Understanding the Role of Hog Rings in Impact Wrenches: A Comprehensive Guide

Impact wrenches are powerful tools that are widely used in various industries, such as automotive, construction, and manufacturing. These tools are designed to deliver high torque output, making them essential for tasks that require heavy-duty fastening and loosening of nuts and bolts.

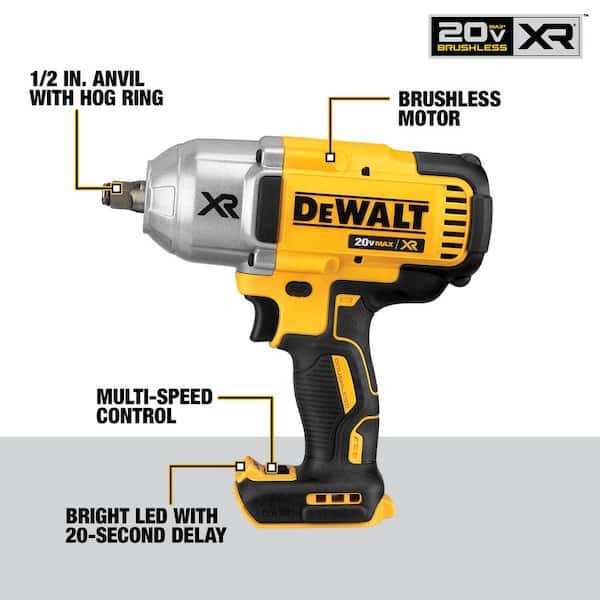

One crucial component of impact wrenches is the hog ring, which plays a vital role in securing sockets and extensions to the wrench’s anvil. The hog ring acts as a safety mechanism, ensuring that the socket or extension remains securely attached to the wrench during operation, preventing any sudden detachment or slippage.

The hog ring is made of durable steel and is typically shaped like a closed loop with a small opening. When the socket or extension is inserted into the wrench’s anvil, the hog ring fits into a corresponding groove or groove-like structure on the tool. Once in place, the hog ring expands to secure the socket or extension firmly, preventing it from coming loose while the impact wrench is in use.

It is crucial to understand the role and importance of hog rings in impact wrenches to ensure proper and safe operation of these powerful tools. In this comprehensive guide, we will delve deeper into the function of hog rings and explore different types of hog rings available in the market. We will also discuss the maintenance and replacement of hog rings to prolong the lifespan and efficiency of impact wrenches.

Understanding Impact Wrenches: A Comprehensive Guide

Overview

An impact wrench, also known as an impact gun or air wrench, is a powerful tool used to tighten or loosen bolts and nuts. It is commonly used in automotive repair, construction, and industrial applications. This comprehensive guide aims to provide a detailed understanding of impact wrenches, their components, operating principles, and various applications.

Components of an Impact Wrench

An impact wrench consists of the following main components:

- Motor: The motor generates the necessary power to rotate the output shaft.

- Drive Mechanism: The drive mechanism transfers the rotational motion from the motor to the output shaft.

- Output Shaft: The output shaft is responsible for applying torque to fasteners.

- Anvil: The anvil is the end of the output shaft that holds the socket or adapter for attaching to fasteners.

- Trigger: The trigger controls the operation of the impact wrench, allowing the user to start and stop the tool.

Operating Principle

The operating principle of an impact wrench involves a combination of rotary motion and concussive blows to provide high torque output. When the trigger is pressed, the motor spins an internal hammer mechanism, which impacts the output shaft. The hammer mechanism consists of a spring, hammer, and anvil. The spring compresses and releases, causing the hammer to strike the anvil multiple times per rotation. This repetitive striking action generates high torque, allowing for efficient tightening or loosening of fasteners.

Types of Impact Wrenches

There are several types of impact wrenches available, each designed for specific applications:

- Air-powered Impact Wrenches: These impact wrenches are powered by compressed air and are commonly used in automotive and industrial settings.

- Battery-powered Impact Wrenches: These portable impact wrenches are powered by rechargeable batteries and are ideal for remote or on-site applications.

- Corded Electric Impact Wrenches: These impact wrenches require a power outlet and provide consistent power output for heavy-duty applications.

Applications

Impact wrenches are widely used in various industries for different applications, including:

- Automotive Repair: Impact wrenches are essential for removing and installing lug nuts, suspension components, and other fasteners on vehicles.

