How to Determine the Direction to Loosen a Socket Wrench

Working with a socket wrench can be a useful skill to have, whether you are an experienced mechanic or a DIY enthusiast. However, one common challenge that many people face when using a socket wrench is determining which direction to turn it to loosen a bolt or nut. It may seem simple, but there are a few key points to keep in mind to ensure you are turning the wrench in the correct direction.

Firstly, it’s important to understand that the direction to loosen a socket wrench is typically counterclockwise. This is because sockets and bolts are designed with a right-hand thread, which means they are tightened by turning them clockwise. Therefore, to loosen a bolt or nut, you would need to turn the socket wrench counterclockwise.

Secondly, you can also use the “lefty loosey, righty tighty” rule as a general guideline to determine the direction to loosen a socket wrench. This simple saying means that turning something to the left (counterclockwise) will loosen it, while turning it to the right (clockwise) will tighten it.

Pro Tip: If you are still not sure which direction to turn the socket wrench, you can try gently applying pressure in both directions to see which way gives you more movement. If the bolt or nut starts to loosen, then you know you are turning it in the correct direction.

In conclusion, determining the direction to loosen a socket wrench is an important skill to have when working with bolts and nuts. By understanding the basic principles of counterclockwise direction and applying the “lefty loosey, righty tighty” rule, you can confidently use a socket wrench to loosen any stubborn fasteners.

Clockwise or Counterclockwise: Understanding the Basics

When working with a socket wrench, it’s important to know in which direction to turn it to loosen or tighten a bolt or nut. The two main directions are clockwise and counterclockwise, and understanding their basics is crucial for successful operation.

Clockwise (Righty-tighty)

In most cases, turning a socket wrench clockwise tightens a bolt or nut. This is commonly referred to as “righty-tighty.” When you turn the wrench in the clockwise direction, you are applying force to the right and causing the bolt or nut to turn in the same direction, thereby tightening it.

In order to accurately determine if you need to turn the socket wrench clockwise or counterclockwise to loosen, it’s helpful to familiarize yourself with the right-handed thread concept. Most bolts and nuts follow this concept, where the threads wrap around in a spiral pattern as you move along the bolt or nut. Imagine turning a screwdriver clockwise to tighten a screw, and you’ll get the idea.

Counterclockwise (Lefty-loosey)

Contrary to clockwise, turning a socket wrench counterclockwise loosens a bolt or nut. This is commonly referred to as “lefty-loosey.” When you turn the wrench counterclockwise, you are applying force to the left and causing the bolt or nut to turn in the opposite direction, thereby loosening it.

Again, the concept of right-handed threads comes into play when determining the direction to loosen a bolt or nut. Remember that counterclockwise is the opposite of clockwise, so it will undo the tightness created by the right-handed threads.

There are, however, instances where left-handed threads are present. These threads are less common and typically used in special cases such as on certain bicycle pedals or car components. In such cases, you would need to turn the socket wrench clockwise to loosen the bolt or nut.

Summary

Understanding the basics of clockwise and counterclockwise directions is essential when using a socket wrench. Remember that clockwise tightens (righty-tighty) and counterclockwise loosens (lefty-loosey) in most cases, following the concept of right-handed threads. Always double-check the specific situation and the type of thread you’re working with to ensure you’re turning the socket wrench in the correct direction.

Identifying Right-Hand Threads

When using a socket wrench, it is essential to know the direction in which to turn it to successfully tighten or loosen a bolt or nut. Threads on bolts and nuts can either be right-hand or left-hand. Right-hand threads are the most common type and follow the traditional “righty-tighty, lefty-loosey” rule.

To determine if a bolt or nut has right-hand threads, you can look for several visual cues:

- Direction of rotation: Right-hand threads are tightened by rotating the bolt or nut clockwise and loosened by rotating counterclockwise.

- Standardization: Right-hand threads are the standard in most applications, making them more prevalent.

