How to Use a Wrench and Socket: A Beginner’s Guide

When it comes to basic home repairs and DIY projects, knowing how to use a wrench and socket is an essential skill. From tightening loose screws to assembling furniture, a wrench and socket set can be a valuable tool in your arsenal. This beginner’s guide will walk you through the basics of using a wrench and socket, including how to choose the right size, techniques for proper tightening, and common mistakes to avoid.

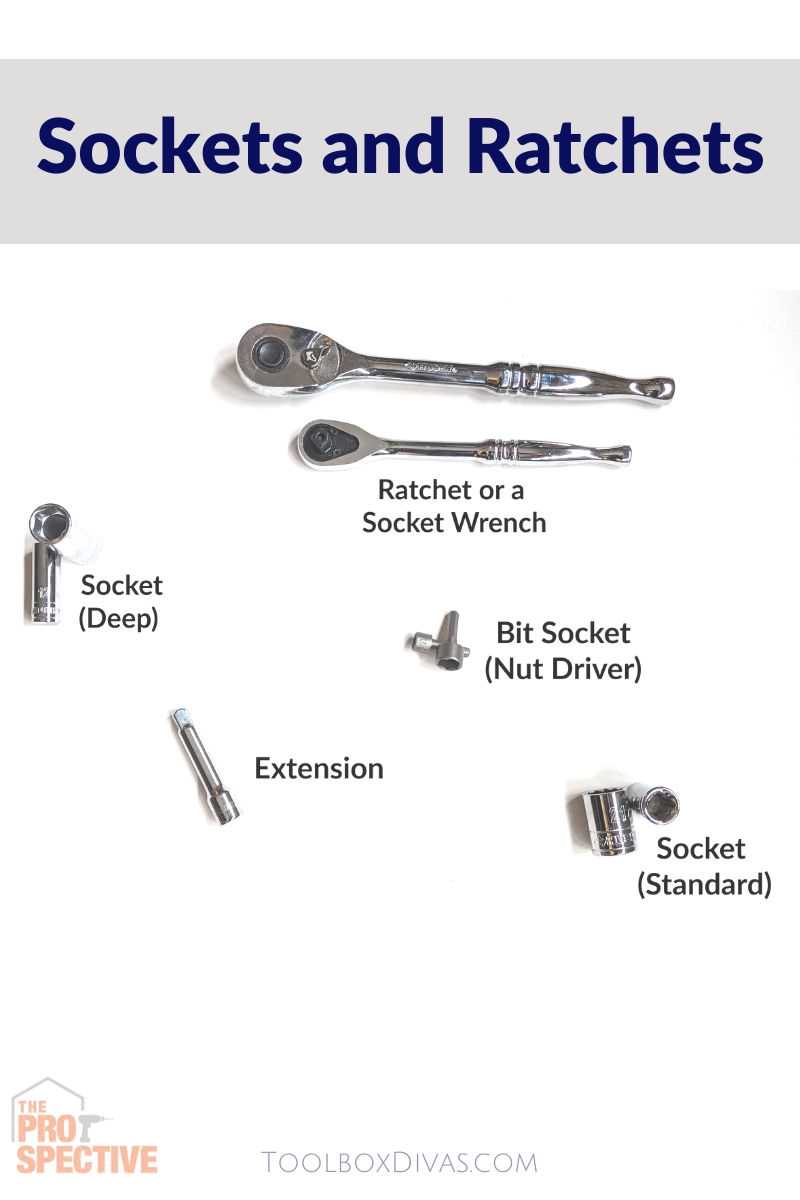

First, it’s important to understand the different types of wrenches and sockets available. Wrenches come in various shapes and sizes, but the most common ones are adjustable wrenches and socket wrenches. An adjustable wrench has a movable jaw that can be adjusted to fit different nut or bolt sizes. Socket wrenches, on the other hand, use interchangeable sockets that can be attached to the handle to fit different sizes. Both types of wrenches have their advantages and can be used for a variety of tasks.

Next, you’ll need to choose the appropriate size of wrench or socket for the job. This can be determined by measuring the size of the nut or bolt you need to tighten or loosen. It’s important to select a wrench or socket that matches the size exactly, as using the wrong size can lead to stripped bolts or ineffective tightening. Most wrenches and sockets will have the size clearly marked on them, making it easy to identify the right tool for the task.

