What is a Pin Spanner Wrench? Uses and Benefits Explained

A pin spanner wrench is a specialized tool designed to tighten or loosen fasteners that feature small holes, such as those found in nuts, bolts, or collars. It typically consists of a long handle with two prongs or pins that fit into the holes of the fastener, allowing for easy rotation.

These wrenches are commonly used in various industries and applications, including automotive, construction, and machinery maintenance. They are particularly useful in situations where regular wrenches or pliers cannot be used due to limited access or the need for a more precise and controlled grip.

The main benefit of using a pin spanner wrench is its ability to provide a secure and non-slip grip on fasteners with small holes. The prongs or pins fit tightly into the holes, preventing any slippage or stripping of the fastener during tightening or loosening. This ensures a safer and more efficient work process, as it reduces the risk of accidents or damage to the fastener and surrounding components.

In addition to their grip, pin spanner wrenches are also known for their durability and versatility. They are often made from high-quality materials, such as hardened steel, which allows them to withstand heavy use and provide long-lasting performance. Furthermore, some models feature adjustable prongs or interchangeable tips, allowing for compatibility with a wide range of fasteners of different sizes and shapes.

In conclusion, a pin spanner wrench is an essential tool for any professional or DIY enthusiast who frequently works with fasteners that have small holes. Its unique design and functionality ensure a secure grip, increased safety, and efficient operation. Whether you’re a mechanic, a carpenter, or a hobbyist, having a pin spanner wrench in your toolbox will undoubtedly prove valuable in various applications.

What is a Pin Spanner Wrench?

A pin spanner wrench is a specialized tool that is used to tighten or loosen pins or fasteners with small holes or notches, such as those found in adjustable angle grinders, locking collars, or machinery components. It is designed to provide a secure grip on the pin or fastener, allowing for increased torque and precise control during tightening or loosening.

A pin spanner wrench typically consists of a handle and two prongs or pins that fit into the holes or notches of the fastener. The prongs are adjustable to accommodate different sizes of pins or fasteners. The handle may have a textured grip or a wrench-like design for easier handling and turning.

Pin spanner wrenches come in various sizes and designs to fit different types of pins and fasteners. They may have a straight or curved handle, and the prongs can be fixed or adjustable. Some pin spanner wrenches may also have additional features, such as a hole or slot for attaching a handle extension for increased leverage.

These wrenches are commonly used in industries such as automotive, manufacturing, and maintenance. They are particularly useful for tasks that involve removing or installing pins or fasteners that are difficult to reach or require a specific amount of torque. The use of a pin spanner wrench ensures that the pins or fasteners are properly tightened or loosened, preventing potential damage or accidents.

Overall, a pin spanner wrench is an essential tool for professionals or individuals who work with machinery and equipment that require precise pin or fastener adjustments. Its unique design and functionality provide a reliable and efficient solution for various maintenance and repair tasks.

Definition and Functionality

Definition

A pin spanner wrench, also known as a pin face spanner or pin spanner, is a specialized tool used for tightening or loosening retaining pins, often found in fasteners and machinery. It is designed to have two prongs or pins that fit into the holes or slots on the head of the retaining pin, allowing for torque to be applied and rotational force to be exerted. Pin spanner wrenches come in various sizes and designs to accommodate different types of retaining pins.

Functionality

The primary function of a pin spanner wrench is to provide a secure grip and rotational force to tighten or loosen retaining pins. Retaining pins are commonly used in applications where bolts or screws are not suitable or secure enough, such as in heavy machinery, automotive parts, or industrial equipment. These pins often have specific hole or slot patterns on their heads that require a specialized tool like a pin spanner wrench for proper installation or removal.

Pin spanner wrenches are typically made of hardened steel or other durable materials to withstand the forces applied during use. The prongs or pins on the wrench are designed to fit precisely into the holes or slots of the retaining pins, ensuring a secure and non-slip connection. By applying torque to the wrench, the user can tighten or loosen the retaining pin as needed.

In addition to their use in fasteners, pin spanner wrenches are also commonly used for adjusting or maintaining various types of machinery, such as locknuts, collars, and certain types of bearings. Their compact size and adjustable features make them versatile tools for a range of applications.

In summary, a pin spanner wrench is a specialized tool used for tightening or loosening retaining pins. Its functionality lies in providing a secure grip and rotational force on the retaining pin, allowing for proper installation, adjustment, or removal. These wrenches come in various designs and sizes to accommodate different types of retaining pins and are commonly used in fasteners, machinery, and other industrial applications.

