Guide to Reading a Torque Wrench in Inch Pounds | [Website Name]

![Guide to Reading a Torque Wrench in Inch Pounds | [Website Name]](https://m.media-amazon.com/images/I/413SsYkfRIL._SL500_.jpg)

Welcome to our comprehensive guide on how to read a torque wrench in inch pounds. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding how to properly use and interpret a torque wrench is essential for accurate and safe fastening.

A torque wrench is a precision tool used to measure and apply a specific amount of torque, or rotational force, to a fastener. It is commonly used in automotive and mechanical applications to ensure that bolts and nuts are tightened to the correct specifications.

Reading a torque wrench in inch pounds requires attention to detail and a basic understanding of the tool’s design. Most torque wrenches have a scale, either marked directly on the handle or displayed digitally, that indicates the torque in inch pounds. This scale represents the maximum amount of rotational force that the wrench can apply before it clicks or releases the applied torque.

When using a torque wrench, it’s important to set the desired torque value before tightening the fastener. This can usually be done by adjusting a dial or knob on the wrench. Once the desired torque is set, apply steady and gentle force to the wrench until you reach the specified torque value.

Remember to always read the torque value on the scale when the wrench clicks or releases the applied torque. This is the point at which the desired torque has been reached. Do not continue applying force after the wrench clicks, as this can lead to over-tightening and potentially damage the fastener or the surrounding components.

By following these steps and using a torque wrench correctly, you can ensure that your fasteners are tightened to the correct specifications and avoid any issues that may arise from under or over-tightening. Stay tuned for more tips and tricks on using torque wrenches in different applications.

What is a Torque Wrench?

A torque wrench is a precision tool used to apply a specific amount of torque to a fastener, such as a bolt or a nut. It helps ensure proper tightening of the fastener to prevent under or over tightening, which can lead to mechanical failures or damage.

Torque wrenches come in various types, including beam-type, click-type, and digital torque wrenches. Each type has its own advantages and is suitable for different applications.

How Does a Torque Wrench Work?

A torque wrench works by measuring the twisting force, or torque, applied to the fastener. It has a handle, a mechanism to measure the torque, and a scale or a digital display to indicate the torque value.

When using a torque wrench, you set the desired torque value on the wrench and tighten the fastener until the wrench indicates that the desired torque has been reached. At this point, the wrench may make an audible click or provide a visual indication to alert you that the desired torque has been applied.

Why is a Torque Wrench Important?

Using a torque wrench is crucial in many applications, especially in industries where precision and safety are paramount. Here are a few reasons why a torque wrench is important:

- Prevents Under or Over Tightening: A torque wrench ensures that fasteners are tightened to the correct torque specification, preventing them from being loose or overly tight, which can lead to mechanical failures.

- Maintains Consistency and Accuracy: A torque wrench allows for consistent and accurate tightening of fasteners across multiple applications, ensuring uniformity and reliability.

- Protects Equipment and Components: Properly tightened fasteners help protect equipment and components from damage caused by vibrations, excessive force, or loosening during operation.

- Ensures Safety: In industries such as automotive, aerospace, and construction, tightness specifications are critical for safety. A torque wrench helps meet these specifications and ensures the safety of the end-users.

Importance of Reading a Torque Wrench Correctly

A torque wrench is an essential tool used in various industries and applications for tightening bolts and nuts to specific torque values. It helps ensure that components are properly secured and prevents issues such as fastener failure or damage to the surrounding materials.

Reading a torque wrench correctly is crucial for the following reasons:

1. Accuracy and Precision

Correctly reading a torque wrench allows for accurate and precise tightening of fasteners. The torque value specified by the manufacturer ensures that the fastener is tightened to the correct level, providing the desired clamping force without causing damage. Failing to read the torque wrench correctly can result in under or over-tightening, leading to potential safety hazards or operational issues.

2. Safety

Properly tightened fasteners are vital for safety, especially in critical applications such as automotive, aerospace, or construction. Accurate torque application prevents bolts from loosening, reducing the risk of accidents or equipment failure. By reading the torque wrench correctly, you can ensure that the fasteners are tightened to the appropriate torque specifications, meeting safety standards and regulations.

3. Consistency and Uniformity

Consistent torque application is essential when assembling multiple components or using multiple fasteners. Reading the torque wrench correctly ensures that each fastener receives the same amount of torque, resulting in uniform clamping force distribution. This promotes structural integrity, minimizes stress concentration, and maximizes the lifespan of the assembly or equipment.

4. Avoiding Damage

Over-tightening fasteners can cause damage to the fasteners, threads, or mating surfaces. Under-tightening, on the other hand, can lead to bolt or joint failure. By reading the torque wrench correctly and applying the specified torque value, you can prevent costly damage to the fasteners, equipment, or surrounding materials.

5. Compliance with Specifications

Many industries have specific torque requirements and standards that must be followed to meet quality and performance standards. By reading the torque wrench correctly, you ensure compliance with these specifications, certifications, and guidelines. This is especially important in regulated industries such as aerospace, automotive, or medical equipment manufacturing.

