Learn how to torque a bolt without a torque wrench

Torquing a bolt is an essential skill for any mechanic or DIY enthusiast. Properly torquing bolts ensures that they are tightened to the correct specifications, preventing them from coming loose or failing under stress. While a torque wrench is the preferred tool for this task, there may be situations where one is not available. In such cases, it is still possible to torque a bolt accurately using alternative methods. This article will guide you through the process of torquing a bolt without a torque wrench.

1. Use a torque angle gauge: A torque angle gauge is a specialized tool that measures the degree of rotation applied to a bolt. It allows you to torque a bolt by tightening it to a specified angle, rather than a specific torque value. To use a torque angle gauge, first, tighten the bolt to the recommended torque value using a regular wrench. Then, attach the torque angle gauge and continue tightening the bolt until the desired angle is reached. This method provides a reliable and accurate way to torque bolts without a torque wrench.

2. Use a calibrated arm: Another method to torque a bolt without a torque wrench is to use a calibrated arm. This involves using a lever arm or breaker bar of known length to apply the required torque to the bolt. The length of the arm and the force applied determine the torque. To use this method, calculate the torque required for the bolt in question, then select an appropriate arm length. Apply force to the end of the arm until the desired torque is reached, ensuring that the force is applied perpendicular to the arm length.

3. Use the “feel” method: Experienced mechanics can often accurately tighten bolts without a torque wrench by relying on their “feel” or intuition. This method requires a deep understanding of the materials and fasteners being used, as well as the required torque specifications. By gradually tightening the bolt and paying close attention to the resistance felt, experienced mechanics can achieve the desired torque. While this method may not be as precise as using a torque wrench, it can still produce reliable results in many cases.

In conclusion, while a torque wrench is the ideal tool for torquing bolts, there are alternative methods to achieve accurate results when one is not available. By using a torque angle gauge, a calibrated arm, or relying on their intuition, mechanics and DIY enthusiasts can ensure that bolts are tightened to the correct specifications, even without a torque wrench.

Why Torque a Bolt?

When it comes to fastening objects together, using the correct amount of torque is essential. Torquing a bolt means applying a specific amount of force to tighten it, ensuring that it is secured properly and can withstand the intended load or stress.

There are several reasons why torqueing a bolt is important:

- Consistency: Torquing a bolt ensures that each bolt in a particular application is tightened to the same level of force. This helps to achieve consistent and even clamping pressure, which is crucial for maintaining structural integrity and preventing leakage or failure.

- Prevent overtightening: If a bolt is overtightened, it can lead to damage or failure of the bolt or the object it is fastening. Torque specifications provide guidance on the maximum amount of force that should be applied to a bolt, preventing the risk of overtightening and its associated consequences.

- Prevent undertightening: On the other hand, if a bolt is undertightened, it may not provide sufficient clamping force, leading to loosening, movement, or failure of the fastened object. Torquing a bolt ensures that it is tightened to the appropriate level, reducing the risk of undertightening.

- Achieve desired performance: Different applications require different levels of clamping force or tension. By torquing a bolt to the specified value recommended by the manufacturer or engineering standards, you can ensure that the fastened joint or assembly performs as intended.

- Ensure safety: Properly torquing bolts is crucial for safety in many industries, such as automotive, aerospace, and construction. By following torque specifications and ensuring that bolts are tightened correctly, you can reduce the risk of accidents, failures, or structural collapses.

Overall, torquing bolts is important for achieving consistent, reliable, and safe connections. While it is possible to torque a bolt without a torque wrench using alternative methods, having a torque wrench and following manufacturer’s specifications is the most accurate and reliable way to ensure that a bolt is tightened correctly.

Benefits of Proper Torque

Properly torquing a bolt is crucial for ensuring the safety and reliability of mechanical assemblies. Here are some key benefits of achieving the correct torque:

- Prevents damage: Applying the proper amount of torque to a bolt helps prevent damage to both the bolt and the surrounding components. Over-tightening can cause the bolt to break or strip the threads, while under-tightening can lead to loose connections and potential failure.

- Ensures consistent performance: By applying the recommended torque, you ensure that each bolt is tightened evenly. This helps distribute the load evenly across the joint, preventing any stress concentrations that can result from uneven tightening.

