What is a Socket Wrench Used For? Explained in Detail

When it comes to fixing or assembling things around the house or in your workshop, having the right tools is essential. One tool that is commonly found in any handyman’s toolbox is a socket wrench. A socket wrench is a versatile hand tool that is used for tightening or loosening nuts and bolts. It consists of a handle and a socket, which is attached to the handle and can accommodate different sizes of nuts and bolts.

The socket wrench is a must-have tool for various applications, such as automotive repairs, plumbing work, and furniture assembly. Its primary purpose is to provide a mechanical advantage, allowing you to apply more force with less effort. The handle of the socket wrench is designed for maximum grip and leverage, ensuring that you can generate enough torque to tighten or loosen the fasteners without straining your wrist or hand.

One of the key features of a socket wrench is its ability to accommodate different sizes of nuts and bolts. The sockets, which come in various sizes and shapes, can be easily interchanged to fit the specific fastener you are working with. This versatility makes the socket wrench an indispensable tool for any DIY enthusiast or professional mechanic.

Pro tip: When using a socket wrench, it’s important to ensure that the socket is securely attached to the handle. This will prevent slippage and reduce the risk of damaging the fastener or injuring yourself.

In conclusion, a socket wrench is a versatile hand tool that is used for tightening or loosening nuts and bolts. Its main advantages include its ability to provide mechanical advantage, its versatility in accommodating different sizes of fasteners, and its ergonomic design for maximum grip and leverage. Whether you’re a DIY enthusiast or a professional mechanic, a socket wrench is an essential tool that should be a part of your toolbox.

Understanding Socket Wrenches

A socket wrench is a versatile tool commonly used in automotive and mechanical applications. It consists of a handle, a ratcheting mechanism, and a set of interchangeable socket heads. The socket heads come in various sizes and are designed to fit different types of nuts and bolts.

How Does a Socket Wrench Work?

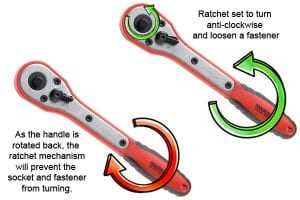

A socket wrench works by using the ratcheting mechanism to turn fasteners. The ratcheting mechanism allows the socket to move in one direction while preventing backward movement. This makes it easier to tighten or loosen nuts and bolts in tight spaces without having to remove the wrench after each turn.

Types of Socket Wrenches

There are several types of socket wrenches available, including:

- Standard Socket Wrench: This is the most commonly used socket wrench and comes with a ratchet handle and a set of sockets.

- Spinner Handle Socket Wrench: This type of socket wrench features a longer handle for increased leverage.

- Flex Head Socket Wrench: This wrench has a hinged head that allows for better access to hard-to-reach areas.

- T-Handle Socket Wrench: This wrench has a T-shaped handle, providing a comfortable grip and increased torque.

Uses of Socket Wrenches

Socket wrenches can be used for a wide variety of tasks, including:

- Automotive repairs and maintenance

- Assembly and disassembly of furniture

- Repairing appliances

- Plumbing installations

- Construction and mechanical work

Tips for Using a Socket Wrench

When using a socket wrench, keep the following tips in mind:

- Select the appropriate socket size for the fastener you are working on

- Ensure the socket is securely attached to the wrench

- Apply consistent pressure while turning to avoid stripping the fastener

- If the fastener is stuck, use penetrating oil or heat to loosen it

- Store your socket wrench in a clean and dry place to prevent rusting

Conclusion

Socket wrenches are essential tools for any mechanic or DIY enthusiast. They provide a convenient way to tighten or loosen nuts and bolts with ease. By understanding the different types of socket wrenches and how they work, you can choose the right tool for the job and complete your tasks efficiently.

Socket Wrench Parts

1. Handle

The handle is the part of the socket wrench that you grip and use to apply force. It is usually made of steel or plastic and has a textured surface to provide a secure and comfortable grip.

2. Ratchet

The ratchet is a mechanism that allows for both clockwise and counterclockwise rotation. It is an essential part of the socket wrench as it allows the user to tighten or loosen fasteners without removing the wrench from the fastener.