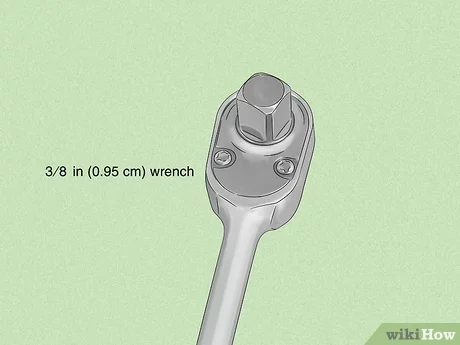

- Hexagonal shape: The majority of bolts and nuts with right-hand threads have a hexagonal shape.

- Thread orientation: Right-hand threads slope up to the right and down to the left when looking at them straight on.

- Markings: Some bolts and nuts may have arrows or other markings indicating the direction to tighten or loosen them.

If none of these visual cues are present or clear, you can also try to turn the bolt or nut slightly. If it moves easily in a counterclockwise direction, it is likely a right-hand thread.

Overall, being able to identify right-hand threads accurately is crucial when working with socket wrenches. It ensures that you apply the correct amount of torque and avoid damaging the fastener or the surrounding components.

Recognizing Left-Hand Threads

A left-hand thread is a type of thread that tightens in the opposite direction as a standard right-hand thread. While most fasteners, such as bolts and screws, have right-hand threads, there are certain applications where left-hand threads are used. Recognizing left-hand threads is important to ensure that you do not inadvertently tighten a fastener when you need to loosen it. Here are some ways to identify left-hand threads:

- Markings: Look for markings on the fastener that indicate it has left-hand threads. These markings may include a letter “L” or the word “LEFT” engraved on the head of the fastener. This can serve as a visual clue to help you determine the direction in which you need to turn the fastener.

- Reverse Direction: Another way to identify left-hand threads is by observing the direction the fastener turns. In most cases, right-hand threads are tightened by turning the fastener clockwise and loosened by turning it counterclockwise. Left-hand threads, on the other hand, are tightened by turning the fastener counterclockwise and loosened by turning it clockwise. If you encounter resistance while turning the fastener counterclockwise, it may indicate that it has left-hand threads.

- Thread Shape: Left-hand threads have a distinctive shape that can help you recognize them. While right-hand threads have a triangular shape, left-hand threads have a square or trapezoidal shape. By carefully examining the thread shape, you can distinguish between left-hand and right-hand threads.

- Reference Manual: If you are unsure about the type of thread a fastener has, consult the appropriate reference manual or guide. These resources often provide detailed information on different thread types, including left-hand threads. They may also include illustrations or photographs to help you visually identify left-hand threads.

By being familiar with the various ways to identify left-hand threads, you can determine the direction to loosen a socket wrench correctly. This knowledge will help you avoid potential damage to fasteners or tools and make your work more efficient.

Using Visual Cues to Determine the Direction

When using a socket wrench, it is important to know which direction to turn to loosen or tighten a bolt or nut. While there are various techniques to determine the direction, one of the easiest and most common methods is by using visual cues.

1. Look for Indicators

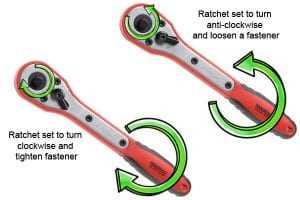

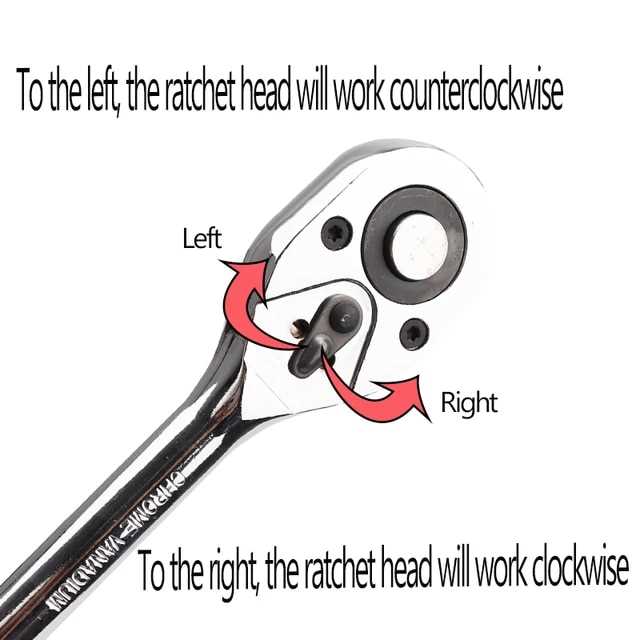

Many socket wrenches have indicators on the handle or the ratchet mechanism to help you determine the direction. These indicators usually have arrows pointing in the direction you need to turn the wrench to loosen or tighten the fastener. Take a close look at your socket wrench and find these indicators.

