How does an air impact wrench work: all you need to know

An air impact wrench is a powerful tool commonly used in the automotive industry and other heavy-duty applications. It is designed to provide fast and efficient torque for loosening or tightening nuts and bolts. This tool utilizes compressed air as its power source, making it a popular choice for professionals and DIY enthusiasts alike.

The inner workings of an air impact wrench are relatively simple yet highly effective. Inside the tool, there is a motor that drives a hammer mechanism. When compressed air is introduced into the wrench, it causes the motor to spin, which in turn moves the hammer back and forth at a high speed. This rapid motion allows the wrench to generate a high amount of torque without requiring excessive force from the user.

The hammer mechanism of an air impact wrench is what sets it apart from other types of wrenches. As the hammer moves back and forth, it strikes an anvil, which is set at a slight angle to the direction of rotation. This angled impact causes the anvil to rotate, effectively transferring the torque to the bolt or nut being tightened or loosened. The repeated impacts create a rapid pulsating motion, allowing the wrench to break loose even the most stubborn fasteners.

One key advantage of using an air impact wrench is its ability to deliver a high amount of torque without the risk of over-tightening. The rapid pulsating motion produced by the hammer mechanism ensures that the torque is applied in short bursts, preventing excessive force from being exerted on the fastener. Additionally, the air power source allows for continuous use without the need for recharging or refueling.

In conclusion, an air impact wrench is a powerful and versatile tool that provides fast and efficient torque for a variety of applications. It utilizes a motor-driven hammer mechanism powered by compressed air to generate high amounts of torque without requiring excessive force from the user. Its unique design allows for rapid pulsating impacts, making it ideal for loosening or tightening stubborn nuts and bolts. Whether you’re a professional mechanic or a DIY enthusiast, an air impact wrench is a valuable addition to your toolkit.

Basics of Air Impact Wrenches

An air impact wrench is a powerful tool used for tightening or loosening nuts and bolts. It operates using compressed air and is commonly used in automotive repair and construction applications. Here are some key basics to understand about how air impact wrenches work:

1. Working Principle

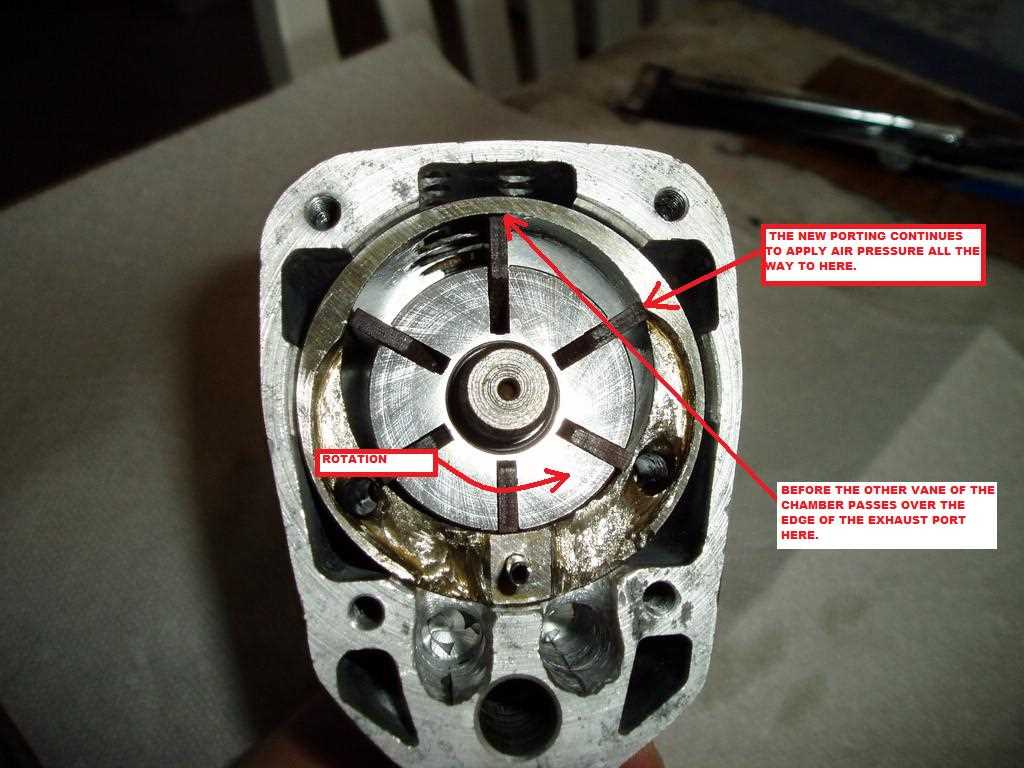

An air impact wrench uses the power of compressed air to generate torque. When triggered, the air supply is directed into a chamber within the wrench. Inside the chamber, a hammer or rotor is mounted on an axis and is free to rotate.

