Ultimate Guide: How to Use a Crowfoot with Torque Wrench Like a Pro

Using a crowfoot with a torque wrench is an essential skill for any professional mechanic or someone who likes to work on their own cars. This versatile tool allows you to reach tight spaces and apply precise torque to bolts and nuts that are difficult to access with a regular torque wrench.

But how do you use a crowfoot with a torque wrench like a pro? In this ultimate guide, we will take you through the step-by-step process and provide you with some valuable tips and tricks.

Step 1: Choose the Right Crowfoot Size

Before starting, it is important to select the correct crowfoot size that matches the size of the fastener you are working on. Crowfoot wrenches are available in various sizes, so make sure to have a set of crowfoot wrenches that cover the range of sizes you commonly encounter.

Step 2: Attach the Crowfoot to the Torque Wrench

Once you have the correct crowfoot size, it’s time to attach it to the torque wrench. Most crowfoot wrenches have a square drive end that fits into the square drive of the torque wrench. Simply insert the crowfoot into the torque wrench and make sure it is firmly locked in place.

Step 3: Position the Crowfoot on the Fastener

Now that you have the crowfoot attached to the torque wrench, position it on the fastener you want to tighten or loosen. Make sure the crowfoot is properly aligned with the fastener and securely attached.

Pro Tip: When positioning the crowfoot, make sure there is enough clearance to apply torque without interference from any surrounding parts or components.

Step 4: Apply Torque

Finally, it’s time to apply torque to the fastener. Slowly and steadily turn the torque wrench handle in the direction specified for tightening or loosening. Pay attention to the torque wrench’s gauge or indicator to ensure you are applying the desired amount of torque.

Pro Tip: If you are unsure about the correct torque specification for the fastener you are working on, consult the manufacturer’s manual or a reliable reference guide.

Congratulations! You have successfully used a crowfoot with a torque wrench like a pro. By following these steps and paying attention to the details, you can confidently tackle any job that requires the use of this versatile tool.

Understanding the Basics of a Crowfoot

A crowfoot is a specialized type of socket wrench that is designed to be used with a torque wrench. It is called a crowfoot because it has a shape similar to a crow’s foot, with multiple prongs that fit into the head of the torque wrench.

A crowfoot is used when there is limited space to work with, such as when the fastener is in a tight or hard-to-reach area. It allows the torque wrench to be used at an angle, which can be more convenient and practical in certain situations.

How does a crowfoot work?

A crowfoot is attached to the torque wrench by inserting one end of the crowfoot into the head of the torque wrench. It is then secured in place using a locking mechanism, such as a set screw or a spring-loaded ball detent.

Once attached, the crowfoot can be used like a regular socket wrench. It is placed over the fastener and turned in the appropriate direction to tighten or loosen it. The torque wrench is used to measure the amount of torque being applied.

Advantages of using a crowfoot

- Allows for work in tight or hard-to-reach areas

- Allows for work at an angle

- Can be more convenient or practical in certain situations

- Compatible with torque wrenches

Considerations when using a crowfoot

While crowfoot wrenches can be useful in certain situations, there are a few things to keep in mind when using them:

- Crowfoot sizes are not standardized across all manufacturers, so it is important to make sure you have the correct size for your application.

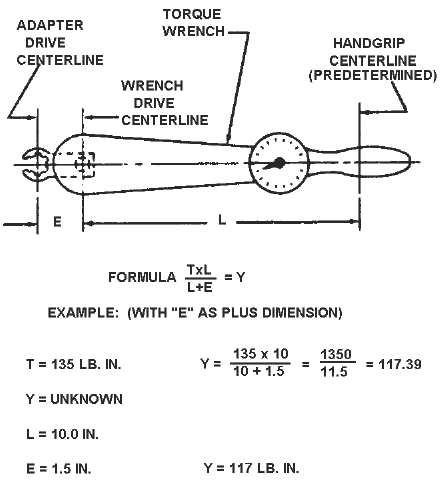

- Using a crowfoot at an angle can affect the accuracy of the torque measurement. It is important to take this into account and adjust the torque accordingly.

- Make sure the crowfoot is securely attached to the torque wrench to prevent slipping or other accidents.

- Always follow the manufacturer’s instructions and guidelines when using a crowfoot or any other tool.

