How Does a Click Torque Wrench Work? | Discover the Mechanics Behind It

A click torque wrench is a tool commonly used in mechanical work to tighten fasteners to a specific torque setting. This type of wrench relies on a mechanical mechanism to apply torque to a bolt or nut. Understanding how this tool functions can help ensure that fasteners are properly tightened and prevent damage or failure due to under or over-tightening.

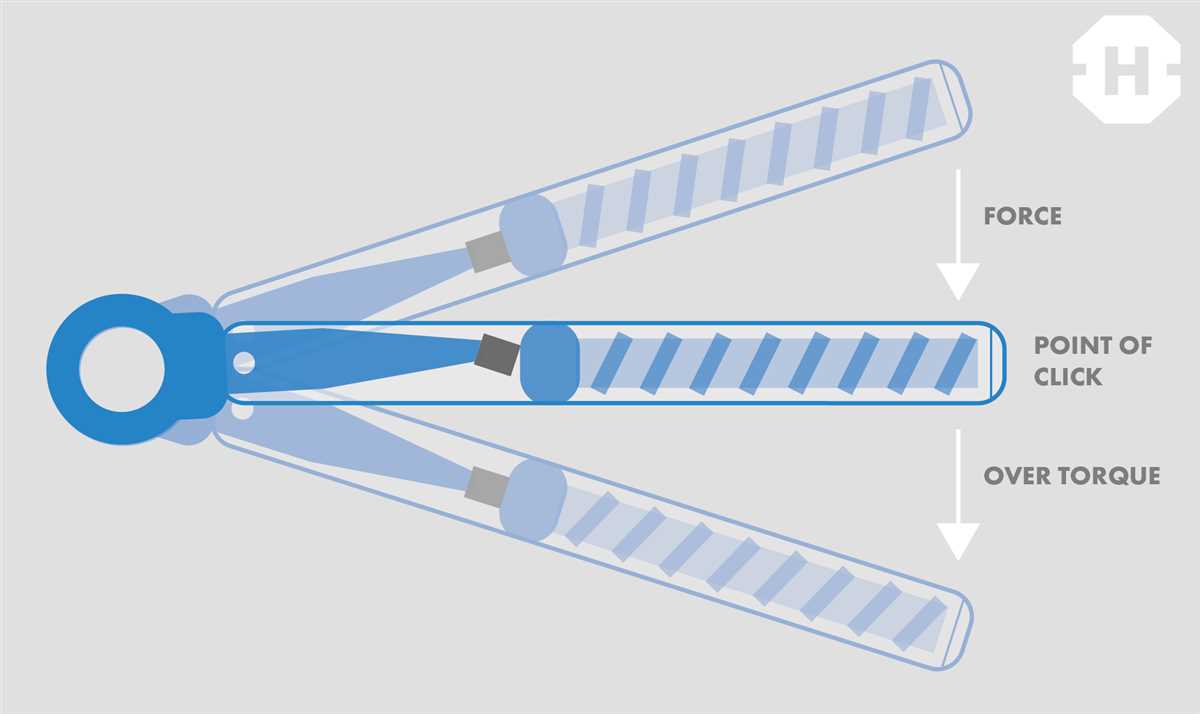

The key component of a click torque wrench is the internal mechanism that allows it to “click” when the desired torque setting is reached. This mechanism, often referred to as a “clicker,” is typically housed within the handle of the wrench. When torque is applied to the fastener, the clicker engages and releases a distinctive “click” sound, indicating that the desired torque has been reached.

To adjust the torque setting on a click torque wrench, a user can typically turn a handle or knob located on the end of the wrench. This adjusts the amount of pressure required to engage the clicker mechanism. Once the desired torque setting is selected, the wrench is ready for use.

When using a click torque wrench, it is important to apply force in a smooth and controlled manner. Fasteners should be tightened gradually and evenly, allowing the clicker mechanism to engage and release at the desired torque setting. This helps ensure that the fastener is properly tightened without being under or over-torqued.

It is worth noting that click torque wrenches can have different levels of accuracy and precision. Some models may have a tolerance of +/- a few percentage points, while others may be certified for more precise torque measurements. It is important to select a wrench that meets the specific needs of the job at hand and follow any manufacturer guidelines or specifications.