2. Follow the Threads

Another visual cue is to look at the threads on the bolt or nut you are working on. When you turn the wrench in the correct direction, the threads should match the direction of the turn. This means they will align with the movement of the wrench, making it easier to loosen or tighten the fastener.

3. Consider Common Thread Standards

In general, most fasteners follow standard thread patterns. For example, right-handed threads are the most common and are tightened by turning the wrench clockwise and loosened by turning it counterclockwise. However, there are instances where left-handed threads are used, so it’s always a good idea to double-check the type of thread you are working with.

4. Use the “Lefty Loosey, Righty Tighty” Rule

A well-known saying in the handyman world is “lefty loosey, righty tighty.” This means that turning left (counterclockwise) loosens the fastener, while turning right (clockwise) tightens it. This rule can be a helpful reminder when visually determining the direction to turn your socket wrench.

5. Practice on a Known Direction Bolt

If you’re still unsure about the direction, you can practice on a bolt or nut with a known loosening or tightening direction. By observing the movement of the threads and paying attention to any visual cues, you can familiarize yourself with the correct direction without the risk of damaging the fasteners.

By using visual cues to determine the direction, you can save time and avoid frustration when working with a socket wrench. Remember to always double-check the type of thread before applying force and use caution to prevent any injuries or damage to the fasteners.

Applying the “Righty Tighty, Lefty Loosey” Rule

When working with a socket wrench, it’s important to know which direction to turn the wrench to tighten or loosen a bolt or nut. One simple rule that can help you determine the correct direction is the “righty tighty, lefty loosey” rule.

The basic idea behind this rule is that turning the wrench to the right (clockwise) tightens the bolt or nut, while turning it to the left (counterclockwise) loosens it.

Here’s how to apply the rule:

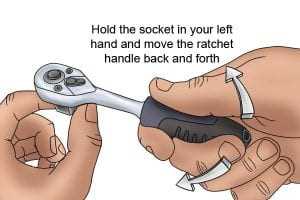

- Hold the socket wrench firmly in your hand, with the handle pointed towards you.

- Identify the direction you need to turn the bolt or nut. If you’re looking at the front of the bolt or nut, you will turn the wrench to the right to tighten (clockwise), or to the left to loosen (counterclockwise).

- To remember which direction corresponds to tightening or loosening, think of the motion of a clock: moving the hands to the right tightens the time, while moving them to the left loosens it.

- Apply steady pressure to the wrench and turn it in the appropriate direction. If the bolt or nut is particularly tight, you may need to use additional tools or techniques to loosen it.

- Once the bolt or nut is loosened or tightened to your desired level, release the wrench and remove it from the work area.

By following the “righty tighty, lefty loosey” rule, you can quickly and confidently determine the correct direction to turn your socket wrench and effectively loosen or tighten bolts or nuts.

Observing Tapered Threads

When determining the direction to loosen a socket wrench, one method is to observe the tapered threads. Tapered threads are commonly found on pipe fittings, and they have a conical shape.

To observe the tapered threads, follow these steps:

- Inspect the socket wrench and the bolt or nut that you need to loosen. Take note of the thread pattern on the bolt or nut.

- Look closely at the threads and see if they have a consistent diameter or if they gradually decrease in size.

- If the threads are consistent in diameter, meaning they have a constant width all the way around, it indicates that the threads are straight. In this case, to loosen the bolt or nut, turn the socket wrench counterclockwise.

- If the threads gradually decrease in size, forming a cone shape, it indicates that the threads are tapered. In this case, to loosen the bolt or nut, turn the socket wrench clockwise.

It is important to remember that not all bolts and nuts have tapered threads. Some may have straight threads or other types of thread patterns. It is always best to consult the manufacturer’s instructions or refer to a reliable source for specific information on a particular bolt or nut.

