What is a flare nut wrench used for? – Essential information

A flare nut wrench, also known as a line wrench or brake wrench, is a specialized tool used for tightening or loosening nuts and fittings on plumbing, automotive, and other mechanical systems. It is designed with a unique head that allows it to fit over the hexagonal or square-shaped nuts found on these systems. The flare nut wrench is an essential tool for anyone working on hydraulic lines, brake lines, fuel lines, or any other system that requires tight connections.

The flare nut wrench is particularly useful in situations where there is limited space to work or where the nut or fitting is difficult to reach. Its slim design and open-ended head make it easy to fit into tight spaces and provide access to hard-to-reach nuts. The open-ended head of the flare nut wrench allows it to slide over the line or fitting while still maintaining contact with the nut, providing a secure grip and preventing damage to the nut or fitting.

One of the unique features of the flare nut wrench is its ability to grip the nut or fitting on multiple sides, providing a more secure grip than a standard wrench or pliers. The wrench’s evenly distributed gripping force helps to prevent rounding or stripping of the nut, ensuring a tight and leak-free connection. This is especially important when working on critical systems such as hydraulic or brake lines, as a loose or damaged connection can result in loss of fluid and compromised performance.

Overall, the flare nut wrench is an essential tool for anyone working on plumbing, automotive, or mechanical systems. Its unique design and ability to securely grip nuts and fittings make it a versatile and reliable tool for a wide range of applications. Whether you are a professional mechanic or a DIY enthusiast, having a flare nut wrench in your toolbox can save you time, frustration, and ensure the proper functioning of your systems.

Understanding flare nut wrenches

A flare nut wrench is a specialized type of wrench that is used to tighten or loosen flare nuts. Flare nuts are typically found in plumbing and automotive applications and are used to connect various components together.

How do flare nuts work?

Flare nuts have a flared end that fits over a pipe or tube. They are designed to create a tight seal when compressed against a fitting or valve. The nut is typically made of a softer metal, such as brass or aluminum, which allows it to be easily compressed.

Why use a flare nut wrench?

Regular wrenches or pliers can damage the soft metal of a flare nut, making it difficult to tighten or loosen. Additionally, flare nuts are often located in tight spaces where it is difficult to get a proper grip. A flare nut wrench has a unique design that allows it to grip the nut on multiple sides, reducing the risk of damage and providing a secure fit.

Types of flare nut wrenches

Flare nut wrenches come in various sizes and configurations to accommodate different flare nut sizes and access requirements. The most common type is a double-ended wrench with open ends of different sizes. Some flare nut wrenches also have a ratcheting mechanism, which allows for faster and easier tightening or loosening of flare nuts.

Tips for using a flare nut wrench

- Always use the correct size wrench for the flare nut you are working on. Using the wrong size wrench can cause damage to the nut or fitting.

- Ensure that the flare nut wrench is properly aligned with the nut. Misalignment can result in stripped threads or rounded corners.

- Apply even pressure when tightening or loosening the flare nut. Avoid using excessive force, as this can also cause damage.

- Take care not to overtighten the flare nut. Over-tightening can distort the flare or crack the fitting.

By understanding how and when to use a flare nut wrench, you can ensure that you have the right tool for the job and prevent damage to your flare nuts and fittings.

Importance of flare nut wrenches

Flare nut wrenches are an essential tool in the world of automotive mechanics and plumbing. These specialized wrenches provide a secure grip on nuts, especially those in tight or hard-to-reach spaces. They are particularly important when working with brake lines, fuel lines, and hydraulic fittings, where proper tightening and loosening is critical to ensure the safety and efficiency of the system.

1. Preventing damage:

One of the main advantages of using a flare nut wrench is that it minimizes the risk of damaging the nuts or fittings. The design of a flare nut wrench allows it to grip the nut from multiple sides, increasing the contact area and reducing the risk of stripping or rounding off the edges.

2. Ensuring a proper seal:

When dealing with fluid systems, such as brake or fuel lines, it is crucial to achieve a proper seal to prevent leaks. Flare nut wrenches are specifically designed to apply even pressure on the nut, ensuring a tight and leak-free connection. This is especially important in high-pressure systems, where any leakage can compromise the performance and safety of the entire system.

3. Accessibility and versatility:

The slim profile and long handle of flare nut wrenches allow them to reach into tight spaces, such as engine compartments or plumbing fixtures. The open-ended design of flare nut wrenches also makes them versatile, as they can be used on various sizes of nuts. This eliminates the need for multiple wrenches and saves time during projects.