3. Socket

The socket is a removable attachment that fits onto the ratchet. It comes in various sizes and is used to match the size and shape of the fastener. Sockets are typically made of chrome vanadium steel, which provides strength and resistance to corrosion.

4. Drive

The drive is the square-shaped end of the socket wrench that connects the handle to the socket. It comes in different sizes, with the most common being 1/4 inch, 3/8 inch, and 1/2 inch. The size of the drive determines the torque capacity of the socket wrench.

5. Extension Bar

An extension bar is an optional accessory that can be attached to the drive of the socket wrench. It extends the reach of the socket wrench, allowing the user to access fasteners in tight or hard-to-reach areas.

6. Swivel Head

A swivel head is another optional accessory that can be attached between the drive and the socket. It allows the socket to pivot and rotate, providing flexibility when working with fasteners at different angles.

7. Torque Wrench Attachment

A torque wrench attachment is a specialized socket that can be used with a torque wrench. It has a built-in mechanism that limits the amount of torque applied to prevent over-tightening and ensure accurate fastening.

8. Quick-Release Button

A quick-release button is a feature found on some socket wrenches. It allows for the easy removal and replacement of sockets by simply pressing a button, eliminating the need to manually detach the socket from the ratchet.

9. Locking Mechanism

Some socket wrenches have a locking mechanism that keeps the socket securely in place on the ratchet. It prevents accidental detachment of the socket during use and provides added stability.

10. Markings

Socket wrenches often have markings on the handle or the drive that indicate the size or type of the wrench. These markings can be in the form of numbers, letters, or symbols, and help the user select the correct wrench for the task at hand.

11. Carrying Case

Many socket wrench sets come with a carrying case to store and organize the wrenches and accessories. The case helps protect the wrenches from damage and makes it easier to transport them.

12. Accessories

In addition to the main parts mentioned above, socket wrenches may have other accessories such as adapters, universal joints, and hex keys. These accessories expand the versatility and functionality of the socket wrench.

Different Types of Socket Wrenches

1. Standard Socket Wrench

The standard socket wrench is the most common type and is widely used in various applications. It consists of a handle and a socket that can be attached to different sizes of bolts and nuts. The handle provides leverage and allows for easy turning of the fasteners.

2. Ratchet Wrench

A ratchet wrench, also known as a ratchet handle, is a type of socket wrench that features a ratchet mechanism. This mechanism allows the wrench to turn in one direction while the handle stays in the same position. It is very useful for working in tight spaces where a full rotation of the handle is not possible.

3. Impact Socket Wrench

An impact socket wrench is specifically designed to withstand high torque and repetitive impacts. It is commonly used in automotive and industrial applications where high power tools such as impact drivers are used. The impact socket wrench is built to handle the heavy force generated by these tools.

4. Allen Socket Wrench

An Allen socket wrench, also known as a hex socket wrench or Allen key, is used for fastening and loosening hexagonal screws and bolts. It has a hexagonal-shaped socket that matches the shape of the fastener, providing a secure grip and preventing stripping or rounding of the bolt or screw. Allen socket wrenches come in various sizes to fit different bolt sizes.

5. Torque Wrench

A torque wrench is a specialized socket wrench that allows you to apply a specific amount of torque to a fastener. It is used in applications where precise tightening of bolts is required, such as in automotive and aerospace industries. Torque wrenches usually have a torque adjustment mechanism and a gauge to measure the applied torque.

6. Spark Plug Socket Wrench

A spark plug socket wrench is a specialized socket wrench designed to remove and install spark plugs in internal combustion engines. It typically has a thin-walled socket with a rubber insert to securely grip the spark plug and prevent damage. Spark plug socket wrenches are available in different sizes to fit various spark plug types.

7. Extension Bar

An extension bar is not a socket wrench itself but an accessory that can be used with socket wrenches. It is a long, cylindrical bar that allows you to extend the reach of the socket wrench. Extension bars come in different lengths and can be connected between the socket and the handle of the wrench.