Conclusion

A crowfoot is a specialized socket wrench that is designed to be used with a torque wrench. It allows for work in tight or hard-to-reach areas and can be used at an angle. However, it is important to use the correct size crowfoot, be aware of the potential impact on torque accuracy, and make sure it is securely attached to the torque wrench. By understanding the basics of a crowfoot and following proper guidelines, you can use this tool like a pro.

Choosing the Right Crowfoot Size

Choosing the right crowfoot size is crucial to ensure that the torque wrench and crowfoot combination can properly fit and engage with the fastener. Here are some factors to consider when selecting the appropriate crowfoot size:

- Fastener size: The crowfoot size should match the size of the fastener you are working with. It is important to measure the fastener accurately to determine the correct size.

- Torque wrench size: The crowfoot size should also match the size of the drive of your torque wrench. For example, if you have a 1/2-inch drive torque wrench, you will need a 1/2-inch drive crowfoot to ensure compatibility.

- Space constraints: Consider the space in which you will be working. If you have limited space, you may need a smaller crowfoot size to fit into tight areas.

- Application: The type of work you will be performing should also be taken into account. Different applications may require different crowfoot sizes. For example, working on a car engine may require different crowfoot sizes compared to working on a motorcycle engine.

It is important to consult the manufacturer’s specifications and guidelines to ensure that you are using the correct crowfoot size for your specific application. Using the wrong size can lead to improper torque application and potential damage to the fastener or equipment.

Using a Crowfoot with a Torque Wrench: Step-by-Step Guide

Step 1: Gather the Necessary Tools

Before you begin using a crowfoot with a torque wrench, make sure you have all the necessary tools and equipment:

