Learn how to effectively use a spanner wrench for various tasks

Whether you’re a professional mechanic or a DIY enthusiast, a spanner wrench is an essential tool that can help you tackle a wide range of tasks. From assembling furniture to repairing appliances, a spanner wrench allows you to tighten or loosen nuts and bolts with ease. But using a spanner wrench effectively requires some skill and knowledge. In this article, we’ll guide you through the basics of using a spanner wrench and share some tips to help you get the most out of this versatile tool.

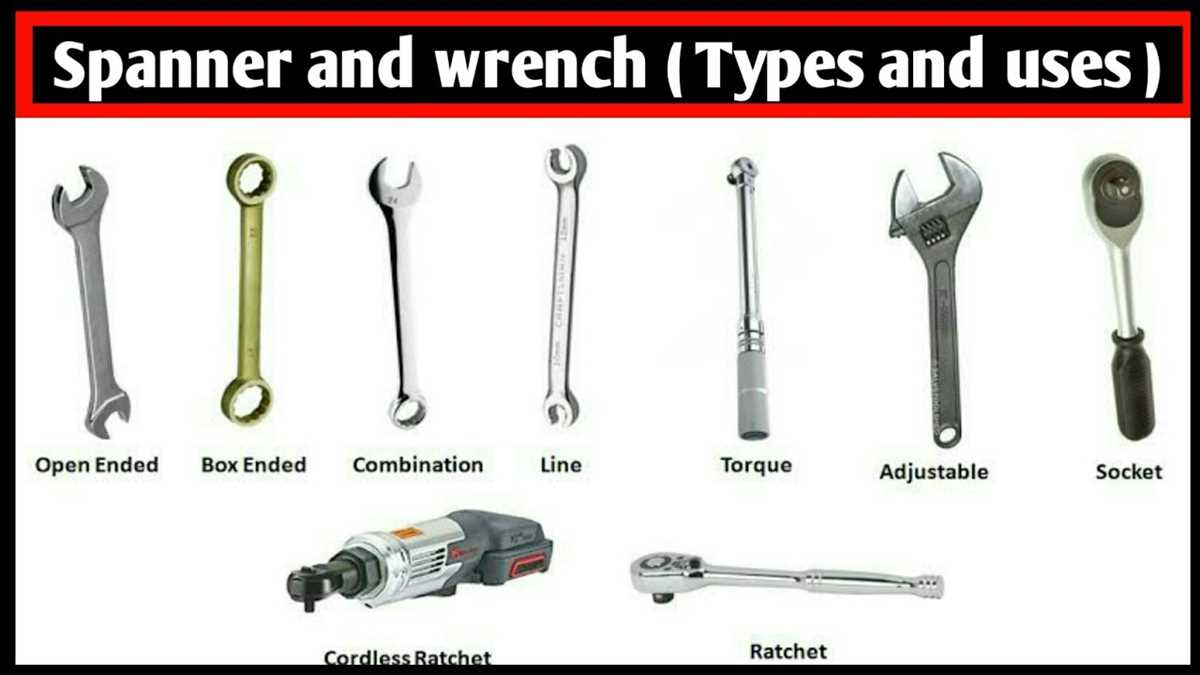

Understanding the different types of spanner wrenches:

Before you start using a spanner wrench, it’s important to familiarize yourself with the different types available. Spanner wrenches come in various sizes and designs, each suited for different tasks. The most common types include adjustable spanner wrenches, open-ended spanner wrenches, and box-end spanner wrenches. Adjustable spanner wrenches, as the name suggests, allow you to adjust the width of the jaws to fit different sizes of nuts and bolts. Open-ended spanner wrenches have two flat jaws that grip the flats of the nut or bolt, while box-end spanner wrenches have a closed, box-like design that provides better grip and torque.

Top tips for using a spanner wrench:

Now that you understand the different types of spanner wrenches, it’s time to learn some tips for using them effectively. First and foremost, always use the right size spanner wrench for the job. Using an incorrect size can damage the nut or bolt and make the task more difficult. When using an adjustable spanner wrench, make sure to tighten the jaws securely around the nut or bolt to prevent slipping. Additionally, always apply force in the correct direction – clockwise for tightening and counterclockwise for loosening. Finally, it’s important to keep your spanner wrench clean and well-maintained to ensure optimal performance.