- Construction: Impact wrenches are used in construction for fastening and loosening structural bolts, anchor bolts, and scaffolding components.

- Manufacturing: Impact wrenches play a vital role in assembly lines for tightening fasteners on machinery and equipment.

- Maintenance and Repair: Impact wrenches are used in general maintenance and repair tasks across multiple industries.

Conclusion

Understanding impact wrenches is essential for selecting the right tool for specific applications. This comprehensive guide has provided an overview of impact wrenches, their components, operating principles, and various applications. By utilizing this knowledge, users can maximize the efficiency and effectiveness of impact wrenches in their respective fields.

The Importance of Hog Rings

1. Holding Power

The primary function of hog rings in impact wrenches is to provide a secure grip on fasteners. These small rings are made of metal and are designed to be inserted through the holes in a fastener, such as a wiring or fencing staple, to hold it in place. Hog rings offer excellent holding power, ensuring that the fastener remains securely attached, even under significant pressure or vibrations.

2. Quick and Efficient Fastening

With the use of hog rings, impact wrenches enable quick and efficient fastening of various materials. By applying pressure to the fastener, the impact wrench drives the hog ring through the holes, creating a strong and durable connection. This saves time and effort compared to manual fastening methods, making hog rings an essential accessory for professionals in industries such as construction, upholstery, and automotive.

3. Versatility

Hog rings provide versatility in different applications. They can be used to secure wires, cables, and mesh fencing. In the upholstery industry, hog rings are commonly used to attach fabric to frames, ensuring a tight and secure fit. The ability of hog rings to accommodate different types of fasteners and materials makes them a valuable tool for a wide range of projects.

4. Durability

Hog rings are known for their durability and resistance to wear and tear. Typically made from stainless steel or galvanized steel, these rings are designed to withstand heavy-duty applications and harsh environments. The strong material ensures that the hog rings maintain their shape and strength over time, making them a reliable choice for long-lasting connections.

5. Easy Installation and Removal

Another advantage of hog rings is their ease of installation and removal. Impact wrenches equipped with hog ring retainers allow for quick and effortless ring replacement when needed. This feature saves time and effort, especially in applications that require frequent removal and replacement of hog rings.

6. Cost-Effective Solution

Using hog rings in impact wrenches provides a cost-effective solution for fastening needs. The durability and long lifespan of hog rings ensure that they can be used repeatedly, reducing the need for frequent replacements. Additionally, the time-saving nature of impact wrenches combined with the efficiency of hog rings leads to increased productivity and cost savings for professionals.

Conclusion

Overall, hog rings play a vital role in impact wrenches by providing essential holding power, enabling quick and efficient fastening, offering versatility, and ensuring durability. With their ease of installation and removal, as well as the cost-effectiveness they bring, hog rings are a valuable tool for professionals across various industries.

How Hog Rings Function in Impact Wrenches

In impact wrenches, hog rings are an essential component that play a crucial role in securing the socket to the anvil. These small, circular metal rings are designed to hold the socket firmly in place, preventing it from becoming loose or detached during operation.

Hog rings are typically positioned inside the square or hexagonal recess on the anvil. The socket is then placed over the anvil and held in position by the hog ring. When the impact wrench is activated, the anvil spins at a high speed, transferring rotational force to the socket and allowing it to tighten or loosen fasteners.

The primary function of hog rings is to provide a secure connection between the anvil and the socket. Without hog rings, the socket would have a tendency to slip or fly off the anvil, making it difficult to use the impact wrench effectively.

The design of hog rings is such that they create a tight grip on the socket, ensuring that it remains firmly attached to the anvil. This allows the impact wrench to apply maximum rotational force to the fastener without any loss of power due to socket slippage.

Benefits of Hog Rings in Impact Wrenches:

- Enhanced Safety: Hog rings provide a secure connection, reducing the risk of the socket coming loose and potentially causing accidents or injuries.

- Improved Efficiency: By preventing socket slippage, hog rings allow for more efficient and effective use of the impact wrench, saving time and effort.

- Increased Durability: The tight grip provided by hog rings helps to reduce wear and tear on the socket, resulting in increased longevity and durability of the tool.

In conclusion, hog rings play a vital role in ensuring the functionality and safety of impact wrenches. By securely holding the socket in place, hog rings allow for reliable and efficient operation, making them an essential component of these powerful tools.