- Provides accurate clamping force: The clamping force generated by the bolt is directly related to its torque. By achieving the proper torque, you ensure that the clamping force is within the desired range. This is essential for maintaining the integrity and stability of the assembly.

- Reduces the risk of fastener loosening: Vibrations and other external forces can cause bolts to loosen over time. Proper torque helps minimize the risk of fastener loosening by providing adequate resistance against these forces. This is particularly important in applications that experience high levels of vibration or undergo frequent thermal cycling.

- Improves assembly efficiency: Knowing how to torque a bolt without a torque wrench can be useful in situations where a torque wrench is not readily available. This knowledge allows you to complete assemblies in the absence of specialized tools, saving time and improving efficiency.

Overall, ensuring proper torque when tightening bolts is crucial for maintaining the integrity, safety, and performance of mechanical assemblies. Whether using a torque wrench or alternative methods, it is essential to understand the importance of torque and follow the manufacturer’s recommendations for achieving the correct torque value.

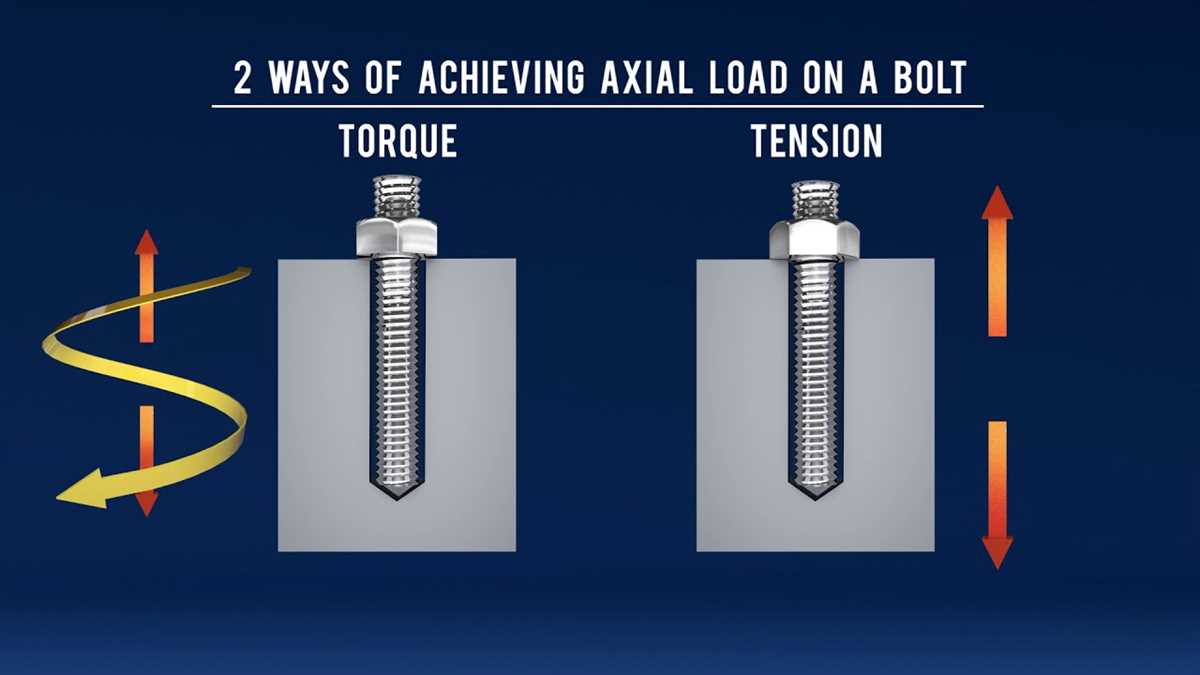

What is Torque?

Torque is a measure of the twisting force applied to an object. It is commonly used to describe the power generated by engines, as well as the force required to tighten or loosen bolts and nuts. Torque is typically measured in units of foot-pounds (ft-lb) or Newton-meters (Nm).

How is Torque Calculated?

Torque is calculated by multiplying the force applied to an object by the distance from the point of application to the axis of rotation. Mathematically, torque (T) can be calculated using the formula:

T = F * r

- T is the torque

- F is the force applied

- r is the distance from the point of application to the axis of rotation

Why is Torque Important?

