What is a Flank Drive Wrench? Get to Know the Essential Tool

A flank drive wrench is an essential tool used in various industries, especially in automotive and mechanical applications. It is designed to provide maximum grip and torque while reducing the risk of slipping or rounding off bolts and nuts. The innovative design of the flank drive wrenches makes them versatile, reliable, and highly efficient.

The flank drive wrench features a unique geometry that allows the wrench to contact the flat sides of the fastener, rather than the corners. This design distributes the forces evenly, reducing the stress on the fastener and preventing damage. The wrench’s design also helps to distribute the torque more evenly, reducing the chances of slippage and providing a more secure grip.

One of the key advantages of the flank drive wrench is its ability to provide a greater amount of torque compared to traditional wrenches. This is achieved by increasing the contact area between the wrench and the fastener, allowing for a higher torque transfer. The increased torque capability of the flank drive wrenches makes them particularly useful in applications that require high levels of torque, such as tightening or loosening stubborn bolts or nuts.

In addition to their torque capabilities, flank drive wrenches also offer superior durability and longevity. The high-quality materials used in their construction, along with the precision machining, ensure that these wrenches can withstand even the toughest working conditions. They are resistant to corrosion and wear, making them ideal for use in harsh environments.

Overall, flank drive wrenches are an essential tool for any professional or DIY enthusiast. Their unique design and superior performance make them indispensable in a wide range of applications. Whether you are working on a car engine, assembling furniture, or tightening bolts around the house, a flank drive wrench can help you get the job done efficiently and effectively.

What is a Flank Drive Wrench?

A flank drive wrench is a specialized tool used in automotive and mechanical applications. It is designed to provide maximum torque and prevent rounding of fasteners, ensuring a secure and efficient grip on nuts and bolts.

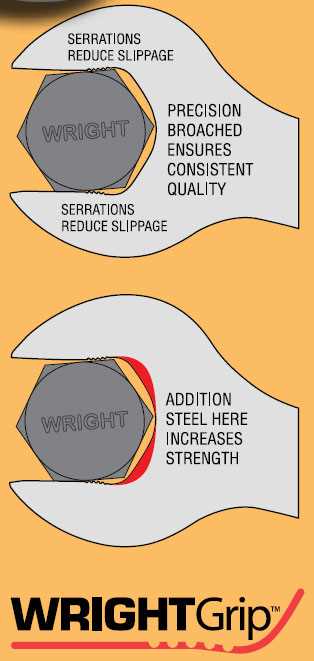

The flank drive wrench features a unique design with angled surfaces on the sides of the wrench’s box end or open end. These angled surfaces create a gripping action that applies force to the flat sides of the fastener, rather than the corners. This reduces the risk of slippage and minimizes the chance of damaging the fastener.

Flank drive wrenches are available in various sizes and configurations to accommodate different types of fasteners. They are commonly used in automotive repair, machinery maintenance, and other mechanical applications where reliable and precise torque is required.

One of the key advantages of flank drive wrenches is their ability to distribute force evenly along the sides of the fastener. This helps to avoid stress concentration on the corners, which can lead to the rounding of the fastener and make it difficult to remove or tighten.

Moreover, flank drive wrenches often feature additional enhancements such as a slim profile or an offset box end, allowing for better accessibility and maneuverability in tight spaces.

In summary, a flank drive wrench is an essential tool for professionals and DIY enthusiasts working in automotive and mechanical industries. Its innovative design provides maximum torque and prevents damage to fasteners, ensuring safe and efficient fastening operations.

How does a Flank Drive Wrench work?

A Flank Drive Wrench is a specialized tool that is designed to provide maximum grip on fasteners, reducing the likelihood of slippage and damage while applying torque.

The wrench features a unique design with specially machined surfaces on the open-end or box-end, creating a pattern of grooves or ridges. These grooves are known as “flanks” and they match the shape of the fastener, whether it’s a hex bolt, square bolt, or other shapes.

When the Flank Drive Wrench is placed on the fastener, the flanks on the wrench fit securely into the corresponding flanks on the fastener. This creates a larger contact surface area between the wrench and the fastener, allowing for increased torque without slippage.

The increased grip strength provided by the Flank Drive design reduces the chance of rounding or stripping the fastener, which can occur when using traditional wrenches. This makes the Flank Drive Wrench especially useful for fasteners that are rusted, damaged, or torqued to high specifications.

Additionally, the Flank Drive design helps distribute torque evenly across the fastener, reducing stress and minimizing the risk of damage to both the fastener and the wrench itself.