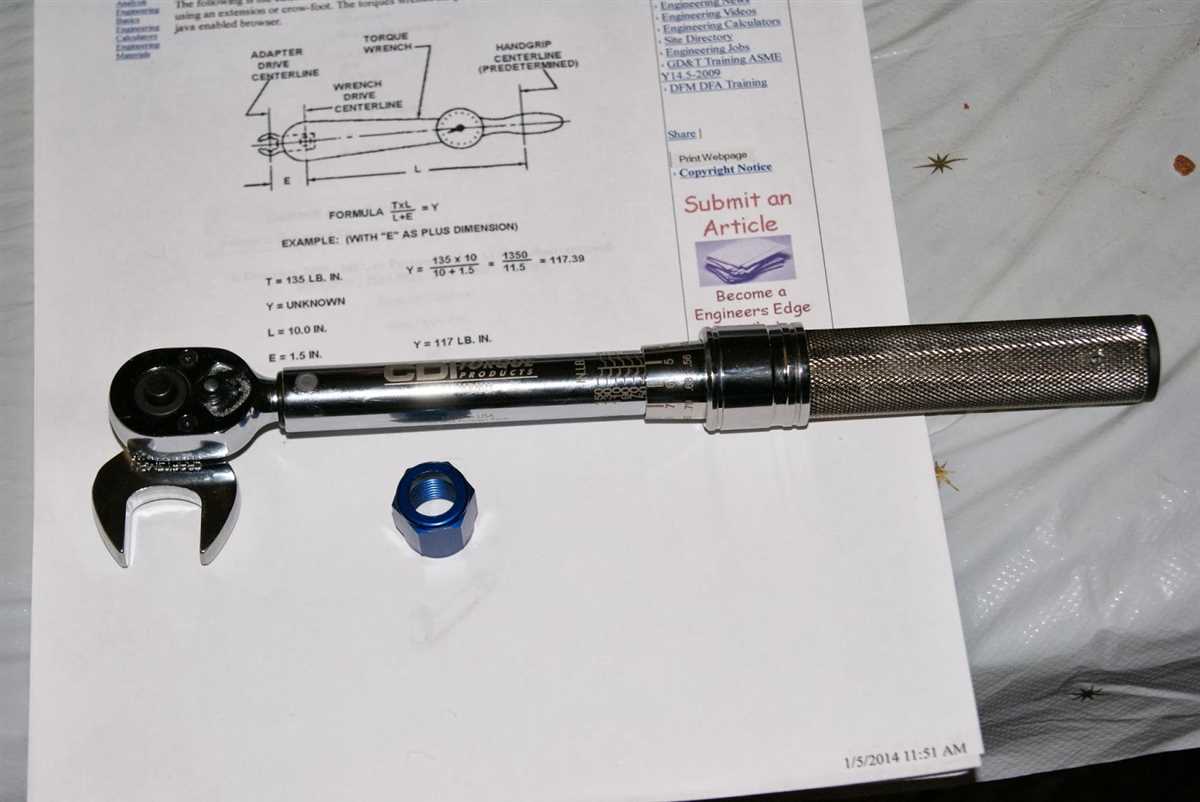

- A quality torque wrench

- A set of crowfoot wrenches

- The appropriate socket for the crowfoot wrench

- A ratchet or breaker bar (optional)

Step 2: Choose the Correct Crowfoot Wrench

Depending on your specific task, select the correct size and type of crowfoot wrench. Ensure that it matches the size and shape of the fastener or nut you need to tighten or loosen.

Step 3: Attach the Crowfoot Wrench to the Torque Wrench

To use a crowfoot with a torque wrench, you need to attach it properly. Follow these steps:

- Inspect the torque wrench to find the square drive at the end.

- Insert the square drive into the socket of the crowfoot wrench until it engages securely.

- Use a twisting motion to ensure the crowfoot wrench is firmly attached to the torque wrench.

- Adjust the torque setting on the torque wrench, if needed, based on the specifications of your task.

Step 4: Position the Crowfoot Wrench Correctly

Now that you have attached the crowfoot wrench to the torque wrench, it’s time to position it correctly on the fastener or nut you want to work on. Follow these steps:

- Place the crowfoot wrench over the nut or fastener, making sure it fits securely.

- Ensure that the crowfoot wrench is aligned properly with the nut or fastener.

- Make sure there is enough space around the crowfoot wrench to allow the torque wrench to move without obstruction.

Step 5: Perform the Task

With the crowfoot wrench securely positioned on the nut or fastener, you can now use the torque wrench to tighten or loosen it. Follow these steps:

- Hold the torque wrench handle firmly and apply pressure in the desired direction (clockwise or counterclockwise) to tighten or loosen the fastener.

- Continue applying pressure until you reach the desired torque value specified for the task.

- Listen or feel for the audible or tactile click of the torque wrench when it reaches the specified torque value.

- Once you hear or feel the click, stop applying pressure to prevent overtightening or damaging the fastener.

Step 6: Clean and Store the Tools

After completing your task, it’s important to clean and store your tools properly to ensure their longevity. Follow these steps:

- Wipe down the crowfoot wrench, torque wrench, and any other tools used with a clean cloth to remove any dirt or debris.

- Store the tools in a dry and secure location, away from moisture and extreme temperatures.

- If necessary, apply a light coat of lubricant to the crowfoot wrench and torque wrench to prevent rust and maintain their functionality.

By following this step-by-step guide, you can effectively use a crowfoot with a torque wrench like a pro and complete your tasks with precision and accuracy.

Tips and Techniques for Proper Crowfoot Usage

1. Use the Right Size Crowfoot

Before using a crowfoot with a torque wrench, make sure you have the correct size crowfoot for the job. Crowfoot wrenches are available in various sizes, so it’s essential to select one that matches the nut or bolt you’re working on. Using an incorrect size crowfoot can lead to inaccuracies and may damage the fastener.

2. Attach the Crowfoot to the Torque Wrench

To use a crowfoot with a torque wrench, you’ll need to attach it properly. Begin by inserting the square drive end of the crowfoot onto the torque wrench’s square drive end. Once the crowfoot is securely in place, make sure it’s tight and won’t come loose during use.

3. Position the Crowfoot Correctly

When using a crowfoot, it’s crucial to position it correctly on the nut or bolt. Make sure the crowfoot is fully seated and aligned with the fastener. If it’s not properly aligned, there’s a risk of slippage or damage to the crowfoot or fastener.

4. Apply Torque Slowly and Steadily

Using a torque wrench with a crowfoot requires applying torque slowly and steadily. Begin by setting the torque value on the wrench to the desired level. Then, start applying pressure gradually, being mindful not to exceed the recommended torque. Applying torque too quickly or forcefully can cause inaccuracies or damage to the fastener.

