How Does a Ratchet Wrench Work: A Comprehensive Guide

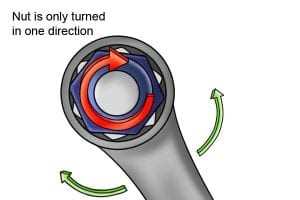

A ratchet wrench, also known as a socket wrench, is a versatile tool that is commonly used for loosening or tightening bolts and nuts. It consists of a handle, a ratchet mechanism, and a set of interchangeable sockets. The ratchet mechanism allows the wrench to turn in one direction while preventing the socket from turning in the opposite direction.

The key component of a ratchet wrench is the ratchet mechanism, which is typically located in the head of the wrench. This mechanism consists of a gear or pawl system that enables the wrench to rotate in only one direction. When the wrench is turned in the desired direction, the gear or pawl engages with the teeth on the socket, allowing the socket to turn along with the handle.

One of the main advantages of a ratchet wrench is its ability to work in confined spaces. The handle of the wrench is typically set at a right angle to the head, allowing the user to apply torque to bolts and nuts even in tight spots where a regular wrench would be difficult to use. This makes the ratchet wrench a valuable tool for mechanics and DIY enthusiasts who often need to work with fasteners in hard-to-reach areas.

Overall, a ratchet wrench is a must-have tool for anyone who frequently works with bolts and nuts. Its innovative ratchet mechanism allows for fast and efficient loosening or tightening of fasteners, while its compact design makes it easy to use in confined spaces. Whether you are a professional mechanic or a hobbyist, a ratchet wrench will undoubtedly simplify your work and save you time and effort.

The Basics of a Ratchet Wrench

A ratchet wrench, also known as a socket wrench, is a versatile tool commonly used for tightening or loosening nuts and bolts. It consists of a handle, a ratchet mechanism, and a socket attachment. The ratchet mechanism allows for both clockwise and counterclockwise motion without the need to lift and reposition the tool.

Ratchet Mechanism

The ratchet mechanism is the heart of a ratchet wrench. It is a device that allows controlled rotation in one direction and prevents it in the opposite direction. This feature is accomplished using a gear and pawl system.

Inside the ratchet mechanism, there is a gear with sloping teeth called the ratchet gear. The gear is attached to a central drive shaft connected to the handle. The handle has a lever that engages or disengages the ratchet. When the ratchet is engaged, the teeth of the ratchet gear interact with a pawl, preventing counterclockwise motion. When the tool is turned in the clockwise direction, the ratchet gear rotates smoothly.

The ratchet mechanism allows for efficient and rapid tightening or loosening of fasteners. The user can keep the tool in contact with the fastener while continuously turning in a single direction, significantly reducing the time and effort required to complete a task.

Socket Attachment

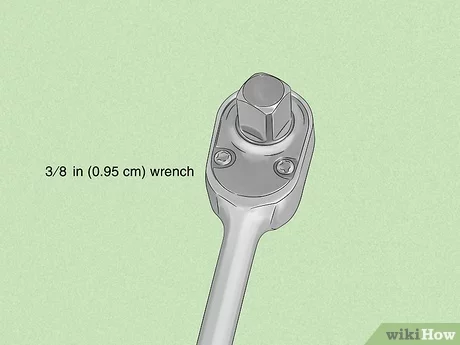

A ratchet wrench features a socket attachment at the end of the drive shaft. The socket attachment is designed to fit different sizes and types of fasteners, such as nuts, bolts, and screws. The most common type of socket attachment is the square-shaped drive, which comes in various sizes, including 1/4-inch, 3/8-inch, and 1/2-inch.

The socket attachment can also have a quick-release mechanism, allowing for easy and quick socket changes without the need for additional tools. This feature is beneficial when working with multiple fasteners of different sizes or when switching between tightening and loosening tasks.

Using a Ratchet Wrench

To use a ratchet wrench, the operator selects the appropriate socket attachment size for the fastener being worked on. The socket is then placed over the fastener, and the ratchet handle is turned in the desired direction. If the ratchet is in the engaged position, it will allow for smooth rotation. If the ratchet needs to be reversed, the user simply flips the lever to disengage it and then turns the tool in the opposite direction.

