How to Test a Torque Wrench: Your Step-by-Step Guide

A torque wrench is an essential tool in any mechanic’s toolbox, used to tighten bolts and nuts to a specific torque value. However, over time, torque wrenches can lose their accuracy, leading to inaccurate torque readings and potentially dangerous situations. That’s why it’s important to regularly test and calibrate your torque wrench to ensure it is providing accurate readings.

In this step-by-step guide, we will walk you through the process of testing a torque wrench to determine its accuracy and make any necessary adjustments. By following these instructions, you can have confidence that your torque wrench is providing reliable torque readings and ensuring proper fastener tightening.

Before we dive into the testing process, it’s essential to understand the two main types of torque wrenches: click-type and beam-type. Click-type torque wrenches have a built-in mechanism that produces an audible click when the preset torque value is reached. Beam-type torque wrenches, on the other hand, have a visual indicator that shows the applied torque directly on the wrench.

Now that you’re familiar with the types of torque wrenches, let’s move on to the testing process. Keep in mind that the specific steps may vary depending on the type and model of your torque wrench, so be sure to consult the manufacturer’s instructions for your particular wrench. However, the general principles outlined here should apply to most torque wrenches.

What is a Torque Wrench?

A torque wrench is a precision tool that is used to apply a specific amount of torque (or tightening force) to a fastener, such as a bolt or nut. It is commonly used in various industries and applications, including automotive, construction, aerospace, and manufacturing.

The primary purpose of a torque wrench is to ensure that fasteners are tightened to the correct torque specification. This is important because insufficient torque can result in loose fasteners, while excessive torque can cause damage or failure by overstressing the fasteners or the materials being joined.

Types of Torque Wrenches

There are several types of torque wrenches available, each designed for different applications and torque ranges. The most common types include:

- Beam Torque Wrench: This type of torque wrench has a long handle with a marked scale and a pointer that indicates the torque being applied. It is simple and reliable but requires manual adjustment.

- Click-Type Torque Wrench: This type of torque wrench produces an audible click or sound when the set torque is reached, providing a clear indication for the user to stop applying force.

- Dial Torque Wrench: This type of torque wrench has a dial or gauge that displays the torque being applied. It offers a more precise and visual reading compared to other types.

- Electronic Torque Wrench: This type of torque wrench features a digital display to provide precise and accurate torque readings. It often comes with additional features, such as memory storage and data output.

How Does a Torque Wrench Work?

A torque wrench works based on the principle of a lever. It has a handle for applying force, a mechanism to measure the applied force, and a gauge or scale to display the torque being applied. When the desired torque is reached, the wrench signals the user to stop applying force.

Most torque wrenches use a spring-loaded mechanism that applies tension to the handle, which is proportional to the torque setting. This tension is transferred to a calibrated mechanism inside the wrench that measures the applied torque. Once the set torque is reached, the mechanism releases or disengages, producing a click, sound, or visual indication.

Importance of Testing a Torque Wrench

Testing a torque wrench is crucial to ensure its accuracy and reliability. Over time, torque wrenches can lose their calibration, resulting in incorrect torque values being applied to fasteners. Regular testing and calibration help maintain the performance and accuracy of the wrench, ensuring that fasteners are tightened to the correct torque specification.

Inaccurate torque can lead to safety hazards, equipment failures, and product defects. Therefore, it is important to follow the manufacturer’s instructions and recommended testing intervals to keep the torque wrench in optimal working condition.

Understanding the Basics of Torque Wrenches

What is a Torque Wrench?

A torque wrench is a specialized tool that is used to apply a specific amount of torque to a fastener, such as a nut or bolt. It is commonly used in various applications, such as automotive, construction, and industrial settings. A torque wrench ensures that the desired level of torque is applied accurately and consistently, preventing under-tightening or over-tightening of fasteners.

How Does a Torque Wrench Work?

A torque wrench operates based on the principle of a lever system. It consists of a handle, a ratcheting mechanism, and a calibrated scale to measure torque. The handle extends to a head, which holds the socket that fits onto the fastener. When the handle is turned, the ratcheting mechanism allows the head to move in one direction while preventing it from moving in the opposite direction.