4. Improved speed and efficiency:

Due to their ability to grip the nut securely, flare nut wrenches provide increased torque, allowing for faster and more efficient tightening or loosening. This can be particularly useful when working on larger systems or projects with multiple fittings that require adjustments.

In conclusion, flare nut wrenches play a vital role in automotive and plumbing industries by ensuring proper tightening, preventing damage, and improving overall efficiency. Investing in a high-quality flare nut wrench is a wise choice for any mechanic or plumber who values precise work and reliable connections.

How do flare nut wrenches work?

A flare nut wrench is a specialized tool used to tighten or loosen flare nuts, which are fittings commonly found in plumbing, automotive, and other mechanical systems. They are designed to provide a tight seal between pipes or fittings, preventing leaks and ensuring proper fluid flow.

Flare nuts have a hexagonal shape, similar to regular nuts, but with a small opening on one side. This opening allows the flare nut wrench to fit around the nut while providing room for a tubing or pipe to be inserted.

When using a flare nut wrench, it is important to position the wrench correctly. The open end of the wrench should be placed over the flare nut, while the closed end should be facing away from the nut.

Once the wrench is properly positioned, it can be used to apply torque to the nut. This is done by turning the wrench in either a clockwise or counterclockwise direction, depending on whether you are tightening or loosening the flare nut.

The design of a flare nut wrench allows it to grip the flats of the flare nut securely, minimizing the risk of rounding off the edges or causing damage to the fitting. The wrench also provides additional leverage, making it easier to apply the necessary force to tighten or loosen the nut.

It is important to note that flare nut wrenches come in different sizes to accommodate various flare nut sizes, so it is crucial to select the correct size wrench for the specific job.

Overall, flare nut wrenches are essential tools for working with flare nuts, providing a secure grip and reliable torque for tightening or loosening fittings in plumbing and mechanical systems.

Types of flare nut wrenches

A flare nut wrench, also known as a line wrench or brake line wrench, is a specialized tool used for turning nuts that have a hexagonal shape, commonly found on brake lines and fuel lines. There are several types of flare nut wrenches available, each designed for specific purposes and applications.

1. Open ended flare nut wrench

This is the most common type of flare nut wrench. It features an open-ended design with a flared shape that allows it to fit over the nut without fully covering it. This design provides a wider contact area, which helps to prevent rounding off the corners of the nut while applying torque.

2. Box-ended flare nut wrench

This type of flare nut wrench features a closed box-end design with either a 6-point or a 12-point configuration. The closed-end design provides better grip and support, making it ideal for high-torque applications. The 6-point configuration provides more contact points, while the 12-point configuration allows for greater accessibility in tight spaces.

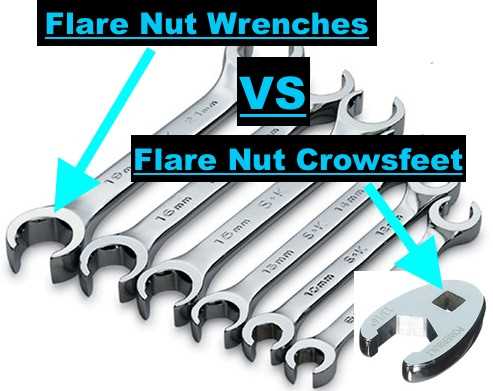

3. Crowfoot flare nut wrench

A crowfoot flare nut wrench is a specialized tool that features a socket-like design with an open end. It is used in combination with a ratchet or extension bar to reach nuts in hard-to-reach areas where a regular flare nut wrench cannot fit. The crowfoot design allows for a greater range of motion and flexibility.

4. Adjustable flare nut wrench

An adjustable flare nut wrench, also known as an adjustable line wrench, is a versatile tool that can be adjusted to fit nuts of different sizes. It features a sliding jaw mechanism that allows for easy adjustment and a secure grip on the nut. This type of wrench is particularly useful when working with nuts of varying sizes or in tight spaces.

5. Combination flare nut wrench

A combination flare nut wrench combines the features of a flare nut wrench and a regular open-end wrench. It has a flared end for use on flare nuts and a flat end for use on regular hexagonal nuts. This type of wrench offers versatility and convenience, as it eliminates the need to switch between different wrenches.

6. Non-marring flare nut wrench

A non-marring flare nut wrench is designed with special coatings or materials to prevent scratching or damaging the nuts. It is commonly used in applications where the nut surface needs to be protected, such as when working on delicate or painted surfaces.

7. Offset flare nut wrench

An offset flare nut wrench features an angled design with a bent handle, allowing for better access to nuts in tight spaces or hard-to-reach areas. The offset design provides leverage and makes it easier to turn the nuts without obstructing other components.