Common Uses of Socket Wrenches

- Tightening and loosening nuts and bolts: One of the most common uses of a socket wrench is for tightening or loosening nuts and bolts. Socket wrenches come in a variety of sizes, allowing them to fit different bolt heads and nuts. This makes them a versatile tool for various applications, such as automotive repairs, plumbing installations, and furniture assembly.

- Assembly and disassembly of machinery: Socket wrenches are frequently used in the assembly and disassembly of machinery and equipment. They allow for quick and efficient tightening or loosening of bolts, helping to streamline the process of putting together or taking apart complex machinery.

- Maintenance and repair work: Socket wrenches are essential tools for maintenance and repair work. Whether it’s fixing a leaky pipe, replacing a spark plug, or tightening screws on household appliances, a socket wrench provides the necessary torque to get the job done efficiently.

- Automobile repairs: Socket wrenches are indispensable in the world of automobile repairs. They are commonly used for tasks such as changing tires, replacing brake pads, or adjusting engine components. The ability to quickly switch between different socket sizes makes a socket wrench a valuable tool for automotive mechanics.

- Construction and woodworking: Socket wrenches find applications in construction and woodworking projects. They are often used for assembling and disassembling scaffolding, securing fasteners in wooden structures, or tightening bolts in metal frameworks.

- Plumbing installations: Socket wrenches are commonly used in plumbing installations for connecting and tightening plumbing fixtures. They provide a reliable grip on nuts and bolts, ensuring leak-free connections in pipes, faucets, and other plumbing components.

- Industrial and manufacturing settings: Socket wrenches are widely employed in industrial and manufacturing settings for a variety of tasks, including equipment assembly, maintenance, and repair. They are often utilized in conjunction with torque wrenches to achieve precise torque specifications.

Advantages of Using Socket Wrenches

A socket wrench is a versatile tool that offers several advantages over other types of wrenches. Here are some benefits of using socket wrenches:

1. Versatility

Socket wrenches come in a wide range of sizes and configurations, making them suitable for various tasks. They can accommodate different sizes of sockets and extensions, allowing you to work with bolts and nuts of different sizes. This versatility makes socket wrenches a handy tool for a wide range of projects.

2. Increased Torque

Socket wrenches have a ratcheting mechanism that allows continuous tightening or loosening without the need to reset the wrench. This feature helps increase torque and makes it easier to apply more force with less effort. With a socket wrench, you can easily tighten or loosen fasteners that require a higher torque rating.

3. Accessibility

Socket wrenches have a slim profile and a long handle, which allows for better accessibility in tight spaces. The socket can fit over bolt heads or nuts in narrow or hard-to-reach areas. This makes socket wrenches an ideal tool for working in confined spaces where other wrenches may not be able to reach.

4. Efficiency

Socket wrenches allow for quick and efficient tightening or loosening of fasteners. The ratcheting mechanism eliminates the need to remove and reposition the wrench for each turn, saving you time and effort. Additionally, the socket wrench’s grip on the fastener is secure, reducing the risk of slipping and damaging the bolt or nut.

5. Interchangeability

Socket wrenches use interchangeable sockets, which means that you can change the socket size to accommodate different fasteners without needing multiple wrenches. This interchangeability makes socket wrenches a cost-effective option, as you only need to invest in a few sockets and extensions to cover a wide range of fastener sizes.

6. Accuracy

Socket wrenches provide better control and accuracy when tightening or loosening fasteners. The ratcheting mechanism allows for precise increments, ensuring that the fastener is properly tightened without over-tightening or damaging the hardware. This accuracy is crucial in applications where specific torque settings are required.

Overall, socket wrenches offer versatility, increased torque, accessibility, efficiency, interchangeability, and accuracy, making them a valuable tool for both professional mechanics and DIY enthusiasts.

Tips for Using a Socket Wrench

1. Choose the Right Size Socket

When using a socket wrench, it is important to choose the socket size that matches the nut or bolt you are working on. Using the wrong size socket can lead to stripped nuts or bolts, as well as potential damage to the wrench itself. Check the size markings on the socket and select the appropriate one for your task.

