How to Set Torque on Impact Wrench: A Step-by-step Guide

Setting the torque on an impact wrench is a crucial step in performing various mechanical tasks. Whether you’re a professional mechanic or a DIY enthusiast, properly adjusting the torque ensures that the fasteners are tightened correctly without damaging them or the surrounding components. In this comprehensive guide, we will walk you through the step-by-step process of setting the torque on an impact wrench, helping you achieve accurate and precise results every time.

Step 1: Familiarize yourself with the impact wrench

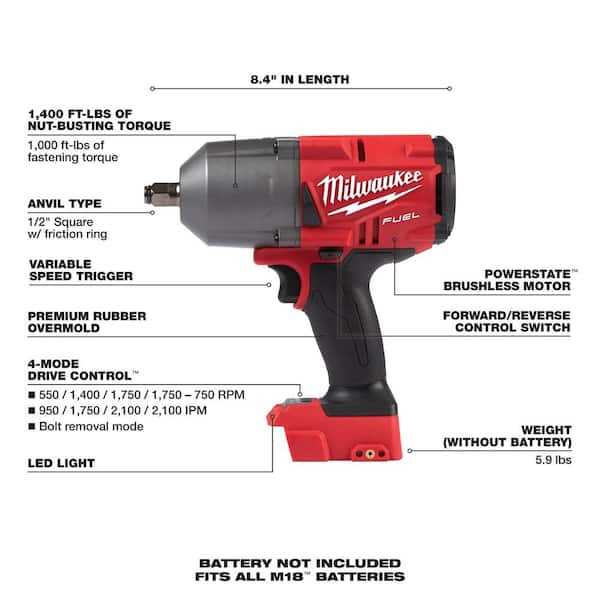

Before you start setting the torque, it’s important to understand the different components and features of your impact wrench. Check the user manual or manufacturer’s instructions to identify the torque adjustment mechanism and locate any specific markings or indicators that indicate the torque settings.

Step 2: Select the desired torque level

Once you are familiar with your impact wrench, determine the appropriate torque level for your specific task. Consider factors such as the size and type of fastener, the material being worked on, and the manufacturer’s recommendations. This information can typically be found in the user manual or on the packaging of the fastener.

Step 3: Adjust the torque setting

Using the torque adjustment mechanism identified in step 1, change the torque setting on your impact wrench. This can be done in different ways depending on the model. Some impact wrenches have a rotating ring or collar that can be turned to adjust the torque, while others may have buttons or switches to change the setting. Refer to the user manual for specific instructions on how to adjust the torque setting on your impact wrench.

Note: It’s important to make sure the impact wrench is switched off or unplugged when adjusting the torque setting to avoid accidents or injury.

Step 4: Test and verify the setting

After you’ve made the necessary torque adjustment, it’s essential to test the impact wrench to verify the set torque level. Do a practice run on a scrap piece of material or in a controlled environment to ensure that the wrench is tightening the fasteners with the desired amount of force. Use a torque wrench or torque testing equipment to measure the applied force and compare it with the target torque level. Adjust the torque setting if needed until the desired results are achieved.

By following these step-by-step instructions, you can easily and accurately set the torque on your impact wrench, allowing you to tackle various mechanical tasks with confidence. Remember to always consult the user manual and follow the manufacturer’s guidelines for your specific impact wrench model to ensure safe and efficient operation.

Why is Torque Setting Important?

The torque setting on an impact wrench is a crucial factor in achieving the desired outcome of a project. It determines the amount of force applied to a fastener, such as a bolt or a nut, and influences the secureness of the connection. Here are a few reasons why torque setting is important:

- Preventing damage: Using the correct torque setting helps prevent damage to the fastener, the tool, and the surrounding components. Over-tightening can strip threads, crack or break the fastener, or damage the material it is being tightened onto. Under-tightening, on the other hand, can result in loose connections, which may lead to accidents or the failure of the system.

- Ensuring safety: Properly tightened fasteners are essential for the safety and reliability of mechanical systems. In industries like automotive, aerospace, and construction, failure due to improper torque can have severe consequences. By using the appropriate torque setting, you can ensure that essential components stay securely fastened, minimizing the risk of accidents or system failure.

- Improving efficiency: The torque setting helps achieve optimal efficiency in various applications. Over-tightening can waste time and effort, while under-tightening may result in frequent reworking or repairs. By setting the torque correctly, you can achieve the desired tightness efficiently and effectively, saving time and resources.

