What is a box end wrench used for? | Guide to the Essential Tool

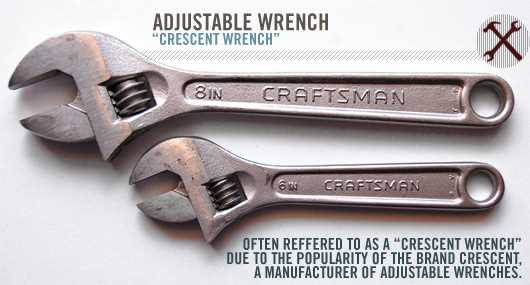

A box end wrench, also known as a closed-end wrench or a ring spanner, is a versatile hand tool that is commonly used in mechanical and automotive repairs. The box end wrench gets its name from its appearance – it has a closed-end design that fits over the head of a nut or bolt, providing a secure grip and allowing for the application of torque. This essential tool is often found in the toolboxes of professional mechanics and DIY enthusiasts alike.

One of the primary uses of a box end wrench is for tightening or loosening fasteners, such as nuts and bolts, that have a hexagonal or square-shaped head. The closed-end design of the wrench ensures a snug fit, minimizing the risk of slippage and preventing damage to the fastener. The box end wrench is particularly useful in tight spaces where a socket wrench cannot be used, making it a must-have tool for tasks in confined areas.

Another advantage of the box end wrench is its ability to provide a greater amount of torque compared to other wrench types. The closed-end design allows for a full 360-degree contact with the fastener, enabling more force to be applied without compromising the grip. This makes it ideal for tasks that require more power, such as loosening rusted or stubborn fasteners.

In addition to its primary use, the box end wrench can also be used for other applications, such as plumbing repairs, bicycle maintenance, and furniture assembly. Its versatility and compact size make it a valuable tool to have in any toolbox.

Whether you’re a professional mechanic or a DIY enthusiast, a box end wrench is an essential tool that should not be overlooked. Its secure grip, torque capabilities, and versatility make it a valuable asset for a wide range of repair and maintenance tasks. So, make sure to have a set of box end wrenches in your toolbox, and you’ll be ready to tackle any job that comes your way.

What is a box end wrench used for?

A box end wrench, also known as a box spanner, is a type of wrench with a closed loop at one or both ends. It is designed to grip the nuts or bolts with flat sides, offering better contact and reduced chances of rounding off the fasteners compared to an adjustable wrench or an open-end wrench.

Key Features:

- Box end: The closed loop design of the wrench allows it to fit snugly over a nut or bolt.

- Fixed size: Unlike an adjustable wrench, the box end wrench comes in a specific size, which provides a more stable grip.

- Multiple points of contact: The box end typically has six or twelve points, allowing for a stronger grip on the fastener.

Uses:

Box end wrenches are commonly used in automotive, plumbing, and mechanical applications. Here are some specific uses:

- Automotive repairs: Box end wrenches are often used to tighten or loosen nuts and bolts in engine compartments, suspension systems, and other automotive components.

- Plumbing installations: When working with pipe fittings, a box end wrench can provide a secure grip on the nuts, ensuring proper installation.

- Furniture assembly: Many furniture pieces come with nuts and bolts that can be tightened using a box end wrench.

- Appliance repairs: Box end wrenches can be handy when working on appliances such as refrigerators, washers, and dryers.

Tips for using box end wrenches:

- Choose the right size: Make sure to use a box end wrench that fits the nuts or bolts you are working with. Using the wrong size can lead to slippage or rounding off the fasteners.

- Apply even pressure: When using a box end wrench, apply pressure evenly to avoid stripping the fastener.

- Use the correct end: Some box end wrenches have different sizes on each end. Make sure to use the correct end to avoid damage to the fastener or the wrench itself.

- Consider a ratchet box end wrench: Ratchet box end wrenches allow for continuous rotation without removing the wrench from the fastener, making it faster and more convenient to use.

Overall, a box end wrench is an essential tool for anyone working with nuts and bolts. Its design provides a secure grip and reduces the chances of damaging fasteners or the wrench itself.

Understanding the Essential Tool

The box end wrench is an essential tool for any toolbox. It is a type of wrench that is specifically designed to fit over the heads of bolts or nuts, providing a secure grip to tighten or loosen them. This tool is commonly used in automotive, construction, and mechanical work.

Types of Box End Wrenches

Box end wrenches come in various sizes and shapes to accommodate different bolt and nut sizes. The most common types include:

- Standard Box End Wrench: This is the most basic type, with a closed loop at one or both ends to fit over the bolt or nut.