Once you have the right size wrench or socket, it’s time to start using it. To tighten a bolt or nut, place the appropriate end of the wrench or socket securely over the head of the bolt or nut. Make sure the wrench or socket is positioned straight and parallel to the bolt or nut, as angling it can result in ineffective tightening or damage to the fastener. Use your dominant hand to apply force in a clockwise direction, while using your other hand to hold the tool steady. Tighten the bolt or nut until it is secure, but be careful not to overtighten as this can cause damage as well.

In conclusion, learning how to use a wrench and socket is an important skill for any DIY enthusiast. By understanding the different types of wrenches and sockets, choosing the right size, and using proper techniques for tightening, you’ll be able to tackle a wide range of repair and assembly tasks with confidence.

Choosing the Right Wrench and Socket

Wrench Types

When it comes to choosing the right wrench for your task, it’s important to consider the different types available. Here are a few common wrench types:

- Adjustable wrench: This versatile wrench has an adjustable jaw which allows it to fit different bolt sizes.

- Combination wrench: This wrench has two ends – one is open and the other is a closed socket, making it ideal for various tasks.

- Socket wrench: This wrench uses various types of sockets to fit bolts and nuts. It offers a better grip and allows for higher torque.

Socket Sizes

Choosing the right socket size is crucial for a proper fit. Sockets typically come in both standard (SAE) and metric sizes. Here are some common socket sizes:

- 1/4 inch

- 3/8 inch

- 1/2 inch

- 3/4 inch

Socket Types

There are various socket types available, each designed for specific tasks. Here are a few common socket types:

- Standard socket: This regular socket is used for general tasks and fits most bolts and nuts.

- Deep socket: This socket is longer and allows for deeper access to bolts in narrow spaces.

- Spark plug socket: This specially designed socket is used for removing or installing spark plugs.

Consideration Factors

When choosing a wrench or socket, keep the following factors in mind:

- Task requirements: Determine the specific task you need to perform and choose a wrench or socket accordingly.

- Budget: Consider your budget and choose a wrench or socket that offers good quality and durability within your price range.

- Comfort: Look for wrenches and sockets with ergonomic handles for a comfortable grip during use.

- Quality: Check the material and construction of the wrench or socket to ensure it can withstand the required torque.

- Size range: Make sure the wrench or socket you choose can handle the range of sizes you will encounter.

By considering these factors and understanding the different types and sizes available, you can choose the right wrench and socket for your specific task and ensure a successful outcome.

Understanding Socket Types and Sizes

In order to effectively use a wrench and socket, it is important to have a good understanding of the different socket types and sizes that are available. This knowledge will allow you to choose the right socket for your specific task and ensure that you achieve a secure and tight fit.

Types of Sockets

There are several types of sockets that you may come across when working with wrenches:

- Standard (Six-Point) Socket: This is the most common type of socket, featuring six points and providing a secure grip on flat-sided fasteners.

- Deep Socket: These sockets have a greater depth than standard sockets and are used for accessing and tightening fasteners that are recessed in deep locations.

- Spark Plug Socket: These sockets have a rubber insert to securely hold spark plugs and prevent damage while installing or removing them.

- Torque Wrench Socket: Designed specifically for use with torque wrenches, these sockets allow for precise tightening of fasteners according to a specified torque value.

Sizes of Sockets

Sockets come in a variety of sizes, which are measured in standard measurement units such as inches or metric units such as millimeters. Common socket sizes include:

- 3/8-inch Drive: This size is commonly used for general automotive repairs and is suitable for most applications.

- 1/2-inch Drive: This larger size is typically used for heavy-duty tasks, such as working on trucks and larger machinery.

- 1/4-inch Drive: This smaller size is commonly used for lighter tasks, such as working on small machinery or electronics.

It is important to select the correct socket size for your specific fastener to ensure a proper fit. Using a socket that is either too large or too small can result in damage to the fastener or the socket itself.

Using Socket Size Converters

If you have a socket that does not match the size of your fastener, you can use a socket size converter. These converters allow you to use a smaller socket on a larger fastener or vice versa. However, it is important to note that using a converter may affect the torque and overall performance of your wrench and socket.