Torque is important in various applications, especially when it comes to tightening bolts and nuts. Proper torque ensures that fasteners are secured tightly, preventing them from loosening or failing under stress. It also helps distribute the clamping force evenly, reducing the risk of damage to components or leakage in sealed systems.

Using the correct torque is crucial, as both under-tightening and over-tightening can lead to problems. Under-tightening may result in loose fasteners, while over-tightening can cause threads to strip or bolts to break.

How is Torque Applied to Bolts?

To apply torque to a bolt, a torque wrench is commonly used. A torque wrench allows users to measure and apply a certain amount of torque to a fastener. This ensures that the bolt is tightened to the manufacturer’s specifications.

However, in some cases, a torque wrench may not be available or practical. In these situations, it is still possible to tighten a bolt without a torque wrench by using other methods, such as using a calibrated hand or estimating the torque based on previous experience.

| Torque Units | Conversion Factor |

|---|---|

| 1 ft-lb | 1.35582 Nm |

| 1 Nm | 0.737562 ft-lb |

When to Torque?

Knowing when to torque a bolt is crucial for ensuring the integrity and safety of the joint. While there may be certain guidelines and specifications provided by manufacturers for specific applications, there are also some general guidelines that can help determine when torquing is necessary.

During Installation

One of the most common times to torque a bolt is during its installation. Whether it’s a structural bolt or a small fastener, ensuring the correct torque is applied can prevent issues such as over-tightening or under-tightening, which can lead to joint failure or loosening over time.

During installation, it is important to follow the recommended torque values provided by the manufacturer or specified in the engineering drawings. These torque values are usually determined through extensive testing and analysis to ensure the optimal performance of the joint.

After a Period of Use

Another important time to torque a bolt is after a period of use. This is especially important for critical or safety-critical applications, where the joint may be subjected to high loads, vibrations, or other external factors that can cause the bolt to loosen over time.

Regular maintenance and inspection intervals should be established to check and retorque bolts, especially those in applications where failure may have severe consequences. This can help identify any loose bolts and prevent potential accidents or failures.

During Repair or Reinstallation

When repairing or reinstalling components or structures, it is essential to torque the bolts correctly. This ensures that the joint will be secure and operate as intended. Failure to apply the correct torque can lead to improper alignment, increased stress on the joint, and potential failure.

During repair or reinstallation, it is crucial to refer to the manufacturer’s specifications or engineering drawings to determine the recommended torque values. Following these guidelines will help ensure the proper assembly and functionality of the joint.

When Dealing with Special Applications

In some cases, special applications may require specific torquing procedures. These can include situations where the bolts are subjected to extreme temperatures, corrosive environments, high pressure, or other unique conditions.

For these special applications, it is important to consult with experts, such as engineers or manufacturers, to determine the appropriate torquing methods. They can provide guidance on the best torque values and techniques to ensure the longevity and performance of the joint.

| Situation | When to Torque |

|---|---|

| During Installation | Follow the recommended torque values |

| After a Period of Use | Regular maintenance and inspection intervals |

| During Repair or Reinstallation | Refer to manufacturer’s specifications |

| Special Applications | Consult with experts for specific guidelines |

Methods to Torque a Bolt

When it comes to torquing a bolt, there are several methods you can use if you don’t have a torque wrench available. While a torque wrench is the most accurate tool for the job, these alternative methods can still provide adequate results.

1. Hand Tightening

One of the simplest methods to torque a bolt is to use hand tightening. Start by using your hand to tighten the bolt as much as possible. Once it feels snug, use a wrench to make a final quarter turn. Keep in mind that this method doesn’t provide precise torque measurements, so it may not be suitable for critical applications.

2. Angle Torque Method

The angle torque method is commonly used as an alternative to using a torque wrench. This method relies on tightening the bolt to a specific angle rather than a specific torque value. The specified angle will depend on the type and size of the bolt, as well as the material being fastened. To use this method, you will need a torque angle gauge or a protractor. Follow the manufacturer’s specifications to determine the required angle for your specific application.