5. Keep the Crowfoot and Fastener Clean

Regularly clean the crowfoot and fastener to ensure optimal performance. Remove any dirt, debris, or grease that may accumulate on the crowfoot or fastener surface. A clean crowfoot provides better grip, minimizing the risk of slippage or damage.

6. Inspect the Crowfoot for Wear or Damage

Before each use, inspect the crowfoot for any signs of wear or damage. Check for cracks, chips, or deformation in the crowfoot’s design. If you notice any issues, replace the crowfoot to avoid potential hazards or inaccuracies.

7. Store the Crowfoot Properly

After use, store the crowfoot in a clean and dry area to prevent corrosion and damage. Avoid keeping the crowfoot in a location with excessive moisture or extreme temperatures. Consider using a toolbox or a dedicated storage location to keep your crowfoot organized and protected.

8. Practice Proper Safety Measures

When using any type of tool, including a crowfoot with a torque wrench, always follow proper safety measures. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards. Take your time and work in a controlled environment to minimize the risk of accidents and ensure accurate results.

Conclusion

Using a crowfoot with a torque wrench can be a valuable technique for accessing fasteners in tight spaces. By following these tips and techniques for proper crowfoot usage, you can achieve accurate and efficient results while maintaining the integrity of your tools and fasteners.

Advantages of Using a Crowfoot with a Torque Wrench

- Increased Flexibility: A crowfoot attachment allows you to access tight spaces where a standard socket may not fit. This increased flexibility is especially useful when working on vehicles or machinery with limited clearance.

- Greater Accuracy: When using a crowfoot with a torque wrench, you can achieve more precise torque measurements, as the crowfoot attachment allows the torque to be applied at a perpendicular angle. This is particularly helpful when working on delicate or sensitive components that require specific torque specifications.

- Time and Cost Savings: By using a crowfoot with a torque wrench, you can save time and money by avoiding the need to purchase specialized tools for specific applications. The crowfoot attachment can be used in various situations, making it a versatile and cost-effective option.

- Easy to Use: Using a crowfoot with a torque wrench is a straightforward process. Simply attach the crowfoot to the torque wrench, connect it to the desired socket, and use it like a regular wrench. This simplicity makes it accessible to both professionals and DIY enthusiasts.

- Compatibility: Crowfoot attachments are usually designed to be compatible with various torque wrench models, so you don’t have to worry about finding a specific attachment for your specific tool. This compatibility adds to the convenience and ease of use of using a crowfoot with a torque wrench.

- Versatility: Crowfoot attachments come in a range of sizes and shapes, allowing them to be used with different types of fasteners and fittings. This versatility makes them a valuable tool for a wide array of applications, including automotive, industrial, and mechanical tasks.

By taking advantage of these benefits, you can ensure accurate and efficient torque applications with the help of a crowfoot attachment and a torque wrench. Whether you’re a professional mechanic or a DIY enthusiast, incorporating a crowfoot into your tool collection can greatly enhance your workmanship.

Common Mistakes to Avoid when Using a Crowfoot

Using a crowfoot with a torque wrench can be a useful technique for reaching fasteners in tight spaces. However, it’s important to use this tool correctly to avoid potential mistakes and ensure accurate torque application. Here are some common mistakes to avoid when using a crowfoot:

- Using the wrong size crowfoot: It’s crucial to select the correct size crowfoot for the fastener you’re working on. Using the wrong size can lead to slippage, inaccurate torque readings, and potential damage to the fastener or tool.

- Not using a compatible torque wrench: Crowfoots are typically used in conjunction with a torque wrench to apply precise torque. Make sure the crowfoot and torque wrench you’re using are compatible and properly calibrated for accurate results.

- Failing to inspect the crowfoot before use: Before using a crowfoot, inspect it for any signs of damage such as cracks, wear, or deformation. Using a damaged crowfoot can compromise the integrity of the tool and lead to inaccurate torque application.

- Applying excessive force: Crowfoots are designed to apply torque, not excessive force. Avoid applying excessive force, as it can lead to overtightening, stripped threads, or damage to the fastener.

- Using an incorrect crowfoot angle: To ensure proper torque application, it’s essential to use the correct crowfoot angle. Using a crowfoot at an incorrect angle can result in uneven torque distribution and potentially damage the fastener.

