What is a Strap Wrench Used For: Everything You Need to Know

When it comes to loosening or tightening stubborn objects with smooth surfaces, a strap wrench is the tool to turn to. This versatile tool is designed to provide maximum grip and torque without damaging the object being worked on. It consists of a long handle with a flexible strap looped around it, which is then wrapped tightly around the object to be turned.

The strap itself is usually made of a durable material such as rubber, nylon, or fabric, and has teeth or ridges on the inside to provide a secure grip. The handle of the strap wrench is often made of metal or sturdy plastic, ensuring durability and comfort during use.

Strap wrenches are commonly used in a variety of applications. They can be used to grip and turn objects such as pipes, fittings, filters, and round or cylindrical objects of various sizes. The strap provides a large contact area, allowing for even pressure distribution and reducing the risk of slippage or damage to the surface of the object being worked on.

In addition to their main function of loosening or tightening objects, strap wrenches can also be used to hold objects in place. This can be particularly useful when working on delicate or fragile objects that need to be held securely without being scratched or crushed by traditional tools.

Definition and Purpose

A strap wrench is a versatile tool that is used to loosen or tighten objects with a round or irregular shape. It consists of a handle and a flexible strap or chain that is wrapped around the object to provide grip and leverage.

The primary purpose of a strap wrench is to grip and turn objects that may be difficult to grip by hand or with other tools. It is commonly used in plumbing, automotive, and maintenance applications. The strap or chain is adjustable, allowing it to fit different sizes of objects, and the handle offers a comfortable grip for applying torque.

Strap wrenches are often used to tighten or loosen items such as pipes, filters, fittings, or cylindrical objects. They are particularly useful in situations where a tight grip is needed but a traditional wrench or pliers may damage the surface or not provide enough leverage.

One of the main advantages of using a strap wrench is that it can provide a secure grip without leaving any marks or scratches on the object being worked on. The strap or chain is made of a non-marring material, such as rubber or nylon, which helps protect the surface from damage.

Overall, the strap wrench is a valuable tool for any professional or DIY enthusiast who needs a reliable way to grip and turn objects with a round or irregular shape. Its versatility, ease of use, and non-damaging properties make it an essential tool in various industries and applications.

Types of Strap Wrenches

- Standard Strap Wrench: This is the most common type of strap wrench. It consists of a handle or a bar and a flexible strap. The strap is looped around the object that needs to be turned or loosened, and the wrench is tightened by pulling on the handle or bar. This type of strap wrench is suitable for a wide range of applications and can be adjusted to fit different sizes.

- Chain Strap Wrench: A chain strap wrench is similar to a standard strap wrench, but it uses a chain instead of a flexible strap. The chain is wrapped around the object to provide a better grip. This type of strap wrench is often used for pipes, plumbing fixtures, and other cylindrical objects.

- Telescoping Strap Wrench: A telescoping strap wrench is designed with an extendable handle. This allows for better leverage and makes it easier to reach objects in tight spaces. The strap can be adjusted to fit different sizes, making this type of strap wrench versatile and convenient to use.

- Metal Strap Wrench: A metal strap wrench is made of durable metal materials such as steel or aluminum. This type of strap wrench is suitable for heavy-duty applications and can provide a stronger grip compared to other types of strap wrenches. Metal strap wrenches are commonly used in industrial settings or for working with large, heavy objects.

These are just some of the common types of strap wrenches available on the market. Each type has its own advantages and is suitable for different applications. It is important to choose the right type of strap wrench based on the specific task at hand.

How to Use a Strap Wrench

A strap wrench is a versatile tool that can be used in a variety of applications. Here are some steps on how to properly use a strap wrench:

- Choose the right strap: Make sure to select a strap that is suitable for the task at hand. The strap should be long enough to fit around the object you are trying to grip.

