What Is the Geometric Shape of an Allen Wrench Hole?

An Allen wrench, also known as a hex key or hex wrench, is a commonly used tool in various industries and DIY projects. It is primarily used to tighten or loosen screws and bolts with hexagonal sockets. The Allen wrench itself has a distinct geometric shape, but what about the shape of the hole it fits into?

The geometric shape of an Allen wrench hole is a hexagon. A hexagon is a polygon with six sides and six angles. Each side of the hexagon is equal in length and each angle measures 120 degrees. This shape allows for efficient torque transfer and ensures a secure connection between the wrench and the bolt or screw.

Using a hexagon as the shape of the Allen wrench hole has several advantages. First, it provides more points of contact between the wrench and the fastener, reducing the risk of stripping or rounding out the socket. Second, the hexagon shape allows for greater torque to be applied, as the flat surfaces of the wrench can easily withstand the force without slipping. Additionally, the hexagon shape is relatively easy to manufacture and provides a stable and secure grip.

In conclusion, the geometric shape of an Allen wrench hole is a hexagon. This shape offers several benefits, including enhanced torque transfer, increased stability, and reduced risk of stripping. The use of a hexagon as the shape of the Allen wrench hole has become a standard in the industry, ensuring a reliable and efficient connection between the wrench and the fastener.

What Is an Allen Wrench?

An Allen wrench, also known as a hex key or hex wrench, is a hand tool used to tighten or loosen screws and bolts that have a hexagonal socket, also known as an Allen recess or Allen hole. It is named after the Allen Manufacturing Company, which first introduced this type of tool in the early 1900s.

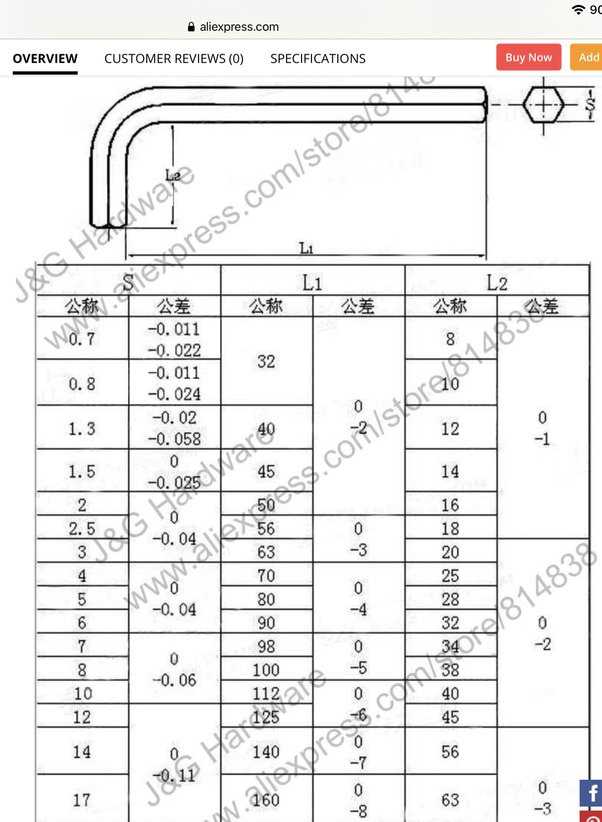

The Allen wrench is typically L-shaped and made of steel or other durable materials. It consists of a long arm and a short arm, both of which feature a hexagonal-shaped end with different sizes. The most common sizes of Allen wrenches include 1/16 inch, 5/64 inch, 3/32 inch, 7/64 inch, 1/8 inch, 9/64 inch, 5/32 inch, and 3/16 inch.

To use an Allen wrench, you insert the hexagonal end into the corresponding hexagonal socket of a screw or bolt and apply force by rotating the wrench clockwise or counterclockwise. The L-shaped design provides leverage and allows for easy access to tight spaces.

The Allen wrench is commonly used in various applications, including furniture assembly, bicycle maintenance, automotive repairs, and electronics. It is a versatile tool that can be found in many toolboxes and is known for its ability to provide a secure grip on hexagonal fasteners.

Overall, the Allen wrench is an indispensable tool for DIY enthusiasts, professionals, and anyone who needs to tighten or loosen screws or bolts with hexagonal sockets. Its compact size, efficiency, and ease of use make it a valuable addition to any toolkit.