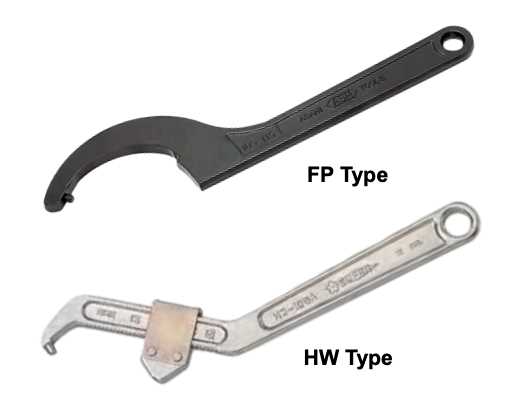

Types of Pin Spanner Wrenches

Pin spanner wrenches are available in various types, each designed for specific applications and tasks. Here are some common types of pin spanner wrenches:

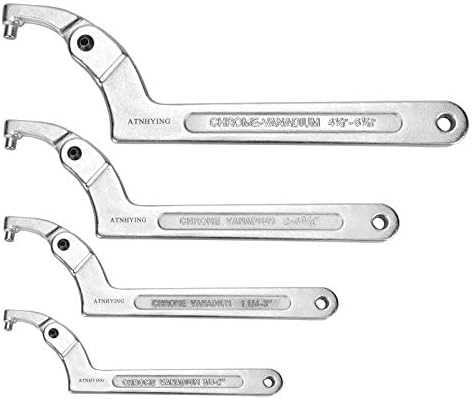

1. Adjustable Pin Spanner Wrench

An adjustable pin spanner wrench features adjustable pins that can be moved inward or outward to accommodate different sizes of pinholes. This type of pin spanner wrench is versatile and can be adjusted to fit various pin sizes, making it a popular choice in many industries.

2. Solid Pin Spanner Wrench

A solid pin spanner wrench is a fixed-size wrench that has solid, non-adjustable pins. This type of wrench is designed for specific pin sizes and cannot be adjusted to fit different pinholes. Solid pin spanner wrenches are commonly used in applications where a specific pin size is required.

3. Bent Nose Pin Spanner Wrench

A bent nose pin spanner wrench, also known as a offset pin spanner wrench, has bent tips or handles that allow for better access to hard-to-reach pinholes. This type of wrench is ideal for use in tight spaces or when the pinholes are located at an angle.

4. Straight Nose Pin Spanner Wrench

A straight nose pin spanner wrench has straight, non-bent tips or handles. This type of wrench is suitable for pinholes that are easily accessible and do not require additional angles or maneuvering.

5. Hook Spanner Wrench

A hook spanner wrench, also known as a C-spanner wrench, has a hook-shaped end that grips the slots or holes on fasteners or collars. Although not specifically designed for pinholes, hook spanner wrenches can be used as a substitute for pin spanner wrenches in some cases.

6. Thin Pin Spanner Wrench

A thin pin spanner wrench is designed with thinner pins, allowing it to fit into narrower pinholes or slots. This type of wrench is commonly used in precision applications, such as in the watchmaking industry, where small pin sizes are required.

These are just a few examples of the types of pin spanner wrenches available. Each type offers its own advantages and is suitable for specific applications. When choosing a pin spanner wrench, it is important to consider factors such as pin size, accessibility, and the nature of the task at hand.

How to Use a Pin Spanner Wrench?

Using a pin spanner wrench is fairly simple, but it is important to follow the proper steps to ensure safety and effectiveness. Here are the steps to use a pin spanner wrench:

- Identify the pin spanner wrench:

- Look for a wrench with two pins, usually in a straight or curved shape, located at the end of the wrench.

- The size and shape of the pins may vary depending on the specific wrench and its intended use.

- Select the correct pin size:

- Check the specifications of the equipment or component you are working on to determine the pin size needed.

- Some pin spanner wrenches may come with multiple sets of pins or interchangeable pins to accommodate different sizes.

- Position the pins:

- Place the pins of the wrench into the corresponding pinholes or slots on the equipment or component.

- Make sure the pins are securely seated in the holes to avoid slipping or damage during use.

- Apply force:

- Hold the wrench firmly and apply force in the desired direction to loosen or tighten the component.

- Be careful not to apply excessive force, as it may damage the equipment or component.

- Continue as necessary:

- If the component requires further adjustment or removal, continue to apply force as needed.

- Take breaks if necessary to prevent fatigue or strain.