In summary, a click torque wrench is a valuable tool for achieving accurate and consistent torque settings. Its internal clicker mechanism provides an audible and tactile feedback, allowing users to tighten fasteners to the desired torque. By understanding the mechanics behind this tool and using it correctly, mechanics and DIY enthusiasts can confidently tighten fasteners without risking damage or failure.

Understanding Click Torque Wrenches and Their Functionality

A click torque wrench is a specialized tool used to accurately measure and apply torque or rotational force to fasteners such as nuts and bolts. It operates based on the principle of torque, which is the measure of the force applied to rotate an object around an axis.

How Does a Click Torque Wrench Work?

A click torque wrench typically consists of a handle, a shaft, and a head. The head contains a ratcheting mechanism that allows for the tightening or loosening of fasteners. The handle usually has a grip for comfortable use and a scale that indicates the applied torque.

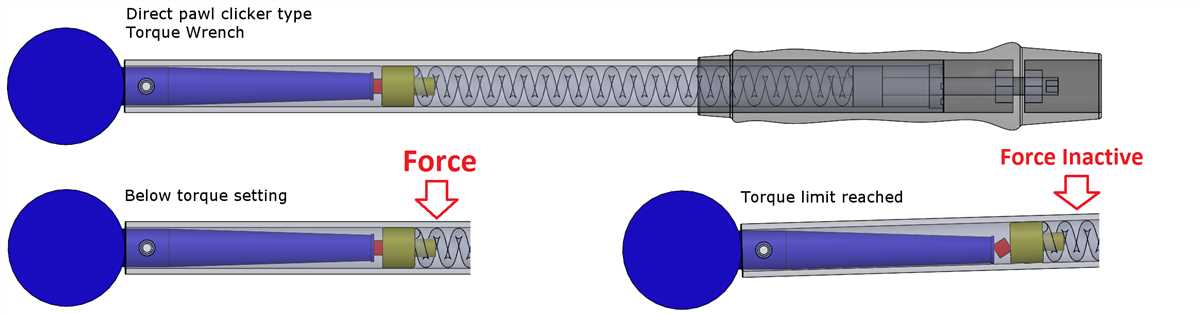

The functionality of a click torque wrench lies in its internal mechanism, which allows for controlled torque application and alerts the user when the desired torque is reached. When using the wrench, the user sets the desired torque by adjusting the scale on the handle.

As the user applies force to rotate the fastener, the click torque wrench measures the torque being exerted. Once the desired torque is reached, the internal mechanism triggers a “click” sound or a tactile feedback, indicating to the user that the correct torque has been achieved.

Advantages of Click Torque Wrenches

Click torque wrenches offer several advantages compared to other types of torque wrenches:

- Precision: Click torque wrenches provide precise torque measurements, ensuring that fasteners are tightened to the specified torque value.

- Consistency: The audible or tactile click feedback of click torque wrenches helps to achieve consistent torque application across multiple fasteners.

- Reliability: The click mechanism eliminates the need for guesswork or estimation, resulting in reliable and repeatable torque applications.

- Safety: Click torque wrenches help prevent overtightening of fasteners, which can lead to thread damage, component failure, or potential safety hazards.

Applications of Click Torque Wrenches

Click torque wrenches are commonly used in various industries and applications, including:

- Automotive maintenance and repair

- Aerospace and aviation

- Heavy machinery and equipment

- Industrial manufacturing

- Construction

These wrenches are especially useful when precise torque values are required to ensure proper assembly, prevent mechanical failures, and maintain safety standards.

Conclusion

Click torque wrenches are essential tools for achieving accurate and controlled torque application. By understanding the functionality of these wrenches, users can effectively tighten fasteners to the recommended torque values, ensuring optimal performance and safety in various industries.

Exploring the Mechanics of Click Torque Wrench

A click torque wrench is a handy tool used to tighten bolts and nuts to a specific torque value. It is commonly used in various industries such as automotive, construction, and manufacturing. To understand how a click torque wrench works, let’s delve into its mechanics.