Depending on the task and the fastener being worked on, different socket extensions and accessories can be used to reach confined or hard-to-reach areas. These extensions and accessories can be attached between the socket and the ratchet handle for added flexibility and convenience.

Overall, a ratchet wrench is an essential tool for any mechanic or DIY enthusiast. Its efficient and ergonomic design makes it easy to use and saves time and effort when working with fasteners of various sizes.

Understanding the Ratchet Mechanism

A ratchet wrench is a versatile tool commonly used in mechanical and automotive applications. It is designed to provide high torque and make the tightening or loosening of fasteners quicker and easier. The main component that allows a ratchet wrench to function is the ratchet mechanism.

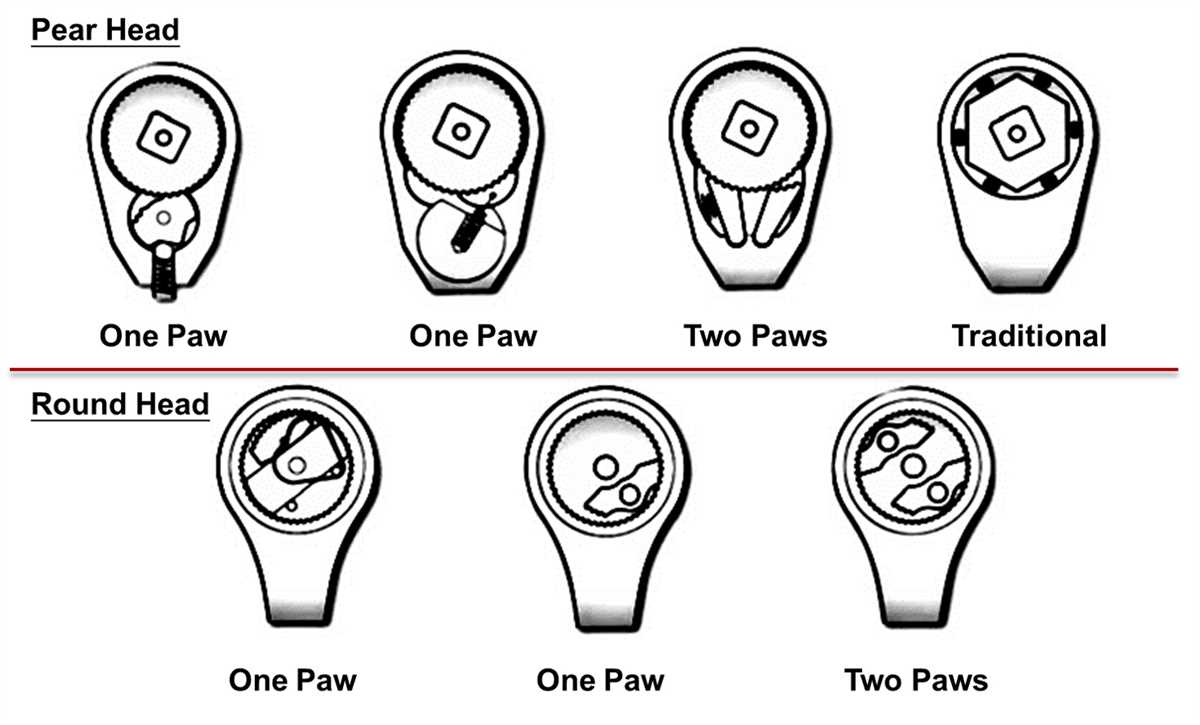

The ratchet mechanism consists of several key parts, including the handle, the ratchet head, the pawl, and the gear teeth. These parts work together to enable the ratcheting action, which allows the wrench to operate in one direction while allowing the user to maintain a consistent grip and only move the wrench in a single direction.

Ratchet Head

The ratchet head of a ratchet wrench is the main body of the tool that holds the socket or other attachments. It is typically square or hexagonal in shape, allowing for easy attachment and detachment of various tool bits. The ratchet head is usually fixed to the handle, allowing it to rotate freely in both directions.