- Offset Box End Wrench: This type has an angled handle, allowing for better accessibility in tight spaces.

- Ratcheting Box End Wrench: With a ratcheting mechanism, this type allows for quicker tightening or loosening of bolts and nuts.

Advantages of Using a Box End Wrench

Using a box end wrench offers several advantages:

- Secure Grip: The closed-loop design of the box end wrench provides a strong and secure grip on bolts and nuts, preventing them from slipping or rounding off.

- Greater Torque: The box end wrench allows for greater torque application compared to other wrench types, making it easier to loosen stubborn bolts or nuts.

- Accessibility: The offset and ratcheting box end wrenches provide better accessibility in tight or hard-to-reach spaces, allowing for efficient work in confined areas.

- Versatility: With various sizes and types available, the box end wrench is versatile and can be used for different applications, from small household repairs to heavy-duty mechanical work.

Usage Tips

To get the most out of your box end wrench, consider the following tips:

- Select the Right Size: Ensure you have the correct size of box end wrench that fits the bolt or nut snugly. Using the wrong size can lead to slippage and damage.

- Apply Even Pressure: When tightening or loosening bolts or nuts, apply even pressure to avoid stripping or damaging the fastener.

- Maintain Your Tools: Regularly clean and lubricate your box end wrenches to keep them in good condition and prevent rust or corrosion.

- Consider the Type: Choose the appropriate type of box end wrench based on the job requirements, such as an offset wrench for tight spaces or a ratcheting wrench for faster work.

With its secure grip and versatility, the box end wrench is an essential tool that should be a part of every toolbox. Whether you’re an automotive enthusiast or a professional mechanic, this tool will prove indispensable for all your fastening needs.

Types of Box End Wrenches

A box end wrench, also known as a ring spanner, is a versatile tool that is used for tightening or loosening nuts and bolts. It is designed to fit over the head of a bolt or nut, providing a secure grip and minimizing the risk of stripping or rounding off the fastener. There are several different types of box end wrenches, each with its own unique design and purpose.

1. Standard Box End Wrench

The standard box end wrench is the most common type of box end wrench. It features a closed-end design with six or twelve points of contact, allowing for a tight fit on fasteners. The standard box end wrench is suitable for a wide range of applications and is available in various sizes to accommodate different bolt and nut sizes.

2. Ratcheting Box End Wrench

A ratcheting box end wrench is a specialized type of box end wrench that offers the convenience of a ratchet mechanism. This allows for quick and continuous tightening or loosening of fasteners without the need to remove and reposition the wrench. It saves time and effort, especially in tight or hard-to-reach spaces.

3. Offset Box End Wrench

An offset box end wrench is designed with an angled head, allowing for increased clearance and access to tight or obstructed spaces. The offset design helps to reach fasteners that are positioned at an angle or close to a surface, where a standard box end wrench would not fit.

4. Double Box End Wrench

A double box end wrench, also known as a bi-hexagonal wrench, features two different sizes of box ends on opposite ends of the wrench. This makes it a versatile tool that can be used for different fasteners without the need to switch wrenches. It is commonly used in automotive and mechanical applications.

5. Crowfoot Box End Wrench

A crowfoot box end wrench is a specialized type of box end wrench that is used in conjunction with a socket wrench or extension bar. It has a box end design without a handle, allowing it to fit into tight spaces where a regular wrench would not fit. It is commonly used in automotive and plumbing applications.

6. Flare Nut Box End Wrench

A flare nut box end wrench, also known as a line wrench, is specially designed for use on hydraulic or fuel line fittings. It has a longer handle and a thin-walled box end, allowing for a secure grip on fittings without damaging them. It is commonly used in automotive and aircraft applications.

These are just a few examples of the different types of box end wrenches available. Each type has its own unique features and uses, making them versatile tools in various industries and applications.

Exploring the Different Varieties

1. Standard Box End Wrench

The standard box end wrench is the most basic and common type of box end wrench. It features a closed-end design with a 6-point hexagonal opening, which allows for a secure grip on the fasteners. This type of wrench is versatile and can be used for a variety of tasks, such as tightening or loosening nuts and bolts.

2. Deep Box End Wrench

A deep box end wrench, also known as a offset box end wrench, has a longer handle than the standard box end wrench. This extended length allows for better access in tight spaces and provides extra leverage for stubborn fasteners. The deep box end wrench has the same hexagonal opening as the standard version and is suitable for tasks that require a longer reach.