1. Click Mechanism

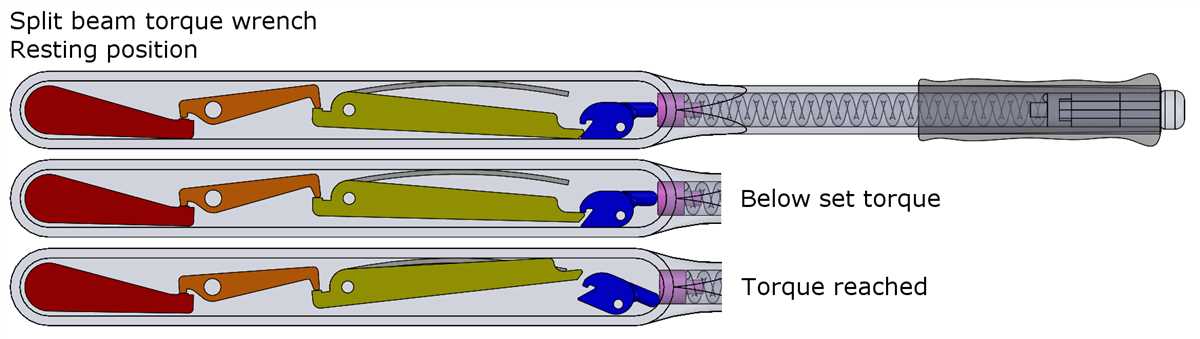

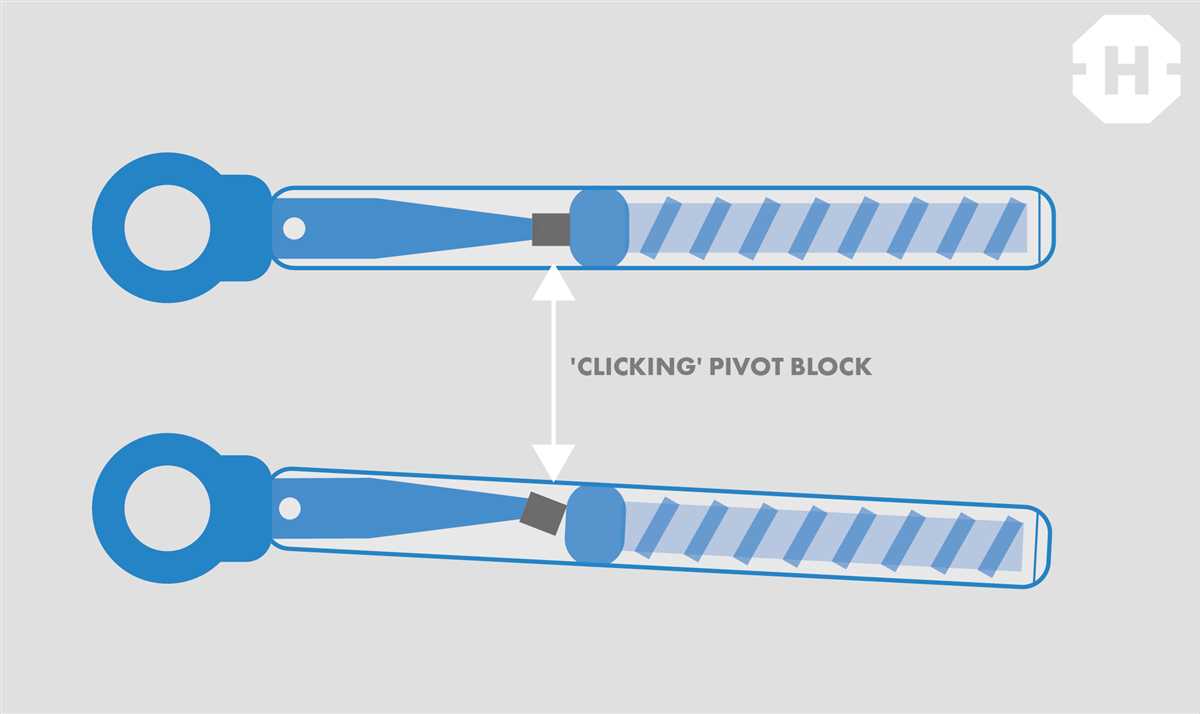

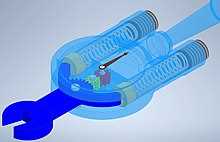

The click mechanism is the heart of a click torque wrench. It ensures that the desired torque value is achieved and prevents over-tightening. When the preset torque value is reached, the click mechanism clicks or releases, indicating that the desired torque has been achieved.