- Maintaining consistency: In projects involving multiple fasteners, maintaining a consistent torque setting is crucial for uniformity and reliability. Each fastener should be tightened with the same level of force to distribute the load evenly and ensure balanced performance. Consistency in torque setting also contributes to the overall quality and durability of the finished product.

- Meeting specifications and standards: Many industries have specific torque requirements and standards that must be met for compliance and quality assurance. By following the recommended torque settings, you can ensure that your work meets the necessary specifications and industry standards, ensuring the integrity and reliability of the finished product.

Overall, setting the torque correctly on an impact wrench is essential for maintaining safety, preventing damage, improving efficiency, ensuring consistency, and meeting industry specifications. It is a critical step in achieving successful and reliable results in various applications.

Step 1: Gather the Necessary Tools

Before you begin adjusting the torque on your impact wrench, make sure you have all the necessary tools on hand. Having these tools ready will help ensure a smooth and efficient process.

Here is a list of the tools you will need:

- Impact wrench: This is the main tool you will be working with to adjust the torque settings.

- User manual: It’s important to have the user manual for your specific impact wrench model. This will provide you with accurate information on how to set the torque properly.

- Torque setting chart: Some impact wrenches come with a torque setting chart that provides recommended torque settings for different applications. If your impact wrench doesn’t have one, you can usually find a torque setting chart online or in a general tool manual.

- Wrench or socket set: You may need a wrench or socket set to loosen or tighten the fasteners on your impact wrench.

- Torque wrench: A torque wrench is a handy tool to have when adjusting the torque settings on your impact wrench. It allows for precise torque measurements.

- Safety gear: Always prioritize safety when working with power tools. Wear safety glasses, gloves, and ear protection to protect yourself from any potential hazards.

By gathering these tools beforehand, you will be well-equipped to handle the task of setting the torque on your impact wrench.

Step 2: Adjust the Torque Setting

After selecting the appropriate socket size and inserting it onto the impact wrench, it’s time to adjust the torque setting. The torque setting determines the amount of force that will be applied by the wrench.

Each impact wrench model may have a different method to adjust the torque, so it’s important to consult the user manual for specific instructions. However, most impact wrenches have a torque adjustment ring located near the base of the tool.

To adjust the torque setting, follow these steps:

- Identify the torque adjustment ring: Look for a rotating ring near the base of the impact wrench. It may have numeric values or symbols to indicate the torque levels.

- Rotate the torque adjustment ring: Use your hand to turn the torque adjustment ring clockwise or counterclockwise to increase or decrease the torque, respectively. Some models may require the use of a torque adjustment tool.

- Refer to the user manual: If you’re unsure about the appropriate torque level for your specific task, consult the user manual or the manufacturer’s guidelines. They usually provide recommendations for different applications.

It’s important to set the torque correctly to avoid overtightening or damaging the fasteners. If the torque is set too high, there is a risk of stripping threads or breaking bolts. On the other hand, if the torque is set too low, the fasteners may not be securely tightened.

Once you have adjusted the torque setting, you can proceed to the next step in using the impact wrench.

Step 3: Test the Torque Setting

Once you have set the torque on your impact wrench, it is important to test the accuracy of the setting before proceeding with any work. This will ensure that the torque applied is sufficient for the task at hand and prevent any damage or accidents.

1. Choose a Testing Surface

Select a firm and stable surface to perform the torque test. It should be able to withstand the force applied by the impact wrench without moving or getting damaged.

2. Prepare the Test Equipment

Gather the necessary test equipment, including a torque wrench and a calibrating tool. The calibrating tool should be compatible with your impact wrench and capable of measuring the torque being applied.

3. Secure the Testing Material

If your task involves tightening fasteners, secure the testing material such as nuts or bolts in place using an appropriate fixture. This will allow you to accurately measure the torque applied to the fasteners.

4. Apply Torque

Using your impact wrench, apply torque to the testing material. Make sure to apply the torque in a controlled and gradual manner. Observe the torque reading on the calibrating tool as you do this.

5. Compare Torque Readings

Compare the torque reading on the calibrating tool with the torque setting you had previously set on your impact wrench. They should be relatively close in value. If there is a significant difference, you may need to readjust the torque setting and repeat the test.