3. Ratcheting Box End Wrench

The ratcheting box end wrench is a handy tool that combines the convenience of a ratchet with the functionality of a box end wrench. It features a ratcheting mechanism that allows for continuous tightening or loosening of fasteners without the need to reposition the wrench. This type of wrench is useful for tasks that require repetitive motion, as it saves time and effort.

4. Spline Box End Wrench

The spline box end wrench, also known as a double open-end wrench, has a unique design with two U-shaped openings on both ends. Each opening corresponds to a different size, providing versatility and the ability to work with a wide range of fasteners. This type of wrench is commonly used in plumbing and automotive applications.

5. Flare Nut Box End Wrench

The flare nut box end wrench, also known as a line wrench, is specifically designed for use with hydraulic fittings and brake lines. It features a thin and elongated design with a closed-end that grips the fastener securely while minimizing the risk of rounding off or damaging the fitting. This type of wrench is essential for maintaining and repairing hydraulic systems.

6. Crowfoot Box End Wrench

The crowfoot box end wrench is a specialized tool that is used in conjunction with a socket and extension. It features a U-shaped opening and is designed to be attached to the socket, allowing for access to fasteners in areas where a regular wrench or socket cannot reach. This type of wrench is commonly used in automotive and aerospace applications.

How to Use a Box End Wrench

A box end wrench, also known as a box wrench or a ring spanner, is a versatile tool used for tightening or loosening nuts and bolts. It has a closed loop design, with a hexagonal or square opening at one or both ends, that fits over the fastener head.

Step 1: Select the Correct Size

Before using a box end wrench, it is important to select the correct size wrench for the job. The opening of the wrench should fit snugly over the fastener head, ensuring a secure grip and minimizing the risk of slipping or rounding off the edges of the nut or bolt.

Step 2: Position the Wrench

Once you have selected the correct size box end wrench, position the wrench over the fastener head. Make sure that the wrench is fully engaged with the fastener, with all sides of the opening in contact with the head.

Step 3: Apply Torque

Using the handle of the box end wrench, apply the necessary force or torque in the direction required to tighten or loosen the fastener. It is important to apply steady and even pressure to avoid damaging the fastener or injuring yourself.

Step 4: Reverse if Necessary

If you need to reverse the direction of the wrench, simply flip it over or use the other end of the wrench (if available). This allows you to quickly switch between tightening and loosening fasteners without the need for another tool.

Step 5: Confirm Tightness

After tightening or loosening the fastener using the box end wrench, make sure to check the tightness using a torque wrench or another suitable tool. This ensures that the fastener is properly secured and reduces the risk of it coming loose over time.

Remember to always use the correct tool for the job to avoid damaging the fastener or the wrench itself. Additionally, it is important to follow safety precautions and wear appropriate personal protective equipment when working with tools.

By following these steps, you can effectively use a box end wrench for tightening or loosening nuts and bolts in various applications.

Step-by-Step Guide for Proper Usage

1. Choose the right size

Before using a box end wrench, it is important to select the right size to ensure a proper fit on the fastener. Box end wrenches come in various sizes, typically measured in inches or millimeters. Use a wrench that matches the size of the fastener you are working on to avoid damaging the tool or the fastener.

2. Position the wrench

Once you have the right size box end wrench, position it over the fastener you want to tighten or loosen. Make sure the wrench fully covers the fastener and engages the corners securely to prevent slipping.

3. Apply steady force

Apply steady force in the direction you want to turn the fastener. Box end wrenches are designed to provide a strong grip, so you can exert more torque without the risk of rounding off the fastener’s edges.

4. Use both hands if necessary

If you encounter a stubborn or tightly fastened nut or bolt, it may require additional force. In such cases, it is recommended to use both hands to increase leverage and improve control. Place one hand on the handle and the other on the opposite end of the wrench for maximum torque.

5. Avoid over-tightening

When tightening fasteners, it is important to avoid over-tightening. Over-tightening can lead to stripped threads or damage to the fastener. Use your best judgment and tighten the fastener until it is secure, but not excessively tight.

6. Clean and store properly

After using a box end wrench, clean it with a rag or a brush to remove any dirt or debris. Properly store the wrench in a dry place to prevent rust or other damage. This will ensure that your box end wrench remains in good condition and ready for future use.

By following these steps, you can effectively and safely use a box end wrench for various tasks. Remember to always choose the right size wrench, apply steady force, and maintain proper care for your tools.