The calibrated scale on the torque wrench displays the amount of torque being applied, typically in units of foot-pounds (lb-ft) or Newton-meters (Nm). As the handle is turned, the wrench applies a twisting force to the fastener. When the desired torque is reached, the wrench will click or release, indicating that the correct amount of torque has been applied.

Types of Torque Wrenches

There are several types of torque wrenches available, each designed for specific applications:

- Beam Torque Wrench: This type of torque wrench uses a calibrated beam and pointer system to indicate the applied torque. It is simple and reliable but does not offer the same level of precision as more advanced torque wrenches.

- Click Torque Wrench: Click torque wrenches are the most commonly used type. They feature a click mechanism that produces an audible click sound when the desired torque is reached. This ensures accurate and consistent torque application.

- Digital Torque Wrench: Digital torque wrenches have an electronic display that provides a digital readout of the applied torque. They are known for their high accuracy and can be set to specific torque values.

- Deflecting Beam Torque Wrench: Deflecting beam torque wrenches use a deflecting beam instead of a calibrated scale. As torque is applied, the beam deflects, indicating the applied torque. They are often used in industries where precise torque measurements are required.

Importance of Testing a Torque Wrench

Testing a torque wrench is crucial to ensure its accuracy and reliability. Regular testing helps identify any calibration issues or mechanical problems that may affect the wrench’s performance. By testing and calibrating a torque wrench, you can have confidence in its readings and ensure that it is providing accurate torque values.

Testing a torque wrench involves checking the wrench against a known standard, such as a torque tester, to verify its accuracy. This can be done using various methods, including static weight testing or using a torque calibration system.

Regular testing and calibration are recommended to ensure that the torque wrench remains within acceptable tolerance levels and provides accurate torque measurements.

Why is Testing a Torque Wrench Important?

A torque wrench is a precision tool used to apply a specific amount of torque to a fastener, such as a bolt or a nut. It is commonly used in industries like automotive, aerospace, and construction, where accurate torque values are crucial for the integrity and safety of the assembled parts.

Testing a torque wrench is important for several reasons:

- Ensuring Accuracy: Regularly testing a torque wrench helps ensure its accuracy. Over time, a torque wrench can lose its calibration and provide incorrect torque values. Incorrect torque can lead to fasteners being over-tightened, causing damage to the parts or under-tightened, leading to loose fasteners and potential failures. Testing the wrench verifies its accuracy and allows for calibration if necessary.

- Maintaining Safety: Accurate torque application is essential for the safety of workers and the overall quality of the assembled products. Testing the torque wrench ensures that torque values are applied correctly, reducing the risk of accidents, failures, and potential injuries. In industries like aviation or automotive, where human lives can be at stake, the accuracy of torque wrenches is of utmost importance.

- Complying with Standards: Many industries have specific torque requirements and standards to ensure product quality and safety. For example, the automotive industry has torque specifications for various components, and failure to meet these specifications can result in warranty claims, recalls, or legal issues. Regularly testing torque wrenches helps ensure compliance with these standards.

- Optimizing Performance: Testing a torque wrench can also help identify any limitations or issues with the tool. If a torque wrench consistently fails to meet the desired torque values, it may need repairs or replacement. Addressing these issues promptly can prevent further damage to the tool or potential issues with the assembled products.

Overall, testing a torque wrench is important for maintaining accuracy, safety, compliance with industry standards, and optimizing performance. By regularly testing and calibrating torque wrenches, users can ensure reliable and precise torque application, leading to better-quality products and safer working environments.

The Consequences of Using an Untested Torque Wrench

Using an untested torque wrench can have serious consequences, both in terms of safety and accuracy. Here are some of the potential risks and problems that can arise:

1. Safety hazards:

- Under-tightening: An untested torque wrench may not apply enough force, resulting in loose connections or fasteners that can pose safety risks.

- Over-tightening: On the other hand, an untested torque wrench may apply too much force, which can lead to overtightened fasteners, stripped threads, or even component failure.

- Structural damage: Using an untested torque wrench can cause damage to delicate or sensitive materials, such as plastic or carbon fiber, if excessive force is applied unknowingly.

2. Inaccurate torque readings:

- Inconsistent torque: An untested torque wrench may provide inconsistent readings, making it difficult to achieve consistent torque values across multiple applications.