Conclusion

Having a good understanding of socket types and sizes is essential for effectively using a wrench and socket. By choosing the right socket for your specific task and ensuring the correct fit, you can achieve a secure and tight connection, making your work safer and more efficient.

Basic Wrench and Socket Techniques

1. Choosing the Right Wrench or Socket

When selecting a wrench or socket for a particular job, it is important to choose the right size and type. The size refers to the width or diameter of the fastener you will be working with. Make sure to match the size of the wrench or socket to the size of the fastener to ensure a proper fit.

2. Using a Wrench

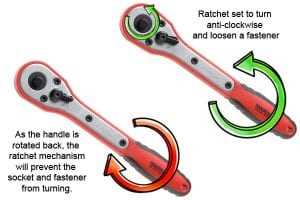

To use a wrench, place the open end or box end of the wrench securely onto the fastener. Apply force in the desired direction, either clockwise (to tighten) or counterclockwise (to loosen). Keep your hand close to the end of the wrench for better control and leverage. If necessary, use both hands for extra power.

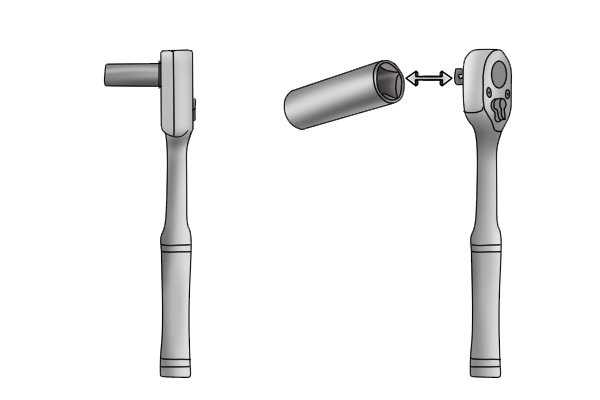

3. Using a Socket

To use a socket, attach it to a ratchet handle. Place the socket firmly onto the fastener, ensuring a snug fit. Turn the ratchet handle in the desired direction to either tighten or loosen the fastener. The ratchet mechanism allows you to keep the socket attached to the fastener while continually rotating the handle.

4. Proper Technique for Tightening

When tightening a fastener, apply force gradually while keeping the wrench or socket perpendicular to the fastener. This helps ensure that the force is evenly distributed and minimizes the risk of damage to both the fastener and the tool. Keep tightening until the fastener is securely tightened, but be careful not to overtighten.

5. Proper Technique for Loosening

When loosening a fastener, apply a steady force in the counterclockwise direction. If the fastener is particularly tight, you may need to use additional leverage, such as attaching a cheater bar to the handle of the wrench or socket. Be cautious and make sure you have a secure grip on the tool and the fastener before applying force.

6. Maintenance and Care

To ensure the longevity and effectiveness of your wrenches and sockets, it is important to keep them clean and properly maintained. After each use, wipe them clean to remove any dirt or debris. Store them in a dry place to prevent rusting. Regularly inspect them for any signs of wear or damage and replace them as necessary.

| Advantages | Disadvantages |

|---|---|

|

|

Using a Wrench and Socket for Loosening Bolts

Introduction

Loosening bolts can be a challenging task, especially if they have been tightened with excessive force or have rusted over time. However, with the right tools and techniques, it can become much easier. In this guide, you will learn how to use a wrench and socket to loosen bolts effectively.

Step 1: Choosing the Right Wrench and Socket

Before starting, it is important to choose the correct wrench and socket size for the bolt you want to loosen. An adjustable wrench or a socket wrench with a set of different socket sizes can come in handy. Make sure the size of the wrench or socket matches the size of the bolt head.

Step 2: Applying Force

To loosen a bolt, you need to apply force in the opposite direction of its tightening. Place the socket onto the bolt head and attach the wrench to the socket. Make sure the wrench is securely fitted onto the socket.

You can use the longer handle of the wrench to generate more leverage and make the loosening process easier. If needed, you can also use a cheater bar or a breaker bar to increase the length and generate even more leverage.

Step 3: Turning the Bolt

Once you have applied force in the opposite direction, start turning the bolt counterclockwise (left) to loosen it. Apply steady and controlled force to prevent slipping or damaging the bolt head.