3. Using a Torque Adapter

If you don’t have a torque wrench but want a more accurate torque measurement, you can use a torque adapter. A torque adapter is a tool that converts a standard ratchet or breaker bar into a torque wrench. It has a predetermined torque setting that will allow you to tighten the bolt to the desired torque. Simply attach the torque adapter to your ratchet or breaker bar and tighten the bolt until you hear or feel the click indicating that the desired torque has been reached.

4. Using a Torque Stick

A torque stick is another alternative tool that can be used to achieve proper torquing without a torque wrench. It is a long, flexible extension that is designed to limit the amount of torque being applied to the bolt. Torque sticks come in different colors, each representing a different torque level. Choose the appropriate torque stick based on the desired torque value and attach it to your ratchet or breaker bar. As you tighten the bolt, the torque stick will flex and absorb the excess torque, ensuring that the specified torque is not exceeded.

While these methods can provide satisfactory results in many applications, it is important to note that they may not be suitable for all situations. For critical applications or when precise torque values are required, it is always recommended to use a calibrated torque wrench.

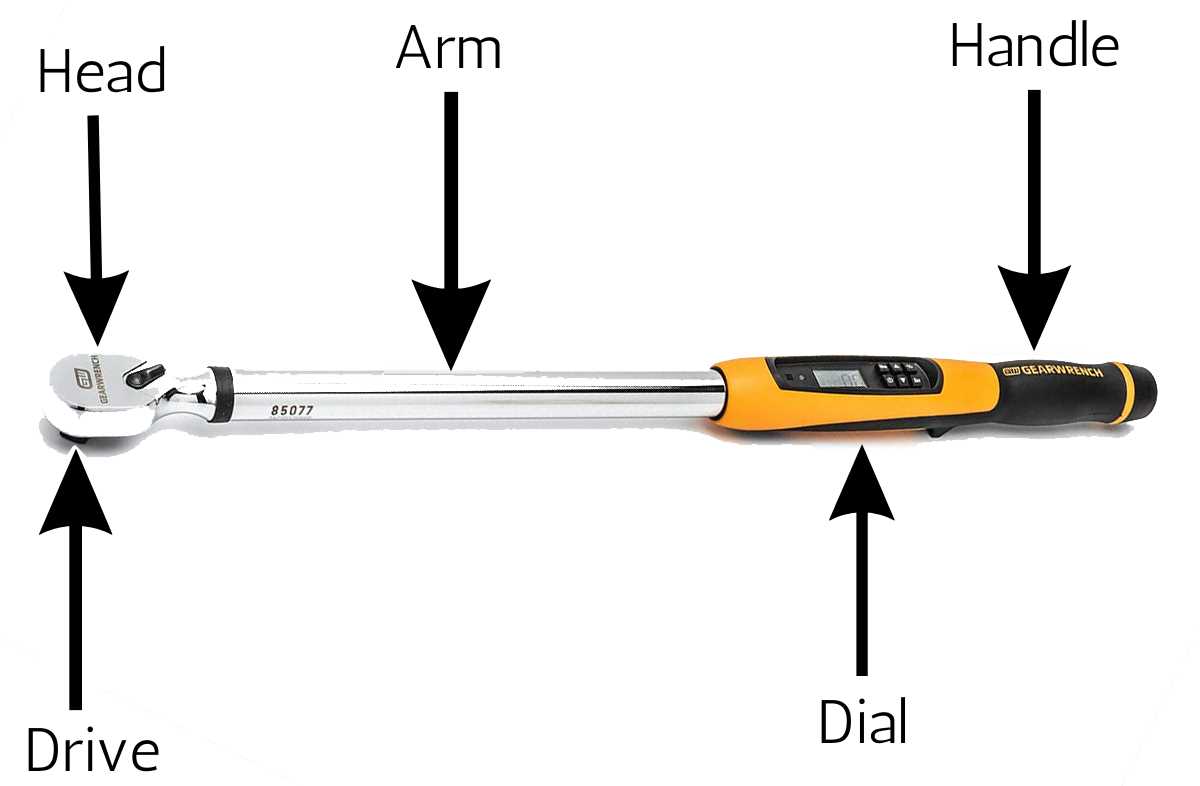

Using a Torque Wrench

A torque wrench is a specialized tool that is used to apply a specific amount of torque to a bolt or nut. It is an essential tool for any mechanic or technician who works with fasteners.