Benefits of Box End Wrenches

- Versatility: Box end wrenches can be used for a wide range of tasks and can fit various sizes of fasteners. They are available in different sizes, allowing you to tackle different projects with ease.

- Torque: The design of box end wrenches allows for increased torque application compared to other types of wrenches. The box end provides a firm grip on the fastener, reducing the chances of slipping and increasing the amount of force you can apply.

- Accessibility: Box end wrenches have a closed design with two sides, making them ideal for reaching fasteners in tight and hard-to-reach spaces. The closed design also helps prevent damage to surrounding components and increases stability during use.

- Ratcheting: Some box end wrenches come with a ratcheting feature, which allows for faster and more efficient work. The ratcheting mechanism eliminates the need to remove and reposition the wrench after each turn, saving you time and effort.

- Durability: Box end wrenches are typically made from durable materials like steel, ensuring they can withstand the demands of heavy-duty use. Their sturdy construction makes them reliable and long-lasting, providing value for your investment.

- Accuracy: The closed design of box end wrenches ensures a snug fit on fasteners, reducing the chances of slippage and increasing the accuracy of your work. This precision is especially important when dealing with delicate or sensitive components.

- Compatibility: Box end wrenches are compatible with various types of fasteners, including hexagonal, square, and 12-point nuts and bolts. This versatility makes them a valuable addition to any toolbox or workshop.

Why Every Toolkit Should Have One

A box end wrench, also known as a box wrench or a spanner wrench, is an essential tool that should be present in every toolkit. Whether you are a professional mechanic, a DIY enthusiast, or someone who occasionally repairs things around the house, a box end wrench is a must-have tool.

Here are a few reasons why every toolkit should have a box end wrench:

Versatility

Box end wrenches come in different sizes and are designed to fit specific nut and bolt sizes. With a set of box end wrenches, you can tackle a wide range of tasks that involve fasteners such as nuts and bolts. From automotive repairs to plumbing work, a box end wrench can handle it all.

Specialized Design

A box end wrench features a closed loop at one or both ends. This design allows the wrench to grip the fastener securely and apply maximum torque without slipping. The closed loop design also helps prevent rounding off the edges of the fastener, ensuring that it remains in good condition.

Space-Efficient

The compact design of a box end wrench makes it ideal for working in tight spaces where a regular wrench might not fit. The closed loop design also allows for a better grip, making it easier to loosen or tighten fasteners in confined areas.

Increased Durability

Box end wrenches are typically made from high-quality materials such as steel or chrome vanadium alloy. These materials provide strength and durability, ensuring that the wrench will last for a long time even with regular use. Investing in a good set of box end wrenches means you won’t have to worry about constantly replacing worn-out tools.

Efficient and Time-saving

Using a box end wrench allows for faster and more efficient work compared to other common wrench types. The closed loop design provides a more secure grip, reducing the chances of slipping and the need for repeated attempts to tighten or loosen a fastener. This can save you valuable time and effort, especially when working on complex projects.

Overall, a box end wrench is a versatile, space-efficient, and durable tool that can greatly simplify your repair and maintenance tasks. Whether you are a professional or a DIYer, having a box end wrench in your toolkit will ensure that you have the right tool for the job, whenever you need it.

Tips for Choosing the Right Box End Wrench

A box end wrench, also known as a box spanner or a ring spanner, is a versatile tool used for tightening or loosening nuts and bolts. It features a closed-end design with a ring-shaped opening that fits around the fastener, providing a secure grip and reducing the risk of slippage. When selecting a box end wrench, there are several factors to consider to ensure you choose the right tool for the job.

1. Size

One of the most important factors to consider when choosing a box end wrench is the size. Wrenches come in various sizes, typically measured in inches or millimeters, and it’s crucial to select a wrench that matches the size of the fastener you’re working with. Using the wrong size wrench can result in rounding off the fastener or damaging the wrench itself.

2. Material

The material of the box end wrench can impact its durability and performance. Most box end wrenches are made from steel, which provides strength and durability. However, there are different grades of steel, with some being more resistant to corrosion and wear than others. Consider the environment in which you’ll be using the wrench and choose a material that is suitable for those conditions.

3. Number of Points

Box end wrenches can come with different numbers of points on the ring end, typically 6 or 12. A 6-point wrench offers more contact points with the fastener, distributing the force evenly and reducing the risk of slipping or rounding off the corners. However, a 12-point wrench allows for a greater range of movement in tight spaces. Consider the specific application and accessibility when choosing the number of points on the wrench.