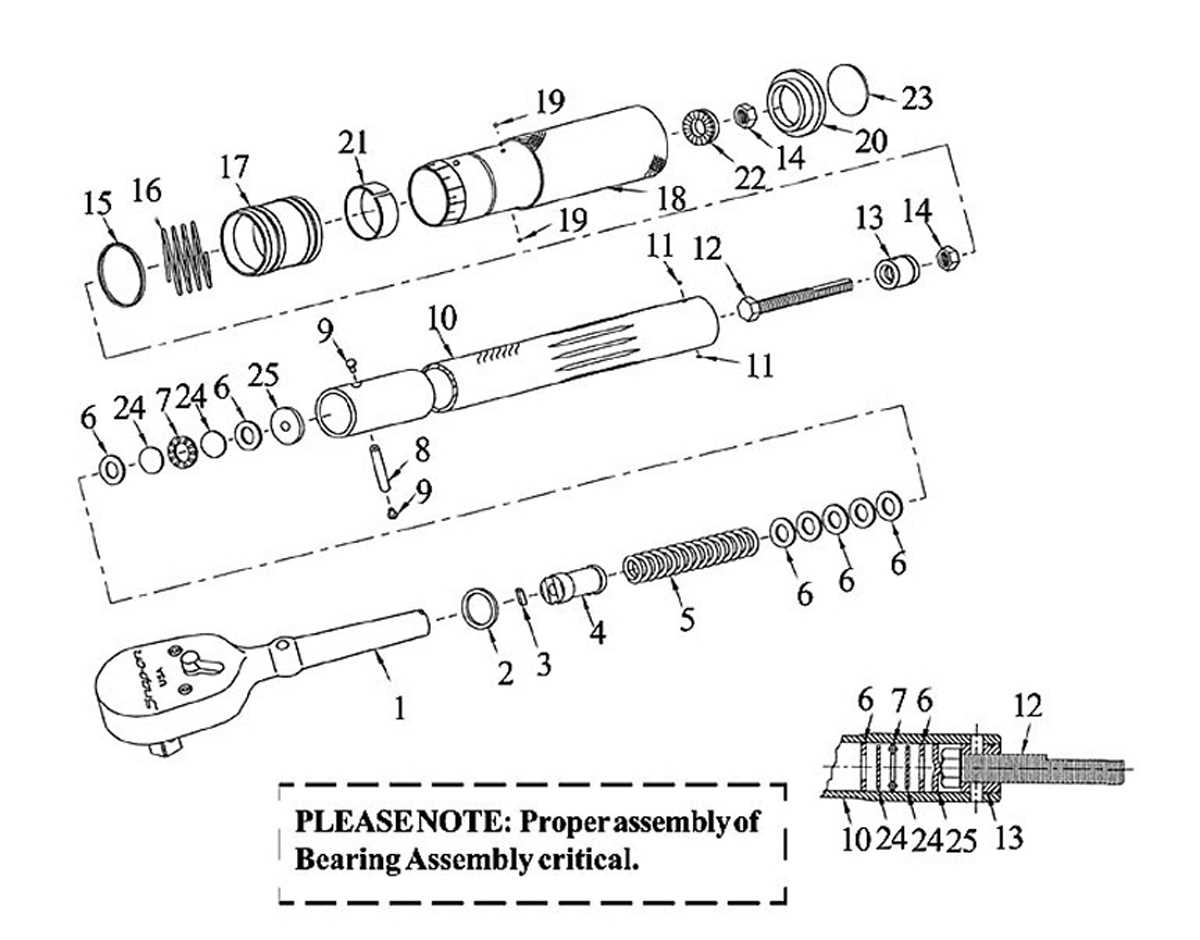

2. Internal Components

A click torque wrench is comprised of several internal components that work together to provide accurate torque measurements:

- Tension Spring: The tension spring provides the necessary tension to keep the internal components in place.

- Ratchet Mechanism: The ratchet mechanism allows for both clockwise and counterclockwise rotation, making the wrench versatile.