8. Flex flare nut wrench

A flex flare nut wrench, also known as a flexible flare nut wrench, has a flexible head that can bend or pivot to reach nuts at different angles. This type of wrench is especially useful in applications where there is limited space or obstacles that prevent straight access to the nut.

| Flare Nut Wrench Type | Design | Advantages | Disadvantages |

|---|---|---|---|

| Open ended | Open-ended with a flared shape | Wide contact area, prevents rounding off corners | Less grip and support compared to box-ended wrenches |

| Box-ended | Closed box-end with 6-point or 12-point configuration | Better grip and support, suitable for high-torque applications | May not fit in certain tight spaces |

| Crowfoot | Socket-like design with an open end | Greater range of motion and flexibility | Requires a ratchet or extension bar for use |

| Adjustable | Sliding jaw mechanism for easy adjustment | Versatile, can fit nuts of different sizes | May not provide as secure of a grip as fixed-size wrenches |

| Combination | Combines flare nut wrench and open-end wrench | Eliminates the need for multiple wrenches | May not offer as secure of a grip on flare nuts as dedicated flare nut wrenches |

| Non-marring | Special coatings or materials to prevent scratching | Protects delicate or painted surfaces | May have reduced grip compared to other wrenches |

| Offset | Angled design with a bent handle | Better access to nuts in tight spaces | May require additional effort due to the angled design |

| Flex | Flexible head that can bend or pivot | Allows for reaching nuts at different angles | May have reduced torque capability due to the flexible design |

Benefits of using a flare nut wrench

- A flare nut wrench allows for a secure grip on fasteners, preventing slipping and stripping of the nuts.

- It is specifically designed to fit over the hexagonal shape of a nut, providing maximum contact and torque.

- Flare nut wrenches are commonly used in plumbing and automotive applications, where tight spaces and delicate parts require precise and controlled wrenching.

- The jaws of a flare nut wrench are typically slightly rounded to grip the sides of the nut, reducing the risk of damage.

- These wrenches are often open-ended, making them easier to use in tight spaces where a socket wrench may not fit.

- Using a flare nut wrench allows for fast and efficient work, as it provides a reliable grip and minimizes the risk of slippage.

- Flare nut wrenches are versatile tools that can be used on various sizes of nuts, providing flexibility in different applications.

- Many flare nut wrenches have a longer handle length, allowing for increased leverage and easier turning of tight or stubborn nuts.

- Overall, using a flare nut wrench ensures safer and more effective nut tightening and loosening, minimizing the risk of damage to both the fasteners and the surrounding components.

Applications of flare nut wrenches

- Used for automotive repairs: Flare nut wrenches are commonly used in automotive repairs, especially in the brake system. They are designed to grip and loosen brake line fittings without rounding them off, ensuring a secure connection.

- Plumbing applications: These wrenches are also commonly used in plumbing work. They are ideal for tightening and loosening compression fittings, such as those found on water supply lines and gas lines. The unique design of flare nut wrenches allows them to provide a better grip on the fitting, reducing the risk of damage.

- Hydraulic systems: Flare nut wrenches are crucial in working with hydraulic systems, where precision and secure connections are vital. They are used to tighten and loosen fittings on hydraulic lines to ensure proper sealing and prevent leaks.

- Automated machinery: In industries that use automated machinery, flare nut wrenches are often used to maintain and repair equipment. They are utilized to tighten or loosen fittings, connectors, and fasteners in hydraulic, pneumatic, and electrical systems.

- Appliance repair: Flare nut wrenches can be handy in appliance repair, particularly with refrigerators and air conditioners. These tools are used to tighten or loosen fittings on coolant lines, ensuring proper functioning and preventing leaks.

- Oil and gas industry: In the oil and gas industry, flare nut wrenches are utilized to work with fittings and hydraulic connections. They are used in the maintenance and repair of pipelines, valves, and other equipment to ensure leak-free connections.

- Industrial maintenance: Flare nut wrenches are commonly found in industrial settings and are used across various maintenance and repair tasks. They are versatile tools that can be employed in working with different types of fluid-carrying systems and fittings.

Overall, flare nut wrenches are essential tools used in a wide range of industries and applications where precise and secure tightening or loosening of fittings is crucial. Their unique design and functionality make them a valuable addition to any mechanic’s or technician’s toolbox.