The Importance of Allen Wrench Holes

In the world of fasteners, Allen wrench holes play a vital role in the assembly and disassembly of various objects. These small, geometrically shaped holes are designed to accommodate the corresponding Allen wrench, also known as a hex key, allowing users to tighten or loosen screws and bolts with ease.

1. Versatility

Allen wrench holes come in a variety of sizes, typically ranging from 0.05 inches to 0.5 inches in diameter. This wide range of sizes allows for versatility in terms of the objects they can be used on. From furniture assembly to automotive repairs, Allen wrench holes are found in numerous applications where precise and secure fastening is required.

2. Torque Distribution

The geometric shape of an Allen wrench hole, which is typically hexagonal, plays a crucial role in distributing torque evenly. This means that when an Allen wrench is inserted into the hole and force is applied, the torque is distributed across all sides of the hole, minimizing the risk of slippage or damage to the fastener.

3. Space Saving

Another advantage of Allen wrench holes is their space-saving design. The hexagonal shape allows for a more compact design compared to other types of fasteners that may require additional space for tools such as screwdrivers or spanners. This makes Allen wrench holes ideal for applications where space is limited, such as in electronic devices or machinery.

4. Security

Due to the hexagonal shape of Allen wrench holes, they offer a greater level of security compared to other types of fasteners. The shape makes it more difficult for unauthorized individuals to tamper with or remove the fastener without the proper tool. This added security can be particularly important in industries where safety and security are critical.

5. Cost Efficiency

Allen wrench holes are cost-effective to produce due to their simple geometric shape. The manufacturing process for these holes is relatively straightforward, which helps to keep production costs low. Additionally, the availability of Allen wrenches in various sizes makes them easily accessible and affordable for both professionals and DIY enthusiasts.

| Advantage | Description |

|---|---|

| Versatility | Can be used on a wide range of objects. |

| Torque Distribution | Distributes torque evenly for secure fastening. |

| Space Saving | Compact design ideal for limited space applications. |

| Security | Offers a greater level of security compared to other fasteners. |

| Cost Efficiency | Simple manufacturing process keeps production costs low. |

The Geometric Shape of an Allen Wrench Hole

An Allen wrench, also known as a hex key or hex wrench, is a commonly used tool with a unique geometric shape. The hexagonal (six-sided) shape of the Allen wrench hole is what sets it apart from other types of screws and bolts. The hole is specifically designed to fit the corresponding hexagonal head of the fastener.

This hexagonal shape provides several benefits. First, it allows for a secure and tight fit between the wrench and the fastener. The six sides of the hole evenly distribute the torque applied to the wrench, preventing slipping or rounding of the fastener. This makes Allen wrenches ideal for high-torque applications.

Another advantage of the hexagonal shape is that it allows for easy identification and selection of the correct size wrench. The size of the hole is determined by the width across opposite flats (sides) of the hexagon. Common sizes include 1/16″, 5/64″, 3/32″, 1/8″, and so on, up to larger sizes for heavy-duty applications. This standardized sizing system makes it simple for users to quickly find the right wrench for the job.

The material of the Allen wrench also affects its performance. Most Allen wrenches are made from hardened steel, which provides strength and durability. Some high-quality wrenches may have a coating, such as black oxide or chrome plating, to enhance corrosion resistance and reduce wear.

In conclusion, the geometric shape of an Allen wrench hole is hexagonal, with six equal sides. This shape ensures a secure fit, even distribution of torque, easy identification of size, and durability. Whether you’re assembling furniture or working on a mechanical project, the Allen wrench’s unique shape makes it a valuable tool in many applications.

Hexagonal Shape

The geometric shape of an Allen wrench hole is hexagonal, meaning it has six sides. This shape is commonly referred to as a hexagon.

The purpose of the hexagonal shape is to provide a secure grip for the wrench, allowing for maximum torque to be applied when turning fasteners. The six flat sides of the hexagon provide multiple points of contact with the wrench, reducing the likelihood of slipping or rounding off the edges of the fastener.

The hexagonal shape is commonly used in a variety of applications, including automotive repairs, furniture assembly, and machinery maintenance. It is a versatile and effective shape for fastening and loosening bolts, screws, and other types of fasteners.

When using an Allen wrench, it is important to ensure that the tool is fully engaged in the hexagonal hole to avoid stripping or damaging the fastener. It is recommended to use the correct size of Allen wrench to ensure a proper fit.