In conclusion, reading a torque wrench correctly is of utmost importance to ensure accuracy, safety, consistency, and compliance with industry standards. By understanding and following the proper torque values, you can prevent damage, ensure proper fastening, and guarantee the reliability and longevity of assemblies or equipment.

Understanding Inch Pounds Measurement

Inch Pounds is a unit of measurement used to quantify torque. Torque is a measure of the force applied to an object to make it rotate around an axis. Understanding how to read and interpret inch pounds is important for using a torque wrench correctly.

What is Inch Pounds?

Inch pounds is a unit of torque measurement commonly used in the United States. It represents the amount of force applied to an object to make it rotate one inch away from the rotational axis. One inch pound is equal to one pound of force applied at a perpendicular distance of one inch.

Using Inch Pounds for Torque Measurements

When working with a torque wrench, the inch pound setting indicates the amount of torque that needs to be applied to a fastener. The torque wrench has a handle that can be adjusted to a specific inch pound value. As the handle is turned, a click or beep sound indicates that the desired torque has been reached.

It is important to follow the manufacturer’s instructions for using a torque wrench and to set the wrench to the appropriate inch pound value. Applying too much or too little torque can result in damage or failure of the fastener or the object being worked on.

Conversion to Foot Pounds

Inch pounds can be converted to foot pounds by dividing the inch pound value by 12. This is because there are 12 inches in a foot. For example, if a torque wrench is set to 60 inch pounds, it is equivalent to 5 foot pounds (60 divided by 12).

Conclusion

Understanding inch pounds is essential for using a torque wrench correctly. It is a unit of torque measurement commonly used in the United States and represents the amount of force applied to make an object rotate one inch away from the rotational axis. By following the manufacturer’s instructions and setting the torque wrench to the appropriate inch pound value, you can ensure accurate and precise torque application.

Components of a Torque Wrench

A torque wrench is a precision tool used to apply a specific amount of torque to a fastener such as a nut or bolt. It typically consists of the following components:

- Handle: The handle is the part of the torque wrench that you grip when using it. It provides leverage and allows you to apply torque to the fastener.

- Ratcheting mechanism: The ratcheting mechanism allows the torque wrench to apply torque in one direction while allowing the handle to move freely in the other direction. This makes it easier to use the wrench in tight spaces.

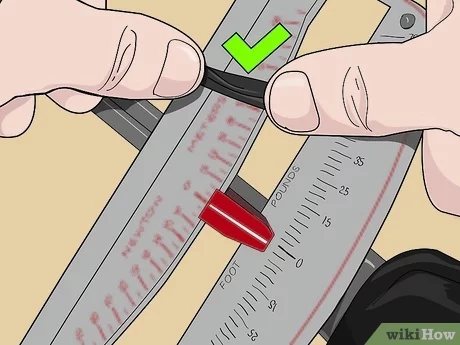

- Scale: The scale is a marked indicator on the torque wrench that shows the amount of torque being applied. It is usually marked in inch pounds (lb-in) or foot pounds (lb-ft), depending on the torque wrench.

- Adjustment mechanism: The adjustment mechanism allows you to set the desired amount of torque to be applied. It is usually located near the handle and can be adjusted by turning a dial or knob.

- Head: The head is the part of the torque wrench that comes into contact with the fastener. It is designed to fit specific types and sizes of fasteners.

A torque wrench is an essential tool for anyone working with fasteners that require precise torque. By understanding the components of a torque wrench, you can ensure that you are using it correctly and achieving accurate results.

Steps to Read a Torque Wrench in Inch Pounds

Step 1: Prepare the Torque Wrench

Before you can start reading a torque wrench in inch pounds, you need to make sure the wrench is properly set up:

- Ensure the torque wrench is set to the desired inch pound measurement. This is typically done by adjusting the wrench’s handle or using a dial or digital display.

- Make sure the torque wrench is properly calibrated. If it hasn’t been calibrated recently, consider getting it calibrated before use for accurate measurements.

Step 2: Apply the Torque

Once the torque wrench is set up, you can apply the desired torque to the fastener or object you are working on. Here’s how:

- Insert the appropriate socket or attachment onto the torque wrench’s square drive.

- Align the socket or attachment with the fastener or object.

- Grip the torque wrench’s handle firmly and apply force in a slow and controlled manner.

- Continue applying torque until you hear or feel a click, which indicates that the desired torque has been reached.

Step 3: Read the Torque Value

Now that you have applied the torque, you need to read the torque value indicated by the torque wrench:

- Look at the torque wrench’s scale or display. It may be in inch pounds or have dual units of measurement.

- Read the value indicated by the pointer or the digital display. This value represents the amount of torque applied in inch pounds.

Step 4: Interpret the Reading

Once you have read the torque value, you need to interpret the reading to ensure it is within the required specifications:

| Torque Specification | Interpretation |

|---|---|

| Within Range | If the reading falls within the specified torque range, it is considered acceptable. |

| Below Range | If the reading is below the specified torque range, additional torque may be required. |

| Above Range | If the reading is above the specified torque range, the fastener or object may be over-tightened, which can lead to damage. |

Step 5: Repeat as Necessary

If you need to apply torque to multiple fasteners or objects, repeat the above steps for each one, ensuring the torque wrench is properly set up each time.