- Cam Over Mechanism: The cam over mechanism ensures that the desired torque value is achieved by applying a fixed amount of force.

- Click Pawl: The click pawl engages with the ratchet mechanism and produces an audible click when the desired torque value is reached.

3. Torque Adjustment

A click torque wrench typically has an adjustable knob or dial that allows the user to set the desired torque value. This adjustment is done by rotating the knob clockwise or counterclockwise to increase or decrease the torque setting.

4. Torque Application

To apply torque using a click torque wrench, follow these steps:

- Select the appropriate socket or attachment for the bolt or nut you want to tighten.

- Attach the socket or attachment to the click torque wrench.

- Set the desired torque value using the adjustable knob or dial.

- Place the socket or attachment onto the bolt or nut.

- Apply force to the click torque wrench handle in a clockwise or counterclockwise direction until you hear and feel the click.

5. Maintenance

Proper maintenance of a click torque wrench is essential to ensure its accuracy and longevity. Here are some maintenance tips:

- Regularly clean the wrench and keep it free from debris or dirt.

- Store the wrench in a dry and safe place to prevent damage.

- Follow the manufacturer’s instructions for calibration and periodic recalibration.

Understanding the mechanics of a click torque wrench is crucial for using it correctly and effectively. By knowing how it works, you can ensure that bolts and nuts are tightened to the appropriate torque, avoiding potential issues caused by under or over-tightening.

Importance of Torque Calibration in Click Torque Wrenches

Calibration is a critical aspect when it comes to click torque wrenches. It refers to the process of checking and adjusting the accuracy of a torque wrench to ensure that it is providing the correct torque measurement. Proper calibration is essential for the reliable and accurate performance of click torque wrenches, and here are several reasons why it is important:

1. Accuracy and Precision:

Calibration ensures that the click torque wrench provides accurate and precise torque measurements. Over time, a torque wrench can experience wear and tear, affecting its accuracy. Calibration helps identify any discrepancies in the torque readings and allows for adjustments to be made to ensure precise torque application.

2. Safety:

Using a click torque wrench that is not properly calibrated can result in under or over-tightened fasteners. Under-tightening can lead to loose connections and potential equipment failure, while over-tightening can cause damage to the fastener or the equipment. By calibrating the torque wrench, the risk of these safety issues is significantly reduced.

3. Compliance with Standards and Specifications:

Many industries have specific standards and specifications for torque requirements. Calibrating click torque wrenches ensures that they meet the required standards and specifications, allowing for compliance with industry regulations. This is particularly important in fields like automotive, aerospace, and manufacturing, where precise torque application is critical for product performance and safety.

4. Longevity of the Torque Wrench:

Regular calibration helps prolong the life of a click torque wrench. By identifying and addressing any issues with accuracy, calibration prevents further damage or deterioration of the wrench. It allows for timely maintenance and adjustments, reducing the risk of premature failure and the need for costly replacements.

5. Quality Control:

Calibration plays a crucial role in quality control processes. It helps ensure that the torque applied to fasteners during assembly or manufacturing is consistent and within the specified range. This consistency is vital for maintaining product quality, preventing failures, and minimizing warranty claims.

6. Traceability and Documentation:

Calibration provides traceability and documentation of torque measurements. This information is necessary for quality audits, compliance checks, and warranty claims. Properly calibrated click torque wrenches contribute to accurate record-keeping and enable manufacturers to demonstrate their commitment to quality and precision in their processes.

Conclusion:

Torque calibration is a vital aspect of maintaining the functionality and reliability of click torque wrenches. It ensures accuracy, safety, compliance with standards, longevity of the wrench, quality control, and proper documentation. By regularly calibrating torque wrenches, professionals can optimize their tool performance and enhance overall work quality.