Six Sides on an Allen Wrench Hole

An Allen wrench, also known as a hex key or hex wrench, is a common tool used for tightening or loosening bolts and screws with a hexagonal socket. The socket, which is also referred to as an Allen wrench hole or Allen head, is designed with six sides.

The shape of the Allen wrench hole allows for a secure grip when turning the tool. The six sides provide multiple contact points, distributing the force evenly and reducing the likelihood of the tool slipping or stripping the socket.

The six-sided shape of the Allen wrench hole is known as a hexagon. A hexagon is a polygon with six sides and six angles. Each angle measures 120 degrees, and all the sides are equal in length. The hexagon’s symmetry allows for easy alignment of the wrench with the socket.

The Allen wrench hole is typically machined with precise dimensions to ensure a tight fit. The size of the hexagonal socket is determined by the distance between opposite parallel sides, known as the distance across flats (DAF) or the wrench size. Common sizes include 1.5mm, 2mm, 2.5mm, 3mm, and so on.

Hex keys are commonly used in various applications, including assembling furniture, repairing bicycles, and working on machinery. The six-sided shape of the Allen wrench hole, combined with its versatility and compact size, makes it a valuable tool in many industries and households.

Why Hexagonal Shape is Used

The hexagonal shape is commonly used for the hole of an Allen wrench because of several practical reasons. Here are some of the main reasons why the hexagonal shape is preferred:

1. Secure Grip

The hexagonal shape provides a more secure grip on the wrench compared to other shapes. The six sides of the hexagon distribute the torque evenly, reducing the chances of slipping or stripping the fastener. This makes it easier to apply and control the necessary force to turn the screw or bolt.

2. Versatility

The hexagonal shape is versatile and can fit different sizes of screws and bolts. The six flat sides allow for a range of sizes, making it a popular choice for various applications. With a single set of hex wrenches, you can work with multiple fastener sizes, reducing the need for multiple tools.

3. Space Efficiency

The hexagonal shape requires relatively less space compared to other shapes. This makes it suitable for tight spaces where other types of wrenches may not fit. The compact design allows for more accessibility and maneuverability in confined areas, such as in machinery, engines, or electronic devices.

4. Durability

The hexagonal shape offers excellent strength and durability. The six-sided design provides ample surface area for distributing force, reducing the risk of breaking or bending the wrench. This makes hex wrenches reliable and long-lasting tools.

5. Industry Standard

Hexagonal shape has become an industry standard for many fasteners. It is widely used in construction, automotive, furniture assembly, and other industries. Using a hexagonal shape ensures compatibility and interchangeability, as many manufacturers design their fasteners to fit hexagonal holes.

In conclusion, the hexagonal shape of an Allen wrench hole is preferred due to its secure grip, versatility, space efficiency, durability, and industry standardization. It offers practical advantages that make it a go-to choice for various applications.

Strength and Durability

One of the key advantages of using the geometric shape of an allen wrench hole is its strength and durability. The hexagonal shape of the hole allows for a tight and secure fit between the allen wrench and the screw or bolt it is being used on.

The shape of the allen wrench hole distributes the force applied by the wrench evenly, minimizing the risk of slipping or stripping. This design feature helps prevent damage or wear to both the wrench and the screw or bolt, ensuring a longer lifespan for both tools.

Additionally, the hexagonal shape provides multiple contact points between the wrench and the screw or bolt, creating a more stable connection. This increased stability not only improves the effectiveness of applying torque but also reduces the chances of the wrench slipping out or rounding off the corners of the hole.

Furthermore, the material used to manufacture the allen wrench hole, such as hardened steel, further enhances its strength and durability. This ensures that the hole can withstand the repeated torque and pressure applied during various tasks.

Overall, the shape and material of the allen wrench hole combine to create a strong and durable tool that is capable of handling various tasks without compromising its integrity.

Efficient Design for Tight Spaces

In tight spaces, every inch counts. Whether you’re working in a cramped kitchen or trying to assemble furniture in a small apartment, efficient design is key. This is where the shape of an Allen wrench hole plays a crucial role.

The Allen wrench, also known as a hex key, uses a specific shape to turn screws and bolts. The most common shape for the Allen wrench hole is a hexagon, which has six sides. This shape allows for a secure grip and prevents slipping while applying torque.

When it comes to designing products for tight spaces, manufacturers often choose the Allen wrench hole for its efficient shape. Here are some reasons why:

- Fits in compact spaces: The hexagon shape of the Allen wrench hole allows for a tighter fit in small and confined areas. This is especially beneficial in appliances and electronic devices where space is limited.