The air pressure causes the rotor to rotate rapidly, building up kinetic energy. This energy is then transferred to the hammer, which delivers repeated blows to the output shaft of the wrench.

The rapid rotation and hammering action create a high amount of torque, allowing the wrench to easily loosen or tighten stubborn nuts and bolts.

2. Torque Control

One important feature of air impact wrenches is the ability to control the amount of torque applied. This is typically achieved through an adjustable torque setting on the wrench.

By adjusting the torque setting, the user can control the amount of force applied to the fastener. This is especially important when working with delicate or fragile materials, as using too much torque can cause damage.

3. Socket and Anvil

In order to attach a socket to an air impact wrench, a square-shaped drive called an anvil is used. The anvil has a small ball bearing that locks the socket in place, ensuring a secure connection.

Sockets come in various sizes and are interchangeable, allowing the wrench to be used with different fastener sizes. The user simply selects the appropriate socket for the job at hand and attaches it to the anvil.

4. Air Supply

An air impact wrench requires a source of compressed air to operate. This is typically provided by an air compressor.

The air compressor supplies a continuous flow of compressed air to the wrench, allowing it to generate the necessary power. The air pressure can be adjusted based on the desired torque output.

5. Advantages and Disadvantages

Air impact wrenches have several advantages over other types of wrenches. They are lightweight, powerful, and can deliver high amounts of torque. Additionally, they do not have cords or batteries, making them highly portable.

However, air impact wrenches require an external air compressor and can be loud during operation. They also have a limited range of movement due to the need for an air hose.

Overall, air impact wrenches are indispensable tools in many industries due to their efficiency and power. Understanding their basic functioning can help users utilize them effectively and safely.