Pawl

The pawl is a small metal component that is spring-loaded and sits within the ratchet head. It has a gear-like shape with a set of teeth on one end. The pawl engages with the gear teeth of the ratchet head, allowing it to move in only one direction and preventing it from moving backward.

Gear Teeth

The gear teeth are located inside the ratchet head and engage with the teeth of the pawl. When the handle of the ratchet wrench is rotated in one direction, the gear teeth catch the pawl, allowing the ratchet head to rotate. However, when the handle is rotated in the opposite direction, the gear teeth push against the pawl, causing it to lift and disengage from the teeth, preventing the ratchet head from rotating backward.

The ratchet mechanism allows the user to apply force in a single direction while maintaining a tight grip on the handle. This enables the user to quickly tighten or loosen fasteners without having to remove the wrench from the bolt or nut.

Operation

When using a ratchet wrench, the user simply needs to position the ratchet head over the fastener they wish to tighten or loosen. They can then apply force to the handle in a single direction, while the ratchet mechanism ensures that the tool only moves in that direction without the need to reposition the wrench. As a result, the user can work more efficiently and quickly complete their tasks.

Overall, the ratchet mechanism is a clever and effective design that enhances the functionality and usability of a ratchet wrench. It allows for easy tightening and loosening of fasteners, making it an essential tool in any mechanic or DIY enthusiast’s toolbox.

Components of a Ratchet Wrench

A ratchet wrench is a versatile tool that consists of several components working together to provide a convenient and efficient method for fastening and loosening nuts and bolts. Here are the main components of a ratchet wrench:

1. Handle

The handle is the part of the ratchet wrench that you hold on to while using it. It is usually made of a comfortable grip material like rubber or plastic to provide a secure and ergonomic hold. The length and shape of the handle can vary depending on the model and intended use of the ratchet wrench.

2. Ratchet Mechanism

The ratchet mechanism is the heart of a ratchet wrench. It is responsible for the tool’s ability to turn in only one direction while maintaining a constant connection with the fastener. The ratchet mechanism allows the user to rotate the wrench back and forth without having to lift and reposition it on the nut or bolt.

3. Ratchet Switch

The ratchet switch is a small selector located on the head of the ratchet wrench. It allows the user to change the direction of rotation of the ratchet mechanism. By flipping the switch, the user can switch between tightening and loosening modes easily, without the need for additional tools or adjustments.

4. Socket Drive

The socket drive is the square or rectangular opening located on the head of the ratchet wrench. It is where different types and sizes of sockets can be attached. The socket drive allows the user to interchange sockets depending on the size of the fastener being worked on.

5. Sockets

Sockets are attachments that fit onto the socket drive of the ratchet wrench. They come in various sizes and types to accommodate different fastener sizes and shapes. Sockets are often made of durable materials like chrome vanadium steel for strength and longevity.

6. Forward Knob

The forward knob is a small button or lever located on the head of the ratchet wrench. When pressed or flipped, it allows the ratchet mechanism to rotate in the forward direction, which is typically used for tightening fasteners. Releasing the forward knob enables the ratchet wrench to switch to the reverse direction for loosening.

7. Extension Bar

An extension bar is an optional accessory that can be added to a ratchet wrench to increase its reach. It is a long metal rod that attaches to the socket drive and allows the user to access fasteners in tight or hard-to-reach areas. Extension bars come in different lengths to provide flexibility and versatility.

Understanding the different components of a ratchet wrench is essential for effectively using and maintaining this useful tool. By knowing how each part functions and interacts, you can ensure optimal performance and longevity.

Types of Ratchet Wrenches

There are several types of ratchet wrenches available on the market. Each type is designed for different applications and offers unique features. Here are some of the most common types:

- Standard Ratchet Wrench: This is the most basic type of ratchet wrench. It features a ratcheting mechanism that allows for both clockwise and counterclockwise rotation. It is commonly used for general repairs and maintenance tasks.

- Flex-Head Ratchet Wrench: This type of ratchet wrench has a flexible head that can pivot up to a certain angle. It allows for better accessibility in tight and hard-to-reach spaces. It is often used in automotive repairs.

