff members who can assist you in finding the right tools or recommending a professional service.

- Contact a locksmith: Locksmiths are skilled at working with various types of bolts and screws, including stripped ones. They may be able to help you remove the stripped allen wrench bolt.

- Call a professional handyman: Handymen are experienced in solving a variety of household problems, including stuck or stripped bolts. They can come to your location and help you remove the bolt safely.

Remember, attempting to remove a stripped allen wrench bolt on your own can result in further damage or injury. It’s always best to seek professional help if you’re not confident in your abilities or don’t have the necessary tools.

Additionally, seeking professional help will save you time and frustration, as the experts know the most effective techniques for removing stripped bolts. They can also provide advice on preventing similar issues in the future.

FAQ

My allen wrench is stripped, what should I do?

If your allen wrench is stripped, there are a few things you can try. First, you can try using a rubber band to provide extra grip on the stripped bolt or screw. Simply place the rubber band over the head of the allen wrench and press it into the stripped bolt or screw. This can provide enough grip to remove the bolt or screw. Another option is to try using a pair of pliers to grip the stripped bolt or screw and turn it. If these methods don’t work, you may need to use a drill and a drill bit to remove the stripped bolt or screw. Simply place the appropriate sized drill bit on the stripped bolt or screw and slowly drill into it. Once the drill bit has bitten into the stripped bolt or screw, you can use the drill to turn it and remove it. If all else fails, you may need to consult a professional for assistance.

Is there a way to prevent my allen wrench from getting stripped?

There are a few things you can do to prevent your allen wrench from getting stripped. First, make sure you are using the correct size allen wrench for the bolt or screw you are working with. Using the wrong size allen wrench can cause damage and stripping. Additionally, make sure you are applying even pressure when turning the bolt or screw. Applying too much force can cause the allen wrench to slip and strip. Finally, if you are working with older or rusted bolts or screws, it may be helpful to apply a lubricant, such as WD-40, before attempting to turn them.

Can I use a different tool if my allen wrench is stripped?

If your allen wrench is stripped and you don’t have a replacement, you can try using a different tool to remove the bolt or screw. One option is to use a pair of vice grips or pliers to grip the stripped bolt or screw and turn it. Another option is to use a socket wrench with the appropriate sized socket. Simply attach the socket to the socket wrench and place it over the stripped bolt or screw. Turn the socket wrench to remove the bolt or screw. If these methods don’t work, you may need to use a drill and a drill bit to remove the stripped bolt or screw.

What should I do if the bolt or screw is stripped, not the allen wrench?

If the bolt or screw is stripped, not the allen wrench, you have a few options. First, you can try using a pair of pliers or vice grips to grip the head of the bolt or screw and turn it. Apply even pressure and slowly turn the pliers or vice grips until the bolt or screw is removed. Another option is to use a screw extractor tool. This tool is specifically designed to remove stripped bolts and screws. Simply place the screw extractor in the stripped bolt or screw and turn it counterclockwise. The screw extractor will grip the stripped bolt or screw and allow you to remove it.

Can I fix a stripped allen wrench?

Unfortunately, a stripped allen wrench cannot be fixed. Once the metal on the allen wrench has worn down or been damaged, it is no longer effective for turning bolts and screws. However, if you have a set of allen wrenches, you can try using a different size allen wrench to see if it fits the bolt or screw you are working with. If none of the sizes in your set fit, you may need to purchase a replacement allen wrench.

How can I prevent stripping bolts and screws in the future?

To prevent stripping bolts and screws in the future, there are a few things you can do. First, make sure you are using the correct size wrench or tool for the bolt or screw you are working with. Using the wrong size tool can cause damage and stripping. Additionally, make sure you are applying even pressure when turning the bolt or screw. Applying too much force can cause the tool to slip and strip. If you are working with older or rusted bolts or screws, it may be helpful to apply a lubricant, such as WD-40, before attempting to turn them. Regular maintenance and inspection of bolts and screws can also help prevent stripping by identifying and addressing any issues early on.