Components of an Air Impact Wrench

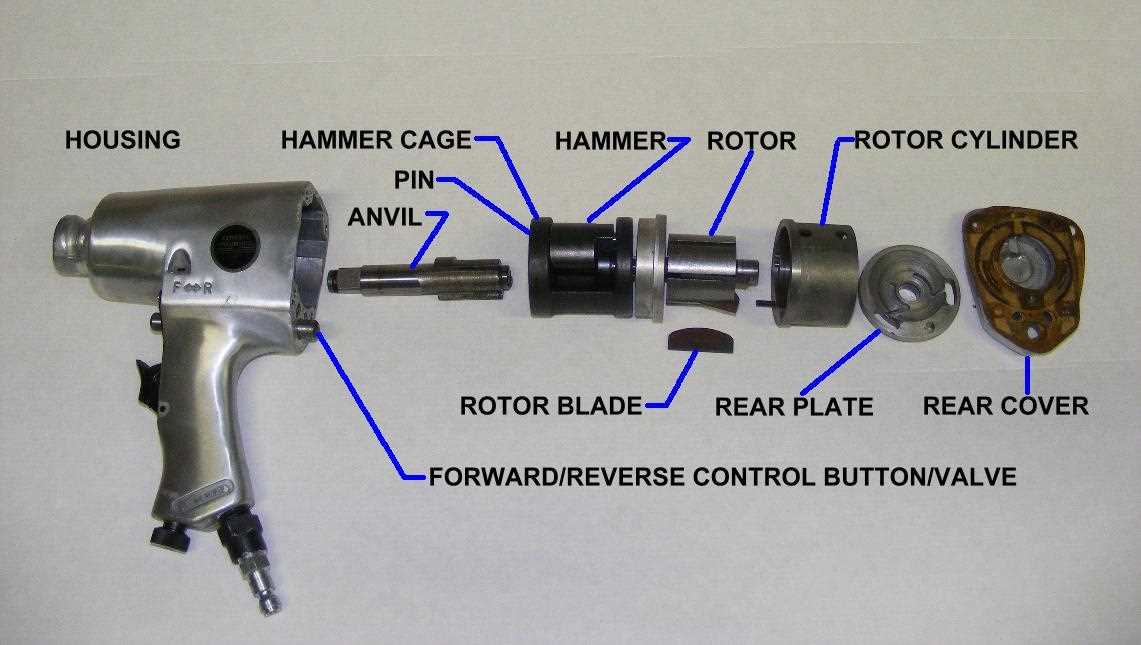

An air impact wrench is a powerful tool that is used to remove and tighten bolts and nuts. It works by converting the air pressure generated by an air compressor into rotational force. There are several key components that make up an air impact wrench, each playing a vital role in its operation.

1. Air Inlet

The air inlet is the point where the air compressor is connected to the impact wrench. It allows compressed air to enter the tool and power its operation.

2. Motor

The motor of an air impact wrench is responsible for converting the energy from compressed air into rotational force. It is usually a pneumatic motor that utilizes the force of the air to rotate an internal hammer mechanism.

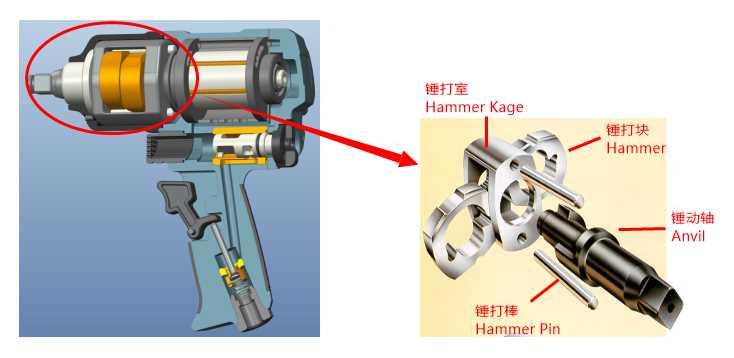

3. Hammer Mechanism

The hammer mechanism is the heart of an air impact wrench. It consists of a rotating hammer that delivers powerful blows to the anvil, generating the torque needed to loosen or tighten fasteners. The hammer is powered by the motor and moves in a rapid back-and-forth motion.

4. Anvil

The anvil is the part of the air impact wrench where the socket or other tool attachment is connected. It is designed to withstand the high levels of torque and impacts produced by the hammer mechanism.

5. Trigger

The trigger is the control mechanism of the air impact wrench. When pressed, it allows air to flow into the motor and activate the hammer mechanism. Releasing the trigger stops the rotation of the hammer mechanism.

6. Air Exhaust

The air exhaust is the point where compressed air exits the impact wrench after powering its operation. It helps to dissipate heat and direct the exhaust away from the user.

7. Housing

The housing of an air impact wrench is the outer casing that protects its internal components. It is usually made of durable materials, such as metal or plastic, and is designed to withstand the rigors of heavy-duty use.

8. Accessories

There are various accessories that can be used with an air impact wrench, such as sockets, extensions, and adaptors. These accessories allow for different sizes and types of fasteners to be used with the tool.

By understanding the components of an air impact wrench, you can better appreciate how this powerful tool is able to deliver high levels of torque and make quick work of tightening and loosening bolts and nuts.

Working Principle of Air Impact Wrenches

An air impact wrench is a powerful tool used to tighten or loosen bolts and nuts. It works on the principle of using compressed air to generate torque, making it a popular choice in automotive, construction, and other industries.

1. Compressed Air Supply

The first step in understanding how an air impact wrench works is to consider its source of power, which is compressed air. The tool is connected to an air compressor through a hose, which delivers high-pressure airflow to the wrench.

2. Rotary Mechanism

Inside the air impact wrench, there is a rotary mechanism that converts the high-pressure airflow into rotational motion. This mechanism consists of an internal motor, an anvil, and a hammer assembly.

3. Anvil and Hammer Assembly

The anvil is the square-shaped socket at the front of the wrench, which holds the socket attachment. When the trigger is pressed, the hammer assembly begins to rotate, hitting the anvil repeatedly in quick succession.

4. Hammering Action

The hammer assembly consists of a series of small hammers around a central shaft. These hammers are free to rotate and move back and forth along the shaft. As the hammer assembly rotates, centrifugal force causes the hammers to move outward.