It is important to note that the specific steps for using a pin spanner wrench may vary depending on the equipment or component being worked on. Always refer to the manufacturer’s instructions or professional guidance for the best results and to ensure safety.

Applications of Pin Spanner Wrenches

Pin spanner wrenches are versatile tools that can be used for a variety of applications. They are commonly used in the following industries:

- Automotive: Pin spanner wrenches are often used in automotive repair and maintenance tasks. They can be used to remove and install various components such as suspension struts, shock absorbers, and steering linkage.

- Mechanical engineering: Pin spanner wrenches are essential tools in mechanical engineering for tasks such as adjusting or replacing bearings, seals, or collars. They can also be used for adjusting or tightening threaded fasteners with slotted or drilled holes.

- Plumbing: Pin spanner wrenches are commonly used in plumbing applications for tightening or loosening various plumbing fittings. They are particularly useful for tasks that require a specialized tool to reach into tight spaces.

- Electronics: Pin spanner wrenches can be used in electronics repair or assembly to tighten or loosen fragile nuts or threaded components.

Pin spanner wrenches can be found in various sizes and designs to accommodate different applications and fastener sizes. They are typically made from durable materials such as hardened steel to withstand heavy use.

When using a pin spanner wrench, it is important to ensure that the pins are securely engaged with the holes or slots in the fastener to prevent slipping or damage. It is also important to choose the correct size of wrench for the task at hand to ensure proper fit and torque.

Overall, pin spanner wrenches are valuable tools that offer versatility and precision for a wide range of applications across different industries.

Benefits of Using Pin Spanner Wrenches

Pin spanner wrenches offer several benefits in various applications. Here are some of the key advantages of using these wrenches:

- Secure grip: Pin spanner wrenches feature two or three small pins that fit into corresponding holes or slots on the object being worked on. This design provides a secure grip, allowing for better control and torque application.

- Adjustability: With multiple pins or adjustable pin positions, pin spanner wrenches can be adjusted to fit different sizes of holes or slots. This versatility makes them suitable for a wide range of applications and reduces the need for multiple wrenches.

- Prevents damage: The pins on a pin spanner wrench are designed to fit precisely into the holes or slots of the object being turned. This minimizes the risk of slipping, which can cause damage to the object or the wrench itself.

- Specific applications: Pin spanner wrenches are commonly used in automotive, industrial, and machinery applications. They are particularly useful for removing and installing bearings, collars, and other components with slotted designs.

- Compact size: Pin spanner wrenches are typically small and compact, making them easy to carry and store. Their compact design also allows for easy access in tight spaces where larger wrenches may not fit.

Overall, pin spanner wrenches offer a reliable and effective tool for various tasks that require a secure grip and precise control. Whether you’re a professional mechanic or a DIY enthusiast, having a pin spanner wrench in your toolbox can greatly enhance your ability to tackle a wide range of projects.

Factors to Consider When Buying a Pin Spanner Wrench

1. Type of Pin Spanner Wrench

When purchasing a pin spanner wrench, it’s important to consider the type of wrench that will best suit your needs. Pin spanner wrenches come in various designs and sizes, each designed for specific applications. Some common types include adjustable pin spanner wrenches, fixed pin spanner wrenches, and hook pin spanner wrenches. Consider the type of pins or locknuts you will be working with and choose a wrench that is compatible with those components.

2. Size and Capacity

The size and capacity of the pin spanner wrench are crucial factors to consider. You need to ensure that the wrench will fit the pins or locknuts you will be working with. Pay attention to the maximum diameter and thickness that the wrench can accommodate. It’s recommended to choose a pin spanner wrench with a slightly larger capacity than what you currently need, as it allows for future flexibility and versatility.

3. Material and Construction

Check the material and construction of the pin spanner wrench to ensure durability and longevity. The wrench should be made of high-quality materials, such as hardened steel or alloy, to withstand heavy-duty use and resist wear and tear. Look for wrenches with a sturdy handle and a well-designed pin head for optimal performance.

4. Ergonomic Design

Consider the ergonomics of the pin spanner wrench. Look for wrenches with comfortable grips and handles that provide a secure and non-slip hold. An ergonomic design will not only make your work more comfortable but also improve overall efficiency and reduce the risk of hand fatigue or injuries.

5. Brand Reputation and Reviews

When investing in a pin spanner wrench, it’s always a good idea to check the reputation of the brand and read reviews from other users. Look for well-established and reputable brands known for manufacturing high-quality tools. Reading reviews can give you insights into the performance, durability, and overall satisfaction of other users, helping you make an informed decision.