Different Types of Click Torque Wrenches

A click torque wrench is a precision tool used to apply a specific amount of torque to a fastener or bolt. There are several different types of click torque wrenches available, each with its own unique features and benefits. Here are the most common types:

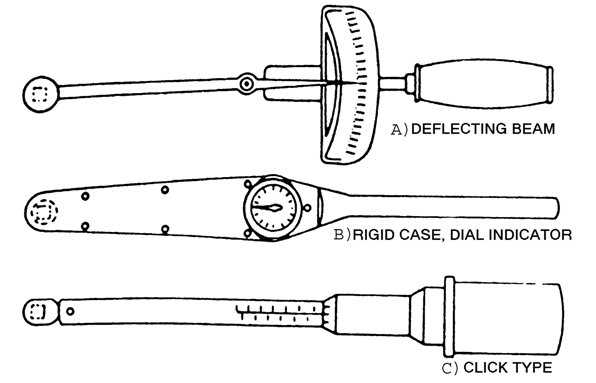

1. Beam Torque Wrenches

Beam torque wrenches are the simplest and most basic type of click torque wrench. They consist of a long lever arm with a scale that measures the torque being applied. The torque is indicated by a pointer on the scale. When the desired torque is reached, the wrench will click or release, indicating that the desired torque has been achieved.

2. Dial Torque Wrenches

Dial torque wrenches are similar to beam torque wrenches but have a dial instead of a scale. The dial displays the torque being applied, making it easier to read and more accurate than a beam torque wrench. Dial torque wrenches are commonly used in applications where precise and repeatable torque values are required.

3. Click-Type Torque Wrenches

Click-type torque wrenches, also known as ratcheting torque wrenches, are the most popular type of torque wrench. They have a ratcheting mechanism that allows the wrench to apply torque in one direction while allowing free movement in the other direction. Click-type torque wrenches emit an audible click when the desired torque is reached, indicating that the fastener is properly tightened.

4. Electronic Torque Wrenches

Electronic torque wrenches are the most advanced type of click torque wrench. They use electronic sensors to measure torque and display the readings on a digital screen. These wrenches often have additional features such as data logging, memory storage, and the ability to switch between different units of measurement. Electronic torque wrenches are commonly used in industries where accuracy and precision are critical.

5. Interchangeable Head Torque Wrenches

Interchangeable head torque wrenches allow for the use of different types and sizes of sockets or heads. They have a detachable head that can be easily replaced with a different size or type. With these wrenches, you can use a single tool for various fastening applications, reducing the need for multiple wrenches.

- Beam torque wrenches

- Dial torque wrenches

- Click-type torque wrenches

- Electronic torque wrenches

- Interchangeable head torque wrenches

Each type of click torque wrench has its own advantages and disadvantages, so it’s essential to choose the right one for your specific application needs. Consider factors such as accuracy, durability, ease of use, and cost when selecting a click torque wrench.

Step-by-Step Guide on How to Use a Click Torque Wrench

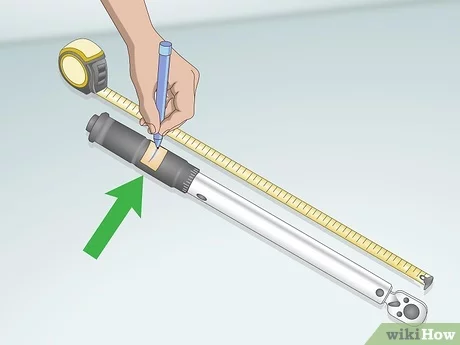

1. Set the Desired Torque Level

Before using a click torque wrench, you need to set the desired torque level. This can typically be done by adjusting the wrench’s handle or using a torque adjustment tool that is included with the wrench. Make sure to consult the manufacturer’s instructions for specific guidance on setting the torque level.

2. Prepare the Fastener

Before applying torque, ensure that the fastener and the tool are clean and free from any debris or dirt. This will help ensure proper torque measurement and prevent any damage to the fastener or the tool.

3. Attach the Wrench to the Fastener

Place the appropriate socket or driver attachment on the click torque wrench and secure it onto the fastener. Ensure that it is securely attached and aligned properly to prevent any slippage during the application of torque.

4. Apply Torque

Hold the handle of the click torque wrench firmly and apply force in a controlled manner. As you apply torque, you will hear a clicking sound or feel a small vibration. This indicates that the desired torque level has been reached.

5. Stop Applying Torque

Once the click sound or vibration is felt, stop applying torque. This is an important step to prevent over-tightening, which can lead to damage or failure of the fastener.