By following these tips and practicing your technique, you’ll soon become proficient in using a spanner wrench for various tasks. Whether you’re tightening a loose hinge or disassembling a piece of machinery, a spanner wrench will be your go-to tool for getting the job done quickly and efficiently. So, why wait? Start mastering the art of using a spanner wrench today!

Understanding the Basics of a Spanner Wrench

A spanner wrench is a versatile tool that is commonly used for various tasks that involve tightening or loosening nuts, bolts, and other fasteners. It typically consists of a handle and two adjustable jaws that can be positioned to fit different sized fasteners.

Types of Spanner Wrenches

There are several types of spanner wrenches available, each designed for specific purposes:

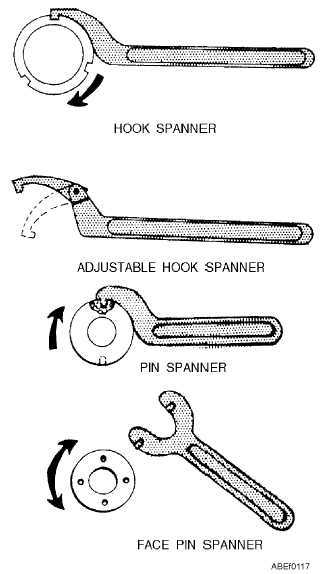

- Pin spanner wrench: This type of spanner wrench is commonly used to tighten or loosen cylindrical objects, such as the collars on shafts or the clamps on hose fittings. It consists of two curved arms that fit into holes or slots on the object and a handle for turning.

- Hook spanner wrench: Hook spanner wrenches are used to tighten or loosen threaded collars or rings. They have a hook-shaped jaw that fits onto the collar and a handle that provides leverage for turning.

- C-shape spanner wrench: This type of spanner wrench has a C-shaped or open-ended jaw that is used to grip and turn fasteners with square or rectangular heads, such as nuts or bolts.

Using a Spanner Wrench

To use a spanner wrench effectively, follow these steps:

- Choose the right type and size of spanner wrench for the task at hand.

- Position the jaws of the spanner wrench around the fastener, making sure they fit securely.

- Hold the handle of the spanner wrench firmly and apply pressure in the desired direction to either tighten or loosen the fastener.

- If necessary, adjust the position of the jaws to ensure a secure grip on the fastener.

- Continue turning the handle until the fastener is tightened or loosened to the required level.

Tips for Using a Spanner Wrench

Here are some tips to keep in mind when using a spanner wrench:

- Ensure the jaws of the spanner wrench are positioned correctly and fit snugly around the fastener to prevent slipping or stripping.

- When tightening or loosening a fastener, apply steady and even pressure to minimize the risk of damaging the fastener or the surrounding components.

- If a spanner wrench is not available or suitable for the task, consider using an alternative tool such as a socket wrench or an adjustable wrench.

With a basic understanding of the different types of spanner wrenches and their uses, as well as some helpful tips for using them effectively, you can confidently tackle various tasks that require the use of a spanner wrench.

Choosing the Right Spanner Wrench for Your Task

Selecting the right spanner wrench for your task is crucial to ensure the job is done effectively and efficiently. With various types and sizes of spanner wrenches available, it can be overwhelming to decide which one to use. This guide will help you understand the different types of spanner wrenches and their specific uses, allowing you to make an informed decision for your task.

1. Adjustable Spanner Wrench

An adjustable spanner wrench, also known as an adjustable wrench, is a versatile option that can fit different fastener sizes. It has an adjustable jaw that can be widened or narrowed using a screw mechanism. This type of spanner wrench is ideal for general tasks where you may encounter various fastener sizes.

2. Open-End Spanner Wrench

The open-end spanner wrench has two U-shaped ends with different sizes for fitting onto fasteners. It is designed to grip the fasteners on two sides, offering a secure hold. However, it only works on specific sizes and may not fit all fasteners. This type of spanner wrench is commonly used for automotive tasks and other applications where the fasteners have easy access.

3. Box-End Spanner Wrench

Similar to the open-end spanner wrench, the box-end spanner wrench also has two U-shaped ends. However, these ends are enclosed with a box-like structure, providing more contact points with the fastener and reducing the risk of slipping off. It is an excellent choice for tasks that require a high level of torque and where the fasteners are more difficult to access.