As the hammers move outward, they make contact with a striker plate, which is connected to the anvil. This impact produces a sudden burst of torque. The hammer assembly continues to rotate, causing the hammers to retract and then strike the striker plate again. This hammering action creates a continuous and powerful rotational force.

5. Torque Control

Most air impact wrenches have a built-in torque control mechanism to prevent overtightening of bolts and nuts. This mechanism allows the user to set the desired torque level, after which the wrench automatically stops applying torque when the set level is reached.

6. Socket Attachment

The socket attachment is connected to the anvil, and it is the part of the wrench that is used to tighten or loosen bolts and nuts. The socket attachment comes in various sizes and can be easily interchangeable.

Overall, an air impact wrench is a reliable and efficient tool for heavy-duty applications. Its use of compressed air and the hammering action makes it suitable for tasks that require high torque and fast operation.

How Air Impact Wrenches Generate Power

Air impact wrenches are powerful pneumatic tools that are commonly used in automotive repair and construction industries. These tools work by converting compressed air into rotational force to tighten or loosen nuts and bolts. Understanding how air impact wrenches generate power can help you better appreciate their capabilities and efficiency.

Compressed Air Supply

The power source for an air impact wrench is a compressed air supply. Typically, air compressors are used to generate the required air pressure. The air compressor takes in ambient air and compresses it to a higher pressure, typically between 90 and 120 pounds per square inch (psi). This compressed air is then stored in a tank or reservoir for use.

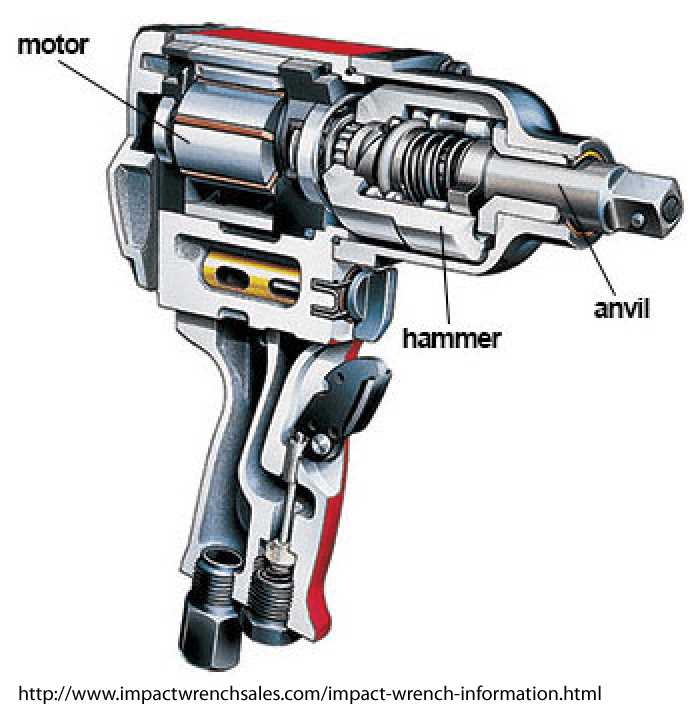

Internal Mechanism

An air impact wrench consists of an internal mechanism that converts the compressed air into rotational force. This mechanism includes a motor, an air inlet, and an anvil.

The motor is usually a powerful hydraulic motor or an electric motor that is designed to handle high torque. It is responsible for driving the rotation of the anvil.

The air inlet is connected to the compressed air supply. When the trigger of the wrench is pressed, the compressed air is directed into the mechanism.

The anvil is the part of the tool that makes contact with the nut or bolt. It has a square drive socket where the appropriate socket attachment can be inserted. The anvil is connected to the motor and rotates in response to the air pressure and trigger activation.

Twin Hammer Mechanism

The most common type of internal mechanism used in air impact wrenches is the twin hammer mechanism. This mechanism consists of two hammers, or pistons, that rotate inside the wrench body.

When compressed air is directed into the twin hammer mechanism, the hammers rotate rapidly, creating a powerful rotational force. As the hammers rotate, they strike against the anvil, which translates the rotational force to the socket attachment.

Variable Torque Control

Air impact wrenches usually have variable torque control, allowing users to adjust the amount of rotational force applied. This feature is important because different applications require different levels of torque. By controlling the air pressure and trigger activation, users can adjust the torque to suit their specific needs.