Step 1: Select the correct torque setting

Before using a torque wrench, it is important to select the correct torque setting. This can usually be found in the manufacturer’s specifications or a torque chart. Set the torque wrench to the desired value by adjusting the torque handle or scale.

Step 2: Attach the correct socket

Next, attach the correct socket to the torque wrench. The socket should match the size and shape of the fastener you are working with. Ensure that the socket is securely attached to avoid any slippage during use.

Step 3: Apply torque to the bolt

Place the socket over the bolt or nut and apply pressure in a clockwise direction to tighten the fastener. As you apply pressure, the torque wrench will start to click or release a audible sound once the desired torque value is reached. This is a signal to stop applying force to prevent over-tightening.

Step 4: Check the torque

After you have tightened the fastener, it is important to check the torque using a torque measuring device or a torque verification tool. This will ensure that the correct torque has been applied and that the fastener is properly secured.

Step 5: Clean and store the torque wrench

After using the torque wrench, clean it properly and store it in a safe place. Keep the torque wrench away from moisture and extreme temperatures to maintain its accuracy and longevity.

- Always follow the manufacturer’s instructions and recommendations for proper use of the torque wrench.

- Never exceed the maximum torque rating of the wrench, as this can lead to damage or failure.

- Regularly calibrate and maintain your torque wrench to ensure accurate and reliable readings.

Using a torque wrench is an important skill for anyone working with fasteners. It allows for precise and consistent tightening, which is crucial for ensuring the safety and integrity of mechanical assemblies.

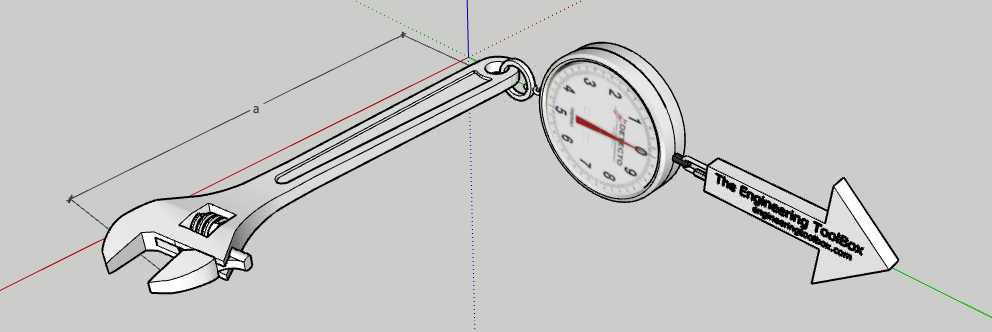

Using a Torque Calculation

When you don’t have a torque wrench available, you can still achieve the correct amount of torque by using a torque calculation. This method involves using the equation:

Torque = Force × Distance

To calculate the torque, you need to know the force applied to the bolt and the distance from the point of rotation to the point where the force is applied. The force can be measured in pounds or newtons, while the distance is typically measured in inches or meters, depending on the unit used for force.

Note: It’s important to use the correct units of measurement in order to obtain accurate results.

Here’s how you can use a torque calculation:

- Determine the force you need to apply to the bolt. This can be determined by consulting the manufacturer’s specifications or guidelines.

- Measure the distance from the point of rotation to where the force will be applied. This can be the length of a wrench, or the distance from the center of a socket to the point where the force is applied.

- Multiply the force by the distance to obtain the torque required. If the force is in pounds and the distance is in inches, the resulting torque will be in inch-pounds. If the force is in newtons and the distance is in meters, the resulting torque will be in newton-meters.

- Apply the calculated torque to the bolt using the appropriate tool, such as a wrench or socket.

It’s important to note that using a torque calculation is not as precise as using a torque wrench, as there are other factors such as friction and bolt pitch that can affect the actual torque applied. However, it can still be a useful alternative when a torque wrench is not available.

Using a Bolt Stretch Method

The bolt stretch method is another technique that can be used to torque a bolt without a torque wrench. This method involves measuring the amount of stretch or elongation of the bolt to ensure the proper tightness.