If the bolt is particularly difficult to loosen, you can try tapping the wrench handle gently with a hammer while applying force. The impact can help break loose any rust or corrosion that may be holding the bolt tightly.

Step 4: Continuing the Process

If the bolt does not loosen immediately, do not force it excessively. Instead, try applying a lubricant such as penetrating oil or WD-40 to help loosen the rust or corrosion. Let the lubricant sit for a few minutes before attempting to loosen the bolt again.

If the bolt is still not loosening, you may need to repeat the process multiple times or seek additional assistance. When dealing with stubborn bolts, it is important to exercise patience and avoid using excessive force that could cause damage.

Conclusion

By following these steps and using a wrench and socket correctly, you can effectively loosen bolts for various applications. Remember to choose the right tools, apply steady force, and use techniques such as lubrication and tapping if necessary. With practice, you will become more comfortable and proficient in loosening bolts with a wrench and socket.

Using a Wrench and Socket for Tightening Bolts

Using a wrench and socket is a common method for tightening bolts. It offers a secure and efficient way to apply torque and ensure that bolts are tightened properly. Here are the steps to using a wrench and socket for tightening bolts:

1. Select the appropriate wrench and socket size

Before you begin, identify the size of the bolt and choose the corresponding wrench and socket. Using the wrong size can damage the bolt and make it difficult to tighten or loosen.

2. Attach the socket to the wrench

Insert the socket onto the end of the wrench. Make sure it fits securely and is aligned properly.

3. Position the wrench on the bolt

Place the wrench over the bolt head or nut that you need to tighten. Ensure that the wrench is aligned properly and fits securely.

4. Apply pressure

Hold the wrench firmly and apply pressure in a clockwise direction to tighten the bolt. The amount of force required will depend on the size and type of bolt you are working with. Use your judgment and avoid applying excessive force, which can cause damage.

5. Check the tightness

After tightening the bolt, check its tightness by attempting to turn it with the wrench. It should feel secure and not move or loosen easily. If necessary, apply additional pressure until the bolt is properly tightened.

6. Repeat if necessary

If you are working with multiple bolts, repeat the process for each one. Make sure to use the appropriate wrench and socket size for each bolt.

Using a wrench and socket is an essential skill for any DIY enthusiast or mechanic. It allows you to tighten bolts securely and ensures that your work is safe and reliable. Remember to always use the correct wrench and socket size, apply pressure carefully, and check the tightness of each bolt before moving on. With practice, you’ll become more proficient in using a wrench and socket for tightening bolts.

Tips for Maintaining and Caring for Wrenches and Sockets

Clean and Dry Tools After Use

After using wrenches and sockets, it is important to clean them properly. Remove any dirt, grease, or debris that may have accumulated during use. Use a cloth or brush to wipe away the dirt and then dry the tools thoroughly to prevent any corrosion.

Keep Tools Organized

Proper organization is key to maintaining wrenches and sockets. Keep them in a designated storage area or toolbox to prevent misplacement and damage. Use drawer organizers or foam trays to separate and protect each tool individually.

Avoid Rust and Corrosion

To prevent rust and corrosion, keep your wrenches and sockets in a dry place. Moisture can cause the metal to degrade over time. Apply a thin layer of oil or use a rust-preventive spray on the tools to provide additional protection.

Inspect for Damage

Regularly inspect your wrenches and sockets for any signs of damage or wear. Check for any cracks, bent handles, or stripped threads. If you notice any issues, replace the damaged tool to ensure safe and effective usage.

Use with Proper Technique

Using wrenches and sockets with proper technique can extend their lifespan. Avoid excessive force that can cause damage to the tools. Always use the correct size of wrench or socket for the job to prevent slippage and potential injuries.

Store with Care

When storing wrenches and sockets, make sure they are not haphazardly thrown together or piled up. This can cause them to become tangled or damaged. Use organizers or racks specifically designed for wrenches and sockets to keep them neatly stored and easily accessible.

Regularly Oil Moving Parts

To keep wrenches and sockets functioning smoothly, apply a small amount of oil to the moving parts. This will lubricate the mechanisms and prevent them from becoming stuck or difficult to use.

