How Does a Crowfoot Wrench Work: All You Need to Know

When it comes to working on tight spaces, a crowfoot wrench can be a handy tool in your toolbox. This unique wrench design allows you to access nuts and bolts in areas where a regular wrench or socket simply won’t fit. But how exactly does a crowfoot wrench work?

A crowfoot wrench is a specialized tool that features a “crowfoot” shape at one end. This crowfoot shape resembles a crow’s foot, hence the name. The crowfoot shape consists of multiple curved jaws that can grip onto a nut or bolt head.

To use a crowfoot wrench, you first need to attach it to a ratchet or a breaker bar. The open end of the wrench fits onto the ratchet or breaker bar, allowing you to apply torque to the nut or bolt. The crowfoot end of the wrench is then placed onto the nut or bolt head, similar to how you would use a regular socket.

One key advantage of a crowfoot wrench is its ability to reach nuts and bolts in tight spaces. The crowfoot design allows for access from a side angle, as opposed to inline like a regular socket. This can be especially useful when working in engine bays, under car dashboards, or any other cramped areas where access is limited.

What is a Crowfoot Wrench?

A crowfoot wrench is a type of wrench that is used for tightening or loosening nuts and bolts in hard-to-reach areas. It is designed to be used with a ratchet or a torque wrench, allowing for increased torque and control when working in tight spaces.

The crowfoot wrench gets its name from its distinctive shape, which resembles a crow’s foot. It typically has a thick, Y-shaped body with three or more arms or prongs extending from the center. Each arm is usually equipped with a socket of a specific size to fit different types of nuts or bolts.

One of the main advantages of a crowfoot wrench is its ability to access nuts and bolts in tight spaces where a traditional wrench would not fit. The design of the crowfoot wrench allows it to be positioned perpendicular to the nut or bolt, providing easier access and better leverage than a standard wrench.

Another advantage of a crowfoot wrench is its versatility. It can be used with a ratchet or a torque wrench, allowing for various applications. The crowfoot wrench can be attached to the ratchet or torque wrench using a drive square, typically 1/2 inch or 3/8 inch in size.

Crowfoot wrenches are commonly used in automotive and industrial applications where access to tight spaces is necessary. They are especially useful for working on engines, plumbing fixtures, and other hard-to-reach areas.

The Anatomy of a Crowfoot Wrench

A crowfoot wrench is a versatile tool that is used for tightening or loosening nuts and bolts in hard-to-reach places. It is specifically designed for use with a ratchet or torque wrench, giving you extra leverage and flexibility in tight spaces. Understanding the anatomy of a crowfoot wrench will help you make the most of this handy tool.

1. Head

The head of a crowfoot wrench is the part that attaches to the ratchet or torque wrench. It is typically square or hexagonal in shape, allowing it to fit securely into the corresponding socket of the wrench. This connection ensures that the tool can withstand the high amounts of torque applied during use.

2. Drive

The drive of a crowfoot wrench refers to the size of the square or hexagonal opening on the head. This determines the size of the ratchet or torque wrench that can be used with the crowfoot wrench. Common drive sizes for crowfoot wrenches include 3/8 inch, 1/2 inch, and 3/4 inch.

3. Socket Size

The socket size of a crowfoot wrench refers to the size of the opening on the opposite end of the head. This is where the crowfoot wrench attaches to the nut or bolt being tightened or loosened. Crowfoot wrenches come in a variety of socket sizes to accommodate different fastener sizes, ranging from small sizes like 8mm up to larger sizes like 32mm.

4. Handle

Unlike traditional wrenches, crowfoot wrenches do not have a handle. Instead, they are designed to be used with a ratchet or torque wrench. The handle of the ratchet or torque wrench provides the leverage and control needed to turn the crowfoot wrench and apply the necessary force to tighten or loosen the nut or bolt. This design allows for greater maneuverability in tight spaces where a traditional wrench handle may not fit.