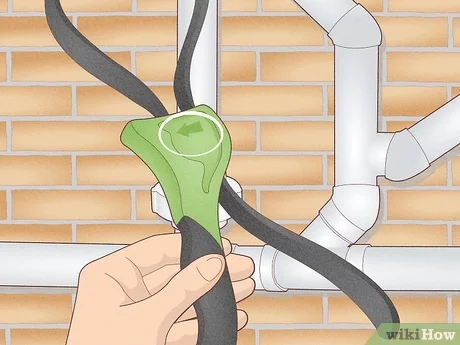

- Wrap the strap around the object: Take the strap and wrap it around the object, making sure it is positioned securely. The strap should be placed in a way that provides maximum grip and leverage.

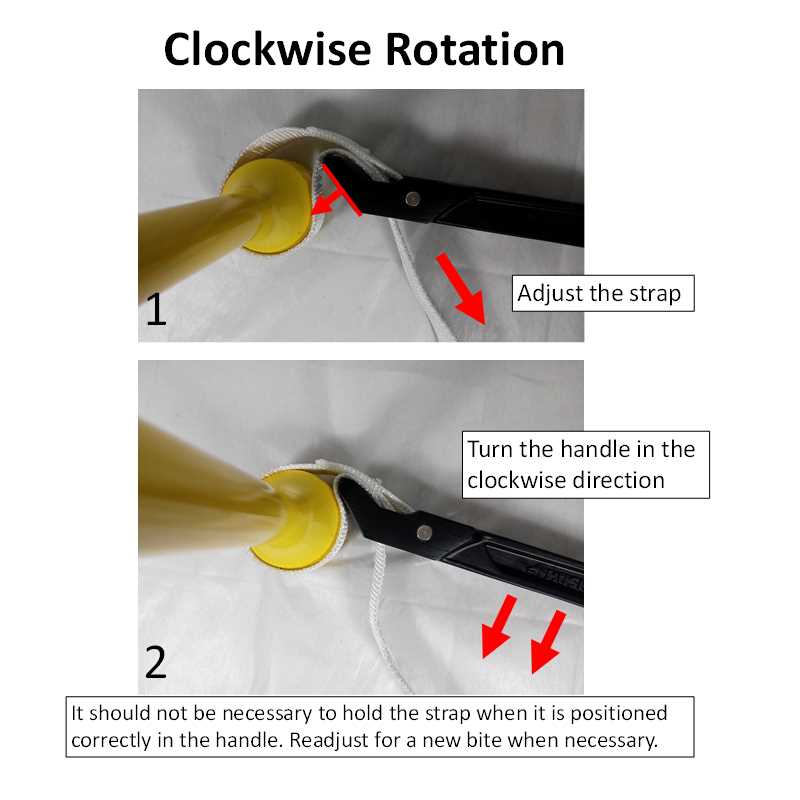

- Tighten the strap: Once the strap is wrapped around the object, pull the strap tight and secure it in place. This will create tension and help the strap grip the object more effectively.

- Turn the object: With the strap securely wrapped and tightened around the object, you can now turn the object using the strap wrench. Apply steady pressure and use the leverage provided by the tool to loosen or tighten the object as needed.

- Adjust the strap if needed: If the strap starts to slip or lose grip, you may need to readjust it. Loosen the strap a bit and then tighten it again, ensuring that it is positioned securely around the object.

- Clean and store the strap wrench: After using the strap wrench, make sure to clean it properly and store it in a safe place. This will help maintain its effectiveness and prolong its lifespan.

Note: When using a strap wrench, it is important to apply the right amount of pressure and avoid excessive force. It is also recommended to wear gloves for added grip and protection.

Benefits of Using a Strap Wrench

- Wide range of applications: A strap wrench can be used in various industries and for different tasks. It is commonly used in plumbing, automotive, and maintenance work. The adjustable strap allows for versatility in gripping objects of different shapes and sizes.

- Gentle on surfaces: Unlike traditional wrenches that use teeth or ridges to grip, a strap wrench uses a flexible strap. This makes it less likely to cause damage to delicate surfaces such as polished or painted objects.

- Non-slip grip: The strap of a strap wrench is designed to provide a firm and non-slip grip on objects. This ensures that you can apply maximum torque without the risk of the wrench slipping and causing injury.