4. Quality

The quality of the box end wrench can significantly impact its performance and lifespan. Look for wrenches that are made by reputable manufacturers and have a solid reputation for quality. Quality wrenches are less likely to break or wear out quickly, ensuring that you can rely on them for multiple projects.

5. Set or Individual Wrench

Depending on your needs, you may choose to purchase a set of box end wrenches or individual wrenches. A set typically includes a range of sizes, allowing you to tackle a variety of tasks. However, if you only need a specific size or have limited storage space, individual wrenches may be a more practical option.

6. Ergonomics

Consider the ergonomics of the box end wrench, particularly if you’ll be using it for extended periods. Look for wrenches with comfortable and non-slip handles that provide a secure grip. Additionally, some wrenches feature an offset design that allows for better access and leverage in tight spaces.

By considering these factors when choosing a box end wrench, you can ensure that you have the right tool for the job and achieve optimal results in your projects.

Factors to Consider for a Perfect Fit

When choosing a box end wrench, there are several factors to consider in order to ensure a perfect fit for your specific needs. These factors include:

- Size: Box end wrenches come in different sizes to fit different nut and bolt heads. It is important to choose a wrench that matches the size of the fastener you are working on. Using an incorrectly sized wrench can lead to stripped or damaged fasteners.

- Material: Box end wrenches are typically made of steel or chrome vanadium. Steel wrenches are affordable and durable, but they can be heavier. Chrome vanadium wrenches are lighter and have better resistance to corrosion, but they are more expensive.

- Number of Points: The number of points on a box end wrench refers to the number of angles or corners on the wrench head. Common options include 6, 8, 12, and even 16 points. More points provide a higher number of contact points with the fastener, leading to a better grip and less chance of slipping. However, wrenches with more points can be bulkier and may not fit in tight spaces.

- Offset: Some box end wrenches have an offset design, where the handle is angled away from the wrench head. This allows for better access to fasteners in tight or hard-to-reach areas. Offset box end wrenches are particularly useful when working on automotive or plumbing projects.

- Quality: It is important to choose a box end wrench of high quality. Look for wrenches that are well-made, have smooth and precise openings, and are made by reputable manufacturers. Investing in a high-quality wrench will ensure its durability and longevity.

By considering these factors and choosing a box end wrench that meets your specific requirements, you can ensure a perfect fit and achieve efficient and effective results in your work.

FAQ

What is a box end wrench?

A box end wrench, also known as a box wrench, is a type of wrench with a closed loop at one or both ends. It is designed to grip and turn nuts or bolts with a square or hexagonal head.

What are the different types of box end wrenches?

There are several different types of box end wrenches, including single-end, double-end, offset, and ratcheting box wrenches. Single-end wrenches have a box end on one side and an open end on the other, while double-end wrenches have a box end on both sides. Offset wrenches have a curved handle for easier access to tight spaces. Ratcheting box wrenches have a mechanism that allows for continuous tightening or loosening without having to remove and reposition the wrench.

What is a box end wrench used for?

A box end wrench is mainly used for turning nuts or bolts with a square or hexagonal head. It provides better grip and torque compared to other types of wrenches, such as adjustable wrenches or open-end wrenches. The closed loop design of the box end wrench also helps prevent rounding off the edges of nuts or bolts.

When should I use a box end wrench?

A box end wrench is suitable for situations where you need a secure grip on a nut or bolt and want to minimize the risk of slipping or rounding off the edges. It is often used in automotive and mechanical repairs, as well as for assembly or disassembly of machinery and equipment.

What are the advantages of using a box end wrench?

Using a box end wrench offers several advantages. It provides a secure grip on nuts or bolts, minimizing the risk of slipping and causing damage. The closed loop design helps prevent rounding off the edges, ensuring a tight fit. Additionally, box end wrenches are available in various sizes and configurations to accommodate different fasteners and access requirements.

Can a box end wrench be used on any type of fastener?

No, a box end wrench is specifically designed for nuts or bolts with a square or hexagonal head. It may not be suitable for other types of fasteners, such as those with a rounded or irregular shape. For those types of fasteners, different tools like adjustable wrenches or socket wrenches may be more appropriate.

Are box end wrenches available in different sizes?

Yes, box end wrenches are available in various sizes to fit different nuts or bolts. The size of the wrench is determined by the distance across the flats of the fastener head. Common sizes include 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, and 1 inch, among others. It is important to use the correct size of wrench to ensure a proper fit and avoid damaging the fastener.