- False sense of security: Relying on an untested torque wrench can lead to a false sense of security, assuming that fasteners are properly tightened when they may not be.

- Failure to meet specifications: If torque specifications are not met accurately, it can lead to product failure, compromised performance, or premature wear.

3. Increased maintenance and repair costs:

Using an untested torque wrench can result in increased maintenance and repair costs due to the potential for loosened or broken fasteners, damaged components, or rework that is required as a result of incorrect torque applications.

4. Legal implications:

In certain industries, such as automotive or aerospace, there may be legal implications for not using calibrated and tested torque wrenches. Non-compliance with industry regulations can result in fines, penalties, or legal liabilities.

Overall, using an untested torque wrench can compromise safety, accuracy, and reliability. It is crucial to regularly test and calibrate torque wrenches to ensure they are performing within the required specifications and providing accurate torque readings.

Step 1: Gather the Necessary Tools

In order to test a torque wrench, you will need the following tools:

- A calibrated torque tester

- A calibration certificate for the torque tester

- A torque wrench that needs to be tested

- A test load, such as a calibrated weight or a torque calibration simulator

- A torque wrench adapter or socket that matches the size of the torque wrench being tested

- A torque wrench calibration chart or specification sheet for the specific torque wrench being tested

- A clean and stable work surface

- Protective gloves and safety glasses

It is important to use a calibrated torque tester and a calibration certificate to ensure accurate testing results. The test load should be appropriate for the torque range of the wrench being tested. The torque wrench adapter or socket should fit securely onto the wrench being tested. The calibration chart or specification sheet will provide the required torque values for testing and comparison.

Make sure to work on a clean and stable surface to prevent any accidents or damage to the torque wrench and other tools. Wearing protective gloves and safety glasses is also recommended to ensure personal safety during the testing process.

What You’ll Need to Test a Torque Wrench

- A torque wrench

- A torque wrench calibration tool or a known calibrated torque wrench

- A torque wrench tester or a torque verifying tool

- A set of weights or a torque multiplier

- A torque calibration certificate (recommended)

- A flat and stable surface

- A clean and well-lit workspace

- A user manual for your specific torque wrench model

- Protective gloves and eyewear

- A notepad and pen to record your measurements

Before starting the test, ensure that your torque wrench is clean and free from any debris or contaminants. Make sure that there are no visible signs of damage or wear on the wrench. If you notice any issues, it may be necessary to have it serviced or repaired before testing.

Additionally, it’s important to have a torque calibration certificate for your torque wrench. This certificate provides documentation that the wrench has been tested and calibrated to meet industry standards. If you don’t have a calibration certificate, you can still perform a basic test, but it’s recommended to have your torque wrench calibrated by a professional if accuracy is critical to your work.

Having a torque wrench calibration tool or a known calibrated torque wrench is essential for testing the accuracy of your torque wrench. This tool will allow you to compare the torque wrench being tested with a known standard. You can verify the accuracy of your torque wrench by comparing the applied torque measurement to the value indicated by the calibration tool.

In addition to a calibration tool, you will also need a torque wrench tester or a torque verifying tool. This tool will help you measure the applied torque accurately and provide a reference for comparison. It’s important to choose a torque verifying tool that meets the calibration accuracy requirements of your torque wrench.

To apply a known torque to the torque wrench, you will need a set of weights or a torque multiplier. These tools allow you to apply a controlled torque to the wrench and ensure that you are testing it within its specified range. Make sure you are using the correct weight or torque multiplier based on the torque range of your torque wrench.

Lastly, make sure you have a flat and stable surface to perform the test on. A stable surface will ensure that you are applying torque evenly and accurately. Additionally, having a clean and well-lit workspace will help you see any changes or discrepancies during the test process.

By gathering these essential tools and materials, you will be well-equipped to test your torque wrench and ensure its accuracy for your applications.

Step 2: Preparing the Torque Wrench for Testing

Before you can start testing your torque wrench, it’s important to ensure that it is prepared properly. This involves a few simple steps to ensure accuracy and reliability during the testing process. Follow the steps below to prepare your torque wrench for testing:

- Clean the torque wrench: Begin by cleaning the torque wrench to remove any dirt, debris, or oil that may affect its performance. Use a clean cloth or a mild solvent to wipe down the wrench, paying close attention to the moving parts and the torque scale.