In conclusion, air impact wrenches generate power through a compressed air supply and an internal mechanism that converts the compressed air into rotational force. Understanding how these tools work can help users utilize them effectively and safely.

Types of Air Impact Wrenches

There are several types of air impact wrenches available on the market, each designed for different purposes and applications. Here are some of the most common types:

-

Standard Duty Air Impact Wrenches: These wrenches are commonly used for general automotive repairs and light industrial applications. They are typically compact and lightweight, making them easy to use in tight spaces.

-

Heavy Duty Air Impact Wrenches: These wrenches are more powerful and built to handle tougher jobs. They are commonly used in heavy machinery repair, automotive tire work, and construction applications. Heavy duty wrenches often have higher torque outputs and larger anvils to accommodate larger sockets.

-

Cordless Air Impact Wrenches: These wrenches are powered by batteries and offer the convenience of portability without the need for an air compressor. Cordless wrenches are gaining popularity due to their versatility and ease of use in remote locations and areas without access to electricity.

-

Compact Air Impact Wrenches: These wrenches are designed to be lightweight and small in size, making them ideal for tasks that require maneuverability and access to tight spaces. They are commonly used in automotive and equipment repair, as well as assembly lines where precision and speed are important.

-

Angle Air Impact Wrenches: These wrenches have a unique angled design that allows for easier access to fasteners in confined spaces. They are commonly used in automotive and machinery repair, as well as in construction applications.

-

In-Line Air Impact Wrenches: These wrenches have a slim and elongated design, making them suitable for tasks where space is limited and a traditional wrench may not fit. They are commonly used in automotive, industrial, and manufacturing applications.

It is important to choose the right type of air impact wrench based on your specific needs and the tasks you will be performing. Consider factors such as power, torque, size, and access requirements before making a purchase.

Advantages of Using Air Impact Wrenches

When it comes to loosening or tightening bolts and screws, an air impact wrench is a powerful tool that can make the job much easier and faster. Here are some advantages of using air impact wrenches:

- High Torque: Air impact wrenches are capable of delivering high torque, which is essential for fastening or loosening tough nuts and bolts. The high torque generated by these wrenches allows them to handle even the most stubborn fasteners with ease.

- Faster Operation: Compared to manual wrenches or electric impact wrenches, air impact wrenches provide faster operation. This is because they use compressed air to deliver force and rotational power, allowing for quick and efficient tightening or loosening of fasteners.

- Versatility: Air impact wrenches come in a variety of sizes and are suitable for a wide range of applications. Whether you’re working on automotive repairs or construction projects, there is an air impact wrench that can meet your specific needs.

- Compact and Lightweight: Most air impact wrenches are compact and lightweight, making them easy to handle and maneuver in tight spaces. Their small size also makes them portable, allowing you to easily carry them to different job sites.

- Less Fatigue: Using an air impact wrench requires less physical effort compared to manual wrenches. The pneumatic power generated by the compressed air allows for smooth and effortless operation, reducing the risk of hand and arm fatigue during prolonged use.

- Cost-Effective: Air impact wrenches are generally more affordable compared to other types of power tools. Additionally, they have a longer lifespan and require less maintenance, making them a cost-effective investment in the long run.

Overall, air impact wrenches offer numerous advantages over other types of wrenches. Their high torque, fast operation, versatility, compactness, and cost-effectiveness make them indispensable tools in various industries.

Tips for Using an Air Impact Wrench Safely

An air impact wrench is a powerful tool that can be very useful for a variety of tasks. However, it is important to use this tool safely to avoid accidents and injuries. Here are some tips to help you use an air impact wrench safely:

- Wear appropriate safety gear: Before using an air impact wrench, make sure you are wearing safety glasses, gloves, and ear protection. These will help protect you from flying debris, vibrations, and loud noise.

- Inspect the tool: Before using the wrench, inspect it for any damage or defects. Check if all the parts are in good condition and ensure that the tool is properly lubricated.

- Choose the right socket and accessories: Use sockets and accessories that are designed for use with an air impact wrench. Make sure they are properly sized and compatible with the tool to prevent slippage or damage.

- Properly secure the workpiece: Before using the wrench, ensure that the workpiece is securely clamped or held in place. This will prevent it from moving or becoming dislodged while you are working.

- Control the air pressure: Adjust the air pressure of the tool according to the task at hand. Using excessive pressure can cause the wrench to deliver more torque than necessary and lead to accidents or damage.