- Easy to use: Strap wrenches are simple and straightforward tools to use. They typically have an adjustable strap that can be tightened or loosened using a handle. This makes them user-friendly and suitable for both professionals and DIY enthusiasts.

- Minimal tool marks: The strap, being flexible, evenly distributes the gripping force across the object’s surface. This reduces the likelihood of leaving behind tool marks or indentations that can mar the appearance of the object.

- Works well in tight spaces: The strap wrench’s design allows it to be used in tight spaces where conventional wrenches may not fit. The adjustable strap can be positioned at different angles, making it easier to access hard-to-reach areas.

- Cost-effective solution: Strap wrenches are generally affordable and versatile tools. They can replace multiple specialized wrenches, saving both money and space in your toolbox.

Applications of a Strap Wrench

A strap wrench is a versatile tool that can be used in a variety of situations. Here are some common applications of a strap wrench:

- Opening and closing jars: One of the most common uses of a strap wrench is to open or close jars that are difficult to grip. The adjustable strap allows you to secure the wrench tightly around the lid, providing you with a strong grip to twist and open the jar.

- Removing oil filters: A strap wrench is often used to remove oil filters from cars, motorcycles, or other machinery. The adjustable strap can be wrapped around the filter and tightened, allowing you to easily loosen and remove the filter.

- Tightening or loosening pipes: In plumbing applications, a strap wrench can be used to tighten or loosen pipes. The strap can be wrapped around the pipe, providing a secure grip for turning and adjusting the pipe fittings.

- Turning stubborn or damaged nuts and bolts: When traditional wrenches fail to turn stubborn or damaged nuts and bolts, a strap wrench can come to the rescue. The adjustable strap can be securely wrapped around the nut or bolt, providing the necessary grip to turn and loosen it.

- Securing or loosening irregularly shaped objects: The flexible strap of a strap wrench allows it to be used on irregularly shaped objects, such as round or cylindrical objects with no flat sides. This makes it a handy tool for securing or loosening objects that are difficult to grip with other tools.

- Working with delicate surfaces: The strap of a strap wrench is often made from a non-marring material, such as rubber or nylon, which makes it suitable for use on delicate surfaces. It provides a strong grip without causing any damage or leaving marks on the surface.

Overall, a strap wrench is a versatile tool that can be used in various DIY projects, automotive repairs, plumbing tasks, and general household applications. Its adjustable strap and non-marring design make it a valuable tool to have in your toolbox.

Tips for Choosing the Right Strap Wrench

When it comes to choosing the right strap wrench, there are a few factors to consider. Here are some tips to help you make an informed decision.

- Size: Start by considering the size of the objects you will be working with. Strap wrenches come in different sizes, so it’s important to choose one that matches the diameter of the objects you will be gripping.

- Material: The material of the strap is crucial for its performance. Look for a strap made from durable and non-slip material, such as rubber or nylon. This will ensure a secure grip and prevent slipping during use.

- Adjustability: Choose a strap wrench that offers adjustable tension. This will allow you to tighten or loosen the strap according to your needs. Adjustable strap wrenches are versatile and can be used on a wide range of objects.

- Handle: Consider the handle design of the strap wrench. Look for a model with a comfortable grip that allows for easy and controlled handling. A handle that provides a secure and ergonomic grip will make your work more comfortable and efficient.

- Weight: The weight of the strap wrench is another important factor to consider. A lightweight wrench will be easier to handle and maneuver, especially when working in tight spaces or in awkward positions.

- Brand and Quality: Finally, it’s always a good idea to choose a strap wrench from a reputable brand known for its quality tools. Investing in a high-quality strap wrench will ensure its durability and reliable performance for years to come.

By considering these tips, you can choose the right strap wrench that will meet your needs and make your work easier and more efficient. Whether you need to loosen or tighten objects with a smooth surface, a strap wrench is an essential tool to have in your arsenal.