- Inspect the torque wrench: Carefully inspect the torque wrench for any visible signs of damage or wear. Check the handle, ratchet mechanism, and scale for any cracks, dents, or other abnormalities. If you notice any issues, it’s crucial to have the wrench repaired or replaced before testing.

- Calibrate the torque wrench: If your torque wrench requires calibration, follow the manufacturer’s instructions to perform the calibration process. This usually involves using a certified torque tester to verify the wrench’s accuracy and make any necessary adjustments. Calibration ensures that the torque wrench is measuring torque correctly and provides accurate readings.

- Set the torque value: Determine the torque value that you want to test and set it on the torque wrench. This can usually be done by rotating the torque adjustment collar or handle to align the desired torque value with the indicator or scale on the wrench. Make sure to set the torque value within the wrench’s specified range.

By following these steps and properly preparing your torque wrench, you can ensure that it is ready for accurate and reliable testing. Taking the time to clean, inspect, calibrate, and set the torque value will help you obtain precise torque measurements and maintain the performance of your torque wrench.

How to Set Up the Torque Wrench Correctly

Setting up the torque wrench correctly is essential to ensure accurate torque measurements. Follow these steps to properly set up your torque wrench:

- Select the appropriate torque setting: Before using the torque wrench, determine the torque specification required for the specific task you are working on. This can usually be found in the product manual or the manufacturer’s specifications. Set the torque value on the wrench by adjusting the torque adjustment mechanism accordingly.

- Ensure the torque wrench is calibrated: Regular calibration is necessary to maintain the accuracy of a torque wrench. If it has been a while since your wrench was last calibrated, it is recommended to have it calibrated before use. Calibration can be done by a professional or using a torque calibration device.

- Prepare the fastener: Make sure the fastener and the surface it is being tightened onto are clean and free from debris, rust, or other contaminants. Any irregularities could affect the accuracy of the torque measurement.

- Attach the appropriate socket: Select the correct size of socket that matches the fastener you will be working with. Attach the socket securely to the torque wrench, ensuring a tight fit to prevent slipping during use.

- Position the torque wrench: Position yourself and the torque wrench in a way that allows for a comfortable and stable grip. Ensure you have sufficient clearance to operate the wrench without any obstructions.

- Apply torque: To use the torque wrench, apply force to the handle in a steady and controlled manner. Continue applying force until you hear or feel the click sound or the desired torque value is reached on the wrench’s scale.

- Release pressure: Once you have applied the desired torque, release the pressure on the wrench gradually. Avoid suddenly releasing the tension to prevent any abrupt movements or damage to the fastener.

- Store properly: After using the torque wrench, store it in a safe and dry place to protect it from damage and ensure its longevity. Avoid any excessive force or impact that may affect the accuracy of the wrench.

By following these steps, you can ensure that your torque wrench is set up correctly and ready to deliver accurate torquing measurements for your specific task or project.

Step 3: Performing the Test

Once you have prepared your torque wrench and torque tester, it is time to perform the test. Follow these steps to ensure accurate and reliable results:

- Prepare the torque tester: Set up the torque tester according to the manufacturer’s instructions. Make sure it is securely attached to a stable surface.

- Set the desired torque: Adjust the torque tester to the desired torque value that you want to test your torque wrench against.

- Attach the torque wrench: Attach your torque wrench to the torque tester. Make sure it is securely fastened and aligned correctly.

- Apply torque: Apply torque to the torque wrench by applying force to the handle. Gradually increase the force until you reach the desired torque value.

- Observe the torque tester: Pay close attention to the torque tester as you apply force to the torque wrench. The torque tester will show the amount of torque being applied in real-time.

- Check the reading: Once you reach the desired torque value, observe the reading displayed on the torque tester. Compare it with the expected torque value you set earlier. If the reading matches or is within an acceptable range, the torque wrench passes the test.

- Repeat the test: For a more accurate result, it is recommended to repeat the test two or three times. This will help you verify the consistency and repeatability of your torque wrench.

- Record the results: Keep a record of the test results, including the torque value applied and the readings displayed on the torque tester. This will help you keep track of the performance of your torque wrench over time.