5. Material

Crowfoot wrenches are typically made from durable materials such as chrome vanadium steel or alloy steel. These materials are known for their strength, resistance to wear and tear, and ability to withstand high amounts of torque. The use of high-quality materials ensures that the crowfoot wrench will be reliable and long-lasting.

6. Use with Ratchet or Torque Wrench

To use a crowfoot wrench, it is necessary to have a ratchet or torque wrench with the corresponding drive size. The ratchet or torque wrench is inserted into the head of the crowfoot wrench and locked into place. The handle of the ratchet or torque wrench is then used to turn the crowfoot wrench and apply the necessary force to tighten or loosen the nut or bolt.

Overall, the crowfoot wrench is a valuable tool for any DIY enthusiast or professional mechanic. Its unique design allows for increased access and maneuverability in tight spaces, making it an essential addition to any toolbox.

How Does a Crowfoot Wrench Grip?

A crowfoot wrench is a special type of open-end wrench that is designed to grip fasteners in tight spaces. It is commonly used in automotive and mechanical applications where a regular wrench or socket cannot fit.

The grip of a crowfoot wrench is achieved through its unique design. It features a rounded opening with a series of teeth or grooves along its inner surface. These teeth or grooves are designed to match the shape and size of the fastener being worked on.

When the crowfoot wrench is placed onto the fastener, the teeth or grooves on the wrench’s inner surface provide multiple points of contact. This allows the wrench to grip the fastener securely from multiple angles, providing a firm hold and reducing the risk of slipping or rounding off the edges of the fastener.

Additionally, crowfoot wrenches are often equipped with a locking mechanism to ensure that the wrench remains securely attached to the fastener during use. This can be a spring-loaded ball bearing that engages with corresponding detents on the wrench or a separate locking mechanism that holds the wrench in place when pressure is applied.

Overall, the grip of a crowfoot wrench is essential for effectively applying torque to fasteners in tight spaces. It allows mechanics and technicians to access and work on hard-to-reach areas while maintaining a strong and stable connection to the fastener.

How to Use a Crowfoot Wrench

Using a crowfoot wrench is fairly simple and straightforward. Here are the basic steps to follow when using a crowfoot wrench:

- Step 1: Identify the size of the nut or bolt that you need to loosen or tighten. This will determine the size of the crowfoot wrench that you will need.

- Step 2: Attach the crowfoot wrench to a ratchet or extension bar. The wrench will have a square drive hole that fits onto the square drive of the ratchet or extension bar.

- Step 3: Place the crowfoot wrench onto the nut or bolt and ensure that it is securely seated. Make sure that the wrench is aligned properly with the nut or bolt to avoid slippage.

- Step 4: Begin turning the wrench in the desired direction to either loosen or tighten the nut or bolt. You can use the ratchet or extension bar for added leverage if needed.

- Step 5: Continue turning the wrench until the nut or bolt is loosened or tightened to the desired level.

- Step 6: Once you have finished using the crowfoot wrench, remove it from the ratchet or extension bar and store it in a safe place.

It’s important to note that crowfoot wrenches are typically used in conjunction with a ratchet or extension bar, as they do not have a handle of their own. This allows for greater reach and flexibility in tight spaces where a regular wrench may not fit.

Additionally, it’s essential to choose the right size crowfoot wrench for the job to ensure a proper fit and avoid damaging the nut or bolt. Always refer to the manufacturer’s guidelines or consult a professional if you are unsure.

Overall, with the right technique and proper use, a crowfoot wrench can be a versatile tool in your toolbox, making it easier to tackle a variety of tasks that require loosening or tightening nuts and bolts in tight or hard-to-reach spaces.

When to Use a Crowfoot Wrench

A crowfoot wrench is a specialized tool that is often used in situations where a standard wrench or socket cannot be used due to space limitations. The unique design of the crowfoot wrench allows it to be used in tight spaces where traditional wrenches cannot reach.