- Easy to use: The Allen wrench hole is user-friendly and can be used with a simple twist. Its shape ensures a stable grip, making it easier to apply the necessary force to loosen or tighten screws.

- Durable and reliable: The hexagon shape provides a strong and reliable connection between the wrench and the screw or bolt. This reduces the risk of stripping or damaging the fastener, ensuring a long-lasting and secure connection.

Manufacturers are constantly striving to optimize their products for tight spaces, and the Allen wrench hole is a testament to that effort. Its efficient design allows for easy assembly and maintenance in even the most challenging environments.

Next time you find yourself working in a tight space, take a moment to appreciate the clever design of the Allen wrench hole. It is a small but important feature that can make a big difference in your productivity and overall experience.

Other Geometric Shapes for Allen Wrench Holes

In addition to the common hexagonal shape, Allen wrench holes can also come in other geometric shapes. While the hexagon is most commonly used due to its efficient use of space and ease of manufacturing, there are situations where other shapes are preferred.

1. Torx (Star) Shape

The Torx shape is a six-pointed star-like shape. It is often used in applications where a higher level of torque is required or where there is a need for better resistance to cam-out. The Torx shape provides increased contact area between the wrench and the screw, allowing for higher torque transmission. This shape is commonly found in automotive and electronics industries.

2. Square Shape

The square shape is another alternative to the hexagonal shape. It provides a larger contact area, which can help prevent slippage and striping of the screw. Additionally, the square shape allows for the use of a larger wrench size, which can provide more torque. However, the square shape requires more space compared to the hexagonal shape, limiting its use in compact designs.

3. Tri-Wing Shape

The tri-wing shape is a three-pointed shape that is often used in specialized applications where additional security is required. It is commonly found in electronic devices, such as game consoles, to prevent unauthorized tampering. The tri-wing shape requires a specific tool to fit the holes, making it harder for individuals without the proper equipment to access the screws.

4. Spline Shape

The spline shape is a series of grooves or splines around the opening. It provides a larger surface area for torque transmission, which can prevent stripping of the screw. The spline shape is often used in high-torque applications or in situations where a compact design is required. It is commonly found in industrial machinery and equipment.

Conclusion

While the hexagonal shape is the most common and versatile for Allen wrench holes, there are several other geometric shapes that can be used for specific applications. The choice of shape depends on factors such as desired torque transmission, space constraints, and security requirements. Manufacturers select the appropriate shape based on the specific needs of their products.

Square Shape

One of the most common geometric shapes for an Allen wrench hole is the square shape. This shape is found in many different types and sizes of Allen wrenches, and is used to fit into corresponding square-shaped screws or bolts. The square shape provides a secure fit and allows for maximum torque transfer between the wrench and the fastener.

The square shape of an Allen wrench hole is designed to prevent slipping and stripping of the fastener. The four sides of the square shape provide multiple contact points with the screw or bolt, ensuring a firm grip and reducing the risk of rounding off the corners of the fastener.

When using an Allen wrench with a square-shaped hole, it is important to align the wrench properly with the fastener to ensure a snug fit. The square shape allows for easy identification and alignment, making it convenient for use in various applications.

Allen wrenches with square-shaped holes are commonly used in furniture assembly, automotive repairs, bicycle maintenance, and many other applications. They are an essential tool in any toolbox or workshop, providing a reliable and efficient way to tighten or loosen screws and bolts with a square head.

FAQ

What is an Allen wrench hole?

An Allen wrench hole is a six-sided hole that is used to drive Allen wrenches or hex keys.

What is the geometric shape of an Allen wrench hole?

The geometric shape of an Allen wrench hole is a hexagon.

Why are Allen wrench holes shaped like hexagons?

Allen wrench holes are shaped like hexagons because the six-sided shape provides better grip and prevents slipping during use.

Do all Allen wrench holes have the same size?

No, Allen wrench holes come in different sizes to fit different Allen wrenches or hex keys. Common sizes include 1/16″, 5/64″, 3/32″, 7/64″, 1/8″, 9/64″, 5/32″, and so on.

Can Allen wrench holes be found in other tools besides wrenches?

Yes, Allen wrench holes can be found in various tools and equipment, such as screws, bolts, furniture assembly kits, bike pedals, and more. They are commonly used in applications that require a secure tool connection.

Video