Observing the tapered threads is a simple and effective way to determine the direction to loosen a socket wrench when dealing with tapered thread fittings.

Understanding Reverse-threaded Fasteners

Reverse-threaded fasteners, also known as left-hand threaded fasteners, are a type of mechanical fastener that has threads that wind in the opposite direction compared to standard right-hand threaded fasteners. These bolts or screws are designed to be tightened by turning them clockwise, which is the opposite of the usual clockwise tightening motion.

Reverse-threaded fasteners serve specific purposes and are commonly used in various industries, including automotive, marine, and aerospace. They are often found in applications where there is a higher risk of the fastener becoming loose due to vibrations or other external factors. By using reverse-threaded fasteners, it provides an additional layer of security, helping to prevent the fastener from unintentionally loosening over time.

Why Use Reverse-threaded Fasteners?

There are several reasons why reverse-threaded fasteners are utilized in certain situations:

- Prevent loosening: The opposite threading direction helps prevent the fastener from unscrewing due to vibrations or other external forces.

- Specific applications: In certain applications, such as propellers or rotating equipment, reverse-threaded fasteners can ensure that the component stays securely in place.

- Security: The use of reverse-threaded fasteners adds an extra level of security, making it more difficult for unauthorized individuals to tamper with or remove the fasteners.

Recognizing and Working with Reverse-threaded Fasteners

It is crucial to be able to identify reverse-threaded fasteners to prevent any damage or incorrect handling. Here are some tips on how to recognize and work with reverse-threaded fasteners:

- Markings: Some manufacturers may mark the head of a reverse-threaded fastener with an “L” or another distinguishing mark to indicate that it is reverse-threaded.

- Thread direction: Reverse-threaded fasteners have threads that turn counterclockwise to tighten and clockwise to loosen. This is the opposite of standard right-hand threaded fasteners.

- Use the correct tool: When working with reverse-threaded fasteners, always use an appropriate left-hand threaded wrench or socket. Using the wrong tool can result in damage to the fastener or the tool itself.

Conclusion

Understanding reverse-threaded fasteners is essential for working with them effectively. By knowing why they are used, how to recognize them, and how to work with them, you can ensure the proper installation and avoid any potential issues or damage. Always consult the manufacturer’s guidelines and specifications when working with reverse-threaded fasteners to ensure optimal performance and safety.

Dealing with Seized or Stuck Fasteners

When working with a socket wrench, you may encounter fasteners that are seized or stuck. This can be frustrating, as it may require additional effort and techniques to loosen them. Here are some tips for dealing with seized or stuck fasteners:

1. Apply Penetrating Oil

Before attempting to loosen a seized or stuck fastener, it’s a good idea to apply a penetrating oil. Penetrating oil can help dissolve corrosion and lubricate the threads, making it easier to turn the fastener. Spray the penetrating oil onto the fastener and let it sit for a few minutes to allow it to work its way into the threads.

2. Use Heat

If a penetrating oil doesn’t work, you can try applying heat to the fastener. Heat can help expand the metal, breaking the bond between the threads and making it easier to loosen. Use a heat gun or a propane torch to warm up the fastener. Be careful not to overheat the surrounding materials, as this can cause damage.

3. Tap with a Hammer

In some cases, a stuck fastener may require some gentle persuasion. Use a hammer to tap the end or side of the wrench to help loosen the fastener. The impact can help jolt the fastener and break any rust or corrosion that may be holding it in place.

4. Use Additional Tools

If a fastener is particularly stubborn, you may need to use additional tools to help loosen it. For example, you can try using a breaker bar instead of a regular socket wrench to provide more leverage. Alternatively, you can use a socket extension or a pipe to increase the length of the wrench handle, which can also help provide more torque.

5. Seek Professional Help

If you’ve tried all the above methods and still can’t loosen the fastener, it may be best to seek professional help. A professional mechanic or technician will have the experience and tools to safely remove seized or stuck fasteners without causing damage.

Remember to always exercise caution when working with stuck or seized fasteners, as excessive force or improper techniques can lead to injury or damage. Take your time and be patient, and if all else fails, don’t hesitate to ask for help.