Features to consider when buying a flare nut wrench

When looking to purchase a flare nut wrench, there are several important features to consider. These features can help ensure that the wrench meets your specific needs and will provide effective use for your intended tasks. Here are some key features to consider:

- Size: Flare nut wrenches come in various sizes to fit different nut sizes. It is crucial to choose a wrench that matches the size of the nuts you will be working with. Common sizes include 1/4 inch, 5/16 inch, 3/8 inch, 7/16 inch, and 1/2 inch.

- Material: Check the material of the flare nut wrench to ensure its durability and strength. Wrenches made from high-quality steel or chrome vanadium are generally more durable and resistant to wear and tear.

- Adjustability: Some flare nut wrenches have an adjustable head, which allows for a wider range of sizes to be accommodated. This feature can be especially useful if you work with nuts of varying sizes.

- Grip: Consider the grip of the flare nut wrench. Look for wrenches with comfortable handles that provide a firm grip, minimizing the risk of slipping and potential injuries.

- Flexibility: Depending on the tasks you plan to use the wrench for, consider the overall length and design of the wrench. Longer wrenches can provide more leverage, while flexible designs can help reach nuts in tight spaces.

- Quality and Brand: Opt for flare nut wrenches from reputable brands known for manufacturing high-quality tools. This can ensure that the wrench will last longer and withstand heavy usage.

By considering these features, you can make an informed decision and select the right flare nut wrench that will meet your needs and provide efficient and effective performance.

Maintenance and care of flare nut wrenches

Proper maintenance and care of flare nut wrenches are crucial for their longevity and optimal performance. By following some simple steps, you can ensure that your flare nut wrenches stay in good condition and are ready to use whenever you need them.

Cleaning

After each use, it is important to clean your flare nut wrenches to remove any debris, dirt, or grease that may have accumulated. Use a clean cloth or rag to wipe down the wrenches and remove any residue. For stubborn grease or grime, you can use a mild detergent or degreaser. It is important to dry the wrenches thoroughly after cleaning to prevent rust or corrosion.

Storage

When storing flare nut wrenches, it is important to keep them in a dry and clean environment. Moisture or dampness can cause the wrenches to rust or corrode, reducing their effectiveness. You can store the wrenches in a toolbox or a designated storage area to protect them from dust and moisture. It is also a good idea to hang them on a pegboard or use a wrench organizer to keep them organized and easily accessible.

Lubrication

Regular lubrication is key to keeping your flare nut wrenches working smoothly. Apply a few drops of lubricating oil to the moving parts of the wrench, such as the pivot points and the head. This will help reduce friction and wear, as well as prevent rust and corrosion. Be sure to wipe off any excess oil to prevent it from attracting dirt or dust.

Inspection

Periodically inspect your flare nut wrenches for any signs of wear or damage. Check for any bent or cracked parts, loose screws, or signs of rust or corrosion. If you notice any issues, it is important to address them promptly. Worn or damaged wrenches may not provide a secure grip, which can lead to slipping and potential injury.

By following these maintenance tips, you can ensure that your flare nut wrenches remain in good condition and are always ready for use. Proper care and regular inspection will not only extend the life of your wrenches but also help you work more efficiently and effectively.

FAQ

What is a flare nut wrench used for?

A flare nut wrench is used to tighten or loosen nuts that have a flared or rounded shape, such as those found on brake lines and other automotive fittings.

How does a flare nut wrench differ from a regular wrench?

A flare nut wrench has a unique design that allows it to grip the sides of a nut, providing better torque and reducing the risk of rounding or damaging the nut.

Can I use a regular wrench for tasks that require a flare nut wrench?

While it is possible to use a regular wrench for some tasks, a flare nut wrench is specifically designed for working with nuts that have a flared or rounded shape. Using the proper tool will help prevent damage to the nut and make the job easier.

What sizes are available for flare nut wrenches?

Flare nut wrenches come in various sizes, ranging from small to large. The most common sizes are typically 8mm, 10mm, 12mm, 14mm, 16mm, and 18mm.

Are flare nut wrenches only used for automotive work?

No, while flare nut wrenches are commonly used in automotive work due to their ability to handle brake lines and other fittings, they can also be used in plumbing, refrigeration, and other industries where flared or rounded nuts are present.

What are the benefits of using a flare nut wrench?

The main benefit of using a flare nut wrench is that it provides a tight grip on nuts with rounded or flared shapes, reducing the risk of stripping or damaging the nut. It also allows for increased torque, making it easier to tighten or loosen stubborn nuts.

Can a flare nut wrench be used on both standard and metric nuts?

Yes, flare nut wrenches are available in both standard and metric sizes, allowing them to be used on a wide range of nuts in different systems.

Video