Maintenance and Care for Strap Wrenches

Proper maintenance and care are important for ensuring the longevity and effectiveness of your strap wrenches. By following a few simple steps, you can keep your strap wrenches in great condition and ready to tackle any job.

Cleaning

After using a strap wrench, it is important to clean it thoroughly to remove any dirt, debris, or residue that may have accumulated. You can use a damp cloth or sponge to wipe down the strap and handle of the wrench. If necessary, you can also use mild soap or detergent to help remove stubborn dirt.

Storage

When not in use, it is best to store strap wrenches in a cool, dry place to prevent rust or corrosion. You can hang them on a pegboard or store them in a toolbox, making sure they are not in contact with any sharp or abrasive tools that could damage the strap or handle.

Tightening the Strap

If the strap of your wrench becomes loose or loses its grip, you can easily tighten it to restore its effectiveness. Simply locate the tensioning device on the handle, usually a screw or a lever, and adjust it until the strap is taut. Be careful not to overtighten, as this may cause damage to the strap or handle.

Inspecting for Damage

Regularly inspect your strap wrenches for any signs of damage, such as cracks, fraying, or bent handles. If you notice any issues, it is best to replace the wrench to ensure safe and effective use. Using a damaged strap wrench can result in accidents or damage to the object you are working on.

Using the Right Size

When using strap wrenches, it is important to select the right size for the job. Using a wrench that is too small or too large may not provide the necessary grip or torque, leading to ineffective results or potential damage. Always check the specifications of the strap wrench and compare them to the size of the object you will be working on.

Respect Weight Limits

Strap wrenches have weight limits that should not be exceeded. Exceeding these limits can put undue stress on the wrench and cause it to fail. Always check the weight limits specified by the manufacturer and ensure that you are using the right wrench for the job.

Regular Maintenance

In addition to cleaning and inspecting, it is recommended to perform regular maintenance on your strap wrenches. This can include lubricating any moving parts, tightening screws or bolts, and checking alignment. By keeping your wrenches properly maintained, you can ensure their optimal performance and extend their lifespan.

| Tip 1 | Store strap wrenches in a dry and cool place to prevent rust and corrosion. |

| Tip 2 | Inspect strap wrenches for any signs of damage regularly. |

| Tip 3 | Use the right size of strap wrench for the job to ensure effective results. |

| Tip 4 | Respect weight limits specified by the manufacturer to avoid wrench failure. |

| Tip 5 | Perform regular maintenance, including lubrication and tightening, to keep strap wrenches in optimal condition. |

FAQ

What are the main uses of a strap wrench?

A strap wrench can be used for a variety of purposes, including loosening or tightening objects with smooth surfaces, such as pipes, plumbing fixtures, or oil filters. Its adjustable strap allows for a secure grip without damaging the surface of the object.

Is a strap wrench effective for removing oil filters?

Yes, a strap wrench is commonly used for removing oil filters. Its adjustable strap can securely grip the filter, making it easier to twist off without damaging it. The strap provides a strong grip and distributes pressure evenly, reducing the risk of crushing or denting the filter.

Are there different types of strap wrenches?

Yes, there are different types of strap wrenches available. Some have a single strap, while others have multiple straps for added strength and stability. There are also strap wrenches with handles or ones that can be used with a ratchet or torque wrench. The type of strap wrench needed depends on the specific task and the size of the object being worked on.

Can a strap wrench be used on delicate surfaces?

Yes, a strap wrench is commonly used on delicate surfaces. The adjustable strap allows for a secure grip without applying excessive force or causing damage. The strap is typically made of durable materials, such as rubber or nylon, which can help prevent scratching or marring the surface. However, it is still important to use caution and not overtighten when using a strap wrench on delicate surfaces.

What are the advantages of using a strap wrench?

There are several advantages to using a strap wrench. Firstly, it can be used on objects with smooth surfaces, such as pipes or plumbing fixtures, where traditional wrenches may not provide a secure grip. Additionally, the adjustable strap allows for a customizable fit, ensuring a tight grip without causing damage. Strap wrenches are also versatile and can be used in various industries, including automotive, plumbing, and maintenance.