FAQ

How can I determine the direction to loosen a socket wrench?

To determine the direction to loosen a socket wrench, you should consider the type of fastener you are working with. For most fasteners, such as bolts and screws, turning the wrench counterclockwise will loosen them. However, there are some exceptions, such as left-handed threaded fasteners, which require turning the wrench clockwise to loosen. It is always a good idea to consult the manufacturer’s instructions or refer to a reliable source before attempting to loosen a fastener.

Can I rely on the arrow mark on the socket wrench to determine the direction to loosen?

Yes, the arrow mark on the socket wrench can be a helpful indicator of the direction to loosen. In most cases, if the arrow points in the counterclockwise direction, you should turn the wrench counterclockwise to loosen the fastener. However, it is important to note that not all socket wrenches have an arrow mark, and even if they do, it is still a good idea to double-check with other indications, such as the position of the ratchet or the type of fastener.

Are there any general rules to determine the direction to loosen a socket wrench?

Yes, there are some general rules that can help determine the direction to loosen a socket wrench. For most fasteners, turning the wrench counterclockwise will loosen them. This is because most fasteners are right-handed threaded, meaning that the threads get tighter as they are turned clockwise. However, it is important to note that there are exceptions to this rule, such as left-handed threaded fasteners, which require turning the wrench clockwise to loosen. It is always a good idea to consult the manufacturer’s instructions or refer to a reliable source for specific directions related to your fastener.

What should I do if the socket wrench is stuck and I can’t determine the direction to loosen?

If the socket wrench is stuck and you can’t determine the direction to loosen, there are a few steps you can take. First, try gently wiggling the wrench back and forth while applying slight pressure in both directions. This may help loosen any debris or rust that could be causing the wrench to stick. If that doesn’t work, you can try applying a penetrating oil, such as WD-40, to the fastener to help loosen it. If all else fails, it may be best to seek the assistance of a professional who can safely loosen the stuck fastener.

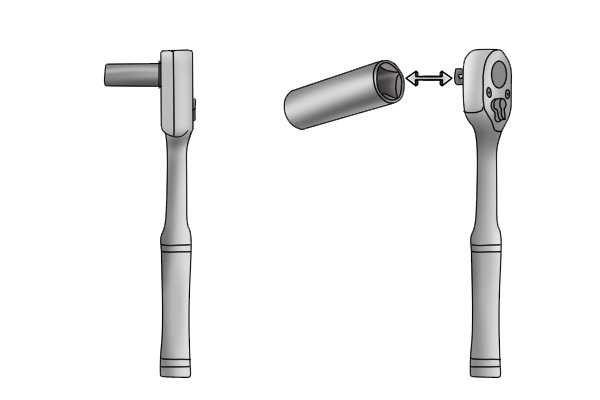

Is there a specific tool I can use to determine the direction to loosen a socket wrench?

While there is no specific tool designed solely to determine the direction to loosen a socket wrench, there are a few tools that can be helpful in this process. One such tool is a ratchet, which is a socket wrench with a built-in mechanism that allows it to move in one direction while preventing it from moving in the other. By observing the position of the ratchet, you can determine the direction to loosen. Additionally, some socket wrench sets come with a reference card or guide that provides information on the correct direction to loosen various types of fasteners.

Can I use a socket wrench to tighten as well as loosen fasteners?

Yes, a socket wrench can be used to both tighten and loosen fasteners. To tighten a fastener, you would turn the socket wrench clockwise. To loosen a fastener, you would turn the socket wrench counterclockwise. It is important to note that when tightening a fastener, you should use the appropriate amount of force to ensure it is securely tightened, but you should be careful not to over-tighten and risk damaging the fastener or the surrounding material.

Are there any safety precautions I should take when using a socket wrench?

Yes, there are some safety precautions you should take when using a socket wrench. First, always wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from any potential hazards. Second, make sure the socket wrench and any associated tools are in good working condition before using them. Inspect the tools for any signs of damage or wear and replace them if necessary. Finally, always use the socket wrench in a controlled manner, applying force gradually and evenly to avoid slippage or injury. If you are unsure about how to use a socket wrench safely, it is best to seek guidance from a professional.