- Stubby Ratchet Wrench: The stubby ratchet wrench is characterized by its shorter handle. It is designed for use in tight spaces where a standard ratchet wrench would be difficult to maneuver. It is commonly used in plumbing and HVAC applications.

- Adjustable Ratchet Wrench: As the name suggests, this type of ratchet wrench features an adjustable head. It allows for different socket sizes to be used with a single wrench, making it versatile and convenient. It is often used in mechanical and industrial applications.

In addition to these types, there are also ratchet wrenches with special features such as quick-release mechanisms, anti-slip handles, and reversible ratchets. Choosing the right type of ratchet wrench depends on the specific task you need to accomplish and the accessibility of the space you are working in.

Ultimately, having a variety of ratchet wrench types in your toolbox will ensure that you are equipped for different repair and maintenance jobs.

Choosing the Right Ratchet Wrench

When it comes to choosing a ratchet wrench, there are several factors to consider. Whether you are a professional mechanic or a DIY enthusiast, selecting the right ratchet wrench can make a big difference in your work. Here are some important factors to keep in mind:

Type of Ratchet

The first thing to consider is the type of ratchet you need. There are three common types available: fixed ratchet, flex-head ratchet, and palm ratchet. Fixed ratchets are the most basic and affordable option, while flex-head ratchets allow for better access in tight spaces. Palm ratchets are compact and perfect for smaller tasks.

Drive Size

Another important factor to consider is the drive size of the ratchet wrench. The most common drive sizes are 1/4-inch, 3/8-inch, and 1/2-inch. It is important to match the drive size of the ratchet wrench to the size of the sockets you will be using. If you plan on working on larger projects, such as automotive repairs, a 1/2-inch drive ratchet will be more suitable.

Tooth Count

The tooth count of the ratchet is also an important factor to consider. The tooth count refers to the number of teeth on the ratchet gear. Ratchets with higher tooth counts provide finer increments and require less movement to engage the next tooth, making them more efficient. However, ratchets with lower tooth counts are more durable and can handle higher torque.

Quality and Price

Finally, it is important to consider the quality and price of the ratchet wrench. While it may be tempting to go for the cheapest option, investing in a high-quality ratchet wrench will save you money in the long run. Look for ratchet wrenches made from durable materials, such as chrome vanadium steel, and check for positive customer reviews.

Overall, choosing the right ratchet wrench involves considering the type of ratchet, drive size, tooth count, and quality. By considering these factors, you can ensure that you have the right tool for the job and make your work much easier.

Tips for Using a Ratchet Wrench Safely

1. Wear appropriate protective gear

When using a ratchet wrench, it is important to wear the appropriate protective gear to ensure your safety. This includes safety goggles to protect your eyes from flying debris and gloves to protect your hands.

2. Position yourself properly

Before using a ratchet wrench, ensure you are in a stable position. Stand with your feet shoulder-width apart and brace yourself against a sturdy surface or object to maintain balance and stability while applying force.

3. Use the correct size socket

Using the correct size socket is essential for safe and effective use of a ratchet wrench. Make sure the socket matches the bolt or nut you are working on to avoid slipping or damaging the fastener.

4. Apply force in the right direction

When using a ratchet wrench, it is important to apply force in the right direction. For tightening, push the handle of the wrench in the direction of the fastener. For loosening, pull the handle towards you. Applying force in the wrong direction can cause the wrench to slip, leading to potential injuries.

5. Check for any damage or wear

Prior to using a ratchet wrench, inspect it for any damage or wear. Check the handle, ratchet mechanism, and socket for any signs of cracks, breakage, or excessive wear. Using a damaged or worn-out wrench can be dangerous and compromise its effectiveness.

6. Avoid over-tightening

Over-tightening can lead to stripped threads or broken fasteners. Use a torque wrench if precise torque values are required. Otherwise, exercise caution and apply just enough force to adequately tighten the fastener without excessive strain.

7. Keep your fingers away from moving parts

Be mindful of keeping your fingers and other body parts clear of the ratchet mechanism and moving parts of the wrench. This will help prevent accidental injuries or pinching.