6. Store and Maintain the Wrench

After using the click torque wrench, ensure that it is properly stored in a clean and dry location. Regularly check and clean the tool to maintain its accuracy and performance. If necessary, follow the manufacturer’s recommendations for calibration or maintenance.

Additional Tips:

- Always use the appropriate size and type of socket or driver attachment for the fastener.

- Do not use the click torque wrench as a breaker bar or for loosening fasteners.

- Do not exceed the maximum torque capacity of the wrench.

- Consult the manufacturer’s instructions for any specific guidelines or precautions.

Common Applications of Click Torque Wrenches

Click torque wrenches are widely used in various industries and applications where precise torque control is essential. Here are some common applications where click torque wrenches are frequently used:

Automotive Industry

- Click torque wrenches are extensively used in the automotive industry for tasks such as tightening wheel lug nuts, cylinder head bolts, and other critical engine components.

- They ensure that each fastener is tightened to the manufacturer’s specified torque, preventing over or under tightening, which could lead to mechanical failures or damage.

Aerospace Industry

- In the aerospace industry, click torque wrenches play a crucial role in assembling aircraft components, such as engine mounts, landing gear, and control surfaces.

- They help maintain the structural integrity of aircraft by ensuring that the fasteners are tightened to precise torque values, ensuring proper alignment and load distribution.

Construction and Engineering

- Click torque wrenches find applications in construction and engineering for tasks like tightening bolts in structural steelwork, assembling heavy machinery, and installing pipelines.

- They help ensure proper joint integrity, preventing leaks, and ensuring the structural integrity of various constructions.

Maintenance and Repair

- Click torque wrenches are valuable tools for maintenance and repair tasks, whether it’s fixing bicycles, motorcycles, appliances, or industrial equipment.

- They enable technicians to tighten critical fasteners to the appropriate torque setting, ensuring the reliability and safety of the repaired equipment.

General DIY and Home Use

- Click torque wrenches are not limited to industrial applications and are also popular among DIY enthusiasts and homeowners.

- They are used for a variety of tasks, such as changing car oil filters, tightening nuts and bolts, and assembling furniture or other household items.

Overall, click torque wrenches are essential tools in various industries and applications where accurate torque control is necessary to ensure safety, reliability, and optimal performance.

Advantages and Limitations of Click Torque Wrenches

Advantages

- Precision: Click torque wrenches allow for precise torque application, ensuring that fasteners are tightened to the correct specifications. This helps prevent overtightening, which can damage components, as well as under-tightening, which can lead to loose connections and potential failure.

- Consistency: With a click torque wrench, you can consistently apply the same amount of torque to multiple fasteners, ensuring uniformity in the assembly process. This is particularly important in industries such as automotive and aerospace, where precise torque is critical for safety and performance.

- Audible and tactile feedback: Click torque wrenches provide a clear audible and tactile “click” when the set torque is reached, giving the operator immediate feedback that the desired torque has been achieved. This eliminates the need for guesswork or relying solely on visual indicators.

- Easy to use: Click torque wrenches are relatively easy to use, even for those without extensive technical knowledge or experience. The click mechanism simplifies the process by providing a clear stopping point, reducing the risk of overtightening or undertightening.

- Versatility: Click torque wrenches are available in various sizes and torque ranges, making them suitable for a wide range of applications. Whether you are working on small electronics or heavy machinery, there is likely a click torque wrench that will meet your needs.

Limitations

- One-directional tightening: Click torque wrenches are designed to tighten fasteners in one direction only. They may not be suitable for applications that require alternating or back-and-forth tightening.

- Accuracy may vary: The accuracy of click torque wrenches can vary depending on factors such as the quality of the wrench and the operator’s technique. Regular calibration and proper use are essential for maintaining accurate torque application.

- Not ideal for non-rigid fasteners: Click torque wrenches are most effective when used on rigid fasteners, such as bolts and nuts. They may not provide accurate results when used on non-rigid fasteners, such as screws or plastic components.

- Higher cost: Click torque wrenches tend to be more expensive compared to other types of torque wrenches. However, the precision and reliability they offer often justify the higher cost, especially in industries where accuracy is crucial.

- Requires periodic maintenance: Click torque wrenches require regular maintenance, including calibration and lubrication, to ensure accurate torque application. Neglecting maintenance can result in decreased performance and reliability.