By following these steps, you can effectively test the accuracy and reliability of your torque wrench. Remember to always refer to the manufacturer’s instructions and guidelines for your specific torque wrench model.

Step-by-Step Guide to Testing a Torque Wrench

Step 1: Gather Materials

Before testing a torque wrench, gather the following materials:

- A torque wrench

- A torque testing device

- Calibration weights

- A torque wrench calibration chart

Step 2: Check the Torque Wrench Range

Refer to the manufacturer’s instructions to determine the torque range of your wrench. Make sure the torque testing device you have is suitable for testing within that range.

Step 3: Set Up the Torque Testing Device

Place the torque testing device on a stable surface and secure it according to the manufacturer’s instructions. Ensure that it is properly aligned and ready for testing.

Step 4: Calibrate the Torque Wrench

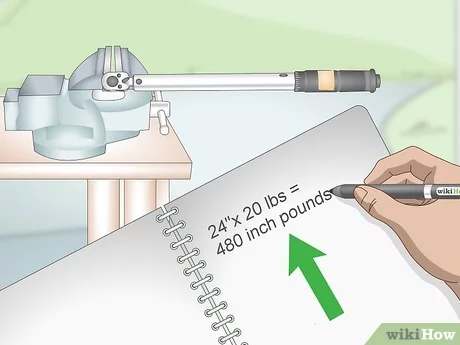

Refer to the calibration chart provided by the torque wrench manufacturer. Use the appropriate calibration weights to set the torque wrench to a specific value within its range. Follow the instructions to properly calibrate the wrench.

Apply the torque to the testing device in a smooth and controlled manner. Make sure to observe the torque reading on the testing device during calibration.

Step 5: Test the Torque Wrench

Select different torque values within the wrench’s range to test its accuracy. Apply the torque to the testing device and compare the reading on the wrench with the reading on the testing device.

Step 6: Adjust and Re-test (if necessary)

If there is a significant difference between the reading on the wrench and the reading on the testing device, adjustments may be needed. Consult the manufacturer’s instructions on how to adjust the torque wrench and repeat the testing process until the readings are within an acceptable range.

Step 7: Record the Results

Keep a record of the torque values tested, along with the corresponding readings on both the wrench and the testing device. This record will help you track the accuracy of your torque wrench over time.

Step 8: Regularly Calibrate and Test

To ensure the accuracy of your torque wrench, it is important to regularly calibrate and test it. Follow the manufacturer’s recommendations for calibration intervals, and repeat the testing process as needed.

| Torque Value | Wrench Reading | Testing Device Reading | Deviation |

|---|---|---|---|

| 20 Nm | 19.8 Nm | 19.9 Nm | -0.1 Nm |

| 30 Nm | 30.2 Nm | 30.3 Nm | -0.1 Nm |

| 40 Nm | 39.7 Nm | 39.9 Nm | -0.2 Nm |

FAQ

What is a torque wrench and why is it important to test it?

A torque wrench is a tool used to apply a specific amount of torque to a fastener, such as a bolt or nut. It is important to test a torque wrench to ensure that it is providing accurate torque readings, as using an inaccurate wrench can result in under or over-tightened fasteners, leading to potential failures or damage.

Can I test a torque wrench without a calibration device?

While it is ideal to have a calibration device to test a torque wrench, it is still possible to test it without one. This can be done by using a torque wrench tester, which is a device specifically designed to check the accuracy of torque wrenches. Another method is to use a torque screwdriver with a known torque value to compare the readings with the torque wrench. However, using a calibration device is recommended for the most accurate results.

How often should a torque wrench be tested?

The frequency of testing a torque wrench depends on several factors, such as the manufacturer’s recommendations and the frequency of use. Generally, it is recommended to test a torque wrench at least once a year or after 5,000 cycles of use. High-quality torque wrenches may require less frequent testing, while lower-quality or heavily-used wrenches may require more frequent testing.

Can I use a torque wrench that has not been tested?

While it is possible to use a torque wrench that has not been tested, it is not recommended. Using an untested torque wrench can result in inaccurate torque readings, leading to improper tightening or loosening of fasteners. This can cause potential failures, damage, or safety hazards. It is always best to test and verify the accuracy of a torque wrench before using it.

Video