8. Store the wrench properly

After use, store the ratchet wrench in a clean and dry environment. Make sure to keep it in a dedicated tool storage area or toolbox to prevent damage and ensure it is readily accessible for future use.

Maintaining Your Ratchet Wrench

Regular Cleaning

Keeping your ratchet wrench clean is essential for its longevity and optimal performance. Here are a few steps to follow when cleaning your ratchet wrench:

- Ensure the wrench is disconnected from any power source or air supply before cleaning.

- Remove any dirt, debris, or grease buildup from the wrench using a soft brush or cloth. Pay particular attention to the moving parts and the head of the wrench where the sockets attach.

- If necessary, use a mild detergent or solvent to remove stubborn stains or grime. Be sure to check the manufacturer’s instructions for any specific cleaning recommendations.

- Dry the wrench thoroughly before storing or using it again to prevent rusting or corrosion.

Proper Lubrication

Lubrication is vital to ensure the smooth functioning of your ratchet wrench. Follow these guidelines for proper lubrication:

- Check the manufacturer’s recommendations for the type of lubricant to use.

- Apply a small amount of lubricant to the moving parts of the wrench, such as the ratchet mechanism and pivot points. Avoid over-lubricating, as this can attract dust and debris.

- After applying the lubricant, work the wrench back and forth several times to distribute the lubricant evenly and ensure smooth operation.

Inspecting for Damage

Regularly inspecting your ratchet wrench for any signs of damage is important to prevent accidents and ensure safe operation. Here’s what to look out for:

- Check the handle for any cracks, splintering, or excessive wear. If any damage is found, it is best to replace the handle.

- Inspect the ratchet mechanism for any signs of wear, such as skipping or slipping. If the ratchet is not functioning properly, it may need to be repaired or replaced.

- Examine the sockets for any signs of damage or wear. If the sockets are worn or damaged, they should be replaced to ensure a secure fit and prevent accidents.

Storage

Proper storage of your ratchet wrench can prolong its lifespan and prevent damage. Consider the following storage tips:

- Store your ratchet wrench in a clean, dry place away from moisture and extreme temperatures.

- Use a toolbox or storage case specifically designed for wrenches to protect them from dust and impacts.

- Keep the wrench in a position where it will not be knocked or jostled, which can cause damage to the ratchet mechanism.

- Store the wrench with the handle in the closed position to prevent accidental engagement of the ratchet.

Regular Maintenance Schedule

Creating a regular maintenance schedule for your ratchet wrench can ensure that it is always in optimal condition. Consider the following maintenance tasks:

- Clean and inspect your ratchet wrench after each use.

- Lubricate the wrench as needed, following the manufacturer’s recommendations.

- Perform a more thorough inspection and cleaning at least once a year or more frequently for heavy use.

- Replace any worn or damaged parts promptly.

By following these maintenance guidelines, you can keep your ratchet wrench in excellent working condition for years to come.

Frequently Asked Questions about Ratchet Wrenches

1. What is a ratchet wrench?

A ratchet wrench, also known as a socket wrench or ratchet, is a hand tool used for tightening or loosening nuts and bolts. It features a handle and a socket attachment that fits over the fastener. The unique design allows for continuous rotation in one direction while preventing backward movement.

2. How does a ratchet wrench work?

A ratchet wrench works by utilizing a gear and pawl mechanism. The handle contains a gear with sloping teeth, while the socket attachment has a pawl or small lever. When you rotate the handle in one direction, the pawl engages with the gear teeth, allowing the socket to turn. However, when you rotate the handle in the opposite direction, the pawl disengages, allowing the handle to rotate freely without turning the socket.

3. What are the advantages of using a ratchet wrench?

- Versatility: Ratchet wrenches come in various sizes and can accommodate different socket attachments, making them versatile for various applications.

- Efficiency: The ratchet mechanism allows for quick and continuous rotation, making tasks faster and easier.

- Torque control: Ratchet wrenches often have a built-in torque control feature, allowing you to apply the right amount of force without overtightening.

- Compact design: Ratchet wrenches are compact and lightweight, making them easy to carry and store.