There are several situations where a crowfoot wrench can come in handy:

Tight or Confined Spaces

In tight or confined spaces where there is limited clearance, a crowfoot wrench can be used to reach bolts or nuts that are difficult to access with other tools. The thin profile of the crowfoot wrench head allows it to fit into small spaces and still provide enough torque to loosen or tighten fasteners.

Pipes or Tubes

Crowfoot wrenches are often used in plumbing or automotive applications where there are pipes or tubes in the way. The open-end design of the crowfoot wrench allows it to fit over pipes or tubes, providing a secure grip on the fastener without damaging the surrounding components.

Flare Nut Fittings

Crowfoot wrenches are commonly used to tighten or loosen flare nut fittings, which are commonly found in hydraulic systems or other applications that require a secure connection. The crowfoot wrench’s unique design allows it to grip the flare nut fitting without slipping, ensuring a tight and leak-free connection.

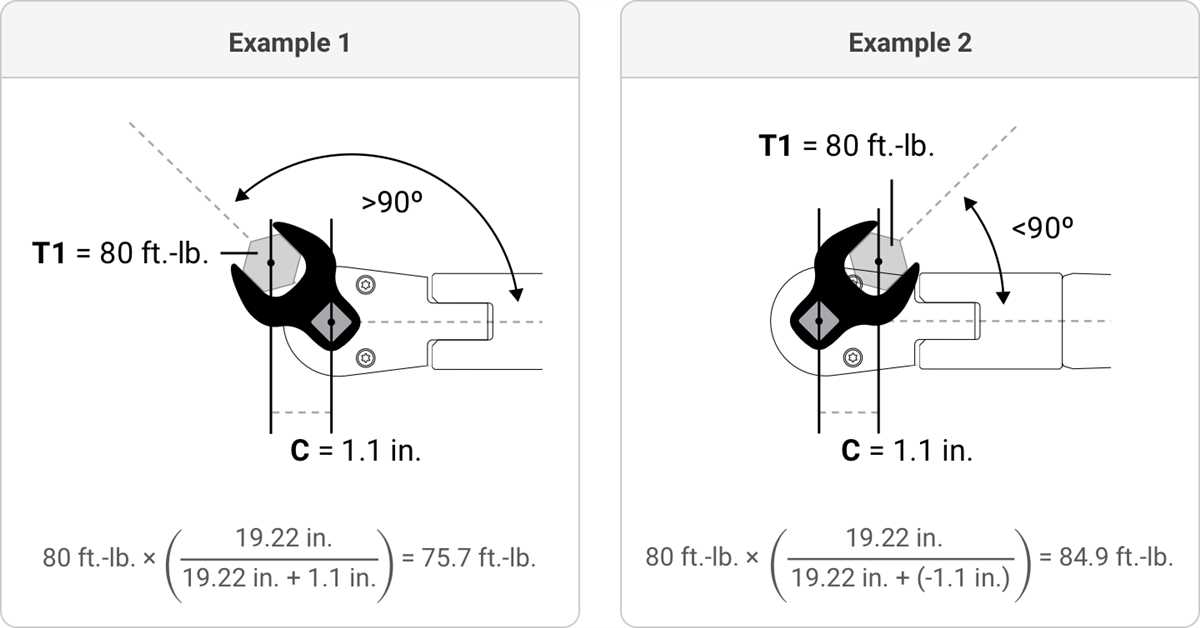

Torque Accuracy

Crowfoot wrenches are often used in situations where precise torque is required. The open-end design of the crowfoot wrench allows it to be used in conjunction with a torque wrench, ensuring that the correct amount of torque is applied to the fastener.

Specialized Applications

There are also specialized crowfoot wrenches available for specific applications, such as aircraft maintenance or heavy machinery repair. These wrenches are designed to fit unique fasteners or provide added leverage in demanding situations.