2. Use the Correct Socket Type

Socket wrenches come in various types, including standard (hexagonal) sockets, deep sockets, and specialized sockets for specific tasks. Make sure you are using the correct type of socket for the job at hand. For example, deep sockets are useful for accessing bolts that are recessed or located in tight spaces.

3. Apply Proper Force

When using a socket wrench, it is important to apply force in the correct direction. Most sockets are designed to be used with a clockwise (righty-tighty) motion to tighten bolts and a counterclockwise (lefty-loosey) motion to loosen bolts. Apply force steadily and evenly to avoid slipping or damaging the nut or bolt.

4. Secure the Socket Properly

Before using a socket wrench, make sure the socket is securely attached to the wrench handle. Ensure that the socket is fully seated on the fastener to avoid slipping or damaging the bolt or nut. If necessary, use an extension bar or adapter to reach the desired location.

5. Use a Ratchet Handle

Socket wrenches often come with ratchet handles, which allow for continuous motion without having to lift and reposition the wrench for each turn. To use the ratchet feature, set the direction switch on the ratchet handle, and then continue using the wrench with a fluid back-and-forth motion.

6. Keep the Wrench Clean and Lubricated

Regularly clean and lubricate your socket wrench to keep it in good working condition. Wipe off any dirt or debris and apply a small amount of lubricating oil to the moving parts of the ratchet mechanism. This will help extend the life of the tool and ensure smooth operation.

7. Follow Safety Precautions

Always wear safety goggles or glasses when using a socket wrench to protect your eyes from flying debris. Additionally, avoid using excessive force or over-tightening bolts, as this can lead to damage or injury. If you encounter resistance while turning a bolt, stop and reassess the situation to avoid any accidents.

8. Store Properly

When you are done using the socket wrench, clean it and store it in a dry, clean place. Avoid exposing it to extreme temperatures or corrosive substances. Proper storage will help prevent rusting and prolong the life of the tool.

By following these tips for using a socket wrench, you can ensure safe and efficient use of this versatile tool for various applications.

FAQ

What exactly is a socket wrench and how does it work?

A socket wrench is a hand tool that is used for tightening or loosening nuts and bolts. It consists of a handle, a socket and a ratcheting mechanism. The socket is attached to the ratchet mechanism and can be used to turn the nut or bolt either clockwise or counterclockwise.

Are there different types of socket wrenches available?

Yes, there are different types of socket wrenches available. Some common types include the standard socket wrench, ratchet wrench, combination wrench, and adjustable wrench. Each type is designed for specific applications and has its own unique features.

What are the advantages of using a socket wrench?

Using a socket wrench has several advantages. First, it provides a secure grip on the nut or bolt, reducing the risk of slipping and causing injury. Second, it allows for quick and efficient tightening or loosening of nuts and bolts. Finally, it is a versatile tool that can be used in various applications.

Can a socket wrench be used for different sizes of nuts and bolts?

Yes, a socket wrench can be used for different sizes of nuts and bolts. The socket is available in various sizes and can be easily interchangeable with the handle. This allows the socket wrench to be used with different sizes of nuts and bolts.

What are some common applications of a socket wrench?

A socket wrench can be used in a wide range of applications. Some common applications include automotive repair and maintenance, plumbing, construction, and assembly work. It is a versatile tool that is essential for any toolbox.

Is a socket wrench suitable for professional use?

Yes, a socket wrench is suitable for professional use. Many professionals, such as mechanics, plumbers, and electricians, rely on socket wrenches to perform their job effectively. Socket wrenches are designed to withstand heavy use and provide reliable performance.

Are there any precautions to be taken while using a socket wrench?

Yes, there are some precautions to be taken while using a socket wrench. It is important to use the correct size of socket for the nut or bolt to prevent slipping or damaging the fastener. It is also important to apply force in a controlled manner to avoid over-tightening or stripping the nut or bolt. Additionally, it is important to wear safety goggles to protect the eyes from flying objects.

Video