Maintenance and Care Tips for Click Torque Wrenches

Clean the Wrench

After each use, it is important to clean the click torque wrench to remove any dirt, grime, or debris that may have accumulated. Use a soft cloth or brush to wipe down the wrench, paying special attention to the moving parts and the click mechanism.

Store Properly

When not in use, it is essential to store the click torque wrench properly to prevent damage. Store it in a dry and clean environment, preferably in a protective case or pouch to protect it from dust, moisture, and other potential hazards. Avoid storing the wrench in a position where it can be easily bumped or knocked over.

Check for Damage

Before each use, inspect the click torque wrench for any signs of damage or wear. Check the handle, ratchet head, and click mechanism for any cracks, dents, or loose parts. If any damage is found, do not use the wrench and have it repaired or replaced by a professional.

Calibration

Regular calibration is essential to ensure the accuracy of a click torque wrench. Follow the manufacturer’s guidelines for calibration intervals and have the wrench calibrated by a certified technician. Proper calibration will ensure that the wrench is providing accurate torque readings.

Avoid Overloading

Do not exceed the maximum torque capacity of the click torque wrench. Overloading the wrench can lead to inaccurate torque readings and potential damage to the tool. Always check the torque specifications for the fasteners being tightened and select the appropriate torque setting on the wrench.

Avoid Using as a Breaker Bar

Avoid using the click torque wrench as a breaker bar or for loosening tight fasteners. The wrench is specifically designed for tightening fasteners to a specific torque value and using it as a breaker bar can cause damage to the click mechanism and compromise its accuracy.

Regular Lubrication

Apply a small amount of lubricant to the moving parts of the click torque wrench, such as the ratchet head and the click mechanism. This will help to keep the parts operating smoothly and prevent excessive wear. Be sure to use a lubricant that is compatible with the materials used in the wrench.

Follow Proper Torque Procedures

Always follow the manufacturer’s recommended torque procedures when using the click torque wrench. This includes ensuring proper alignment of the wrench with the fastener, applying torque steadily and evenly, and stopping when the click mechanism engages.

Professional Inspection and Maintenance

Periodically, it is a good idea to have the click torque wrench inspected and maintained by a professional. This can help identify any potential issues or wear that may affect the performance of the wrench. A professional can also perform any necessary repairs or adjustments to ensure the wrench is working properly.

FAQ

What is a click torque wrench?

A click torque wrench is a type of mechanical tool used to accurately tighten fasteners to a specific torque value. It is designed with a mechanism that produces an audible “click” sound when the desired torque is reached.

How does a click torque wrench work?

A click torque wrench works by utilizing a spring-loaded mechanism. When torque is applied to the fastener, the spring compresses until a specific torque level is reached. At this point, a ball bearing or pawl mechanism inside the wrench releases, producing the audible “click” sound and preventing further tightening.

What are the advantages of using a click torque wrench?

There are several advantages to using a click torque wrench. Firstly, it ensures that fasteners are tightened accurately and consistently to the specified torque, reducing the risk of damage or failure. Secondly, the click sound provides a clear feedback that the desired torque has been achieved. Lastly, click torque wrenches are generally easy to use and require minimal training.

Are there any limitations to using a click torque wrench?

Yes, click torque wrenches have some limitations. They are typically not suitable for low torque values, as the clicking mechanism may not be sensitive enough. Additionally, they may not be ideal for applications that require precise and continuous torque control, as they are designed to provide a controlled amount of torque and then stop tightening.

Can a click torque wrench be calibrated?

Yes, click torque wrenches can be calibrated to ensure their accuracy. Calibration involves adjusting the spring tension to ensure that the wrench clicks at the specified torque level. It is important to regularly calibrate torque wrenches to maintain their accuracy, especially in industries where precise torque is critical.

What are some tips for using a click torque wrench?

When using a click torque wrench, it is important to ensure that the wrench is set to the correct torque value. It is also recommended to use the wrench in a slow and controlled manner, applying the torque steadily to avoid misalignment or overtightening. Additionally, storing the torque wrench in its lowest torque setting can help maintain its accuracy and prolong its lifespan.

Video