Different Types of Hog Rings

1. Round Hog Rings

Round hog rings are the most commonly used type of hog ring. They are circular in shape and typically made of galvanized steel or stainless steel. Round hog rings are versatile and can be used in various applications, such as attaching wire mesh, closing bags, or securing upholstery.

2. D-Ring Hog Rings

D-ring hog rings are named for their distinctive D-shaped design. They are often used in situations where a strong and secure closure is required, such as fencing applications or automotive upholstery. D-ring hog rings are made of durable materials like stainless steel or aluminum, ensuring long-lasting performance.

3. C-Ring Hog Rings

C-ring hog rings are shaped like the letter C. They are commonly used in applications where the closure needs to be flush or concealed, such as in the manufacturing of bungee cords or the assembly of wire cages. C-ring hog rings can be made of various materials, including galvanized steel or aluminum.

4. M-Ring Hog Rings

M-ring hog rings are named for their M-shaped design. They are primarily used in the manufacturing of mattresses, as they provide a secure and tight closure. M-ring hog rings are usually made of galvanized steel or aluminum to withstand the pressure and tension exerted by the mattress materials.

5. Lacing Hog Rings

Lacing hog rings, also known as lacing rings or staple rings, have a unique curved shape. They are commonly used in the upholstery industry for attaching fabric to furniture frames. Lacing hog rings are typically made of stainless steel or galvanized steel, ensuring durability and resistance to corrosion.

6. Spring Hog Rings

Spring hog rings are designed with an additional feature—a spring that provides extra compression force. This type of hog ring is often used in applications where a strong and tight closure is necessary, such as in the manufacturing of filters or securing piping. Spring hog rings are available in various sizes and materials to suit different applications.

| Type | Shape | Common Uses | Available Materials |

|---|---|---|---|

| Round Hog Rings | Circular | Wire mesh, bags, upholstery | Galvanized steel, stainless steel |

| D-Ring Hog Rings | D-shaped | Fencing, automotive upholstery | Stainless steel, aluminum |

| C-Ring Hog Rings | C-shaped | Bungee cords, wire cages | Galvanized steel, aluminum |

| M-Ring Hog Rings | M-shaped | Mattress manufacturing | Galvanized steel, aluminum |

| Lacing Hog Rings | Curved | Upholstery, attaching fabric to frames | Stainless steel, galvanized steel |

| Spring Hog Rings | Various | Filters, piping | Various materials |

Factors to Consider when Choosing Hog Rings

When selecting hog rings for your impact wrench, it is important to consider several factors to ensure the best performance and efficiency. Here are some key factors to keep in mind:

1. Material

The material of the hog ring plays a vital role in its performance and durability. Hog rings made of high-quality materials such as stainless steel or galvanized steel are highly recommended. These materials are known for their strength, corrosion resistance, and longevity, making them ideal for various applications.

2. Size

The size of the hog ring should match the specific requirements of your application. Hog rings are available in various sizes, typically indicated by the diameter or the gauge of the wire used. It is important to choose a hog ring size that is compatible with the thickness of the material you are working with. Using the wrong size can lead to weak connections or ring breakage.

3. Closure Style

There are different closure styles available for hog rings, including straight, D-shape, or square-shaped. The choice of closure style depends on the specific application and personal preference. Straight hog rings are commonly used for general-purpose applications, while D-shaped or square-shaped rings provide a stronger grip and are often used in heavy-duty applications.

4. Application

The intended application should also be considered when selecting hog rings. Different applications may require different hog ring sizes, materials, or closure styles. For example, if you are working with fabric upholstery, you may require hog rings with a smaller size and a softer material to prevent damage to the fabric. On the other hand, if you are working with fencing or mesh, you may need larger hog rings with a stronger closure style for secure connections.

5. Brand and Quality

Choosing hog rings from reputable brands known for their quality ensures that you are getting a reliable and durable product. It is worth investing in high-quality hog rings to avoid frequent replacements and ensure optimal performance.

By considering these factors, you can select the most suitable hog rings for your impact wrench and achieve efficient and reliable results in your applications.

Tips for Proper Maintenance of Hog Rings

Proper maintenance of hog rings is essential to ensure their longevity and optimal performance. Here are some tips to help you maintain hog rings effectively:

1. Clean the Hog Rings Regularly

Regular cleaning of hog rings is vital to remove any dirt, debris, or residue that may accumulate during use. Use a clean cloth or brush to wipe away any particles from the hog rings. Cleaning them regularly will prevent the buildup of grime and extend their lifespan.