- Use the correct technique: Hold the wrench firmly with both hands while operating it. Do not apply excessive force or torque, as this can cause the wrench to twist or slip, leading to injuries.

- Be aware of kickback: When the wrench encounters resistance, it can cause a sudden jolt or kickback. To prevent this, ensure that you have a secure grip on the tool and keep your body and hands clear of the reaction area.

- Maintain a clean work area: Keep your work area clean and free from clutter. This will help prevent tripping hazards and reduce the risk of damaging the tool or workpiece.

- Store the tool properly: After you have finished using the air impact wrench, store it in a clean and dry place. Make sure it is properly secured and not within reach of children or unauthorized users.

By following these tips, you can use an air impact wrench safely and effectively. Remember to always prioritize safety and take the necessary precautions to protect yourself and others.

Maintenance and Care for Air Impact Wrenches

Regular Cleaning

Regular cleaning is essential for maintaining the performance and longevity of your air impact wrench. After each use, it is important to remove any dirt, dust, or debris that may have accumulated on the tool.

Use a clean cloth or a small brush to wipe down the exterior of the wrench. Pay special attention to the handle, trigger, and air inlet areas where dirt tends to build up. Avoid using any harsh chemicals or solvents that may damage the tool.

Lubrication

Lubrication is crucial for the smooth operation of an air impact wrench. Proper and regular lubrication can prevent wear and tear, reduce friction, and extend the tool’s lifespan.

Before each use, apply a few drops of air tool oil or lubricant to the air inlet of the wrench. This will ensure that the internal components, such as the motor and hammer mechanism, are properly lubricated.

Additionally, it is recommended to add a few drops of oil to the tool’s air fitting before connecting it to the air supply. This will help lubricate the air motor and prevent corrosion.

Checking and Replacing Parts

Regularly check the air impact wrench for any signs of wear or damage. Inspect the cords, hoses, and connections for any fraying or leaks. If you notice any issues, it is important to repair or replace the parts as necessary.

The impact sockets should also be checked regularly for wear or damage. Damaged sockets should be replaced immediately to avoid any accidents or damage to the tool.

Proper Storage

Proper storage is key to keeping your air impact wrench in good condition. After each use, make sure to disconnect the tool from the air supply and release any residual pressure.

Store the wrench in a clean, dry area where it is protected from dust, moisture, and extreme temperatures. It is also recommended to use a tool case or pouch to prevent any damage during transportation or storage.

By following these maintenance and care tips, you can ensure that your air impact wrench remains in excellent working condition and lasts for a long time.

FAQ

How does an air impact wrench work?

An air impact wrench works by using compressed air to create a powerful, rapid hammering motion. When the air is released from the wrench, it enters a chamber where it pushes against a rotor. The rotor then begins to rotate, which causes the hammer mechanism inside the wrench to strike against an anvil, creating a high amount of torque.

What is the purpose of an air impact wrench?

An air impact wrench is used to quickly and efficiently tighten or loosen fasteners, such as bolts and nuts. It is commonly used in automotive and construction industries where large, stubborn fasteners need to be removed or tightened with minimal effort.

How does the hammer mechanism in an air impact wrench work?

The hammer mechanism in an air impact wrench consists of a set of steel balls or pins. When the rotor rotates, these balls or pins move in and out of cavities in the anvil. As they move back and forth, they strike the anvil with a hammering action, generating torque.

What are the advantages of using an air impact wrench?

One major advantage of using an air impact wrench is its high torque output. It can generate much higher torque compared to other types of wrenches, making it suitable for heavy-duty applications. Additionally, air impact wrenches are lightweight and easy to handle, reducing user fatigue during prolonged use.

Can an air impact wrench be used for delicate or precision work?

No, an air impact wrench is not suitable for delicate or precision work. The hammering action of the wrench can cause damage to sensitive materials or break small fasteners. It is best used for applications where strong, rapid tightening or loosening is required.

Are there any maintenance requirements for an air impact wrench?

Yes, regular maintenance is important to keep an air impact wrench in good working condition. This includes lubricating the wrench with air tool oil, checking and replacing worn-out parts, and cleaning the tool to remove debris. Following the manufacturer’s guidelines for maintenance is crucial to ensure the longevity and performance of the wrench.