Overall, a crowfoot wrench is a versatile tool that can be used in a variety of situations where a traditional wrench or socket cannot be used. Whether you are working in tight spaces, dealing with pipes or tubes, or require precise torque, a crowfoot wrench can help you get the job done efficiently and effectively.

Benefits of Using a Crowfoot Wrench

A crowfoot wrench is a versatile tool that offers several benefits in various applications. Here are some advantages of using a crowfoot wrench:

- Accessible Tight Spaces: One of the main advantages of a crowfoot wrench is its ability to access tight spaces that are difficult to reach with traditional wrenches. The design of the crowfoot wrench allows it to fit in confined areas where a regular wrench cannot fit, making it a valuable tool for narrow or hard-to-reach areas.

- Increased Torque: The crowfoot wrench is designed to be used with a ratchet or breaker bar, providing additional leverage and torque. This allows for more power and turning force to be applied to stubborn or rusted bolts and nuts. The increased torque provided by the crowfoot wrench makes it easier to loosen or tighten fasteners.

- Versatility: A crowfoot wrench can be used as an alternative to a socket wrench. It can be used with a variety of socket drivers, extension bars, or universal joints, making it a versatile tool for different applications. This versatility makes the crowfoot wrench a valuable addition to any toolkit.

- Improved Accuracy: The size and shape of the crowfoot wrench allow for better precision and accuracy when working in confined spaces. Its design prevents slippage and provides a secure grip on the fastener, reducing the risk of rounding or stripping the bolt or nut. This increased accuracy can help prevent damage to the fastener and surrounding components.

- Time-Saving: Using a crowfoot wrench can save time by eliminating the need to disassemble parts or remove obstacles to access fasteners. Its compact design and ability to reach tight spaces allow for quicker and more efficient work, especially in automotive and mechanical applications.

- Cost-Effective: Crowfoot wrenches offer a cost-effective solution compared to other specialty wrenches or tools designed for specific applications. With a crowfoot wrench, you can perform a wide range of tasks without the need for multiple tools, saving both space and money.

Overall, the benefits of using a crowfoot wrench make it a valuable tool for any DIY enthusiast or professional mechanic. Its unique design, versatility, and ability to access tight spaces provide numerous advantages in various applications.

Drawbacks of Using a Crowfoot Wrench

While crowfoot wrenches are versatile and useful tools, they do come with a few drawbacks that users should be aware of. These drawbacks include:

- Limited Accessibility: Due to their design, crowfoot wrenches are not suitable for use in tight spaces or areas with limited access. The open end of the wrench requires enough clearance to fit over the fastener, which can be a problem in cramped engine compartments or other confined areas.

- Limited Torque: Crowfoot wrenches are not intended for heavy-duty applications that require high torque. The open-end design can lead to slippage and reduced torque capabilities compared to a standard wrench or socket. For tasks that require significant force, it is better to use a different type of wrench.

- Compatibility Issues: Crowfoot wrenches come in various sizes and shapes, which means they may not be compatible with all fasteners. It is essential to have the correct size and shape of crowfoot wrench to ensure a proper fit and prevent damage to the fastener or the wrench itself.

- Less Control: The design of a crowfoot wrench does not provide the same level of control as a regular wrench or socket. The open end of the wrench can slip off the fastener easily, especially if there is any lateral force or movement. This can make it challenging to apply precise or consistent pressure.

- Cost: Compared to other types of wrenches or sockets, crowfoot wrenches may be more expensive. This is due to their specialized design and the fact that they are not as commonly used or manufactured in high quantities. It is important to consider the cost versus the need for a crowfoot wrench before making a purchase.

Despite these drawbacks, crowfoot wrenches have their place in various industries and applications. They are often used in automotive and aerospace settings, where they can provide access to hard-to-reach areas and facilitate specific tasks. However, it is important to weigh the advantages and disadvantages before deciding to use a crowfoot wrench for a particular job.