Tips for Accurate Torque Wrench Reading

1. Select the Correct Torque Wrench

Choosing the right torque wrench for the job is crucial to ensure accurate readings. Consider the torque range you require and select a torque wrench that can handle that range. Make sure to check the manufacturer’s specifications for the torque wrench to ensure it is suitable for the task at hand.

2. Calibrate the Torque Wrench

Regularly calibrate your torque wrench to maintain its accuracy. Over time, torque wrenches can lose their calibration, resulting in inaccurate readings. Follow the manufacturer’s instructions for calibration or consider sending it to a professional calibration service.

3. Set the Desired Torque Value

Before using the torque wrench, set the desired torque value according to the specific requirements of your task. Use the adjustment knob or dial on the torque wrench to set the appropriate torque level.

4. Use Proper Technique

When using a torque wrench, it is important to apply consistent and steady force to achieve accurate readings. Avoid jerking or twisting motions that can affect the torque measurement. It is also recommended to support your hand or arm while exerting force to stabilize the torque application.

5. Read the Torque Scale

Pay close attention to the torque scale on the torque wrench. Read the scale carefully and ensure that you align the pointer or indicator with the desired torque level. Take note of any units of measurement, such as inch-pounds or foot-pounds, to ensure accurate readings.

6. Slow and Controlled Application

When applying torque with the wrench, do so in a slow and controlled manner. Apply force gradually until you reach the desired torque value. This will help prevent over-tightening or under-tightening, ensuring accurate and consistent results.

7. Maintain Proper Wrench Positioning

Position the torque wrench properly on the fastener or nut you are tightening. Ensure that it is fully engaged and aligned with the nut or bolt. Proper positioning will help maintain accuracy and prevent slippage.

8. Avoid Exceeding the Torque Limit

Never exceed the torque limit specified by the manufacturer. Over-torquing can lead to damage to the fasteners, parts, or the torque wrench itself. If the desired torque value cannot be reached without exceeding the limit, consider using a different torque wrench or seeking professional assistance.

9. Store the Torque Wrench Properly

After use, store the torque wrench in a clean and dry location. Protect it from excessive heat, moisture, and other damaging elements. Storing the torque wrench correctly will help maintain its accuracy and extend its lifespan.

10. Perform Regular Maintenance

Perform regular maintenance on your torque wrench to keep it in optimal condition. Clean it after use and inspect for any signs of damage or wear. Lubricate moving parts as recommended by the manufacturer. Proper maintenance will ensure accurate readings and prolong the life of your torque wrench.

FAQ

What is a torque wrench and why is it important?

A torque wrench is a tool used to apply a specific amount of torque to a fastener such as a bolt or nut. It is important because it ensures that the fastener is tightened to the correct specifications, preventing over-tightening or under-tightening, which can lead to damage or failure of the fastener or the object being fastened.

How do you read a torque wrench in inch pounds?

To read a torque wrench in inch pounds, first set the desired torque value on the wrench’s handle or scale. Then, when tightening a fastener, the wrench will click or make a sound when the desired torque is reached. The torque can be read from the handle or scale where the click occurs.

Are torque wrenches adjustable?

Yes, most torque wrenches are adjustable. They usually have a handle or a scale that allows you to set the desired torque value. This allows you to tighten fasteners to different specifications depending on the requirements of your project.

Can a torque wrench be used for both tightening and loosening fasteners?

Yes, a torque wrench can be used for both tightening and loosening fasteners. When tightening, the wrench clicks or makes a sound when the desired torque is reached. When loosening, the wrench can be used to apply a specific amount of torque to loosen the fastener without overdoing it.

What are the common units for torque measurement?

The most common units for torque measurement are inch pounds and foot pounds. Inch pounds are typically used for smaller fasteners, while foot pounds are used for larger fasteners. Both units measure the amount of force applied to a fastener.

How can I ensure the accuracy of my torque wrench?

To ensure the accuracy of your torque wrench, it is important to calibrate it regularly. You can do this by comparing the readings of your torque wrench with a known accurate torque measurement device. If there are any discrepancies, you may need to adjust or repair your torque wrench.

Can I use a torque wrench for any type of fastener?

A torque wrench can be used for a wide variety of fasteners, including bolts, nuts, and screws. However, it is important to use the correct type and size of socket or attachment for the specific fastener you are working with. Using the wrong socket can lead to inaccurate torque readings and potentially damage the fastener.

![Guide to Reading a Torque Wrench in Inch Pounds | [Website Name]](https://m.media-amazon.com/images/I/41XYq+5LVQL._SL500_.jpg)

![Guide to Reading a Torque Wrench in Inch Pounds | [Website Name]](https://thehuts-eastbourne.co.uk/wp-content/themes/rehub-theme/images/default/noimage_70_70.png)