Overall, the Flank Drive Wrench offers enhanced reliability, durability, and efficiency compared to standard wrenches, making it an essential tool for automotive, mechanical, and industrial applications.

Advantages of using a Flank Drive Wrench

- Improved grip: The Flank Drive wrench features special ridges on the open end that provide better grip on fasteners compared to traditional wrenches. This helps prevent slipping and stripped bolts, allowing for more efficient and effective work.

- Increased torque: With its innovative design, the Flank Drive wrench provides increased torque when applying force on fasteners. The ridges on the wrench distribute the load evenly across the flats of the fastener, reducing the risk of rounding or damaging the corners.

- Enhanced safety: The improved grip and increased torque of the Flank Drive wrench contribute to enhanced safety during use. The reduced chances of slipping and damaging the fasteners not only protect the equipment but also reduce the risk of injury to the user.

- Versatility: Flank Drive wrenches are available in a wide range of sizes to accommodate different types of fasteners. Whether you need to work on small nuts and bolts or larger industrial applications, there is a Flank Drive wrench size to meet your needs.

- Time and cost savings: By providing better grip, increased torque, and enhanced safety, the Flank Drive wrench can help you complete tasks more efficiently. This can lead to time savings and reduce the chances of needing to replace damaged fasteners, resulting in cost savings in the long run.

- Durability: Flank Drive wrenches are made from high-quality materials, ensuring durability and longevity. Their rugged construction enables them to withstand heavy use and last for a long time, making them a reliable and cost-effective investment.

- Wide range of applications: The versatile nature of the Flank Drive wrench makes it suitable for various applications, including automotive, industrial, and DIY projects. Whether you are a professional mechanic or a casual DIY enthusiast, the Flank Drive wrench can be a valuable addition to your tool collection.

Types of Flank Drive Wrenches

There are several different types of flank drive wrenches available, each designed for specific purposes and applications. Here are some common types:

-

Combination Wrench: This type of flank drive wrench features two different sized ends, typically a box end and an open end. It is versatile and can be used to tighten or loosen nuts and bolts in various sizes.

-

Ratcheting Wrench: A ratcheting flank drive wrench has a ratchet mechanism built into the head, allowing for quick and continuous tightening or loosening without needing to lift and reposition the wrench. This makes it ideal for tight spaces or when working with nuts and bolts that require multiple turns.

-

Adjustable Wrench: An adjustable flank drive wrench, also known as a crescent wrench, has an adjustable jaw that can be shifted to accommodate different sizes of nuts and bolts. It offers flexibility and convenience, making it suitable for various tasks.

-

Torque Wrench: A torque flank drive wrench is designed to apply a specific amount of torque to a fastener. It usually has a built-in torque measuring mechanism, such as a dial or digital display, to ensure the correct amount of torque is applied. This is critical for applications that require precise torque specifications, such as automotive work or industrial assembly.

Each type of flank drive wrench has its advantages and is intended for specific uses. It’s important to choose the right type of wrench for the job to ensure efficiency, accuracy, and safety.

Choosing the right Flank Drive Wrench

When it comes to selecting a Flank Drive Wrench, there are a few important factors to consider. Here are some tips to help you choose the right one for your needs:

1. Size

Flank Drive Wrenches come in various sizes, so it’s important to choose one that is appropriate for the job at hand. Consider the size of the nuts and bolts you typically work with and select a wrench that can accommodate them.

2. Type

There are different types of Flank Drive Wrenches available, including open-end wrenches, combination wrenches, and adjustable wrenches. Each type has its own advantages and disadvantages, so be sure to choose the one that best suits your needs.

3. Material

Flank Drive Wrenches are typically made of steel, but the quality of the steel can vary. Look for wrenches that are made of high-quality, durable steel that can withstand heavy use and provide reliable performance.

4. Grip

A good Flank Drive Wrench should have a comfortable grip that allows for easy handling and prevents slipping. Look for wrenches with ergonomic handles and textured surfaces for better grip and control.

5. Budget

Consider your budget when choosing a Flank Drive Wrench. While it’s important to invest in a high-quality wrench that will last, there are also affordable options available that offer good performance.

6. Brand

Finally, consider the reputation and reliability of the brand. There are many reputable companies that produce Flank Drive Wrenches, so do some research and read reviews to ensure you’re buying from a trusted manufacturer.

By considering these factors and doing your research, you can choose the right Flank Drive Wrench that will help you tackle any job with ease and precision.