4. Combination Spanner Wrench

A combination spanner wrench is a versatile tool that combines the features of an open-end spanner wrench and a box-end spanner wrench. One end of the spanner wrench has an open-end design, while the other end has a box-end design. This allows for flexibility when working with different types of fasteners and provides a secure grip when more torque is needed.

5. Ratchet Spanner Wrench

A ratchet spanner wrench is a specialized tool that incorporates a ratchet mechanism into the design. It allows for continuous turning of the fastener without the need to reposition the wrench. This type of spanner wrench is especially useful in tight spaces where limited movement is possible. It provides convenience and saves time during repetitive tasks.

Conclusion

Choosing the right spanner wrench for your task depends on factors such as the type of fastener, accessibility, and required level of torque. By understanding the different types of spanner wrenches and their specific uses, you can select the most suitable tool for your job. Remember to always use the correct size of spanner wrench to avoid damaging the fastener or the wrench itself. With the right spanner wrench in hand, you can confidently tackle any task with ease and precision.

Using a Spanner Wrench for Loosening and Tightening Nuts and Bolts

A spanner wrench is a versatile tool that can be used for various tasks, including loosening and tightening nuts and bolts. With its adjustable jaws, a spanner wrench provides a secure grip on a wide range of fasteners, allowing you to apply the necessary torque to remove or tighten them.

Loosening Nuts and Bolts

To loosen a nut or bolt using a spanner wrench, follow these steps:

- Choose the appropriate size of spanner wrench that matches the nut or bolt you want to loosen.

- Adjust the jaws of the spanner wrench to fit securely around the fastener.

- Hold the handle of the spanner wrench firmly and apply force in the opposite direction of the fastener’s tightening rotation.

- Continue applying force until the nut or bolt starts to loosen. If the fastener is tightly secured, you may need to use additional leverage by extending the handle of the spanner wrench using a pipe or breaker bar.

- Once the nut or bolt is loose, remove it entirely by turning it counterclockwise with the spanner wrench or by switching to a different tool if necessary.

Tightening Nuts and Bolts

To tighten a nut or bolt using a spanner wrench, follow these steps:

- Choose the appropriate size of spanner wrench that matches the nut or bolt you want to tighten.

- Adjust the jaws of the spanner wrench to fit securely around the fastener.

- Hold the handle of the spanner wrench firmly and apply force in the direction of the fastener’s tightening rotation.

- Continue applying force until the nut or bolt is securely tightened. Be careful not to overtighten, as this may damage the fastener or the surrounding material.

- Double-check the tightness of the fastener using a torque wrench if necessary.

Remember to always choose the correct size of spanner wrench for the job to ensure a proper grip and avoid slipping or damaging the fastener. Additionally, make sure to wear appropriate safety gear, such as gloves and eye protection, when working with tools.

Utilizing a Spanner Wrench for Plumbing and Pipe Fittings

Introduction

A spanner wrench is a versatile tool that can be used for a variety of plumbing tasks, including working with pipe fittings. Whether you are a professional plumber or a DIY enthusiast, understanding how to effectively use a spanner wrench can help you complete your plumbing projects with ease.

Types of Spanner Wrenches

There are several types of spanner wrenches available, each designed for specific plumbing tasks. The most common types include:

- Adjustable spanner wrench: This type of wrench has an adjustable jaw that can be adjusted to fit various sizes of pipe fittings.

- Crowfoot spanner wrench: This wrench has a crowfoot-shaped head and is used for tightening or loosening pipe fittings in tight spaces.

- Hook spanner wrench: This wrench has a hook-shaped head and is used for turning or holding pipe fittings with slots or holes.

- Chain spanner wrench: This wrench has a chain that can be wrapped around pipe fittings to provide a secure grip.

Steps for Using a Spanner Wrench

To effectively use a spanner wrench for plumbing and pipe fittings, follow these steps:

- Select the appropriate spanner wrench for the task at hand.

- Position the wrench around the pipe fitting, ensuring a secure grip.

- Apply pressure to turn or secure the fitting, using the leverage provided by the wrench.

- If necessary, use a second wrench to hold the pipe or another fitting in place while using the spanner wrench.

- Continue to apply pressure until the fitting is tightened or loosened to the desired position.