Step 1: Preparing the Bolt

Before starting, make sure the bolt is clean and well-lubricated. This will help reduce friction and ensure accurate measurements.

Step 2: Measuring the Initial Length

Start by measuring the initial length of the bolt using a caliper or ruler. This will serve as a reference point for determining the amount of stretch.

Step 3: Tightening the Bolt

Begin tightening the bolt using a wrench or socket. Apply gradual and even pressure to avoid damaging the bolt or the surrounding components.

Step 4: Measuring the Final Length

Once the bolt is tightened to the desired level, measure the final length using the same method as in Step 2. The difference between the initial and final lengths will indicate the amount of stretch.

Step 5: Calculating the Torque

Using the measured stretch and the known elasticity of the bolt material, a torque value can be calculated. This can be done using a formula or reference table specific to the bolt and material being used.

Step 6: Verifying the Torque

To ensure the accuracy of the torque, it is recommended to use a torque verification tool or a calibrated torque wrench. This will help verify that the desired torque has been achieved.

Note: The bolt stretch method may not be suitable for all applications and may require specialized knowledge or equipment. It is always recommended to consult the manufacturer’s instructions or seek professional advice when torquing critical or high-stress bolts.

Using a Torque Angle Method

The torque angle method is another way to tighten bolts without the use of a torque wrench. This method involves tightening the bolt to a specific torque value, and then rotating the bolt a certain number of degrees further.

Here is how you can use the torque angle method:

- Determine the torque specification: Consult the manufacturer’s specifications to find the required torque value for the bolt you are working with.

- Tighten the bolt to the specified torque value: Use a torque wrench to tighten the bolt to the specified torque value. Make sure to follow proper torque sequence if required.

- Secure the bolt: Once the bolt is tightened to the specified torque value, secure it in place to prevent it from rotating during the torque angle process. This can be done using a locking mechanism or by clamping the bolt in place.

- Calculate the torque angle: Determine the torque angle by referring to the manufacturer’s specifications. This value will typically be given in degrees.

- Rotate the bolt: Use a protractor or torque angle gauge to rotate the bolt the specified number of degrees. This can be done in small increments to ensure accuracy.

- Inspect the bolt: After completing the torque angle process, inspect the bolt for any signs of damage or loosening. Make sure it is properly secured and functioning as intended.

The torque angle method is commonly used in automotive applications, especially for critical bolts that require precise tightening to ensure proper function and safety.

| Advantages | Disadvantages |

|---|---|

|

|

FAQ

Is it possible to torque a bolt without using a torque wrench?

Yes, it is possible to torque a bolt without using a torque wrench. There are alternative methods that can be used to achieve the desired torque.

What are some alternative methods to torque a bolt without a torque wrench?

Some alternative methods include using a torque angle gauge, using a torque limiting extension, or using a calibrated arm and a weight to achieve the desired torque.

What is a torque angle gauge?

A torque angle gauge is a tool that measures the angle through which a fastener is turned, allowing the user to achieve the desired torque without using a torque wrench.

How does a torque limiting extension work?

A torque limiting extension is an extension piece that is placed between the socket and the ratchet wrench. It is designed to flex and absorb torque when the desired torque is reached, preventing over-tightening of the fastener.

Can I use a calibrated arm and a weight to torque a bolt without a torque wrench?

Yes, using a calibrated arm and a weight can be an effective method to torque a bolt without a torque wrench. The length of the arm and the weight used can be adjusted to achieve the desired torque.

Are there any risks involved in torqueing a bolt without a torque wrench?

There are risks involved in torqueing a bolt without a torque wrench, as it is more difficult to ensure precise and accurate torque without the use of a calibrated tool. Over- or under-tightening the bolt can result in damage or failure of the fastener or the assembly.

Video

![Eventronic 38+4 Piece Lock Picking Set, [2023 Difficulty Upgrade & Beginner Friendly] Lock Picking Tool Kit with 4 Transparent Training Padlocks for Lockpicking, Manual for Beginner and Pro Locksmiths](https://m.media-amazon.com/images/I/51sqRvdRZTL._SS520_.jpg)