6. Budget

Lastly, consider your budget when buying a pin spanner wrench. Set a budget range and look for wrenches within that range. While quality and performance should be a priority, there are often affordable options available that offer good value for money. Compare prices from different brands and suppliers to ensure you get the best deal without compromising on quality.

In conclusion, buying a pin spanner wrench requires careful consideration of factors such as the type of wrench, size and capacity, material and construction, ergonomics, brand reputation, and budget. By keeping these factors in mind, you can select the right pin spanner wrench for your specific needs and enjoy the benefits it offers.

Tips for Maintaining and Cleaning Pin Spanner Wrenches

Proper maintenance and cleaning of your pin spanner wrenches is essential to ensure their longevity and optimal performance. Here are some tips to help you maintain and clean your pin spanner wrenches effectively:

1. Regular Inspection

Before and after each use, it’s important to inspect your pin spanner wrenches for any signs of damage or wear. Check the pins, handles, and adjustable legs to ensure they are in good condition and functioning properly. If you notice any issues, such as bent pins or loose attachments, take the necessary steps to repair or replace the affected parts.

2. Cleaning

Clean your pin spanner wrenches after each use to remove dirt, grease, and other contaminants. Use a mild detergent or solvent and a soft cloth or brush to gently scrub the tools. Avoid using abrasive materials or harsh chemicals that could damage the wrenches.

3. Drying

After cleaning, ensure that your pin spanner wrenches are completely dry before storing them. Moisture can lead to rust and corrosion, which can affect the performance of the tools. Use a clean, dry cloth to wipe away any moisture and allow the wrenches to air dry in a well-ventilated area.

4. Lubrication

Apply a thin layer of lubricating oil or grease to the pins and adjustable legs of your pin spanner wrenches to prevent rust and ensure smooth operation. Be sure to use a lubricant that is compatible with the material of your wrenches.

5. Storage

Store your pin spanner wrenches in a clean, dry place away from moisture and excessive heat. Consider using a tool roll or case to protect the wrenches from dust, dirt, and potential damage.

6. Proper Use

Follow the manufacturer’s instructions and guidelines for using your pin spanner wrenches. Avoid using excessive force or using the wrenches for applications they are not designed for, as this can lead to damage or breakage.

By following these tips for maintaining and cleaning your pin spanner wrenches, you can prolong their lifespan and ensure they are always ready for use. Proper care and maintenance will help you get the most out of your tools and prevent unnecessary replacements.

FAQ

What is a pin spanner wrench?

A pin spanner wrench is a tool that is specifically designed to tighten or loosen certain types of nuts or bolts that have holes or slots on their heads. It is used by inserting the pins of the wrench into the corresponding holes or slots on the nut or bolt and then rotating the wrench in the desired direction.

What are the uses of a pin spanner wrench?

A pin spanner wrench is primarily used for tightening or loosening nuts or bolts that have holes or slots, such as retaining rings, collars, and gland nuts. It is commonly used in various industries, including automotive, machinery, and plumbing.

What are the benefits of using a pin spanner wrench?

One of the main benefits of using a pin spanner wrench is its ability to provide a secure grip on nuts or bolts with holes or slots. This ensures proper tightening or loosening of the fasteners without causing damage. Additionally, pin spanner wrenches are generally compact and lightweight, making them easy to carry and use in tight spaces.

Are there different types of pin spanner wrenches?

Yes, there are different types of pin spanner wrenches available, each designed for specific applications. Some have fixed pins, while others have adjustable pins to accommodate different sizes of holes or slots. There are also variations in the length, shape, and material of the wrench, allowing users to choose the most appropriate tool for their needs.

Can a pin spanner wrench be used on any type of nut or bolt?

No, a pin spanner wrench is specifically designed for use on nuts or bolts that have holes or slots on their heads. It should not be used on regular nuts or bolts as it will not provide an effective grip and may cause damage to the fasteners or the wrench itself. It is important to use the correct tool for the specific type of fastener being tightened or loosened.

Are pin spanner wrenches easy to use?

Yes, pin spanner wrenches are generally easy to use. The pins of the wrench are inserted into the holes or slots on the nut or bolt, and then the wrench is rotated in the desired direction. The compact size and lightweight nature of the wrench make it easy to maneuver in tight spaces. However, it is important to ensure that the pins are securely engaged in the holes or slots to prevent slipping or damage.

Video