Tips for Using a Spanner Wrench

Here are some tips to keep in mind when using a spanner wrench for plumbing and pipe fittings:

- Always select a spanner wrench that fits the size of the pipe fitting properly to avoid slipping or damaging the fitting.

- When using an adjustable spanner wrench, double-check that the jaws are securely tightened around the fitting before applying pressure.

- If a pipe or fitting is difficult to turn, consider applying penetrating oil or a lubricant to loosen it.

- Use caution when working with pipes or fittings that may contain pressurized water or gas.

- Regularly inspect your spanner wrench for any signs of wear or damage and replace it if necessary.

Conclusion

A spanner wrench is a valuable tool for any plumbing project involving pipe fittings. By following the proper steps and tips for using a spanner wrench, you can ensure that your plumbing tasks are completed effectively and efficiently.

Applying a Spanner Wrench for Automotive Repairs

A spanner wrench is a versatile tool that can be useful for various tasks in automotive repairs. From loosening and tightening bolts to adjusting different components, a spanner wrench can come in handy in many situations. Here are some common applications of a spanner wrench in automotive repairs:

1. Removing and Installing Oil Filters

When it’s time for an oil change, the spanner wrench can be used to remove and install the oil filter. The spanner wrench provides a secure grip on the filter housing, allowing you to easily twist it off or tighten it without any slipping.

2. Adjusting Suspension Components

Spanner wrenches can be used to adjust various suspension components, such as coilover systems or adjustable shock absorbers. These wrenches are designed to fit the specific adjustment mechanisms, enabling you to fine-tune the suspension settings for improved handling and comfort.

3. Changing Spark Plugs

Some vehicles require a spanner wrench to remove and install spark plugs. The spanner wrench grips the plug securely, preventing any damage to the delicate electrode or ceramic insulator.

4. Aligning Belt Tensioners

A spanner wrench can be used to align belt tensioners in order to adjust the tension on serpentine belts or timing belts. This ensures that the belts are properly tensioned, reducing the risk of slippage or premature wear.

5. Tightening Hose Clamps

Spanner wrenches can also be used to tighten hose clamps, ensuring a secure connection between hoses and various components in the engine or cooling system. The adjustable jaws of the spanner wrench provide a firm grip on the clamp, allowing you to tighten it to the desired torque.

These are just a few examples of how a spanner wrench can be applied in automotive repairs. With its versatility and ease of use, this tool is a valuable addition to any DIY mechanic’s toolbox.

Exploring Unique Applications of a Spanner Wrench

1. Loosening and tightening bolts and nuts

One of the most common uses of a spanner wrench is for loosening and tightening bolts and nuts. The adjustable design of the spanner wrench allows it to fit various sizes of bolts and nuts, making it a versatile tool for any DIY or maintenance project.

2. Adjusting plumbing fixtures

Spanner wrenches are commonly used in plumbing to adjust various fixtures, such as faucets, showerheads, and pipe connections. The slim profile of the spanner wrench allows it to access narrow spaces and provide a firm grip for precise adjustments.

3. Opening and closing fuel and gas valves

When working with fuel or gas systems, a spanner wrench can be used to open and close valves securely. The spanner wrench’s adjustable jaws provide a tight grip on valve handles, ensuring proper control and preventing any leaks.

4. Removing and installing light fixtures

Installing or removing light fixtures often requires the use of a spanner wrench. The adjustable nature of the spanner wrench allows users to loosen or tighten the nuts that hold the fixture in place, making it easier to perform the task safely without damaging the fixture or surrounding area.

5. Adjusting automobile belts and pulleys

A spanner wrench is an essential tool for adjusting belts and pulleys in automobiles. The adjustable jaws of the spanner wrench can fit different sizes of pulley nuts, allowing users to easily tighten or loosen them to achieve the desired tension.

6. Maintaining and repairing machinery

Spanner wrenches are commonly used in maintenance and repair work on various machinery. They can be used to access and adjust nuts and bolts in tight spaces, ensuring proper operation and preventing any potential issues that may arise from loose components.

7. Assembling and disassembling furniture

When assembling or disassembling furniture, a spanner wrench can be a handy tool. It can help to loosen or tighten the bolts or nuts that hold furniture pieces together, making it easier to move and transport them.