- Not cleaning and lubricating the crowfoot: Regularly clean and lubricate the crowfoot to maintain its performance and prolong its lifespan. Dirt, debris, or lack of lubrication can hinder the crowfoot’s ability to properly engage the fastener and deliver accurate torque.

Avoiding these common mistakes will help you use a crowfoot with a torque wrench like a pro, ensuring accurate and reliable torque application in tight spaces. Remember to always follow the manufacturer’s instructions and guidelines for the specific crowfoot and torque wrench you’re using.

Maintenance and Care for Crowfoot and Torque Wrench

1. Regular Cleaning

Proper maintenance of your crowfoot and torque wrench is essential to ensure their longevity and accuracy. One of the first steps in maintenance is regular cleaning. After each use, wipe down the crowfoot and torque wrench with a clean cloth to remove any dirt, grease, or debris.

Make sure to pay special attention to the torque wrench’s ratchet mechanism, as any buildup can affect its performance. A soft brush can be used to clean hard-to-reach areas.

2. Lubrication

To keep the crowfoot and torque wrench operating smoothly, it is important to lubricate the moving parts. Apply a small amount of lubricating oil to the pivot points, ratchet mechanism, and other movable parts.

However, be cautious not to over-lubricate, as excess oil can attract dirt and cause sticky residue buildup. Follow the manufacturer’s instructions regarding the appropriate lubricant for your crowfoot and torque wrench.

3. Store Properly

When not in use, it is crucial to store the crowfoot and torque wrench properly to protect them from damage. Keep them in a dry and clean environment, away from moisture and extreme temperatures.

Avoid storing them in a crowded toolbox or with heavy objects that can cause accidental damage. Consider investing in a dedicated case or pouch to protect your crowfoot and torque wrench from scratches and impacts.

4. Regular Calibration

Calibration is an essential aspect of maintaining the accuracy of your torque wrench. Over time, frequent use or accidental mishandling can lead to calibration drift, compromising the tool’s performance.

It is recommended to have your torque wrench calibrated annually or as recommended by the manufacturer. This can be done by a professional calibration service or by using a torque wrench calibration tool.

Keep a record of the calibration dates and results to track the performance and identify any anomalies.

5. Periodic Inspection

Regularly inspect your crowfoot and torque wrench for any signs of wear, damage, or fatigue. Look for cracks, bends, or broken parts that may affect the tool’s functionality.

If you notice any issues, it is advisable to discontinue using the tool and have it inspected or repaired by a qualified technician. Using a damaged or compromised tool can lead to inaccurate torque measurements and potential safety hazards.

6. Follow Safety Guidelines

Lastly, always follow the safety guidelines provided by the manufacturer for your crowfoot and torque wrench. This includes using the tool within its specified torque range, avoiding excessive force, and wearing appropriate personal protective equipment (PPE) when necessary.

Using the tool improperly or exceeding its limits can cause irreversible damage to the tool and compromise the accuracy of torque measurements.

By following these maintenance and care tips, you can ensure your crowfoot and torque wrench remain in excellent working condition and provide accurate torque measurements for an extended period.

FAQ

What is a crowfoot?

A crowfoot is a type of wrench attachment that is used with a torque wrench to tighten or loosen bolts in tight spaces or at odd angles.

How do you attach a crowfoot to a torque wrench?

To attach a crowfoot to a torque wrench, you first need to ensure that the sizes match. The crowfoot should have the same drive size as the torque wrench. Once you have the correct size, simply insert the square end of the crowfoot into the square drive of the torque wrench and secure it using a locking mechanism.

What are the advantages of using a crowfoot with a torque wrench?

Using a crowfoot with a torque wrench allows you to access bolts in tight spaces or at odd angles that would be difficult or impossible to reach with a regular wrench or socket. This makes it a valuable tool for automotive and mechanical work, where bolts are often located in hard-to-reach areas.

Are there any limitations to using a crowfoot with a torque wrench?

While a crowfoot can be a useful tool, it does have some limitations. It may not provide the same level of accuracy as a standard socket or wrench, as the length and shape of the crowfoot can affect torque readings. Additionally, care must be taken to ensure that the crowfoot is securely attached to the torque wrench, as any slippage or movement could lead to inaccurate torque measurements.