6. Repeat the Test

For the sake of accuracy, it is recommended to repeat the torque test multiple times. This will help ensure consistent results and confirm the reliability of the torque setting on your impact wrench.

7. Document the Results

Record the torque readings from the calibrating tool and any adjustments made to the torque setting. This documentation will be useful for future reference and maintenance purposes.

By following these steps, you can test the torque setting on your impact wrench and ensure it is accurate and suitable for your specific task. Remember to always consult the manufacturer’s guidelines and recommendations for your particular impact wrench model.

Step 4: Fine-tune the Torque Setting

Once you have set the initial torque setting on your impact wrench, it’s important to fine-tune the torque to ensure accuracy and prevent damage. Here are the steps to follow:

- Choose the right setting: Refer to the manufacturer’s instructions or torque specification chart to determine the appropriate torque setting for your specific application. This will depend on factors such as the size and type of fastener being used.

- Make small adjustments: If the torque setting is not meeting your needs, you can make small adjustments to increase or decrease the torque output. Most impact wrenches have a torque adjustment ring or dial on the handle that allows for easy changes.

- Test and check: After making adjustments, it’s important to test the impact wrench on a scrap piece of material or in a controlled environment to verify the torque output. You can use a torque wrench to measure the actual torque being applied and compare it to your desired torque setting.

- Repeat if necessary: If the torque setting is still not accurate, repeat the adjustment process until you achieve the desired torque output. It may take a few tries to get it just right.

Remember to always follow the manufacturer’s instructions and specifications when fine-tuning the torque setting on your impact wrench. This will ensure proper use and prevent any damage or accidents.

Step 5: Maintain the Torque Setting

Once you have set the desired torque on your impact wrench, it is important to ensure that the setting is maintained throughout your work. Here are a few tips to help you maintain the torque setting:

- Check the torque setting regularly: It is important to periodically check the torque setting on your impact wrench to ensure that it is still accurate. Over time, vibrations and other factors may cause the setting to change.

- Use a torque wrench: To ensure that the torque setting remains accurate, you can use a torque wrench to periodically check the torque output of your impact wrench. This will help you to identify any changes in the torque setting and make adjustments if necessary.

- Keep the impact wrench clean: Keeping your impact wrench clean and free from debris can help to prevent any interference with the torque setting. Regularly clean the tool and check for any signs of dirt or damage.

- Store the impact wrench properly: When not in use, it is important to store your impact wrench in a clean and dry area. This will help to prevent any damage to the tool and ensure that the torque setting remains accurate.

- Follow the manufacturer’s instructions: It is always a good idea to refer to the manufacturer’s instructions for your specific impact wrench model. They may provide additional tips or recommendations for maintaining the torque setting.

By following these tips, you can ensure that the torque setting on your impact wrench remains accurate and consistent throughout your work.

FAQ

What is an impact wrench?

An impact wrench is a power tool designed to deliver high torque output to loosen or tighten nuts, bolts, and other fasteners.

Why do I need to set torque on an impact wrench?

Setting the torque on an impact wrench is important to ensure that you do not over-tighten or under-tighten fasteners, which can lead to damage or failure.

How do I set torque on an impact wrench?

To set torque on an impact wrench, you will need to use a torque setting scale and adjust the wrench to the desired torque level. This can usually be done by rotating a adjustable collar or using a torque adjustment button on the tool.

What is the correct torque setting for my application?

The correct torque setting for your application depends on several factors, including the specific fastener being used, the size of the fastener, and the material you are working with. It is best to consult the manufacturer’s specifications or a torque chart for the appropriate torque setting.

How do I know if I have set the torque correctly?

You can test if you have set the torque correctly by using a torque wrench to manually tighten the fastener to the desired torque. If the impact wrench stops rotating when it reaches the set torque, then you have set it correctly.

Can I use an impact wrench without setting the torque?

While it is possible to use an impact wrench without setting the torque, it is not recommended. The lack of torque control can lead to over-tightening or under-tightening, which can cause damage or failure of the fastener or the equipment being worked on.

Are there any safety precautions I should take when using an impact wrench?

Yes, there are several safety precautions you should take when using an impact wrench. These include wearing proper eye protection, using the tool in a well-ventilated area, keeping your hands and clothing clear of the moving parts, and securely holding the workpiece or fastener.