Tips for Maintaining a Crowfoot Wrench

Proper maintenance of your crowfoot wrench is essential for its longevity and optimal performance. Here are some tips to keep in mind:

1. Regular Cleaning

After each use, make it a habit to clean your crowfoot wrench. Wipe off any dirt, grease, or residue using a clean cloth or brush. This will prevent the accumulation of debris that can affect the tool’s functionality.

2. Lubrication

Apply a light coat of lubricant to the crowfoot wrench regularly. This helps to reduce friction and ensures smooth operation. Use a lubricant that is suitable for your specific wrench’s material to avoid any damage.

3. Inspection

Inspect the crowfoot wrench before each use to ensure that there are no signs of wear, damage, or rust. Check the teeth for any chips or deformities, and make sure the wrench is not bent or misaligned. Using a damaged wrench can lead to accidents and ineffective performance.

4. Storage

Store your crowfoot wrench in a dry and clean place. Moisture can cause rust and corrosion, so it’s important to keep the tool protected. Use a toolbox or a designated storage area to prevent any dirt or debris from accumulating on the wrench.

5. Avoid Overloading

Avoid using excessive force or overloading the crowfoot wrench beyond its recommended capacity. This can cause the wrench to break or fail, leading to potential injuries. Always use the appropriate size and type of wrench for the job.

6. Regular Maintenance

Consider scheduling regular maintenance checks for your crowfoot wrench. This can include professional servicing to ensure that the tool is in optimal condition. This is especially important if you use the wrench frequently or in demanding conditions.

7. Safe Handling

Proper handling is crucial for both your safety and the longevity of the crowfoot wrench. Always hold the wrench securely and use it in a controlled manner. Avoid mishandling or using the wrench for purposes it is not designed for.

By following these maintenance tips, you can extend the life of your crowfoot wrench and ensure that it continues to perform accurately and reliably for your various projects.

FAQ

What is a crowfoot wrench?

A crowfoot wrench is a type of wrench that has a hexagonal or square-shaped socket on one end and a fitting for attaching a handle or ratchet on the other end. It is designed to be used in tight spaces where a regular wrench cannot fit.

How does a crowfoot wrench work?

A crowfoot wrench works by attaching it to a handle or ratchet, and then using it to tighten or loosen nuts and bolts. The wrench is placed over the nut or bolt, and the handle or ratchet is turned to apply torque. The crowfoot wrench is designed to allow access to fasteners in tight spaces that are difficult to reach with a regular wrench.

What are the advantages of using a crowfoot wrench?

There are several advantages of using a crowfoot wrench. Firstly, it allows you to access nuts and bolts in tight spaces where a regular wrench cannot fit. Secondly, it enables you to apply torque in a controlled manner, thanks to the use of a handle or ratchet. Lastly, it is versatile and can be used with different handle sizes and lengths.

Can a crowfoot wrench be used with any handle or ratchet?

Yes, a crowfoot wrench can be used with any handle or ratchet as long as they have compatible fittings. The wrench typically has a square or hexagonal opening on one end, which can fit onto the square or hexagonal drive of a handle or ratchet. It is important to ensure that the wrench and handle/ratchet are compatible in terms of size and shape.

Can a crowfoot wrench replace a regular wrench?

No, a crowfoot wrench cannot completely replace a regular wrench. While it is useful in tight spaces, it may not provide the same level of leverage as a regular wrench. Additionally, it may not be able to fit certain types of fasteners or provide enough torque for certain applications. It is best to have both a crowfoot wrench and a regular wrench in your toolset to cover a wide range of situations.

Are there any limitations to using a crowfoot wrench?

Yes, there are some limitations to using a crowfoot wrench. Firstly, it may not be able to provide as much torque as a regular wrench, especially if it is used with a short handle or ratchet. Secondly, it may not be able to fit certain types of fasteners, such as those with non-standard shapes or sizes. Lastly, it may require more effort to use in certain situations due to its design.

Video