Tips for using a Flank Drive Wrench

Using a Flank Drive wrench properly is essential to ensure the safety and effectiveness of your work. Here are some tips to help you use this essential tool effectively:

- Tighten bolts in a star pattern: When using a Flank Drive wrench to tighten bolts, it’s important to tighten them in a star pattern. This ensures even pressure distribution and helps prevent the risk of stripping or damaging the bolt threads.

- Apply consistent force: To avoid over-tightening or under-tightening, it’s crucial to apply consistent force when using a Flank Drive wrench. You can use your hand or a torque wrench to achieve the desired torque. Following the manufacturer’s recommended torque specifications is highly recommended.

- Keep the wrench perpendicular to the fastener: When using a Flank Drive wrench, make sure to keep it perpendicular to the fastener. This ensures that the force is applied directly to the bolt or nut, minimizing the risk of slippage or damage.

- Inspect the tool regularly: Regularly inspecting your Flank Drive wrench is important to ensure its proper functioning. Check for any signs of wear, damage, or rust. If any issues are found, consider replacing or repairing the tool to maintain its effectiveness.

- Use the right size wrench: It’s crucial to use the correct size Flank Drive wrench for the job. Using a wrench that is too small or too large can lead to inefficient or ineffective tightening. Always consult the tool’s user manual or a size chart to determine the appropriate wrench size for the fastener.

Following these tips will help you maximize the performance of your Flank Drive wrench and ensure safe and efficient use.

Maintenance and care for a Flank Drive Wrench

Regular Cleaning

One important aspect of maintaining a Flank Drive wrench is regularly cleaning it. After each use, wipe down the wrench with a clean cloth to remove any dirt or debris. This will help prevent buildup and ensure smooth operation.

Lubrication

To keep the Flank Drive wrench functioning properly, it is important to lubricate it regularly. Apply a small amount of lubricant to the moving parts of the wrench, such as the hinge and ratchet mechanism. This will help reduce friction and extend the lifespan of the tool.

Inspection

Regularly inspect the Flank Drive wrench for any signs of wear or damage. Check for any cracks, chips, or bends in the handle or the head of the wrench. If any damage is found, it is important to replace the tool to ensure optimal performance and safety.

Storage

Proper storage is essential to maintain the condition of the Flank Drive wrench. Store the wrench in a clean and dry place, away from moisture and extreme temperatures. It is also a good idea to store the wrench in a tool box or pouch to protect it from dust and other debris.

Proper Use

Using the Flank Drive wrench for its intended purpose is crucial to its maintenance. Avoid using the wrench for tasks that exceed its maximum torque capability, as this can cause damage to the tool. Additionally, always use the right size and type of socket or bit that is compatible with the wrench.

Periodic Calibration

To ensure accurate and precise torque application, it is recommended to periodically calibrate the Flank Drive wrench. This can be done by a professional or using a torque calibration tool. Calibration will help maintain the accuracy of the wrench and ensure consistent results.

Manufacturer’s Instructions

Finally, it is important to follow the manufacturer’s instructions and guidelines for maintenance and care of the Flank Drive wrench. The manufacturer may provide specific recommendations and precautions that are important to follow to ensure the longevity and performance of the tool.

FAQ

What is a Flank Drive Wrench?

A Flank Drive wrench is a type of wrench that is designed to provide maximum torque without damaging the fastener. It uses a special shape on the open end of the wrench that allows for a better grip on the fastener, reducing the risk of slipping and rounding off the corners.

How does a Flank Drive wrench work?

A Flank Drive wrench works by using a special shape on the open end of the wrench. This shape allows for a better grip on the fastener, reducing the risk of slipping and rounding off the corners. The wrench applies torque to the fastener in a way that minimizes the stress on the corners, reducing the risk of damage.

What are the benefits of using a Flank Drive wrench?

There are several benefits of using a Flank Drive wrench. Firstly, it provides a better grip on the fastener, reducing the risk of slipping and rounding off the corners. Secondly, it allows for maximum torque to be applied without damaging the fastener. This can be especially important when working with tight or stubborn fasteners. Finally, it helps to prolong the life of the fastener by reducing the stress and damage that can be caused by other types of wrenches.

Are Flank Drive wrenches expensive?

Flank Drive wrenches can vary in price depending on the brand and quality. However, they are generally considered to be a higher-end tool and can be more expensive than standard wrenches. The added cost is often justified by the increased performance and durability of the Flank Drive wrench.