8. Opening and closing fire hydrants

In emergency situations or during maintenance work, a spanner wrench can be used to open and close fire hydrants. The sturdy construction of the spanner wrench allows users to exert the necessary force to operate the hydrant valves.

In conclusion, a spanner wrench is a versatile tool that can be used for various applications, from loosening and tightening bolts to adjusting plumbing fixtures and maintaining machinery. Its adjustable design and sturdy construction make it an indispensable tool in many industries and everyday tasks.

Mastering the Proper Techniques for Using a Spanner Wrench

1. Understanding the Basics

A spanner wrench is a versatile tool that is commonly used in various industries and applications. Unlike other types of wrenches, it features adjustable jaws that can be set to fit different sizes of nuts, bolts, or pipe fittings. Understanding the basics of how to use a spanner wrench is essential for successfully completing tasks.

2. Choosing the Right Size

Before using a spanner wrench, it is crucial to select the appropriate size for the task at hand. Most spanner wrenches come with adjustable jaws that can be widened or narrowed to fit different sizes. Ensure that the jaws of the wrench are correctly adjusted to provide a tight and secure grip on the object you are working on.

3. Applying Proper Grip

When using a spanner wrench, it is important to maintain a firm and comfortable grip on the handle. Make sure your hand is positioned near the end of the handle to maximize leverage and control. Avoid gripping the handle too tightly, as this can lead to fatigue or difficulties in maneuvering the wrench.

4. Using the Wrench at the Correct Angle

Using the spanner wrench at the correct angle is crucial for achieving the desired results. Align the jaws of the wrench with the object you are working on and ensure they are securely positioned around it. Make sure the jaws are fully engaged with the object before applying force to avoid slipping or damaging the surface.

5. Exerting Controlled Force

When using a spanner wrench, it is important to exert controlled force to avoid over-tightening or damaging the object. Apply force gradually and steadily, making sure to monitor the resistance and adjust accordingly. If the object is not loosening or tightening as desired, reassess your grip, angle, and force before making any adjustments.

6. Maintaining the Wrench

Proper maintenance of the spanner wrench is essential for its longevity and optimal performance. After each use, clean the wrench thoroughly to remove any dirt, debris, or grease that may have accumulated. Additionally, regularly inspect the wrench for any signs of wear or damage, such as bent jaws or worn-out handles, and replace any worn parts as necessary.

7. Safety Considerations

When using a spanner wrench, it is important to prioritize safety. Always wear appropriate protective gear, such as gloves and safety glasses, to minimize the risk of injury. Be cautious of your surroundings and ensure that the object you are working on is secure and stable to prevent accidents or injuries.

Conclusion

By mastering the proper techniques for using a spanner wrench, you can effectively complete various tasks with ease and precision. The key is to understand the basics, choose the right size, apply proper grip and angle, exert controlled force, maintain the wrench, and prioritize safety throughout the process.

FAQ

How do you use a spanner wrench to tighten a nut?

To use a spanner wrench to tighten a nut, place the wrench over the nut and turn it clockwise. Apply firm pressure to ensure the nut is securely tightened.

Can a spanner wrench be used to loosen stubborn bolts?

Yes, a spanner wrench can be used to loosen stubborn bolts. Place the wrench over the bolt and turn it counterclockwise. If the bolt is particularly stubborn, you can use a hammer to tap the wrench to provide extra force.

What are some common tasks that require the use of a spanner wrench?

A spanner wrench is commonly used for tasks such as tightening or loosening nuts and bolts, adjusting machinery, assembling or disassembling furniture, and maintaining plumbing fixtures.

What are the different types of spanner wrenches available?

There are several types of spanner wrenches available, including adjustable spanner wrenches, fixed spanner wrenches, hook spanner wrenches, and pin spanner wrenches. Each type is designed for specific tasks and has its own unique features.

Is it possible to use a spanner wrench on round objects?

Yes, it is possible to use a spanner wrench on round objects. The adjustable spanner wrench can be adjusted to fit different sizes of round objects, allowing you to tighten or loosen them with ease.

Can a spanner wrench be used on plumbing fixtures?

Yes, a spanner wrench is commonly used on plumbing fixtures such as faucets and shower heads. The spanner wrench allows you to tighten or remove these fixtures without causing any damage.

Video