2. Lubricate the Hog Rings

Applying a lubricant to the hog rings helps reduce friction and wear during operation. Use a recommended lubricant or grease suitable for hog rings and apply a small amount to the moving parts. This will ensure smooth movement and prevent undue stress on the hog rings.

3. Inspect for any Damage or Wear

Periodically check the hog rings for any signs of damage or wear. Look for bent or broken parts, as well as any signs of rust or corrosion. If you notice any issues, it is best to replace the hog rings to prevent further damage and maintain optimal performance.

4. Store in a Dry and Clean Environment

When not in use, store the hog rings in a dry and clean environment. Moisture and dirt can accelerate wear and cause damage to the hog rings. Keep them in a closed container or drawer to protect them from dust, moisture, and other elements.

5. Follow Manufacturer’s Guidelines

Always refer to the manufacturer’s guidelines for specific maintenance instructions for your hog rings. Certain brands or models may have unique requirements or recommendations for cleaning and lubrication. By following the guidelines provided, you can ensure the proper maintenance of your hog rings and maximize their lifespan.

By following these tips, you can ensure the proper maintenance of your hog rings, prolong their durability, and optimize their performance. Regular cleaning, lubrication, and inspection are key to keeping your hog rings in excellent condition for years to come.

Advantages of Using Hog Rings in Impact Wrenches

- Hog rings provide a secure and reliable connection between the impact wrench and the fastener. They ensure that the fastener remains in place during the operation, reducing the risk of accidents or injuries.

- Hog rings are easy to install and remove, allowing for quick and efficient tool changes. This is especially beneficial in industrial settings where time is of the essence.

- Using hog rings in impact wrenches can increase productivity and efficiency. The secure connection they provide allows for more consistent torque application, resulting in faster and more accurate fastening.

- Hog rings are versatile and can be used with a variety of fasteners, including bolts, screws, and nails. This allows for greater flexibility in different applications, making them a valuable tool in many industries.

- By reducing the need for manual tightening, hog rings minimize the risk of repetitive strain injuries for operators. This can lead to improved ergonomics and increased worker comfort.

- Due to their durability and resistance to corrosion, hog rings offer a long service life, making them a cost-effective solution for impact wrench applications.

- Furthermore, hog rings can help prevent loosening and disengagement of fasteners, ensuring the longevity and reliability of assembled structures.

FAQ

What is the purpose of hog rings in impact wrenches?

Hog rings in impact wrenches are used to secure sockets or other attachments to the anvil of the wrench. They provide a tight and secure connection, preventing the attachments from slipping off during use.

Are hog rings necessary in impact wrenches?

While hog rings are not absolutely necessary in all impact wrenches, they are commonly used to ensure a secure connection between the wrench and the attachment. Without hog rings, there is a risk of the attachment slipping off during use, which can be dangerous.

What are hog rings made of?

Hog rings are typically made of steel or other strong metals. They are designed to be durable and withstand the high levels of force and vibration that impact wrenches generate.

Can hog rings be replaced if they break or get damaged?

Yes, hog rings can be replaced if they break or get damaged. Most impact wrenches have easily accessible hog rings that can be removed and replaced with new ones. It is important to use the correct size and type of hog ring for your specific impact wrench.

How do I choose the right size hog ring for my impact wrench?

The right size hog ring for your impact wrench will depend on the size of the anvil and the attachments you plan to use. It is important to consult the manufacturer’s guidelines or specifications for your specific impact wrench to determine the correct size of hog ring to use.

Are there alternative methods for securing attachments to impact wrenches?

Yes, there are alternative methods for securing attachments to impact wrenches. Some impact wrenches use ball detents or quick-change mechanisms instead of hog rings. These alternative methods can provide a secure connection and make it easier to change attachments quickly.

What are some common issues or problems with hog rings in impact wrenches?

Some common issues with hog rings in impact wrenches include them becoming loose over time, breaking under high levels of force, or getting damaged during use. It is important to regularly inspect the hog rings and replace them if necessary to maintain a secure connection between the wrench and the attachments.

Video

![The Natural World - Understanding Oceans [DVD]](https://m.media-amazon.com/images/I/51wPvU4qWnL._SS520_.jpg)