4. How do I choose the right ratchet wrench size?

The size of the ratchet wrench corresponds to the size of the socket attachment. To choose the right size, match the wrench size to the size of the nuts or bolts you commonly work with. Most ratchet wrench sets come with a range of sizes, providing flexibility for different applications.

5. Can I use a ratchet wrench for all types of fasteners?

Ratchet wrenches are suitable for most types of fasteners, including hexagonal, square, and even some rounded fasteners. However, certain specialty fasteners may require specialized tools.

6. How do I maintain and care for a ratchet wrench?

- Clean regularly: Remove dirt, debris, and grease from the ratchet wrench after use to prevent buildup.

- Keep lubricated: Apply a small amount of lubricating oil to the moving parts to ensure smooth operation.

- Store properly: Keep the ratchet wrench in a dry and clean environment to prevent rusting and damage. Consider using a tool chest or a dedicated storage case.

- Inspect for wear: Regularly inspect the gears, teeth, and pawl for any signs of wear or damage. Replace any worn or damaged parts as needed.

7. Can I use a ratchet wrench as a replacement for a torque wrench?

While ratchet wrenches are designed to provide a certain level of torque control, they are not as precise as torque wrenches. For critical applications that require precise torque settings, it is recommended to use a torque wrench.

8. Are ratchet wrenches only used by professionals?

No, ratchet wrenches are commonly used by both professionals and DIY enthusiasts. They are versatile tools that can be used in various industries, including automotive, construction, and maintenance.

9. Can I use a ratchet wrench in tight spaces?

Yes, ratchet wrenches are particularly useful in tight spaces where a regular wrench may not fit. The compact design and the ability to rotate the handle without turning the socket backward allows for efficient use in confined areas.

10. Can I use a ratchet wrench with an extension?

Yes, ratchet wrenches can be used with extensions to reach fasteners located in deeper or hard-to-reach areas. Extensions come in various lengths and can be easily attached between the ratchet wrench handle and the socket attachment.

FAQ

What is a ratchet wrench?

A ratchet wrench is a type of hand tool used to tighten or loosen nuts and bolts. It consists of a handle, a ratchet mechanism, and a socket or a bit at the end.

How does a ratchet wrench work?

A ratchet wrench works by utilizing a ratchet mechanism, which allows the tool to turn in only one direction while the handle is moved back and forth. This mechanism consists of a gear with sloping teeth and a pawl that engages with the teeth. When the handle is moved in one direction, the pawl allows the gear to rotate freely, but when the handle is moved in the opposite direction, the pawl engages with the gear, causing it to turn.

What are the advantages of using a ratchet wrench?

Using a ratchet wrench offers several advantages. Firstly, it allows for easier and more efficient tightening or loosening of nuts and bolts compared to traditional wrenches. Secondly, the ratchet mechanism enables continuous rotation without the need to reposition the wrench, which saves time and effort. Thirdly, the handle of a ratchet wrench is usually longer than that of a regular wrench, providing greater leverage for tightening or loosening stubborn fasteners.

Can a ratchet wrench be used in tight spaces?

Yes, a ratchet wrench can be used in tight spaces. The compact size of the ratchet mechanism allows for usage in confined areas where a regular wrench may not fit. Additionally, the ability of the ratchet wrench to rotate continuously in one direction without the need to reposition it makes it especially useful in tight spaces where there is limited room for movement.

Are ratchet wrenches available in different sizes?

Yes, ratchet wrenches are available in different sizes to accommodate various nuts and bolts. The size of a ratchet wrench refers to the size of the socket or bit at the end of the tool. Common sizes range from as small as 1/4 inch to as large as 1 inch, and there are also metric sizes available for international use.

Can a ratchet wrench be used for other tasks besides tightening or loosening nuts and bolts?

Yes, a ratchet wrench can be used for various tasks besides tightening or loosening nuts and bolts. With the appropriate socket or bit, it can be used for tasks such as assembling furniture, tightening bicycle pedals, or working on small engines. The versatility of the ratchet wrench makes it a valuable tool for both professional mechanics and DIY enthusiasts.