Replace Worn-out Parts

If you notice any worn-out parts, such as ratchets or sockets, it is important to replace them. Continuing to use worn-out tools can lead to poor performance and potential accidents. Invest in high-quality replacement parts to ensure the longevity and effectiveness of your tools.

| Tip | Description |

|---|---|

| 1 | Use a wire brush to remove stubborn dirt or rust. |

| 2 | Store wrenches and sockets in a climate-controlled area. |

| 3 | Regularly check and tighten loose bolts on your tools. |

| 4 | Protect the tools from extreme temperatures. |

| 5 | Consider investing in a torque wrench for accurate tightening. |

Safety Precautions and Best Practices when Using Wrenches and Sockets

1. Wear Safety Gear

Always wear appropriate safety gear when using wrenches and sockets. This includes safety glasses to protect your eyes from flying debris, gloves to protect your hands from cuts or burns, and sturdy shoes to protect your feet from falling objects or accidental slips.

2. Inspect Tools Before Use

Before using a wrench or socket, carefully inspect it for any signs of damage or wear. Check for cracks, rust, or any other defects that could compromise the tool’s integrity. Do not use a tool that is damaged or worn out, as it may break or fail during use, potentially causing injury.

3. Use the Right Size and Type of Tool

Using the wrong size or type of wrench or socket can lead to accidents or damage to your workpiece. Ensure that you select the correct size and type of tool for your specific task. Using a tool that is too small or too large can cause it to slip or round off the fastener, resulting in injuries or a damaged workpiece.

4. Apply Proper Torque

When using a wrench or socket, apply torque evenly and smoothly, using controlled force. Avoid using excessive force or applying sudden jerks, as this can lead to the tool slipping or the fastener suddenly loosening or tightening. Improper torque application can cause stripped or damaged fasteners, or wrist and hand injuries.

5. Use Extension Bars and Adapters with Caution

If you need to use extension bars or adapters with your wrench or socket, be cautious. These accessories can add leverage and increase torque, but they can also introduce instability and increase the risk of tool failure or injury. Ensure that extensions and adapters are securely attached and correctly sized for the job.

6. Secure Your Workpiece

Before applying force with a wrench or socket, ensure that your workpiece is securely held or clamped. Unsecured workpieces can move or spin while you are applying torque, increasing the risk of injury or damage. Use appropriate clamps or a vise to hold your workpiece securely.

7. Keep a Firm Grip

Always maintain a firm and secure grip on the wrench or socket while using it. This will help prevent the tool from slipping out of your hand or losing control. Additionally, avoid using excessive force or overextending yourself, as this can lead to accidents or strain-related injuries.

8. Store Tools Properly

When you are finished using wrenches and sockets, store them properly in a clean and organized manner. This will help prevent accidental injuries and keep your tools in good condition for future use. Consider using tool racks, toolboxes, or tool cabinets to store your tools safely.

By following these safety precautions and best practices, you can minimize the risk of accidents or injuries when using wrenches and sockets. Always prioritize safety and take appropriate measures to protect yourself and others.

FAQ

What is a wrench and socket?

A wrench and socket are tools used for tightening and loosening nuts and bolts.

How do I choose the right size of wrench or socket?

To choose the right size of wrench or socket, you need to know the size of the nut or bolt you are working with. You can measure the size with a ruler or refer to the size markings on the nut or bolt itself.

What is the difference between a wrench and a socket?

The main difference between a wrench and a socket is the way they grip the nut or bolt. A wrench has an adjustable jaw that can be tightened around the nut, while a socket fits over the nut or bolt head.

How do I use a wrench?

To use a wrench, place the adjustable jaw around the nut or bolt, making sure it is securely in place. Then, turn the handle of the wrench in the desired direction to tighten or loosen the nut or bolt.

How do I use a socket?

To use a socket, select the socket size that matches the nut or bolt you are working with. Attach the socket to a ratchet handle or a socket wrench. Place the socket over the nut or bolt head and turn the handle in the desired direction to tighten or loosen.

Is it possible to use a socket with a wrench?

Yes, it is possible to use a socket with a wrench. You can attach the socket to the adjustable jaw of the wrench and use it in the same way as a regular socket.

Video